Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Won't fly around" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

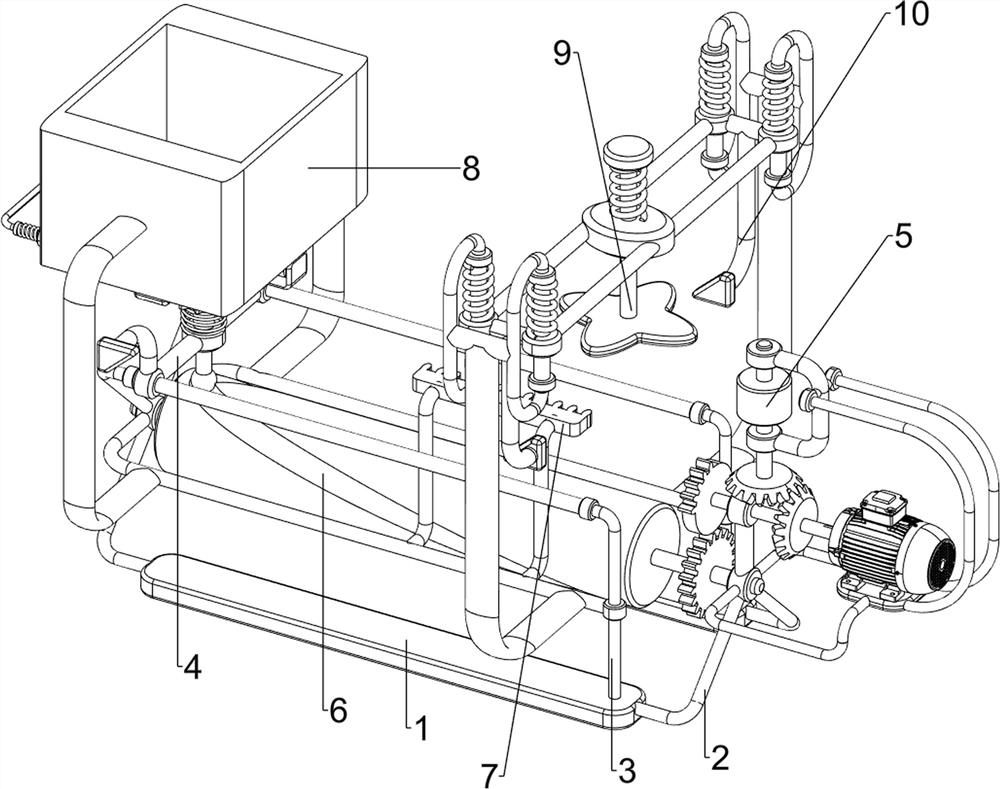

Metal wire production method

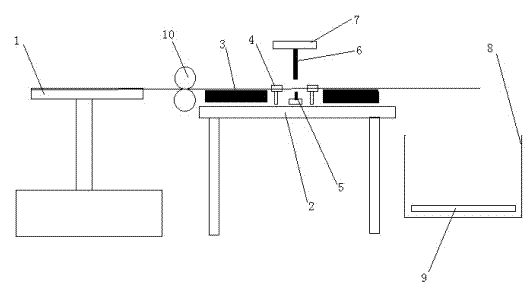

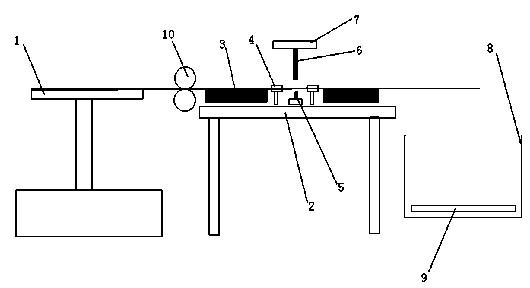

The invention discloses a metal wire production method. The metal wire production method comprises such steps as wire coiled material production, wire coiled material cutting, wire straightening, barreling polishing and packaging warehousing; a wire coiled material is produced through wire drawing equipment and returning equipment, and is put on an active emptying tray of a metal wire cutting device; the active emptying tray is horizontally mounted on the side surface of a frame of the cutting device; two transmission rollers are arranged between the active emptying tray and the frame for emptying assistance; the cutting is performed; after the cutting is finished, the straightening is performed; the barreling and the polishing are performed for straightened metal wires; then, the final checking is performed for the metal wires; and the qualified metal wires are packaged and warehoused. When the metal wires are cut by the metal wire production method, the metal wires are automatically cut without being damaged; meanwhile, when the metal wires are straightened, the straightening precision is largely improved; one motor is needed to provide high-speed rotating power, so that the energy consumption is largely reduced; and the working efficiency is higher.

Owner:DONGQING TECH

Dust removal device

InactiveCN105477951AEasy to remove dustReduce labor intensityDispersed particle filtrationTransportation and packagingEngineeringDust fall

Owner:周桂灵

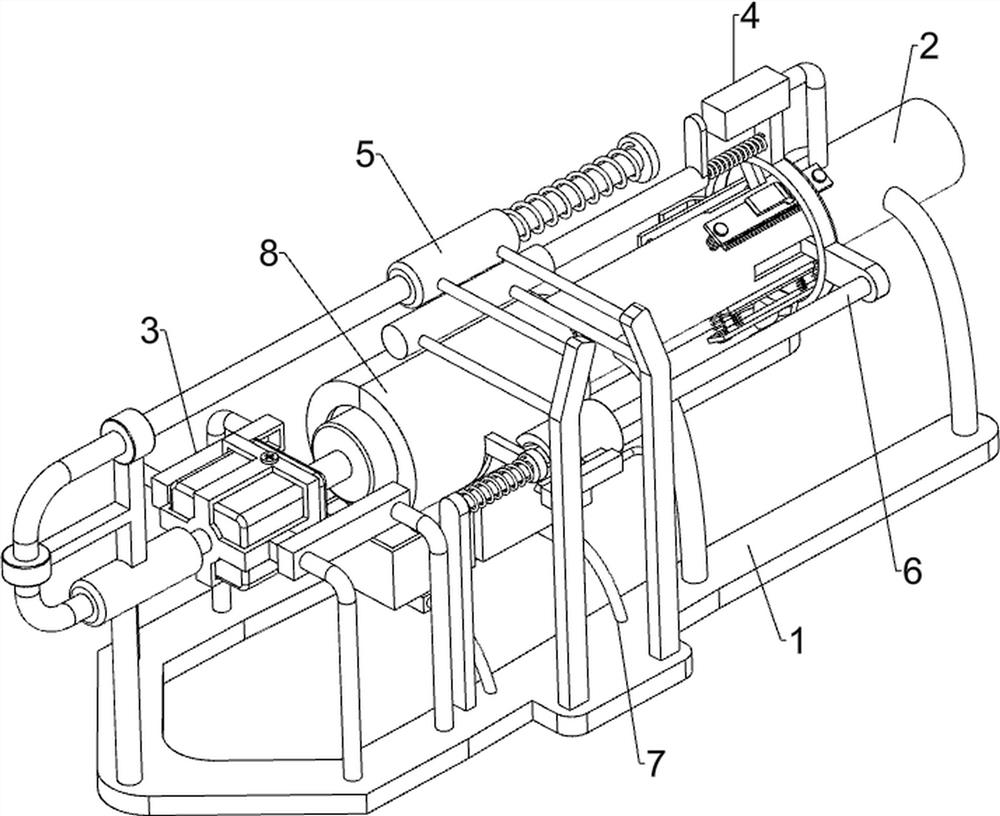

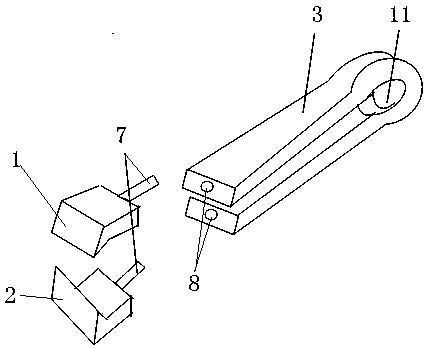

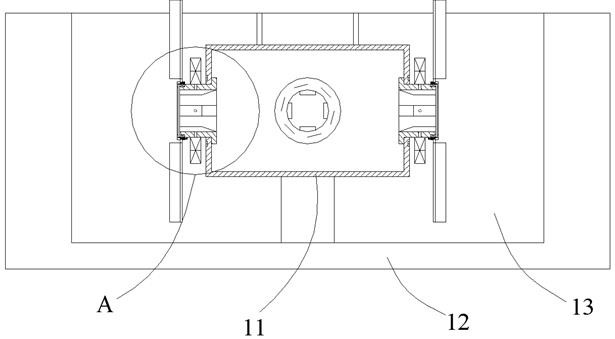

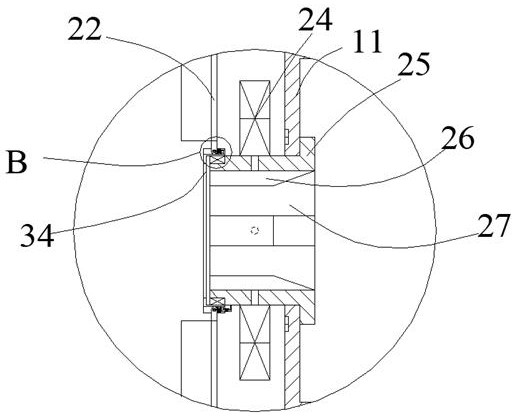

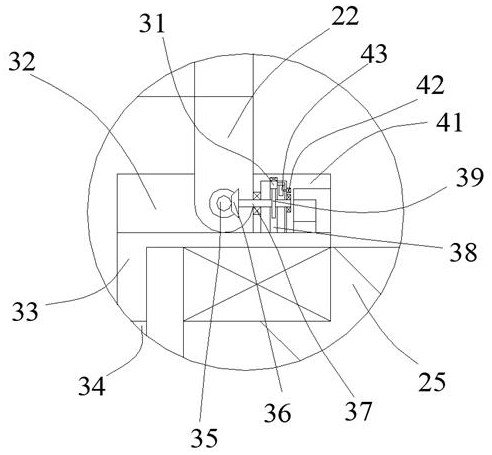

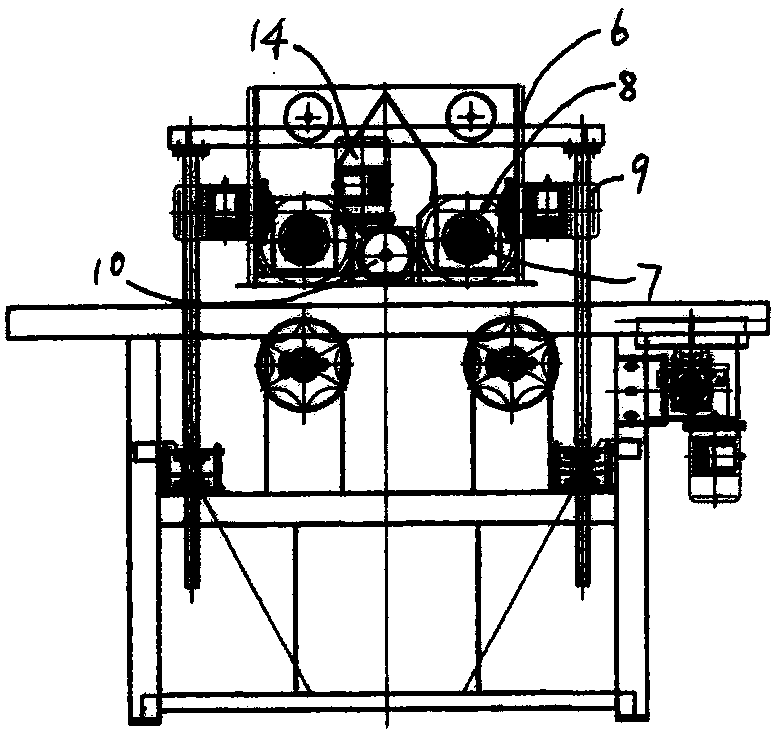

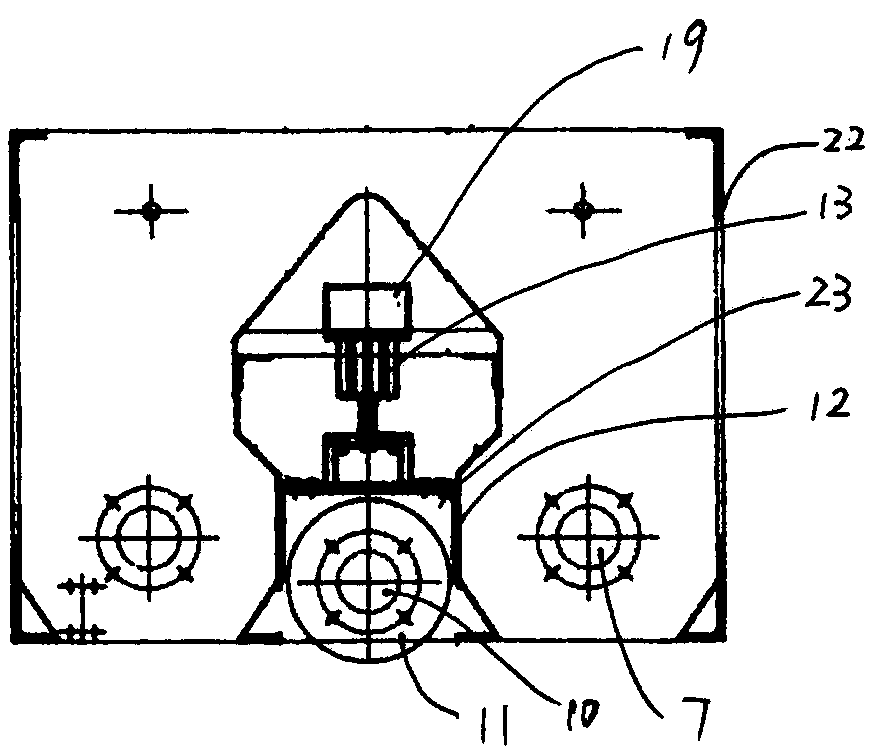

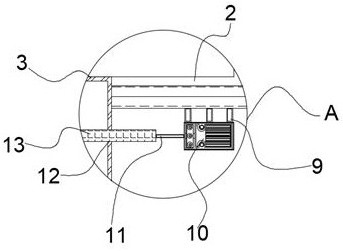

Metal tube cutting device

A metal tube cutting device comprises a machine base, wherein a driving feeding plate of the cutting device is arranged on the side face of the machine base, two transmission rollers are arranged between the driving feeding plate and the machine base for assisting in feeding, the upper surface of the machine base is provided with two conveying rails, the transmission rails, the transmission rollers and the driving feeding plate are driven by the same motor, the motor transmits power in a gear transmission mode, and two pneumatic clamps are arranged between the two conveying rails and are driven by the same air cylinder. Tubes to be cut move forwards under the effect of the two conveying rails and pass through the two pneumatic clamps, and the openings of the tubes are clamped by the two pneumatic clamps so that the tubes and the two conveying rails can be located on the same horizontal plane. According to the metal tube cutting device, the conveying rails are arranged, the pneumatic clamps are arranged between the conveying rails, the metal tubes will not be damaged because power is provided by the air cylinder, the metal tubes are static relative to cutters when conveying is stopped, and therefore the notches of the metal tubes are very smooth.

Owner:DONGQING TECH

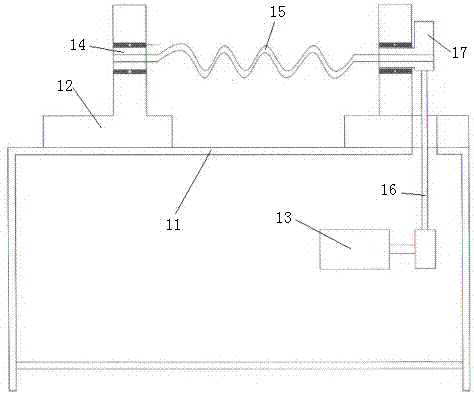

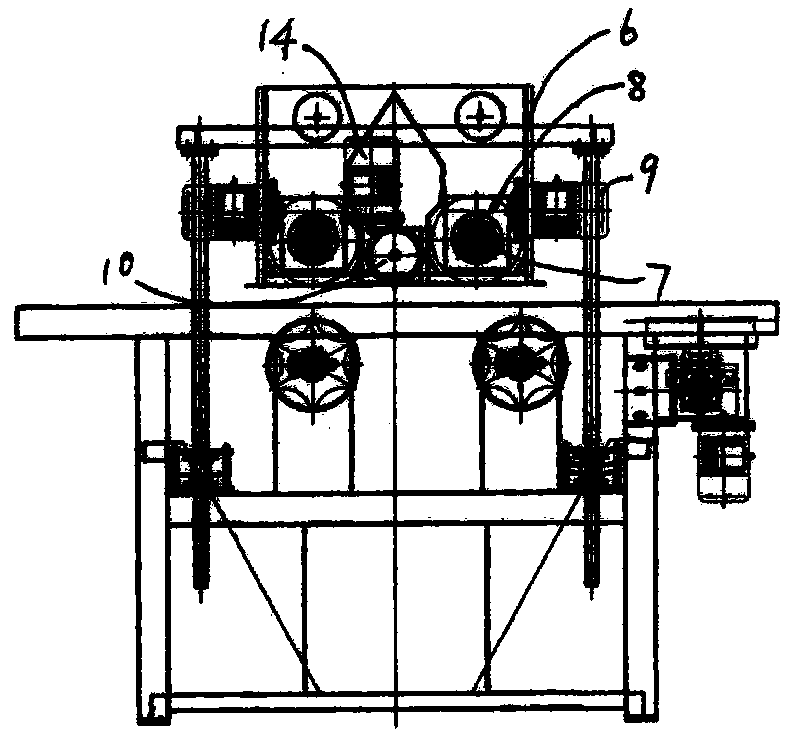

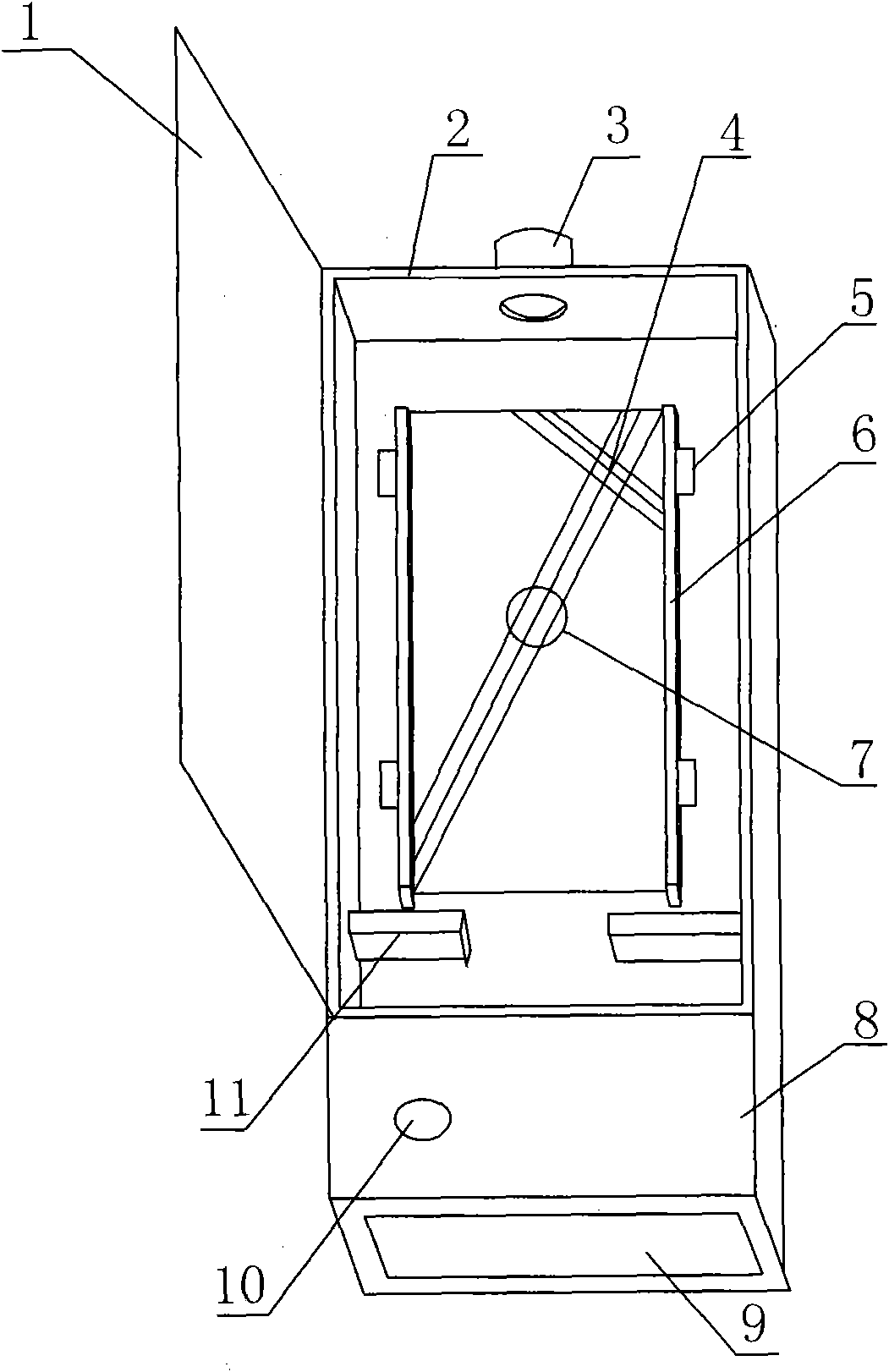

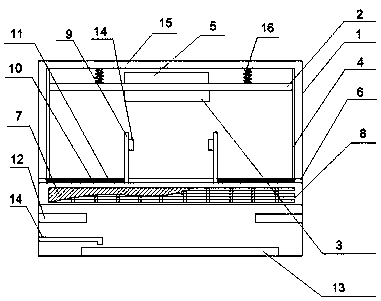

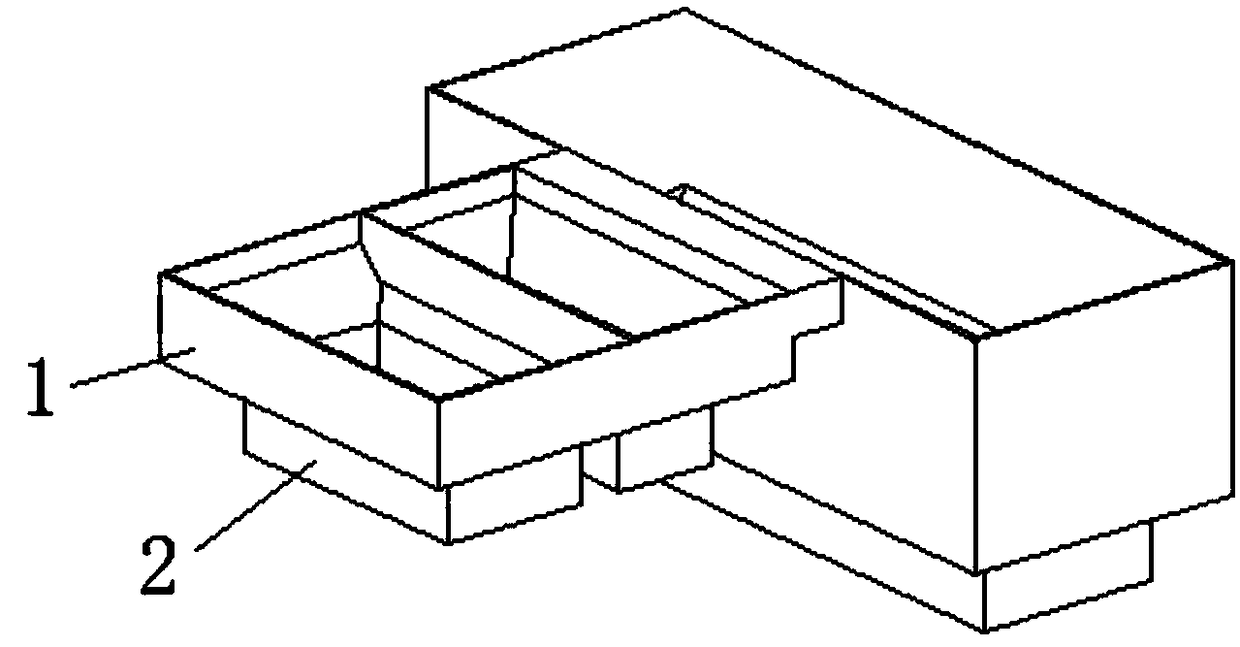

Flocking structure of flocking machine

ActiveCN103447183AImprove efficiencyGuaranteed uniformityLiquid spraying plantsWorking environmentEngineering

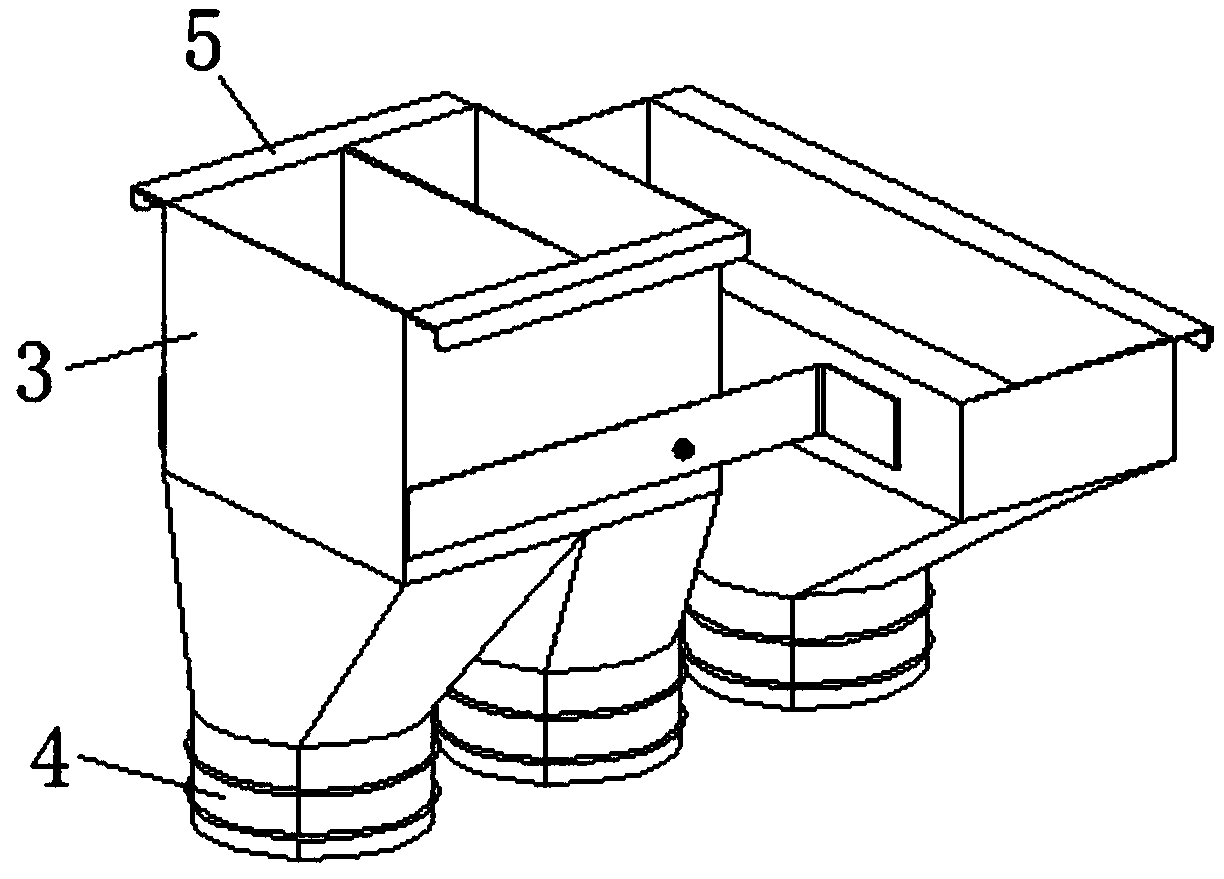

The invention provides a flocking chamber structure, which enables that flocks in a flocking process do not fly around, guarantees the uniformity of flocking, makes the excess flocks easy to collect, reduces the flock cost of flocking, guarantees a good working environment of a workshop and guarantees short length of the flocking workshop and high flocking efficiency due to utilization of a cloth delivery pipe between two flocking chambers. The flocking structure comprises a cloth delivery pipe, flocking chambers and a flock recovery chamber, wherein the cloth delivery pipe is uniformly provided with the flocking chambers; the rear part of the final flocking chamber is provided with the flock recovery chamber; the flocking structure is characterized in that an integral structure of a metal plate and a glass plate is arranged above the cloth delivery pipe between adjacent flocking chambers; one end of the metal plate is connected with a lateral vertical plate of one flocking chamber, and the other end of the metal plate is connected with one end of the glass plate; the other end of the glass plate is connected with a corresponding lateral vertical plate of another flocking chamber.

Owner:WUXI QUANSHUN MACHINERY MFG

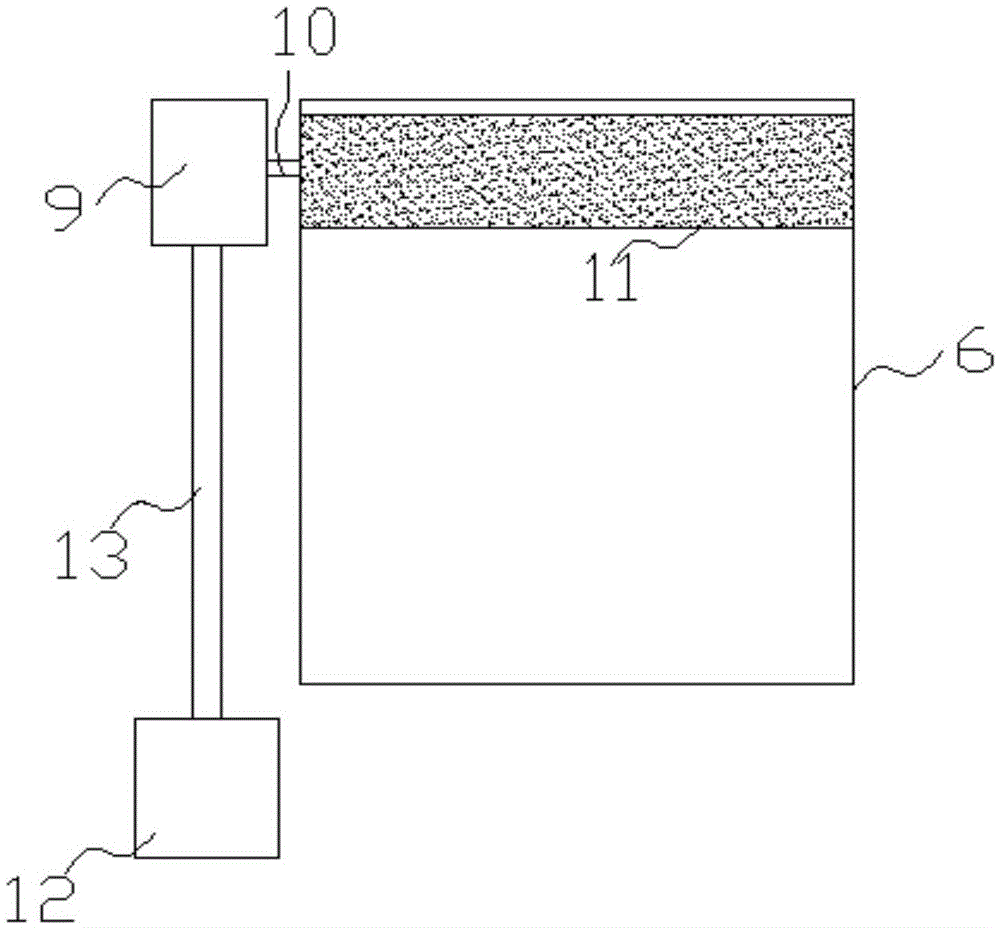

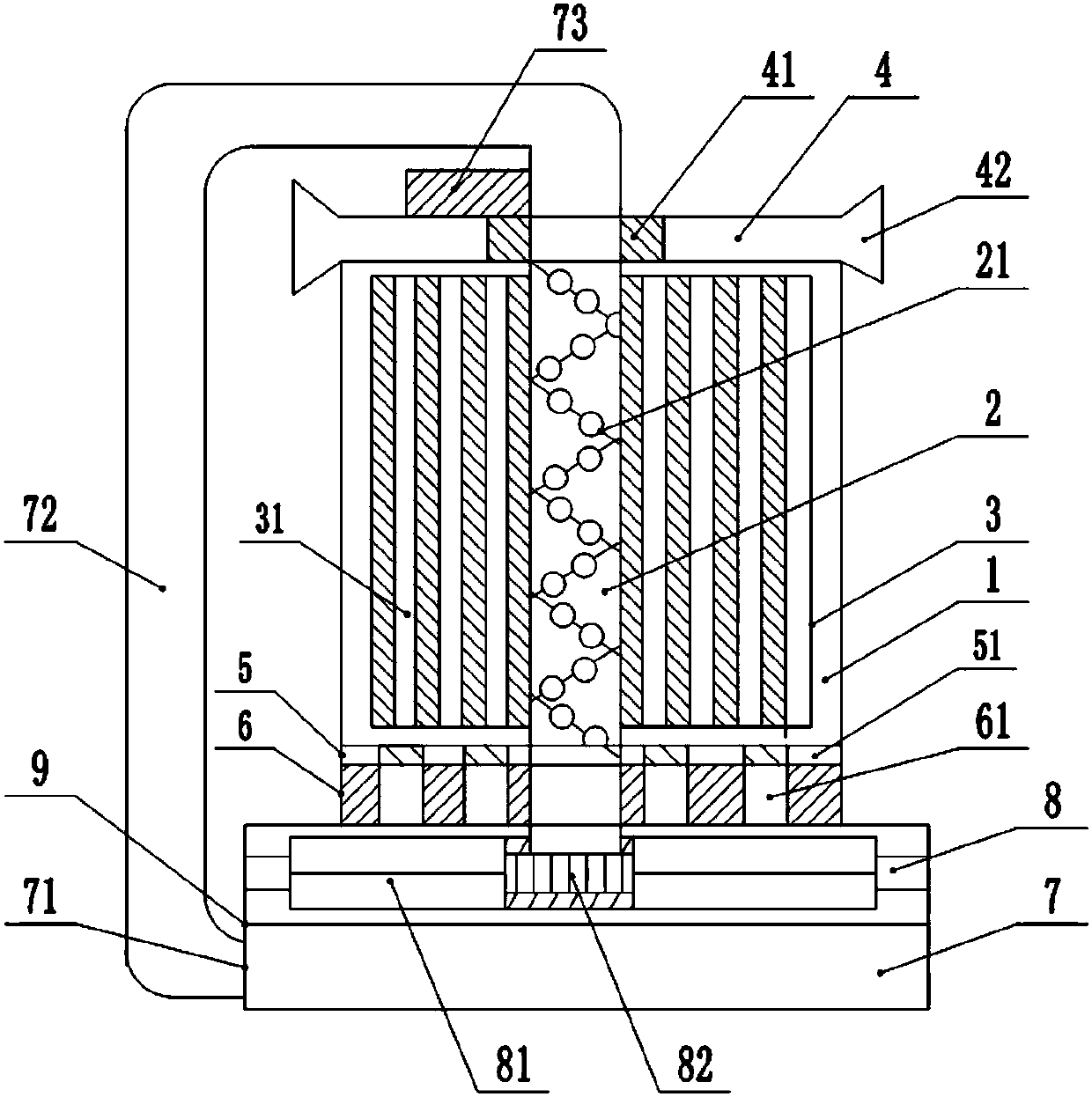

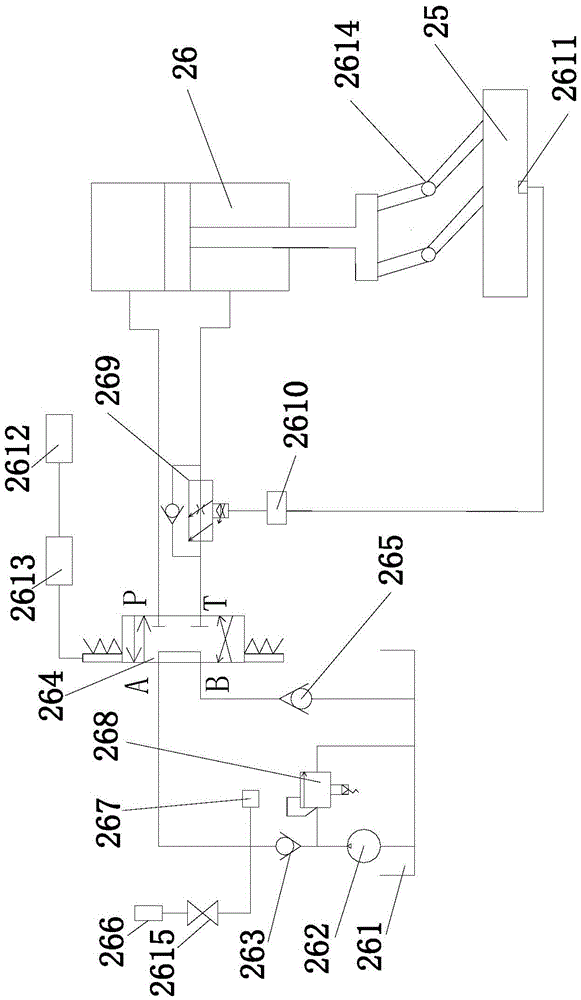

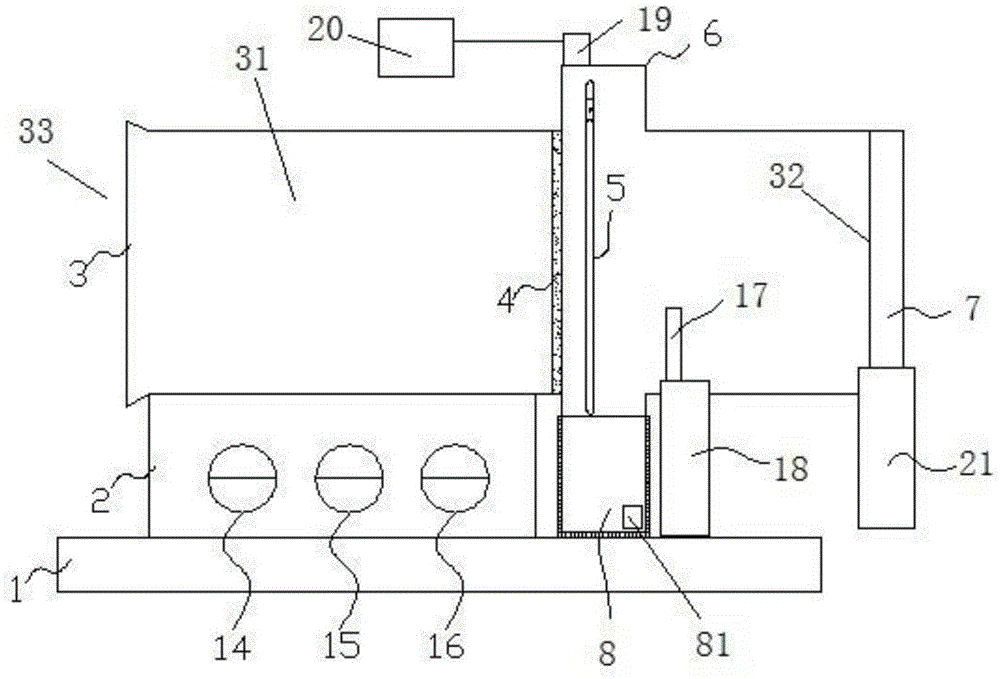

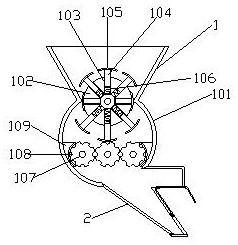

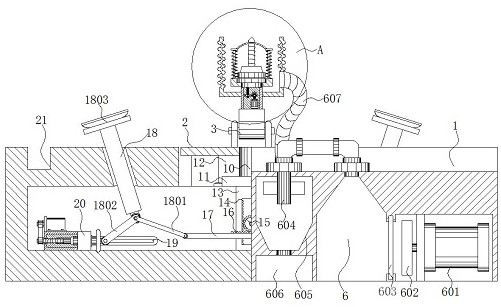

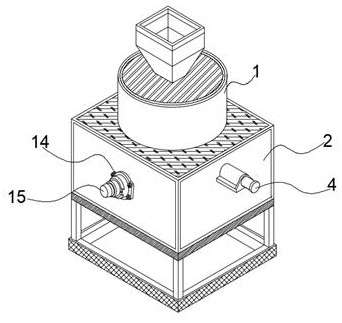

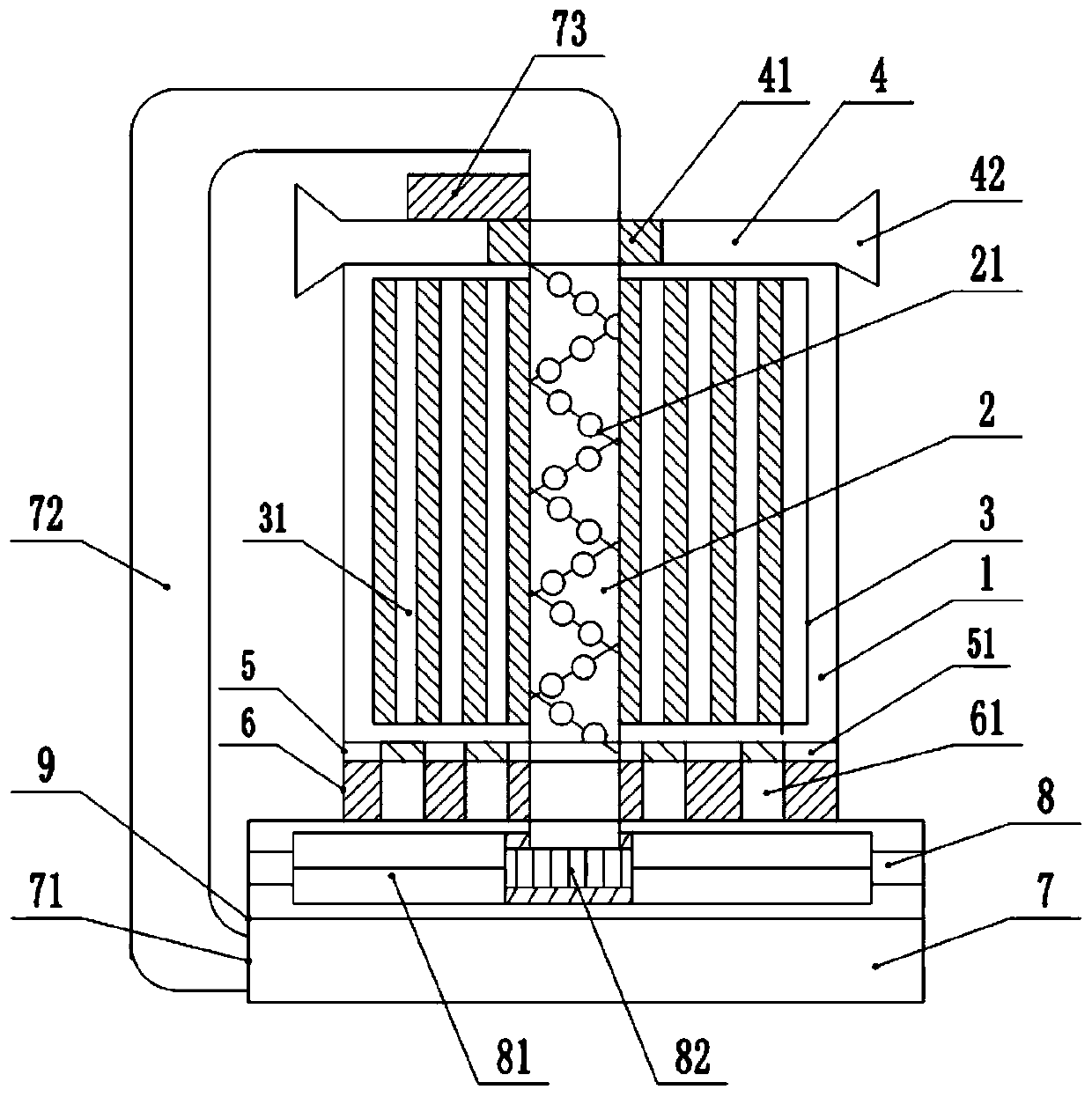

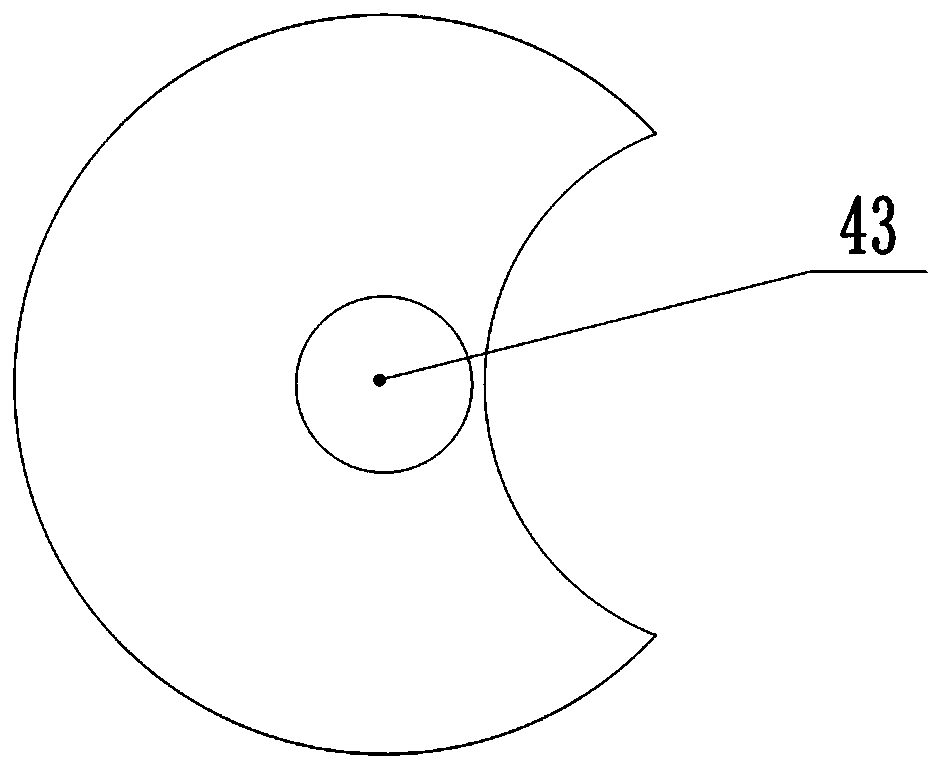

Dust removing and cooling device of high-temperature flue gas

ActiveCN107715634ASave waterWon't fly aroundCombination devicesLighting and heating apparatusFlue gasInlet valve

The invention relates to the technical field of flue gas treatment and particularly discloses a dust removing and cooling device of high-temperature flue gas. The dust removing and cooling device comprises a dust removing and cooling mechanism and a receiving mechanism, wherein the dust removing and cooling mechanism comprises a shell and a rotary shaft; dust removing blades are arranged on the rotary shaft; an air inlet pipeline is arranged at the upper part of the shell, a one-way rotary air inlet valve is arranged at the middle part of the air inlet pipeline, and the upper end of the rotaryshaft penetrates through the upper part of the shell and is connected with the one-way rotary air inlet valve by threads; a blocking part is arranged at the lower part of the shell and is provided with a through hole, and a matching part is arranged at the lower end of the blocking part and is provided with an air outlet; and the receiving mechanism is positioned at the lower end of the matchingpart and comprises a receiving pool and a cross shaft, a blade group is arranged on the cross shaft, a worm wheel and worm structure is arranged at the middle part of the cross shaft, the rotary shaftis connected with a worm wheel, a water outlet is formed in the receiving pool, and a water inlet pipe is connected between the water outlet and the rotary shaft. According to the dust removing and cooling device disclosed by the invention, the problem that flying smoke dust is very difficult to collect due to lower adsorbability for smoke dust in the gas in the cooling process is solved; in addition, cooling water can be recycled, so that the water resource is saved.

Owner:GUIZHOU HUANKE ENVIRONMENT ECOLOGICAL RES & DEV CO LTD

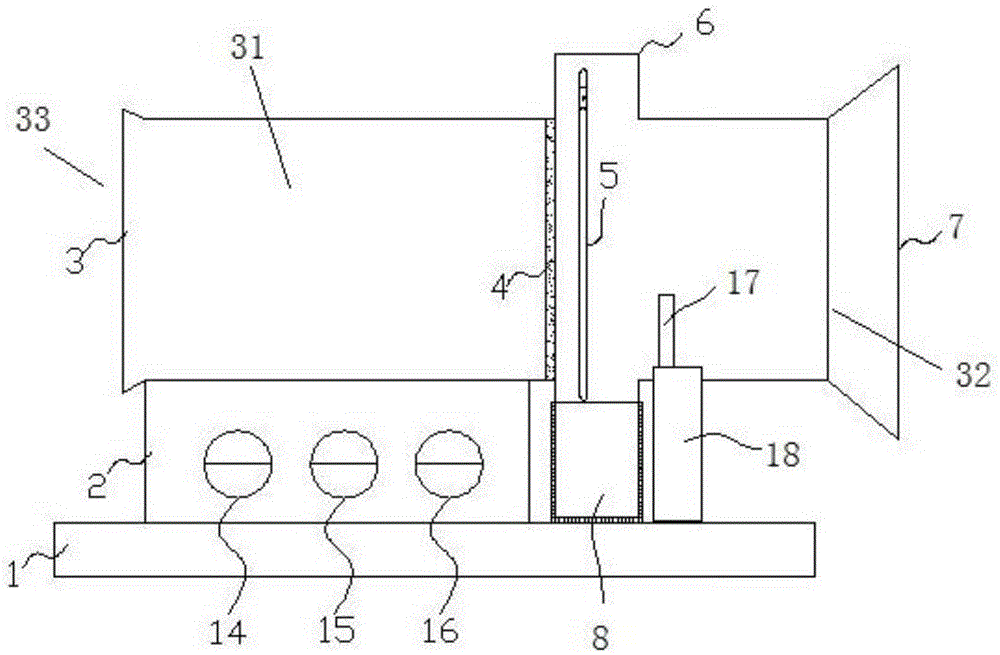

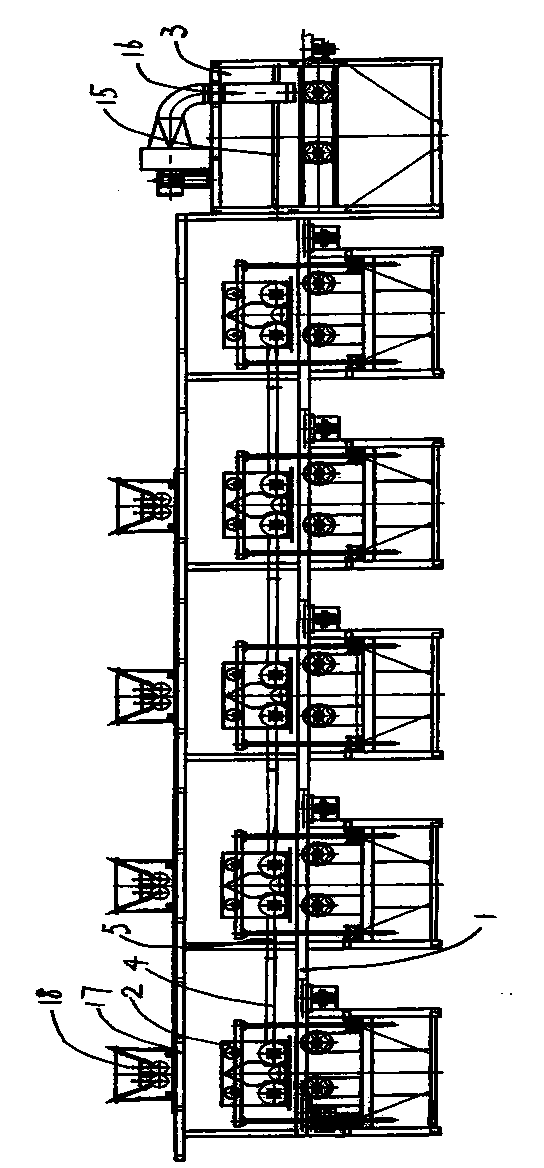

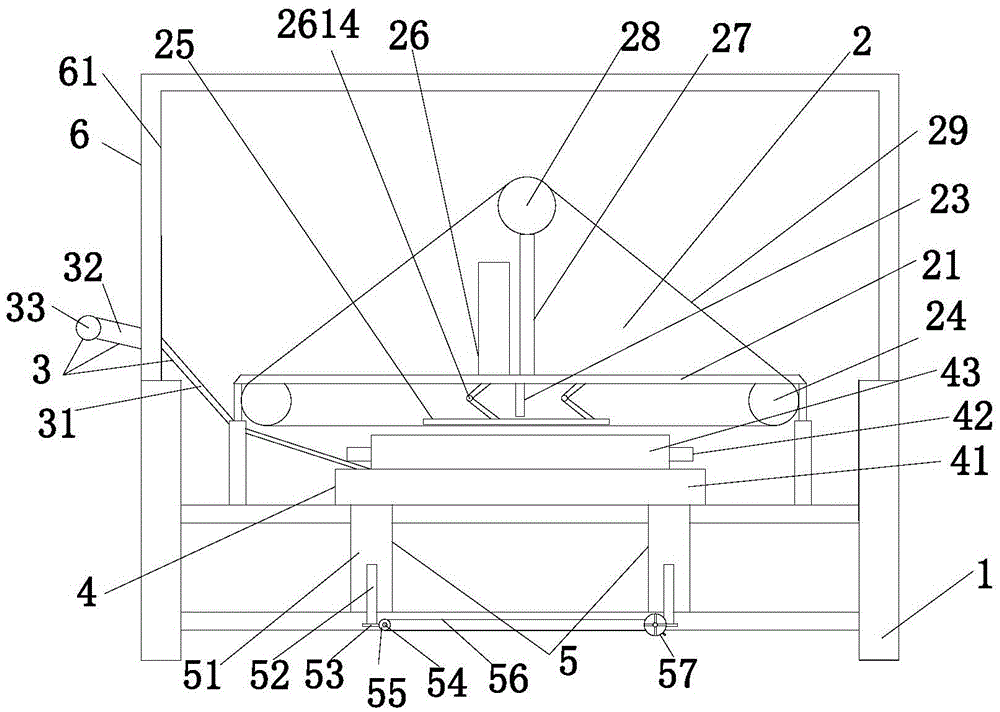

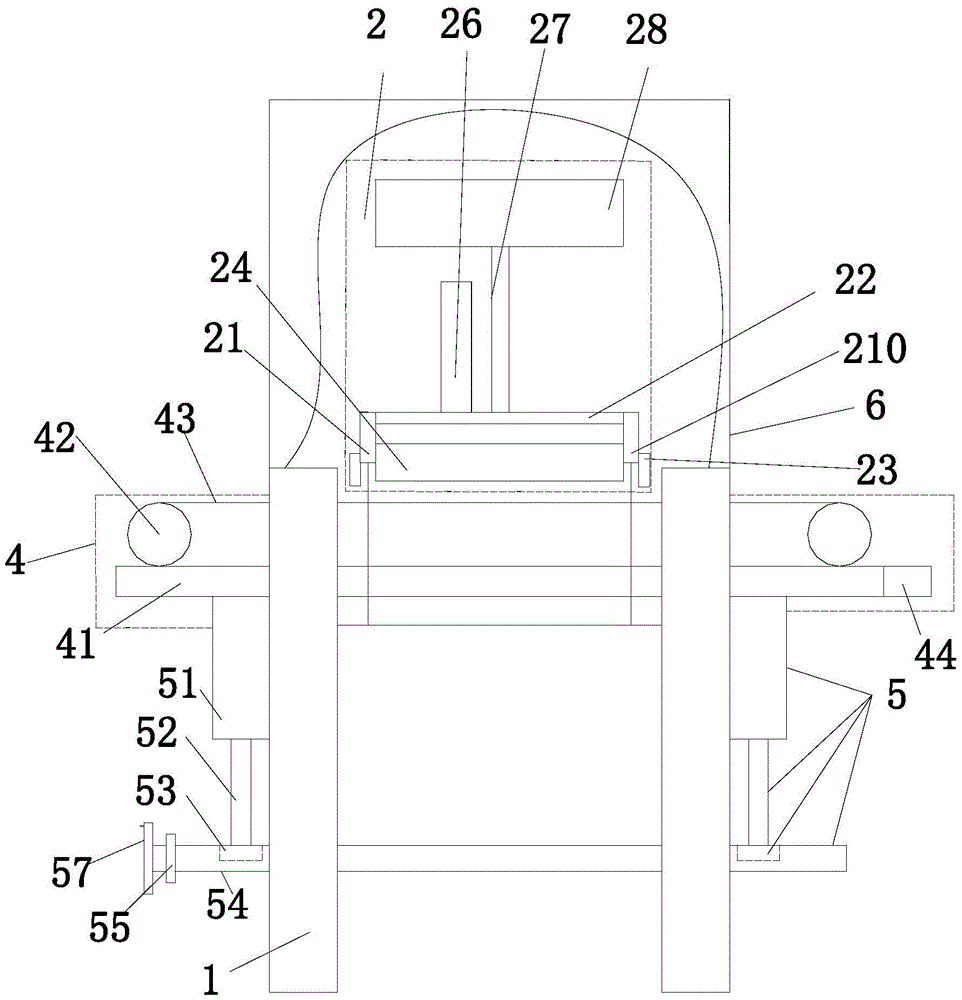

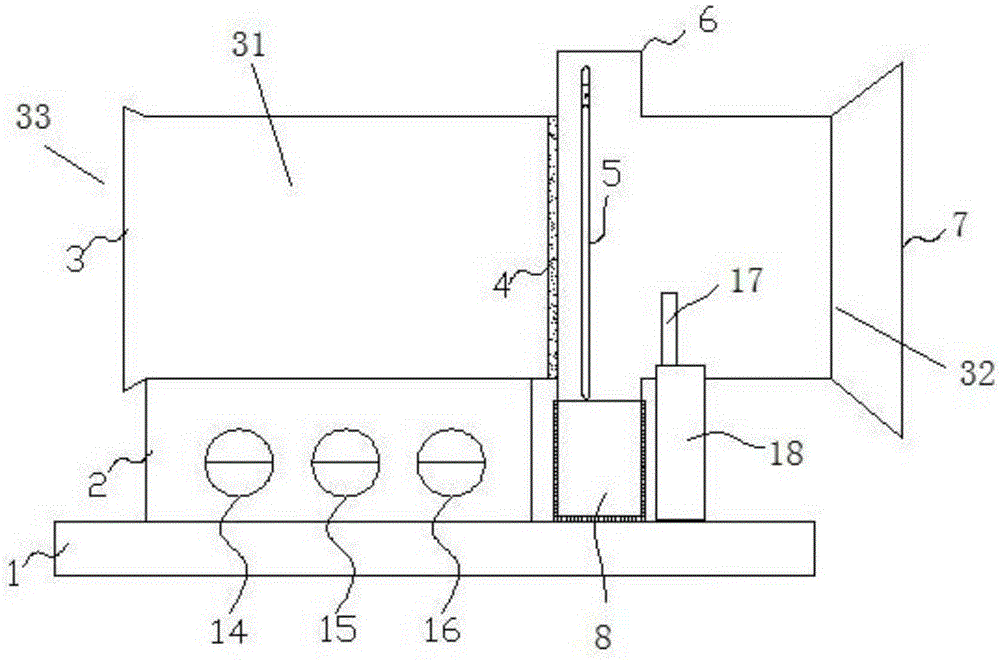

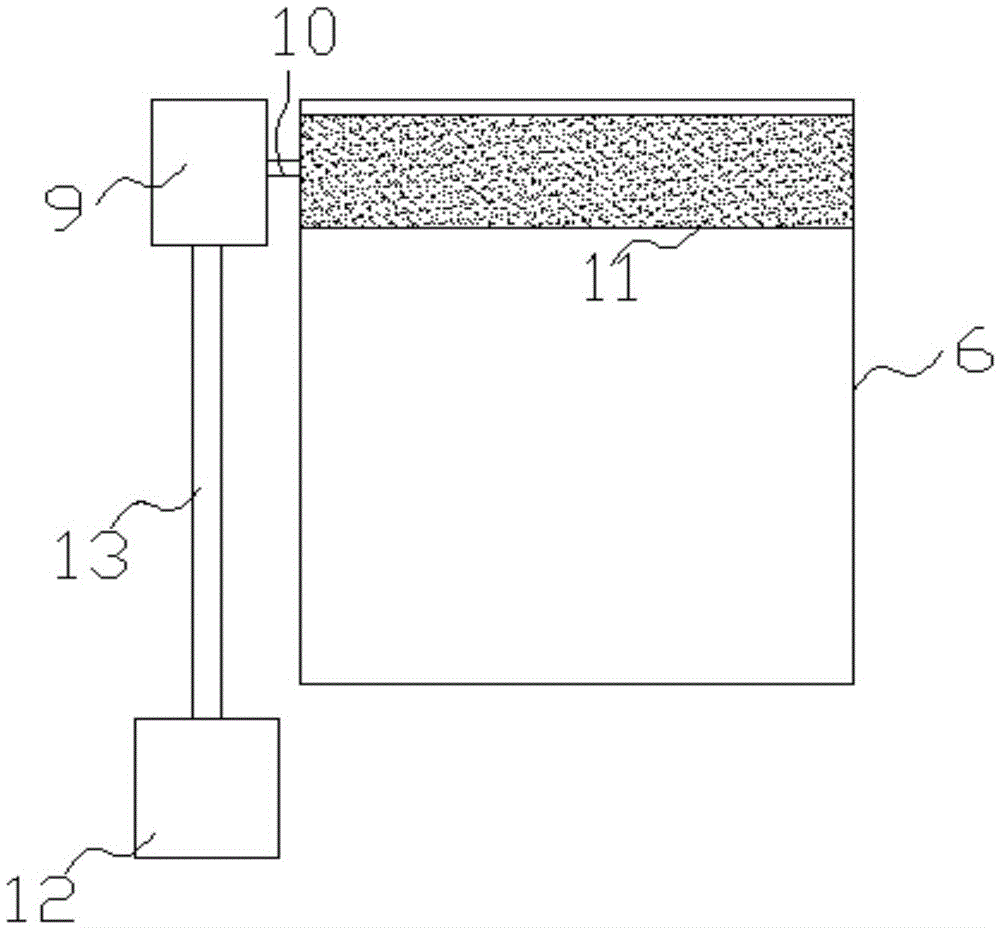

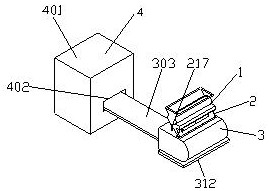

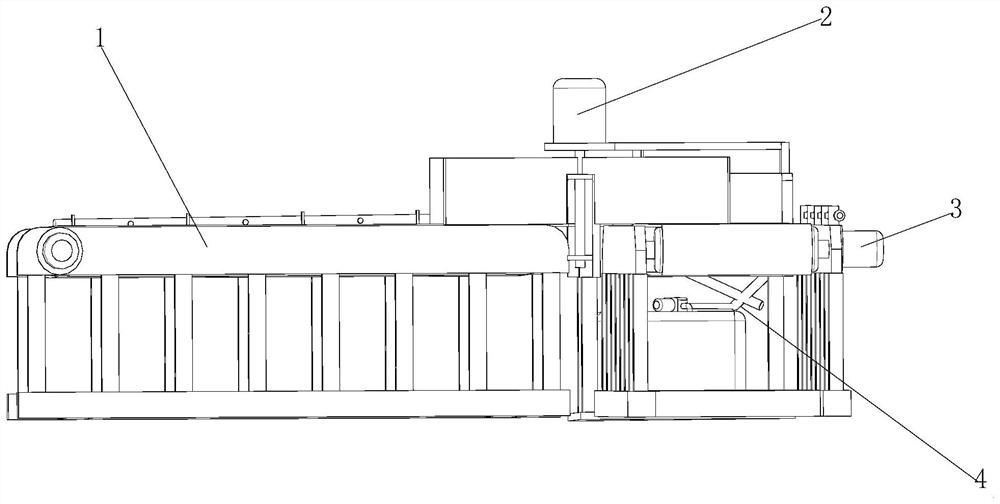

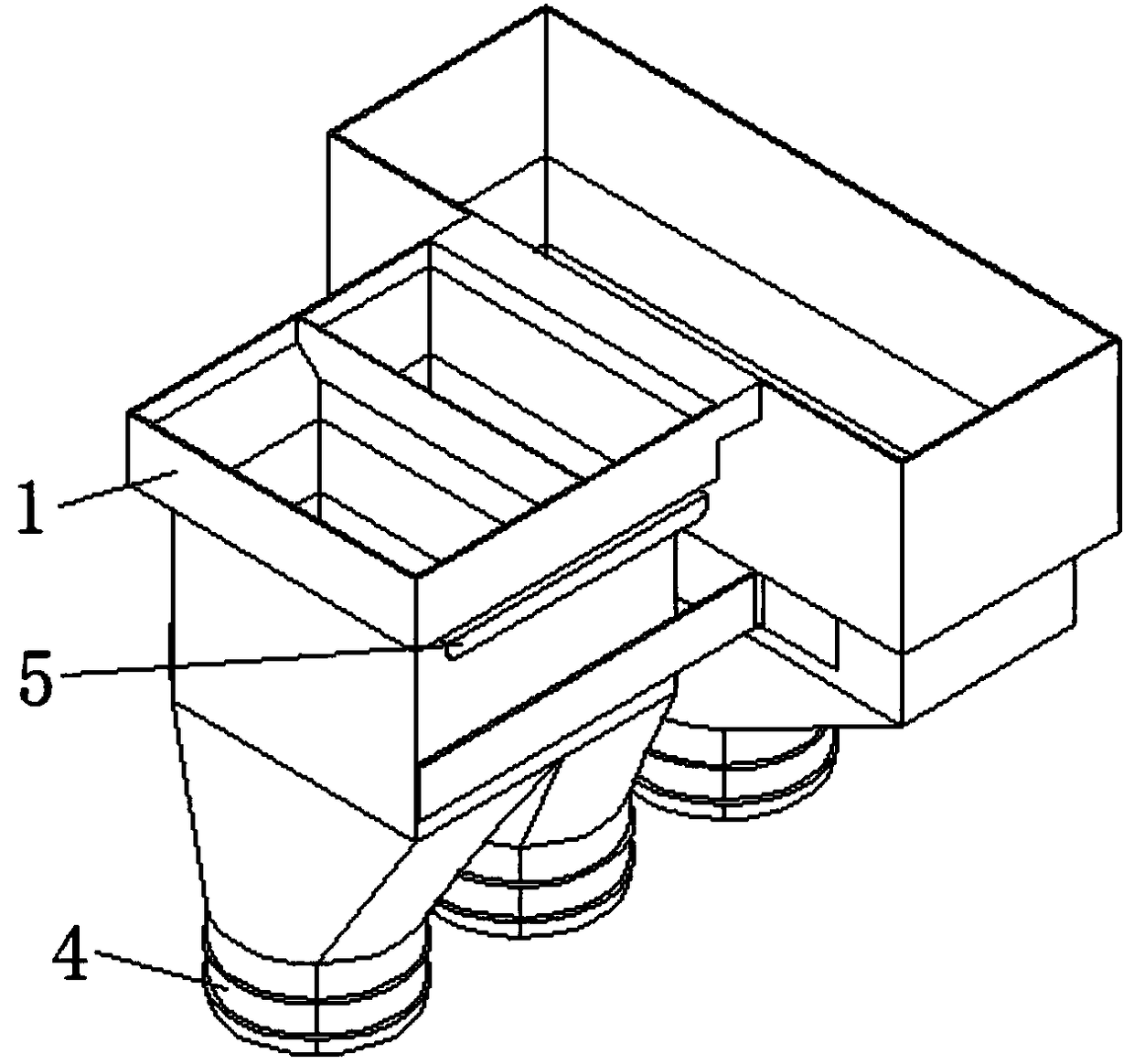

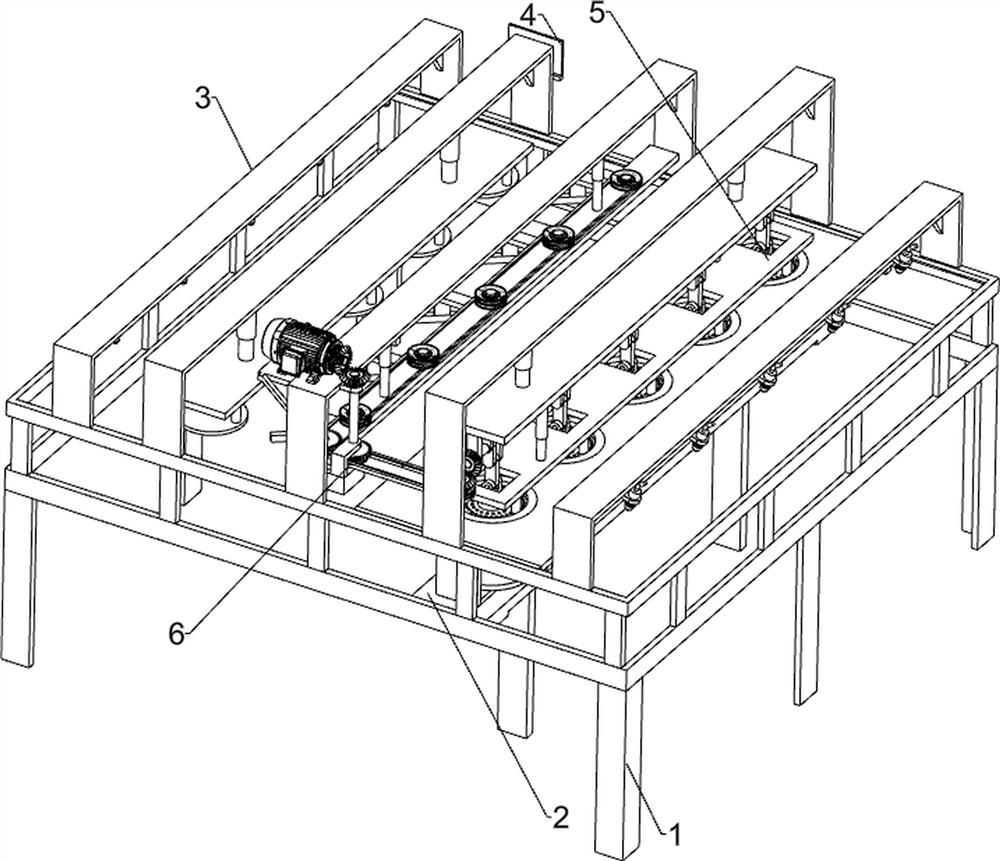

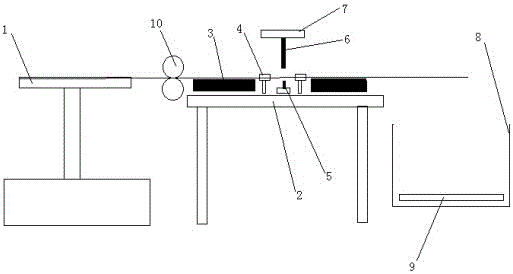

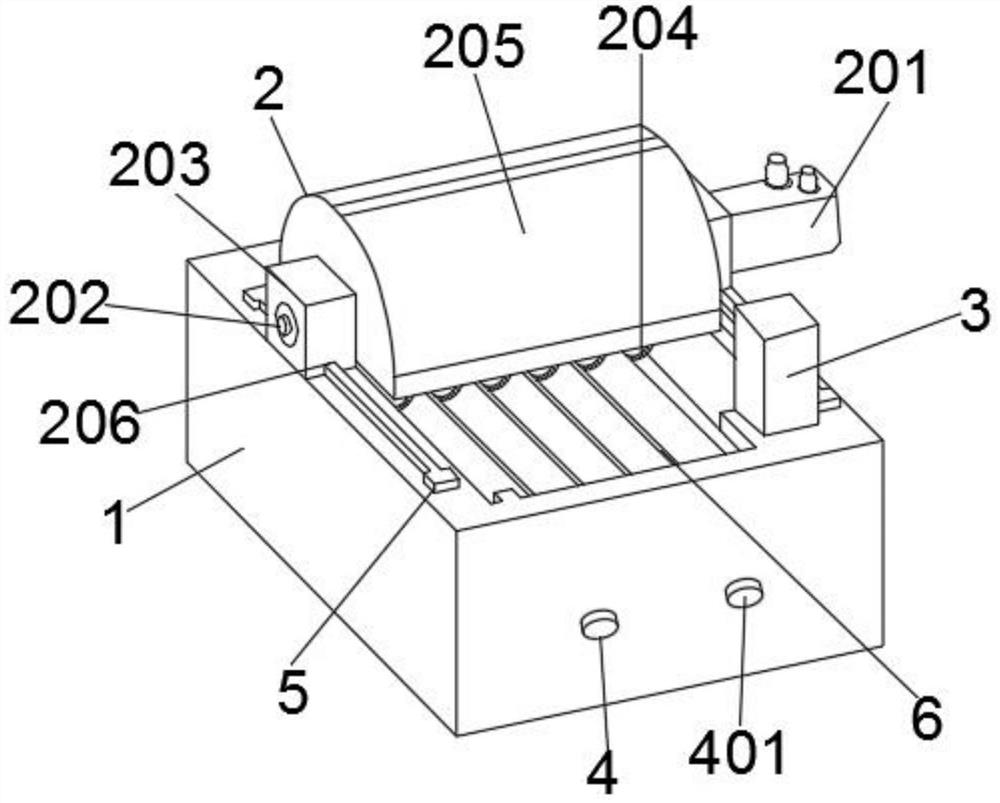

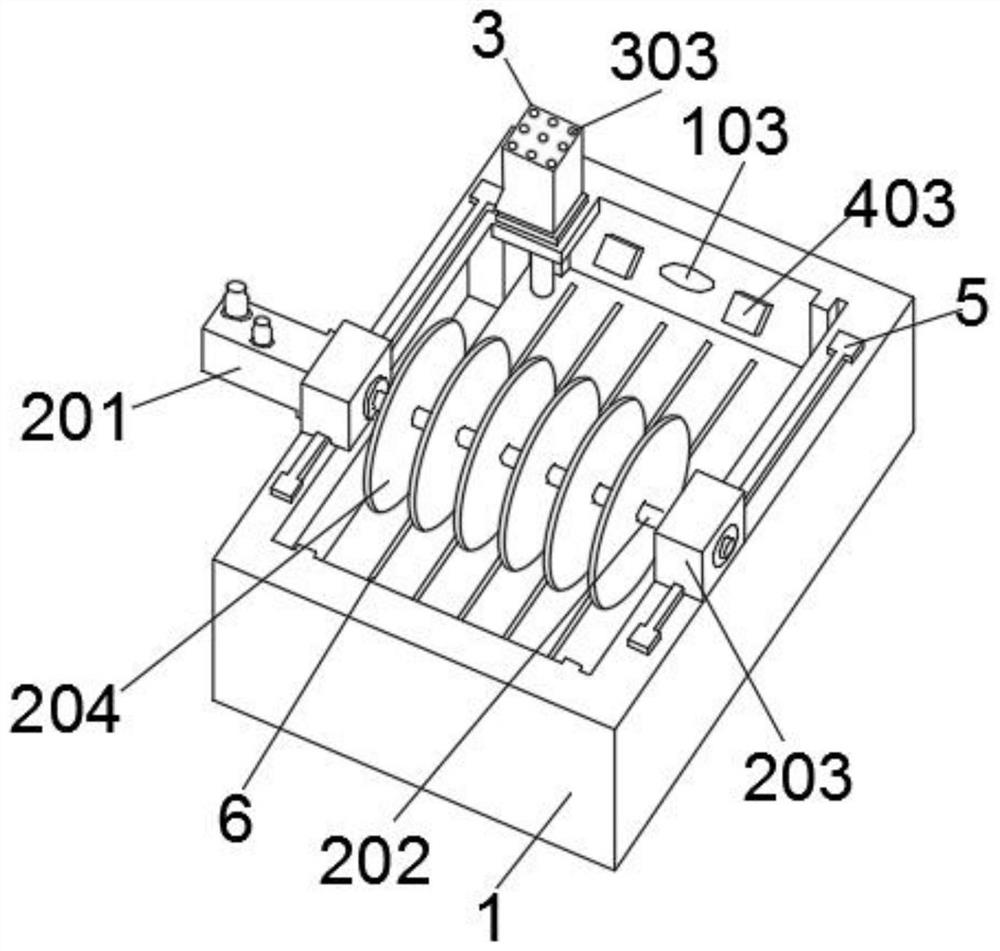

Surface transverse-grinding process and manufacturing machine for solid wood floor

ActiveCN105563277AReduce labor intensityQuality assuranceBelt grinding machinesGrinding/polishing safety devicesSolid woodDust control

The invention discloses a surface transverse-grinding process and a manufacturing machine for solid wood floor. A pressing power mechanism and a conveying device are matched with each other to carry out transverse grinding treatment on wood floor. The manufacturing machine comprises a base (1), wherein the base (1) is connected to height regulating devices (5); the height regulating devices (5) are connected to a conveying device (4); the pressing power mechanism (2) is arranged above the conveying device (4); dust removal equipment (3) is arranged on the side surface of the pressing power mechanism (2); the pressing power mechanism (2) is connected to the base (1); and a gap is arranged between the pressing power mechanism (2) and the conveying device (4). The manufacturing machine has the characteristics that the production efficiency is high, the grinding quality is guaranteed, the labor intensity of a worker is small, and large-scale production can be carried out.

Owner:JIUSHENG WOOD

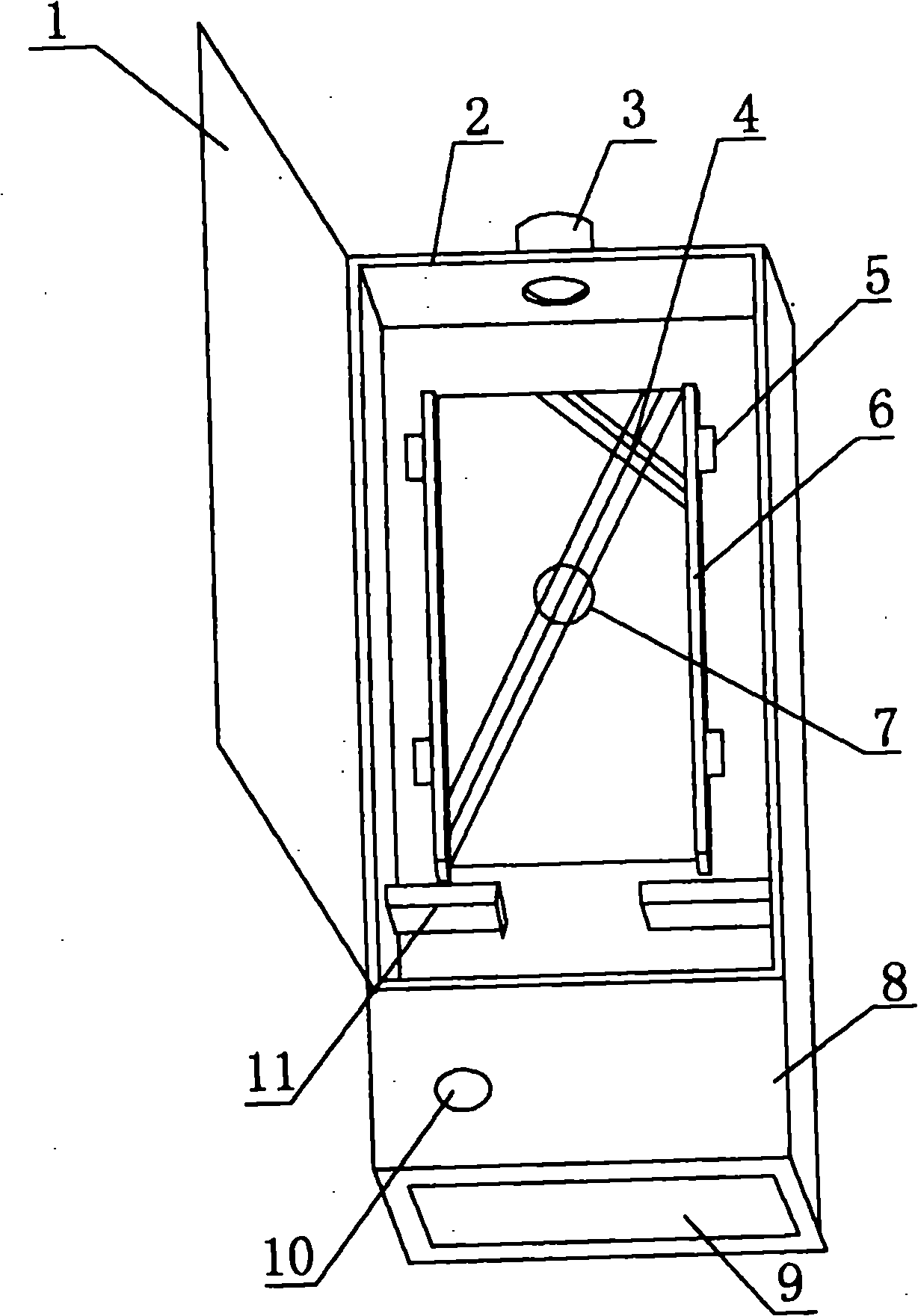

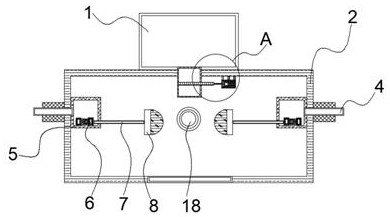

Automatic dust cleaner for blackboard eraser

The invention discloses an automatic dust cleaner for a blackboard eraser, comprising a square box (2) provided with a box cover, a dust collection box (8) and a fan (3), wherein the dust collection box (8) is connected with one end of the square box (2), an upper opening of the dust collection box (8) is communicated with the square box (2), the bottom of the dust collection box is provided with an air outlet opening, and the air outlet opening is covered by a ventilative sponge block (9) which can prevent dust from passing through; the fan (3) is fixed at the other end of the square box (2), and an outlet of the fan (3) is communicated with the square box (2); and two supporting plates (6) which are fixed parallel to the bottom of the square box are arranged in the square box (2), the clearance between the two supporting plates adapts to the width of the blackboard eraser, magnets (5) with different polarities are respectively fixed on the two supporting plates between which a screen mesh (4) is fixed, and a vibrator (7) is arranged on the screen mesh (4). The automatic dust cleaner for the blackboard eraser is convenient and fast to clean dust on the blackboard eraser without causing environmental pollution which harms bodies of teachers and students.

Owner:胡先松

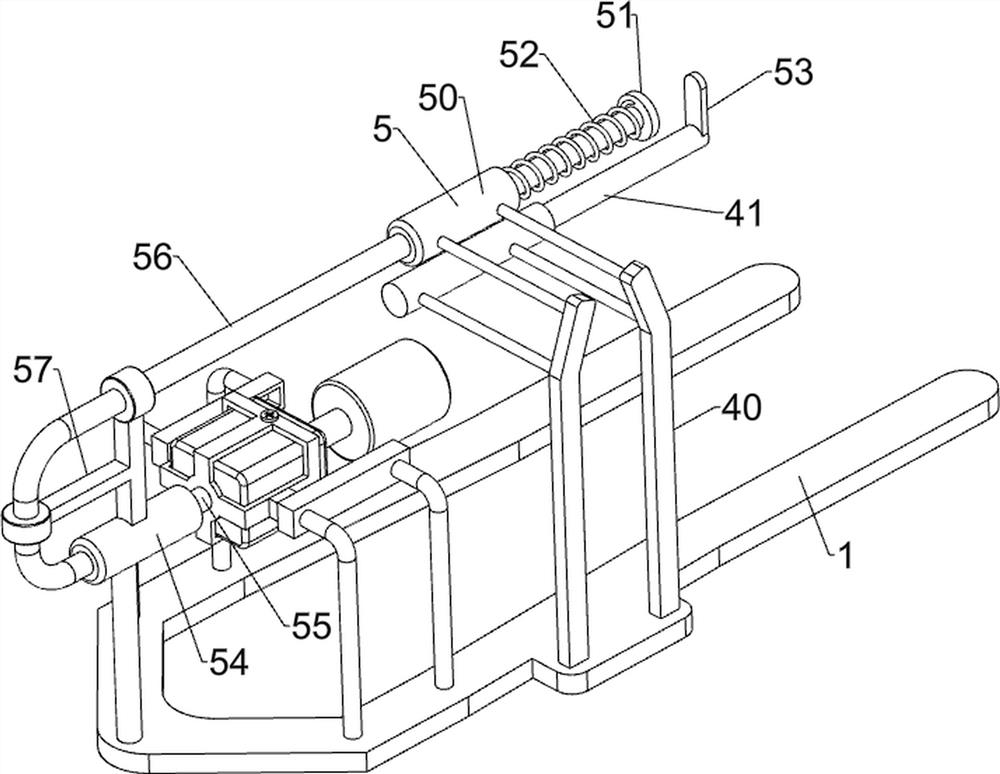

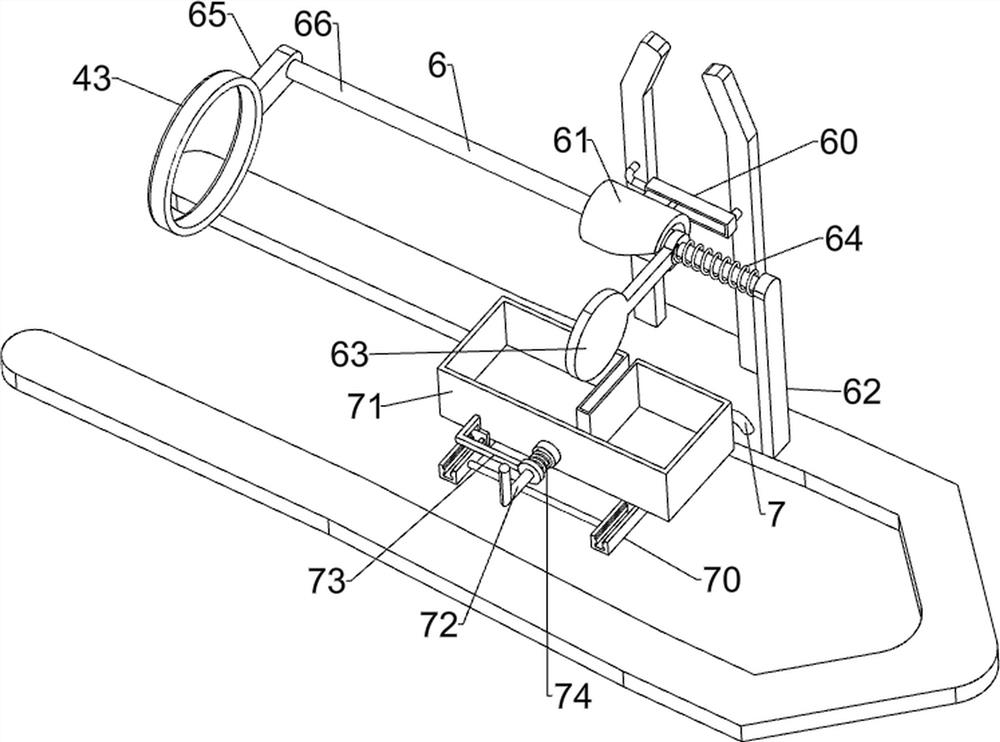

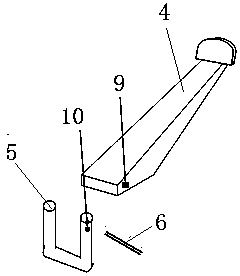

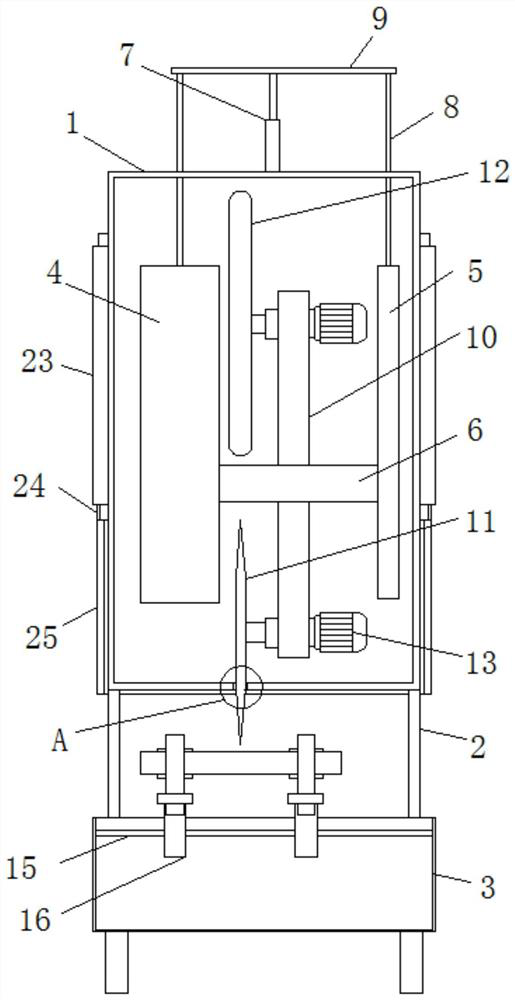

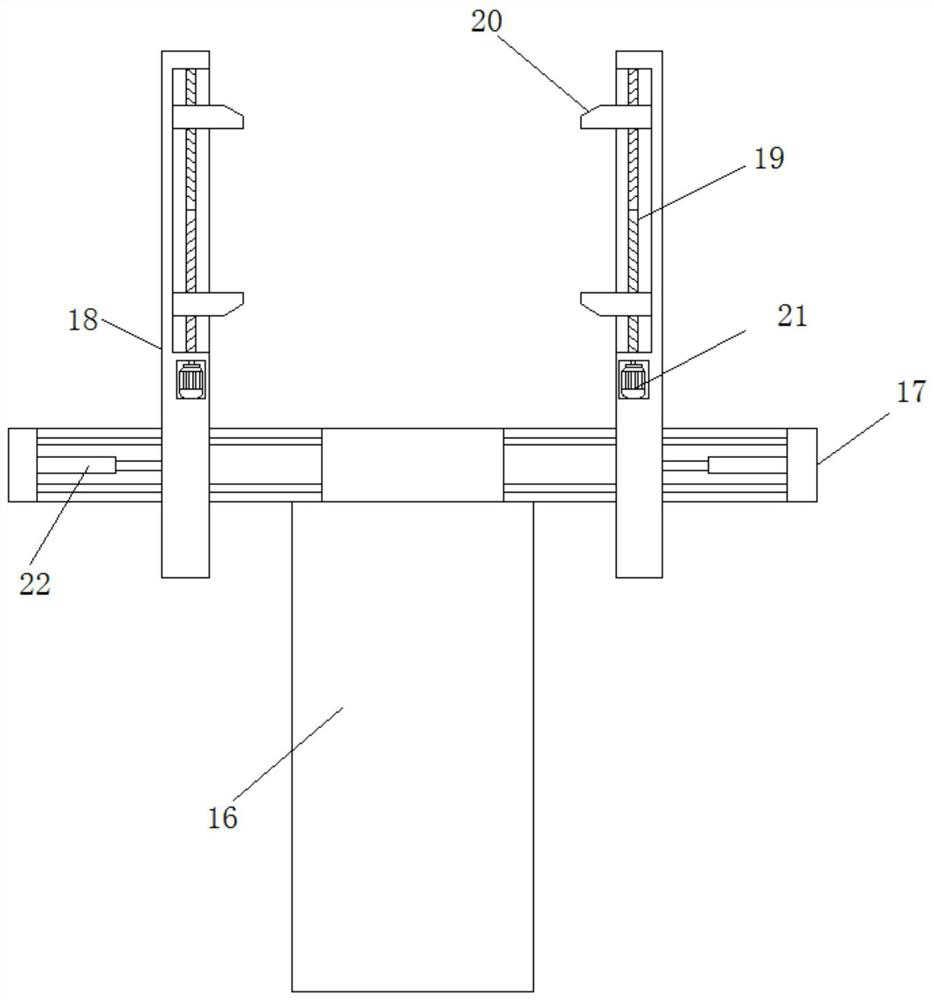

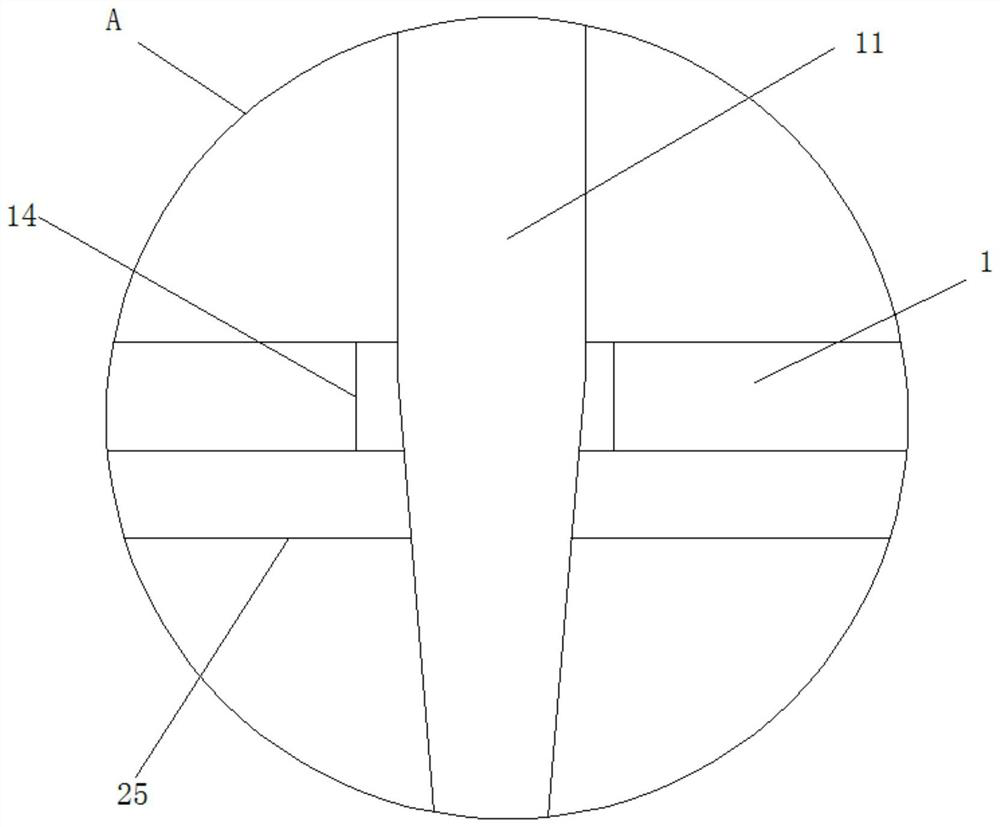

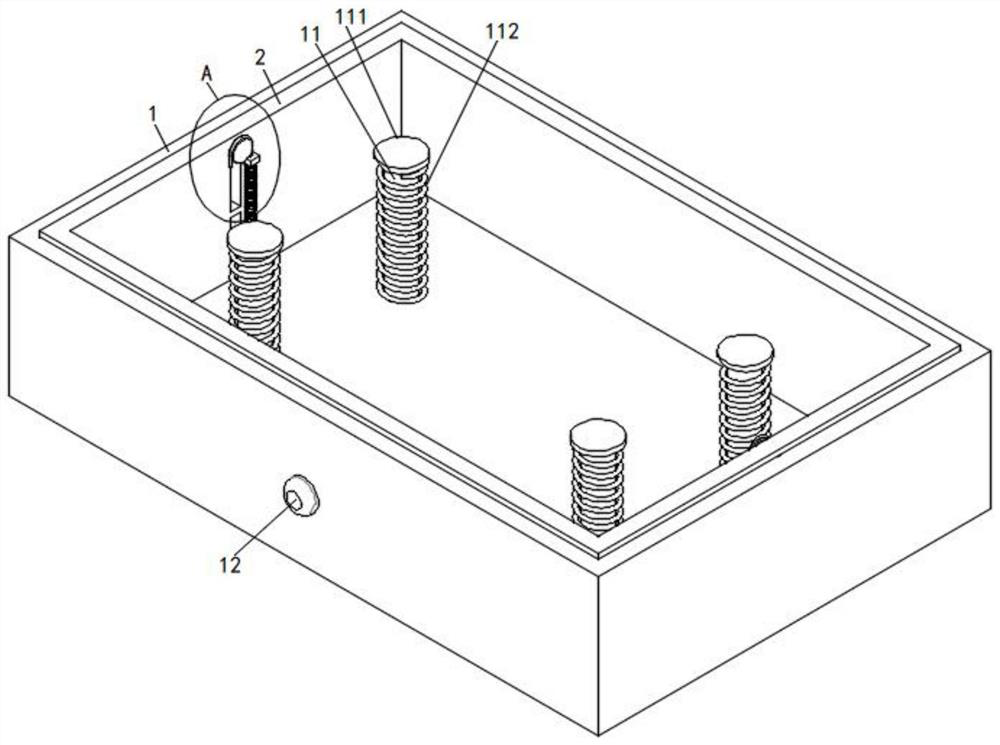

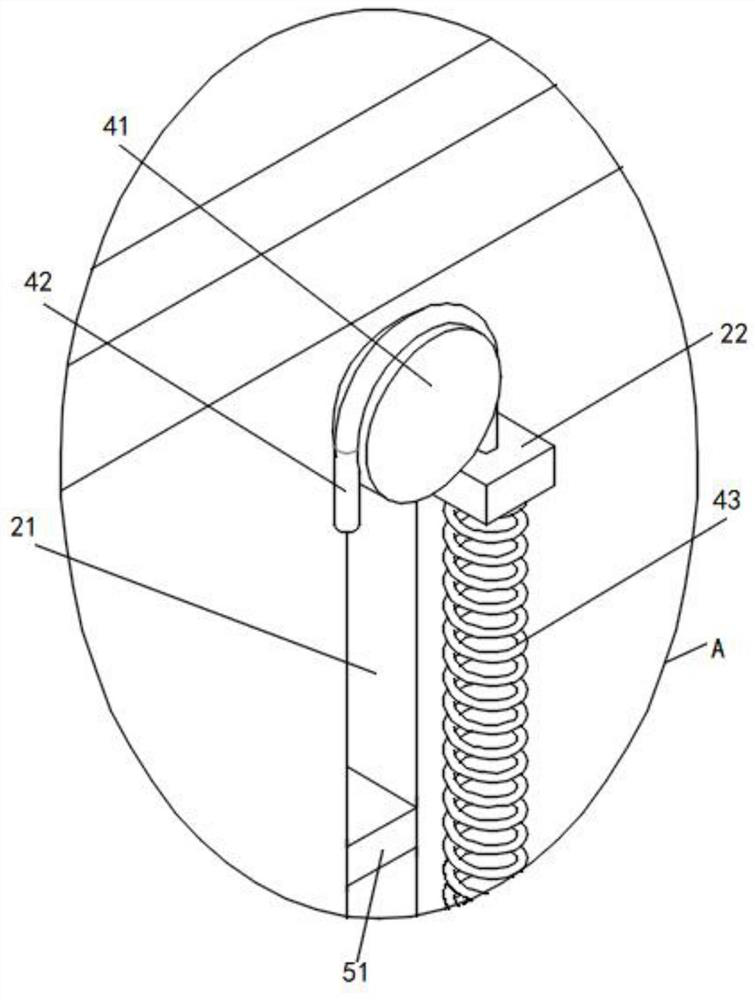

Broom wooden handle bottom cutting equipment

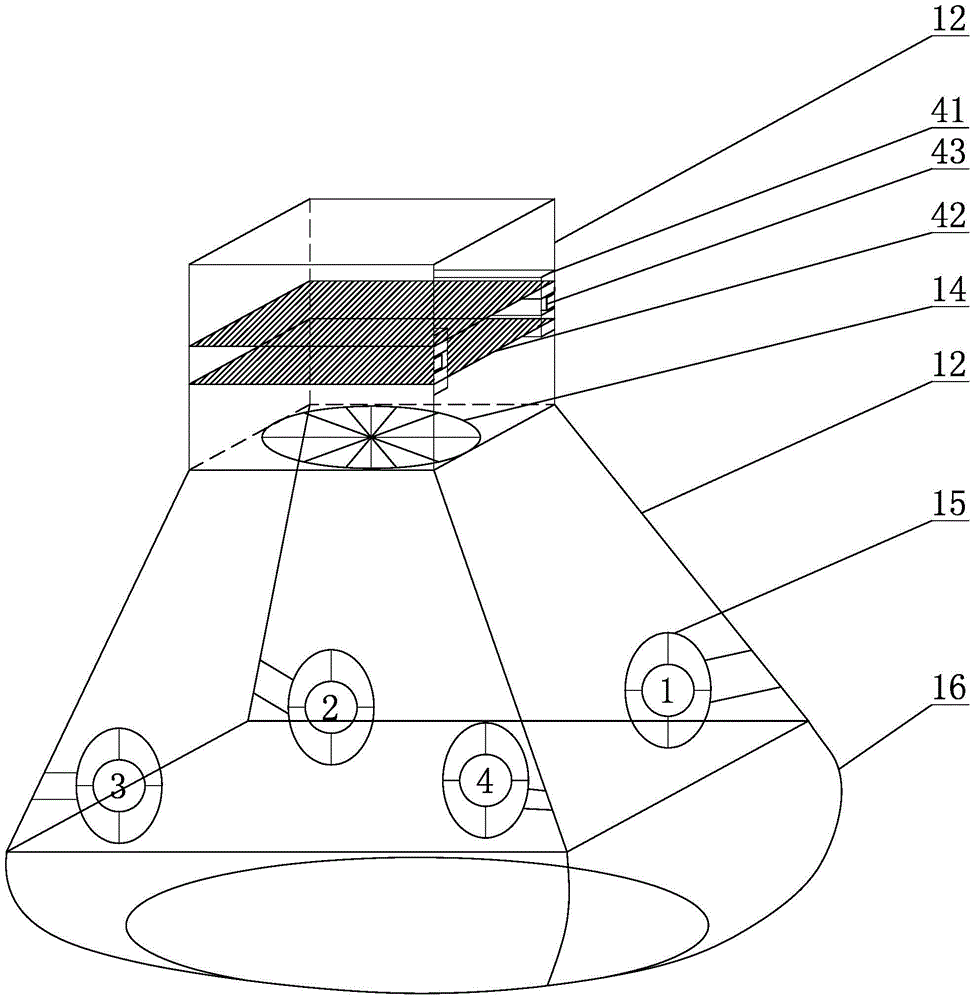

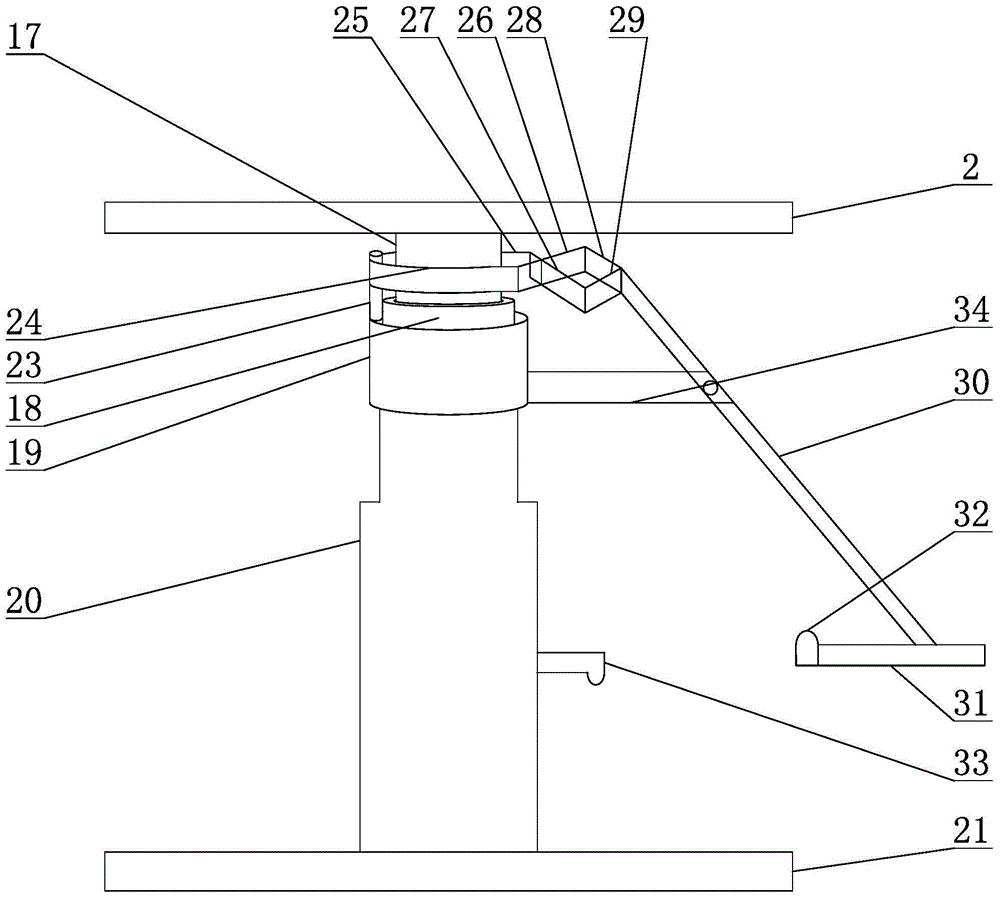

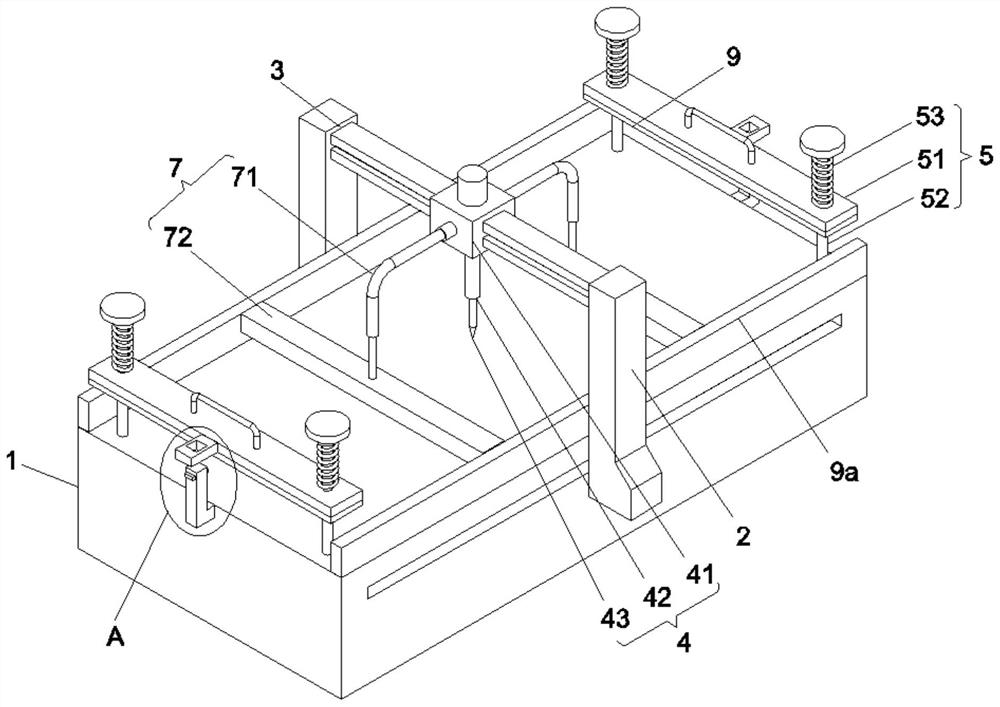

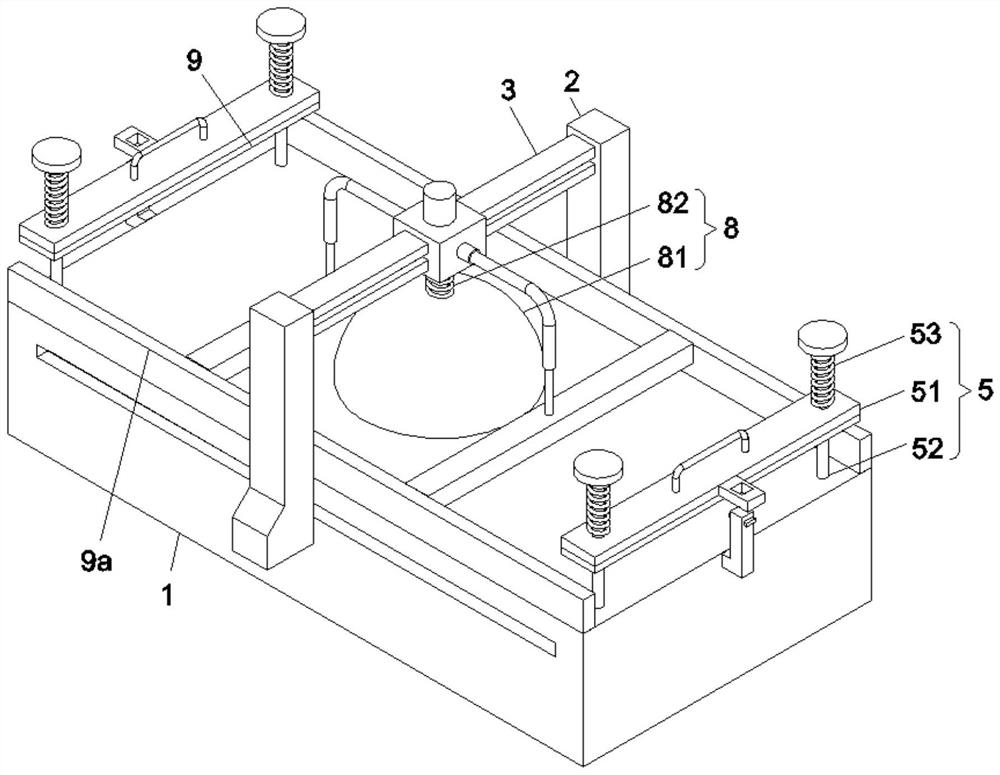

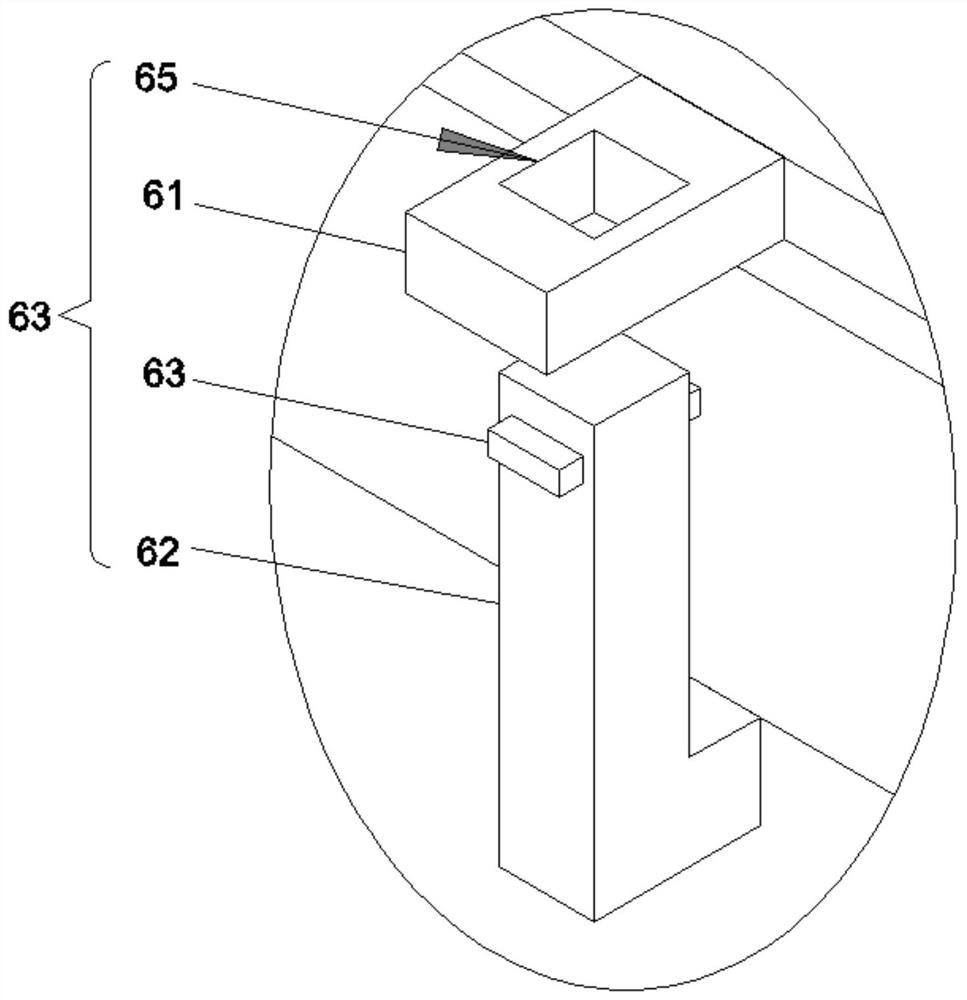

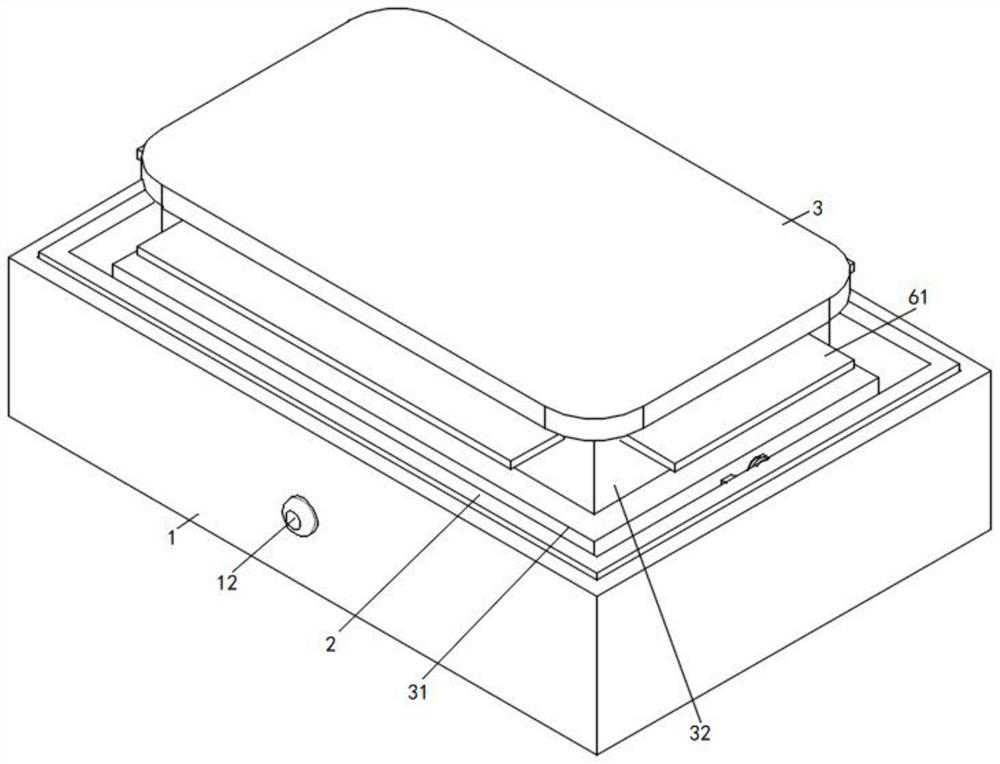

ActiveCN112792920AWon't fly aroundRealize automatic cuttingProfiling/shaping machinesBark-zones/chip/dust/waste removalSlide plateBroom

The invention relates to cutting equipment, in particular to broom wooden handle bottom cutting equipment, and aims to solve the technical problem about how to provide the broom wooden handle bottom cutting equipment which can cut and clamp the bottom of a wooden handle of a broom automatically and can prevent wood chips from flying around when the wooden handle is cut. The broom wooden handle bottom cutting equipment comprises a base, a placing mechanism and a cutting mechanism; the placing mechanism is arranged on one side of the top of the base; the cutting mechanism is arranged on the side, away from the placing mechanism, of the top of the base. The effects that the bottom of the wooden handle of the broom is automatically cut and automatically clamped, and the wood chips cannot fly around when the wooden handle is cut are achieved; a cutting tool is driven by a servo motor to rotate to cut the wooden handle, so that the purpose of automatic cutting is achieved; before the servo motor and the cutting tool move towards the right side to cut the wooden handle, a sliding ring moves towards the left side to press a sliding plate to extrude towards the inner side through a wedge-shaped block, and thus the wooden handle is clamped.

Owner:江苏金鼎建设集团有限公司

Air purifying device

InactiveCN105413344AWill not affect healthDust removal is simpleDispersed particle filtrationTransportation and packagingEngineeringAir purification

The invention provides an air purifying device which comprises a base, a draught fan support, a draught fan, a dust removing structure, a dust brushing structure, a rotating sealing cover and a motor. The draught fan is fixedly installed on the draught fan support and comprises an air draft duct and fan blades installed in the air draft duct, the air draft duct is provided with an air inlet and an air outlet, and the bottom face of the air draft duct is a plane. The dust removing structure is arranged in the middle of the air draft duct and comprises a filter screen and a dust collecting box which is arranged on the side, close to the air inlet, of the filter screen, and the arrangement position of the dust collecting box is lower than that of the air draft duct. The dust brushing structure is used for brushing away dust attached to the side, facing the air inlet, of the filter screen and making the dust fall into the dust collecting box. According to the air purifying device, the dust removing structure is arranged in the middle of the air draft duct, the dust brushing structure is further arranged, when dust removal needs to be performed on the filter screen, the dust brushing structure is started to clean the filter screen, dust removal can be performed without detaching the filter screen, dust removal is easy, and labor intensity is low; dust will not be scattered in all directions or fly upwards and will not be inhaled by workers, and the body health of the workers will not be affected.

Owner:周桂灵

Air cleaning equipment

InactiveCN105582755AWill not affect healthDust removal is simpleDispersed particle filtrationTransportation and packagingAir cleaningEngineering

The invention provides air cleaning equipment. The air cleaning equipment comprises a base, a fan support, a fan, a dust removal structure, a dust brushing structure, a rotary seal cover, a motor, a water spraying pipe, a water pump, a dust cover and a rotating motor, wherein the fan comprises an air suction barrel and fan blades, and the air suction barrel has an air inlet and an air outlet; the dust removal structure is arranged in the middle of the air suction barrel and comprises a filter net and a dust collecting box; the dust brushing structure is used for brushing off dust which is attached on one side, facing the air inlet, of the filter net and enabling the dust to fall into the dust collecting box; the water spraying pipe is mounted above the dust brushing structure and used for flushing the dust brushed off the filter net into the dust collecting box; the water pump is used for supplying water to the water spraying pipe; the dust cover is rotationally mounted on the air suction barrel; the rotating motor drives the dust cover to rotate. According to the air cleaning equipment, the dust removal structure is arranged in the middle of the air suction barrel, the dust brushing structure is arranged and is started to clean the filter net when the dust on the filter net is required to be removed, the dust can be easily removed without dismounting the filter net, and the labor intensity is low; the dust cannot scatter or fly, and body health of workers cannot be affected.

Owner:周桂灵

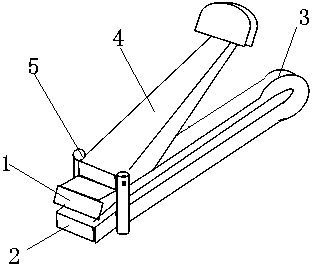

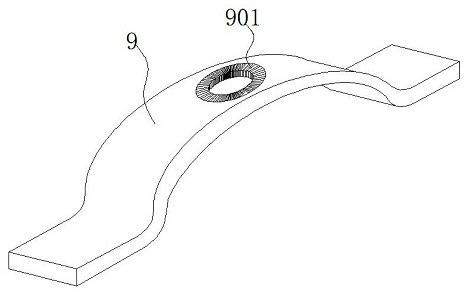

Environment-friendly nail clippers

The invention relates to a pair of environment-friendly nail clippers. The environment-friendly nail clippers are formed by an upper knife edge, a lower knife edge, a spring clip, a handle, a pull ring and a pull ring pin. The rear portion of the upper knife edge and the rear portion of the lower knife edge are each provided with a tail core, the spring clip is in the U shape, inner holes are formed in the two ends of the spring clip, and the tail core of the upper knife edge and the tail core of the lower knife edge are inserted into the two inner holes respectively. The pull ring is concave, transverse holes are formed in the two ends of the pull ring, and the pull ring is clamped to the outer side of the front end of the spring clip from bottom to top; a transverse hole is formed in the lower end of the handle, and the upper end of the handle is in the tongue shape; the lower end of the handle is movably connected with the pull ring through the pull ring pin. When the environment-friendly nail clippers are used, the handle and the pull ring are moved to the front portions of the ends of the spring clip and then are pressed downwards. When the environment-friendly nail clippers are not used, the handle and the pull ring are moved to the rear portion of the spring clip, and the handle is turned forwards. The environment-friendly nail clippers are simple in structure, practical and reliable, and metal materials are saved.

Owner:SHANGHAI INST OF TECH

Polishing machine

InactiveCN108436672AImprove polishing qualityReasonable structureGrinding machinesGrinding/polishing safety devicesElectromagnetic inductionEngineering

The invention discloses a polishing machine. A rack is formed by stand columns and a transverse beam, a polishing system is composed of a polishing mechanism comprising a polishing wheel and a rotating motor for controlling the rotating speed of the polishing wheel, the polishing system is installed on the transverse bean of the rack through the polishing mechanism, first sliding grooves are formed in the left and right stand columns, the transverse beam is installed between the two first sliding grooves, the transverse beam is made of metal materials and is further provided with a control aircylinder, and a power output shaft of the control air cylinder is connected with the polishing mechanism of the polishing system; and the rack further comprises a polishing plate, the polishing plateis internally provided with an iron core, the outer side of the iron core is wound with an electro-magnetic induction wire, two positioning rods are arranged on the surface of the polishing plate, the left and right positioning rods are installed on left and right sliding grooves in the polishing plate, each sliding groove is internally provided with a spring, one end of each spring is fixedly connected with the corresponding positioning rod, and the other end of each spring is fixedly connected to the corresponding stand column. The device is simple in structure and good in polishing effect.

Owner:成都亚沃航空科技有限公司

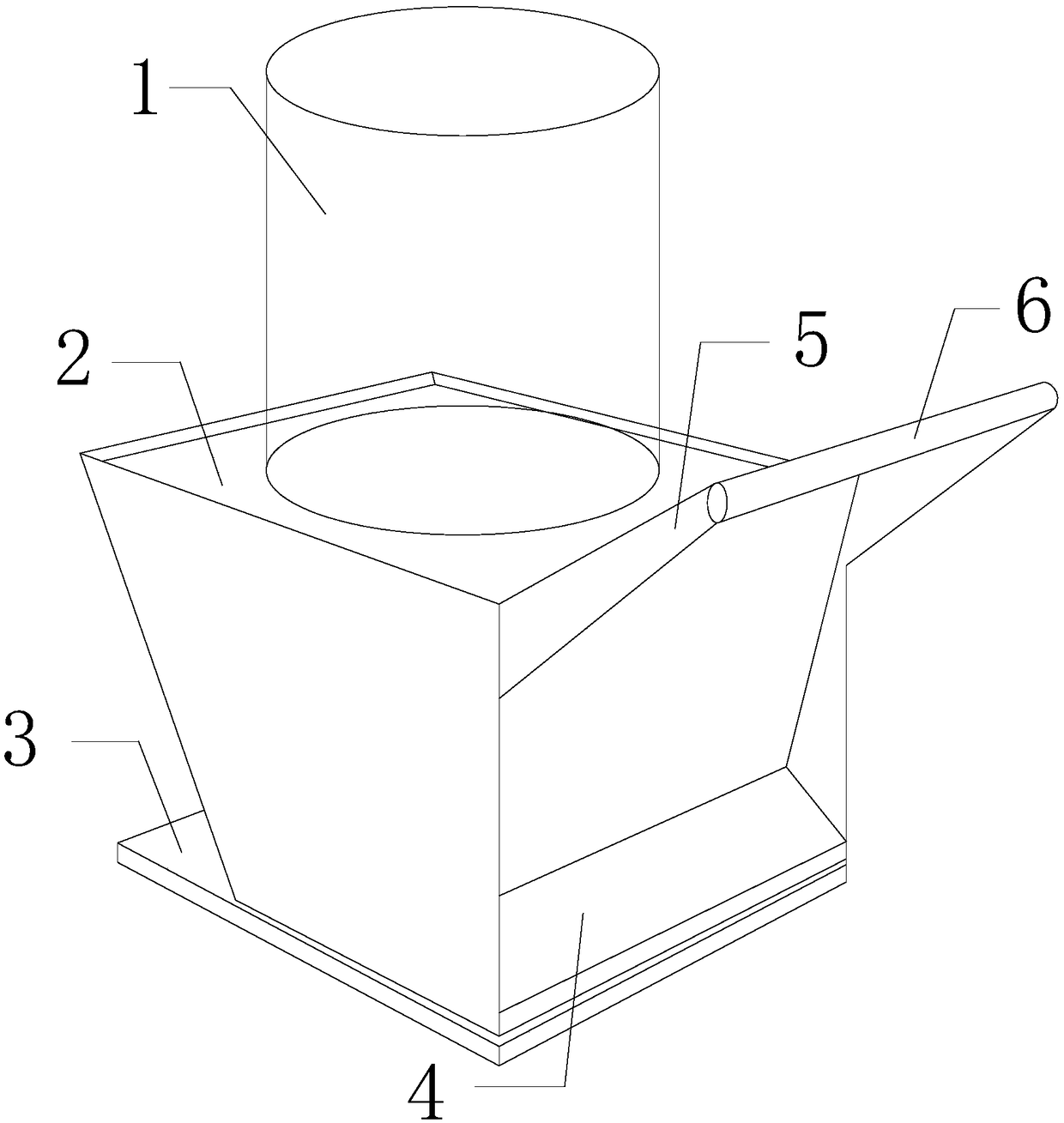

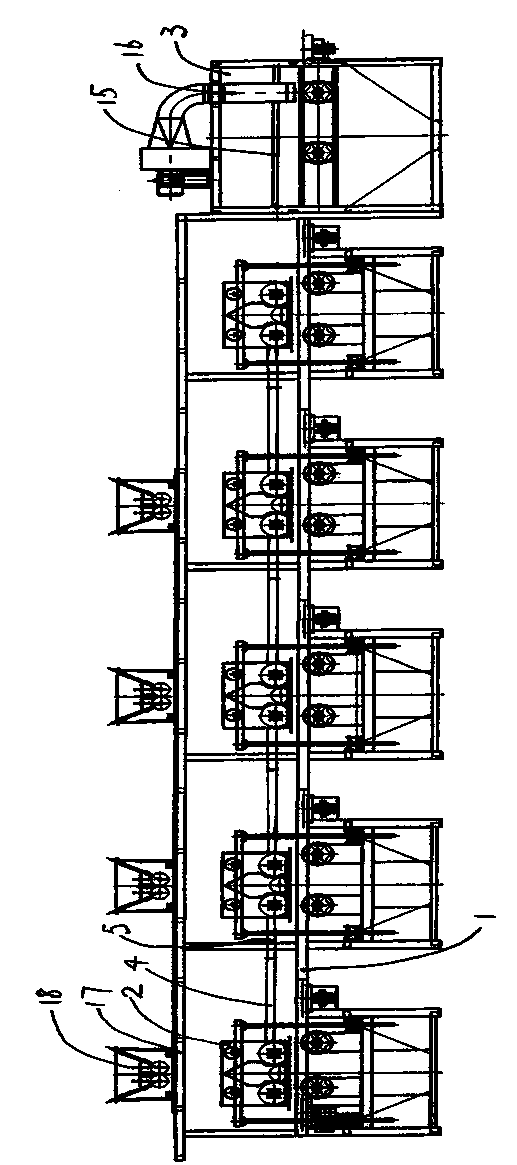

Processing production line of straw mixture artificial board

InactiveCN112248180AImprove protectionDust flying everywhereDomestic articlesFlat articlesElectric machineryManufacturing line

The invention discloses a processing production line of a straw mixture artificial board, and relates to the technical field of artificial boards. The processing production line of the straw mixture artificial board comprises an inlet device, the inlet device comprises a shell I, the lower end of the shell I is cylindrical, the upper end of the shell I is in an inverted triangle shape, and an opening of the shell I faces upwards; a rotating cylinder is arranged at the joint of the upper end and the lower end of the shell I, the rotating cylinder is fixedly connected to the shell I through a motor, grooves I are uniformly formed in the outer side of the rotating cylinder at equal intervals, and columns I are connected to the interiors of the grooves I in a sleeving mode; arc plates are fixedly connected to the ends, far away from the rotating cylinder, of the columns I, the arc plates are in a radian, and the radian of the arc plates is matched with the radian of the outer side of the rotating cylinder; and springs I are fixedly connected to the ends, located in the grooves I, of the columns I, and the ends, far away from the columns I, of the springs I are fixedly connected to theinner walls of the grooves I. The processing production line of the straw mixture artificial board plays a better role in protecting the environment.

Owner:新疆华丹原牧农业科技有限公司

Equipment capable of collecting cuttings of milling machine

InactiveCN108526991AEasy to storeEasy to recycleMaintainance and safety accessoriesEngineeringAir blower

The invention discloses equipment capable of collecting cuttings of a milling machine. The equipment structurally comprises a glass protective cover, a separating and arranging device, a placing bottom plate, a side supporting plate, an extending frame and a pull rod; the glass protective cover is connected above the separating and arranging device through the glue and is perpendicular to the separating and arranging device, the placing bottom plate is horizontally fixed under the separating and arranging device in a welding connecting mode, the side supporting plate is fixed under the right side of the separating and arranging device through screws, the extending frame is connected above the right side of the separating and arranging device through nails, and the pull rod is in threaded connection with the right side of the extending frame and is parallel to the side supporting plate. According to the equipment, through the arranged separating and arranging device, a cooling liquid and the cuttings of input equipment can be separated, moreover, due to the effect of filtering, the equipment can enable the cuttings to be in a relatively dry state, so that the cuttings are convenientto store, and in the final arranging and collecting process, an air blower can blow all the scrap iron to a material taking opening so that people can more easily recover the cuttings.

Owner:李三源

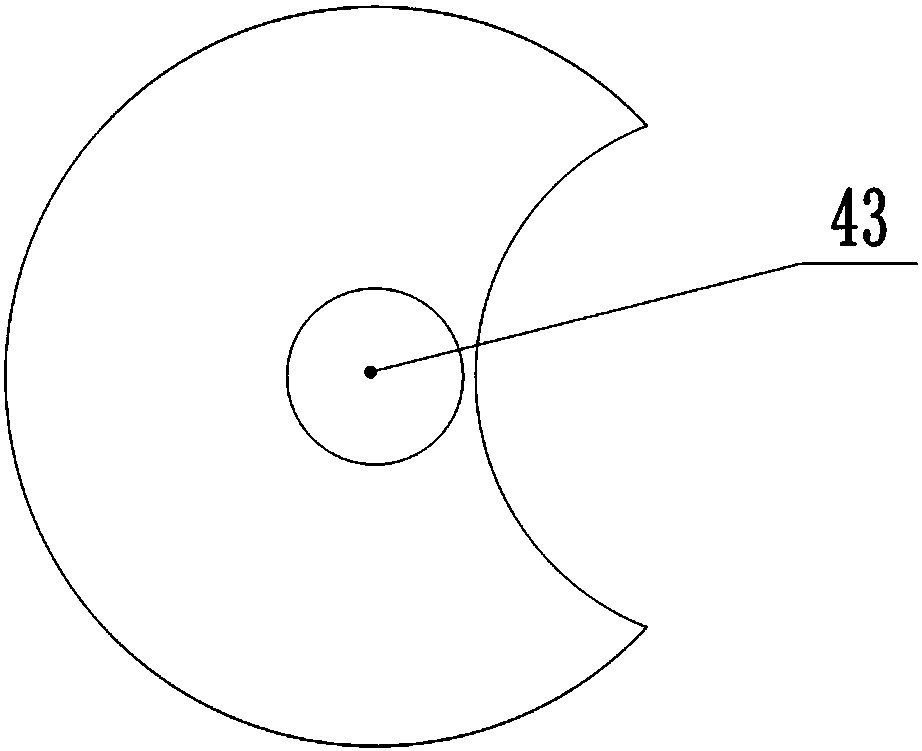

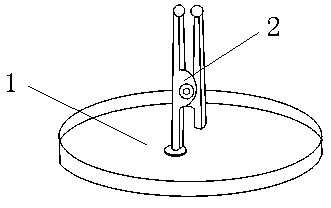

Mosquito-repellent incense support

The invention discloses a mosquito-repellent incense support which comprises a disk-shaped base for containing incense ash. A circle of protrusions are arranged at the edge of the base, a perpendicularly-arranged mosquito-repellent incense clamp is fixed in the middle of the base, a long arm of the mosquito-repellent incense clamp is fixed in the middle of the base, and a short arm of the mosquito-repellent incense clamp is suspended in the air. The mosquito-repellent incense support is provided with the disk-shaped base for containing incense ash, so that when the mosquito-repellent incense support is used, a little water is placed in the base to absorb incense ash to prevent incense ash from flying. In addition, the base is convenient to clean. Furthermore, the mosquito-repellent incense clamp is arranged in the middle of the base, so that various kinds of mosquito-repellent incense can be clamped, and the application range of the mosquito-repellent incense support is widened. The mosquito-repellent incense support is convenient to use, simple in structure and capable of easily achieving good application prospect.

Owner:王双双

Efficient cutting equipment for aluminum material machining

InactiveCN112621247AGuaranteed cutting accuracyStable and firmOther manufacturing equipments/toolsPositioning apparatusPhysicsElectric machinery

The invention belongs to the technical field of aluminum material machining, and particularly relates to efficient cutting equipment for aluminum material machining. The equipment comprises a box body; a supporting column is fixedly mounted at the bottom of the box body; a receiving box with an open top is fixedly mounted at the bottom of the supporting column; a rectangular box and a rectangular block are slidably mounted in the box body; a transverse shaft is rotatably mounted between the rectangular box and the rectangular block; a vertically-arranged mounting plate is fixedly mounted on the transverse shaft; the top and the bottom of the mounting plate penetrate through the transverse shaft; a polishing sheet and a cutting blade are rotatably mounted at the top and the bottom of the mounting plate; and driving motors are arranged at the top and the bottom of the mounting plate. According to the device, the top and the bottom of the two sides of an aluminum material are fixed, the fixing is stable, the electric operation is implemented, the aluminum material is placed stably and firmly, the deviation is avoided during cutting, the cutting precision is guaranteed, and cutting and polishing are integrated, so that the use quality is high, chippings cannot fly around, the cutting safety is improved, and chalk chippings are collected.

Owner:上饶市广利装饰材料有限公司

Multi-axis numerical control intelligent machine tool machining center

InactiveCN112496832AEasy to process in one goSimple structureWork clamping meansMetal working apparatusNumerical controlEngineering

The invention discloses a multi-axis numerical control intelligent machine tool machining center. The multi-axis numerical control intelligent machine tool machining center comprises a machine body, an inner cavity is formed in the machine body, and a middle box body is arranged in the inner cavity. An inner transfer cavity is formed in the middle box body, and a plurality of clamping devices usedfor forming clamping structures to clamp parts are arranged in the end wall of the inner transfer cavity. The top of the middle box body is provided with a top shell, and the top shell and the middlebox body are internally provided with conveying devices used for guiding the parts in the external space into the equipment and conveying the parts into the clamping devices to be clamped so as to facilitate machining. According to the multi-axis numerical control intelligent machine tool machining center, by means of the mode that the parts can extend out from different positions in the equipment, multi-axis one-time machining of the parts is facilitated, the working efficiency of the equipment is improved, and the parts can be covered to prevent chippings from flying.

Owner:王涛

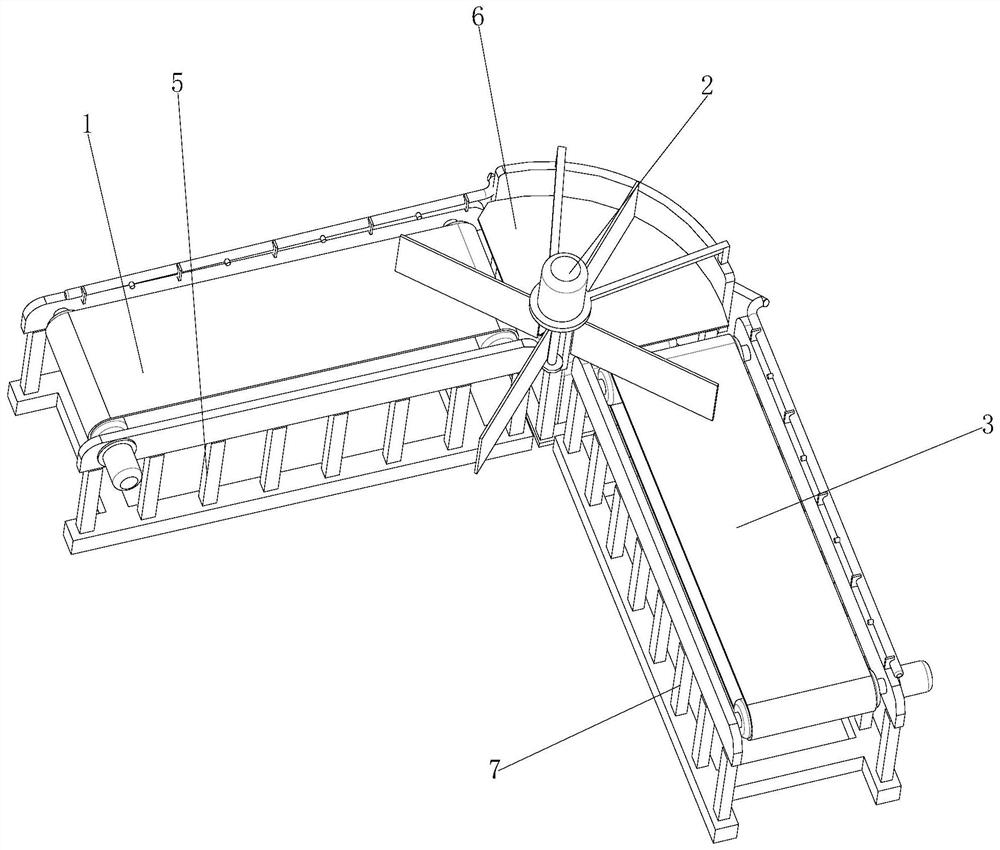

Wide-angle turning belt conveyor

InactiveCN114044336ATo achieve the purpose of turning at a large angleWon't fly aroundLoading/unloadingConveyor partsMineral SourcesElectric machinery

The invention relates to the technical field of mineral equipment, and discloses a wide-angle turning belt conveyor, which is characterized in that a first conveyor is fixedly connected to the top of a first support, a turning groove is formed in the right side of the first conveyor, a turning mechanism is fixedly connected to the inner side of the turning groove, and a second support is arranged on the front side of the turning groove, a second conveyor is fixedly connected to the top of the second support, and the top edges of the first conveyor and the second conveyor are both fixedly connected to a dustproof mechanism. According to the wide-angle turning belt conveyor, through the arranged turning mechanism, when mineral resources are conveyed into the turning groove through the first conveyor, a motor is started to drive a rotating shaft to rotate, the rotary rotating shaft rotates to drive a turnover plate to rotate, the mineral resources in the turning groove are moved to the second conveyor, and therefore the purpose of wide-angle turning is achieved; the problem that due to a belt structure, a belt conveyor is inconvenient to turn, or wide-angle turning conveying is not convenient is effectively solved.

Owner:山东海纳智能装备科技股份有限公司

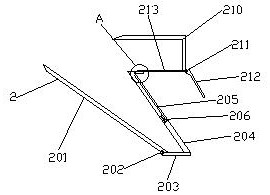

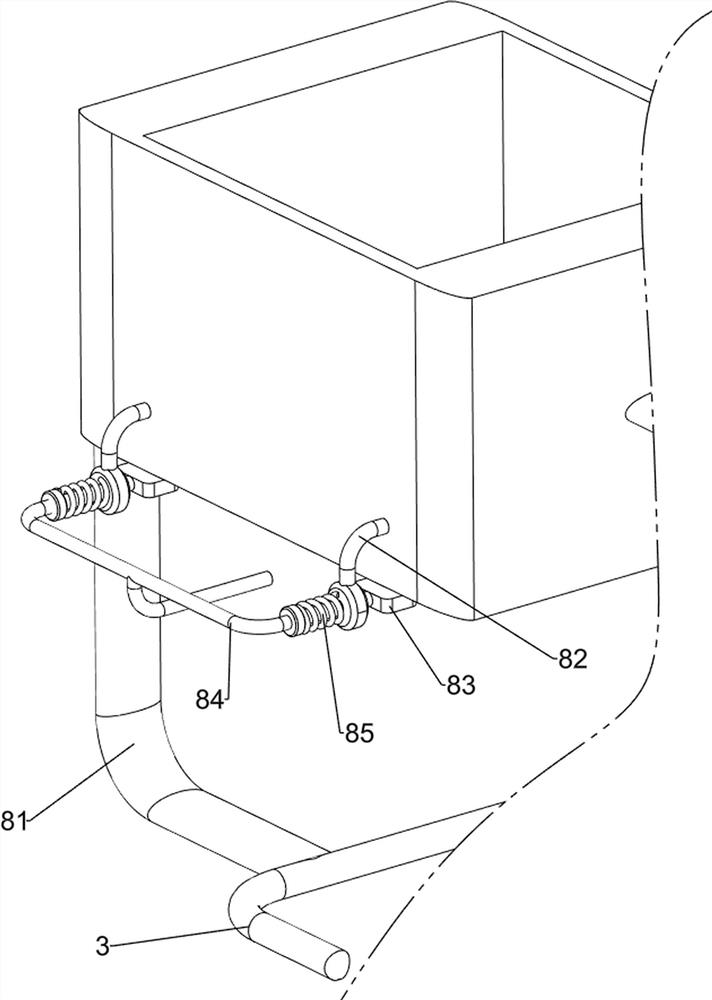

A color sorter discharge tooling

The invention relates to a discharging tool of a color sorter.The discharging tool comprises a hopper and a discharge opening conversion device.The hopper comprises a hopper feeding segment and a hopper discharging segment.The hopper feeding segment is fixed to the color sorter.The hopper discharging segment is fixed to the discharging opening conversion device.The hopper discharging segment is a hollow square shell.The discharging opening conversion device comprises a square feeding segment and a round discharging segment.The size of the inner wall of the square feeding segment is matched with that of the outer wall of the hollow square shell.An L-shaped connection plate is arranged on the square feeding segment and comprises a top plate and a side plate, the top plate is fixed to the square feeding segment, the top plate and an opening of the square feeding segment are located in the same horizontal plane, the side plate is fixed to the top plate and perpendicular to the top plate, and the top plate is provided with a plurality of evenly distributed strong magnetic pieces.A discharging opening of the discharging tool of the color sorter is round so as to be sleeved by a cloth bag conveniently to achieve a flow guide function, materials can be conveniently conveyed into a material receiving frame and cannot splash, and the hopper and the discharging opening conversion device are convenient to assemble and disassemble.

Owner:ANHUI JIEXUN OPTOELECTRONICS TECH

Machining equipment facilitating waste collection and used for drilling of inner cavity of LED lamp protective cover

InactiveCN111940782AEasy to suck awayEasy to drillCleaning using toolsPositioning apparatusThermodynamicsWaste collection

The invention discloses machining equipment facilitating waste collection and used for drilling of an inner cavity of an LED lamp protective cover. The machining equipment comprises a collecting box,a workbench is arranged in a groove in the middle of the upper surface of the collecting box, adsorption mechanisms are arranged at the outer side of the workbench and on the surface of the collectingbox in a manner of being symmetrical with respect to the center line, and clamping grooves are formed in the outer sides of the adsorption mechanisms and at the surface of the collecting box. According to the machining equipment, a drilling mechanism and a dust suction mechanism are arranged on the surface of the collecting box and in the collecting box correspondingly, and through the arrangement of a folding cover, the effect of being isolated from the outside is conveniently achieved when the interior of the LED protective cover is drilled through the drilling mechanism; and meanwhile, through the arrangement of the dust suction mechanism, waste chipping particles generated during drilling can be conveniently sucked away by the drilling mechanism, the phenomena of insufficient power and blockage caused by the fact that the waste chipping particles enter the drilling mechanism are avoided, and drilling of the LED dust cover is facilitated.

Owner:重庆数智源智能装备科技有限公司

A flocking structure of a flocking machine

ActiveCN103447183BImprove efficiencyGuaranteed uniformityLiquid surface applicatorsCoatingsWorking environmentEngineering

The invention provides a flocking chamber structure, which enables that flocks in a flocking process do not fly around, guarantees the uniformity of flocking, makes the excess flocks easy to collect, reduces the flock cost of flocking, guarantees a good working environment of a workshop and guarantees short length of the flocking workshop and high flocking efficiency due to utilization of a cloth delivery pipe between two flocking chambers. The flocking structure comprises a cloth delivery pipe, flocking chambers and a flock recovery chamber, wherein the cloth delivery pipe is uniformly provided with the flocking chambers; the rear part of the final flocking chamber is provided with the flock recovery chamber; the flocking structure is characterized in that an integral structure of a metal plate and a glass plate is arranged above the cloth delivery pipe between adjacent flocking chambers; one end of the metal plate is connected with a lateral vertical plate of one flocking chamber, and the other end of the metal plate is connected with one end of the glass plate; the other end of the glass plate is connected with a corresponding lateral vertical plate of another flocking chamber.

Owner:WUXI QUANSHUN MACHINERY MFG

Wood floor chamfering device for house decoration

ActiveCN112894536AReduce sandingLabor savingEdge grinding machinesProfiling/shaping machinesPolishingAgricultural engineering

The invention relates to a chamfering device, in particular to a wood floor chamfering device for house decoration. The wood floor chamfering device for house decoration can carry out rapid chamfering on wood floors and save manpower. The wood floor chamfering device for house decoration comprises bases, first supporting frames, second supporting frames, fixing mechanisms, and a polishing mechanism, wherein the first supporting frames are arranged on the two sides between the two bases; the second supporting frames are arranged on one sides of the two bases, and the two second supporting frames are connected with the first supporting frames on the side portions; the fixing mechanisms are arranged on the first supporting frames; and the polishing mechanism is arranged on one side of the base. According to the wood floor chamfering device, through mutual cooperation of the fixing mechanisms and the polishing mechanism, a wood floor is fixed through a tray, the wood floor is conveyed and is polished and cut through a cutting knife, and the effect of saving manpower to polish the wood floor is achieved.

Owner:深圳市美置乡墅科技有限公司

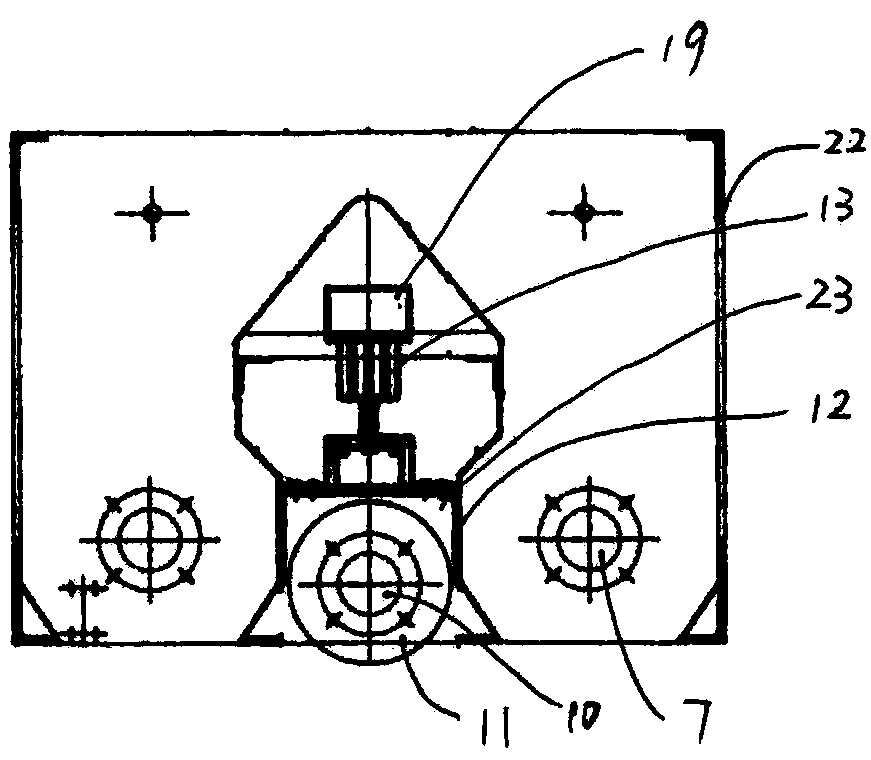

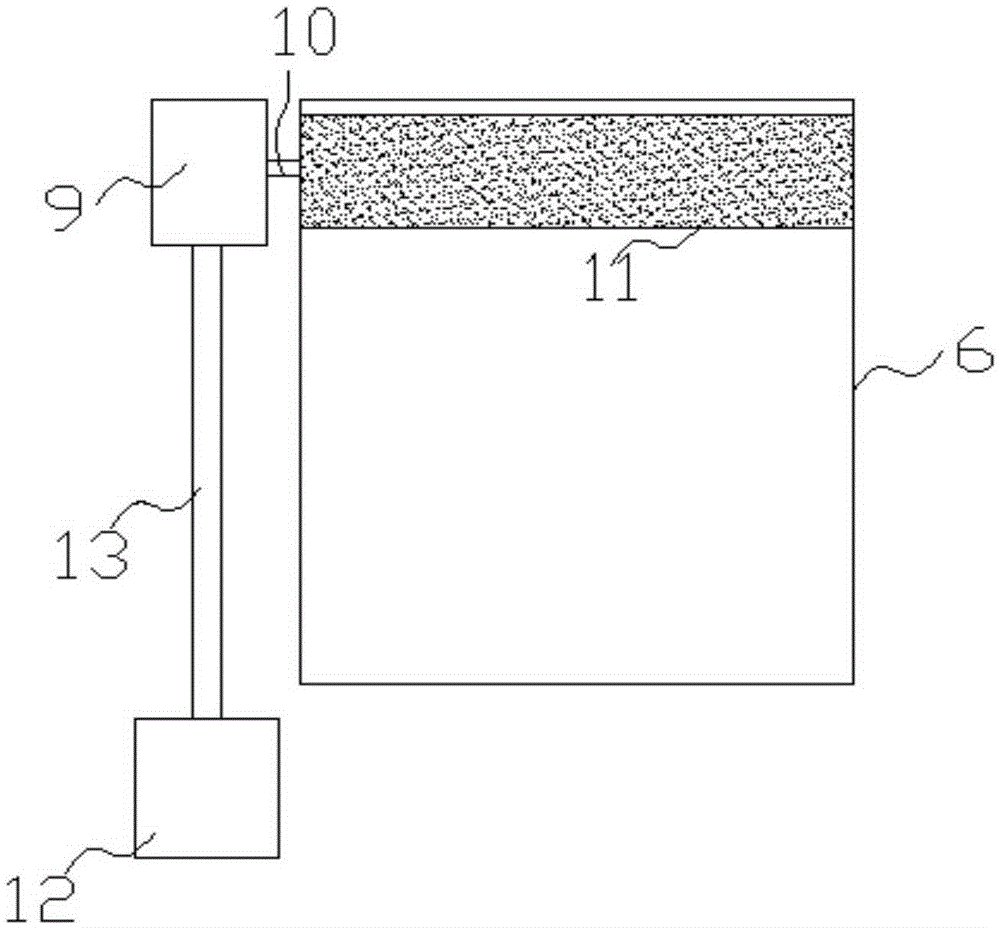

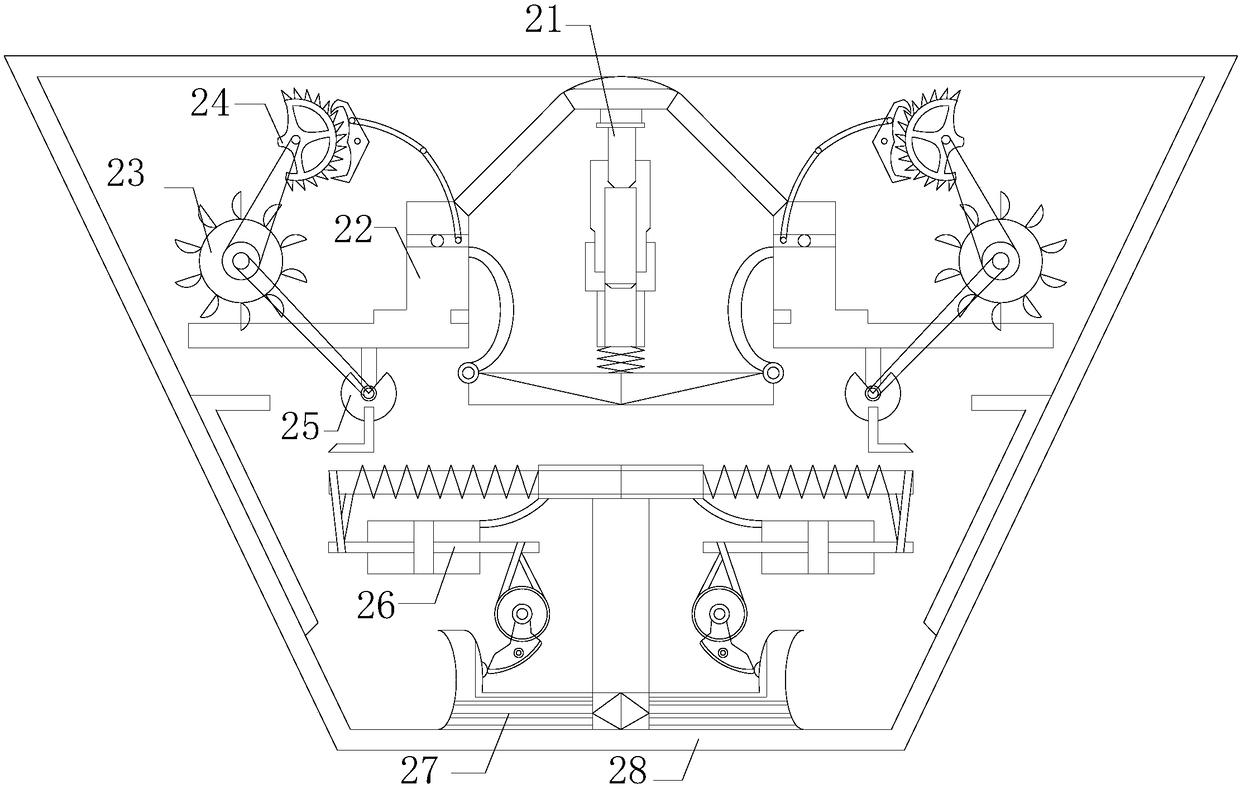

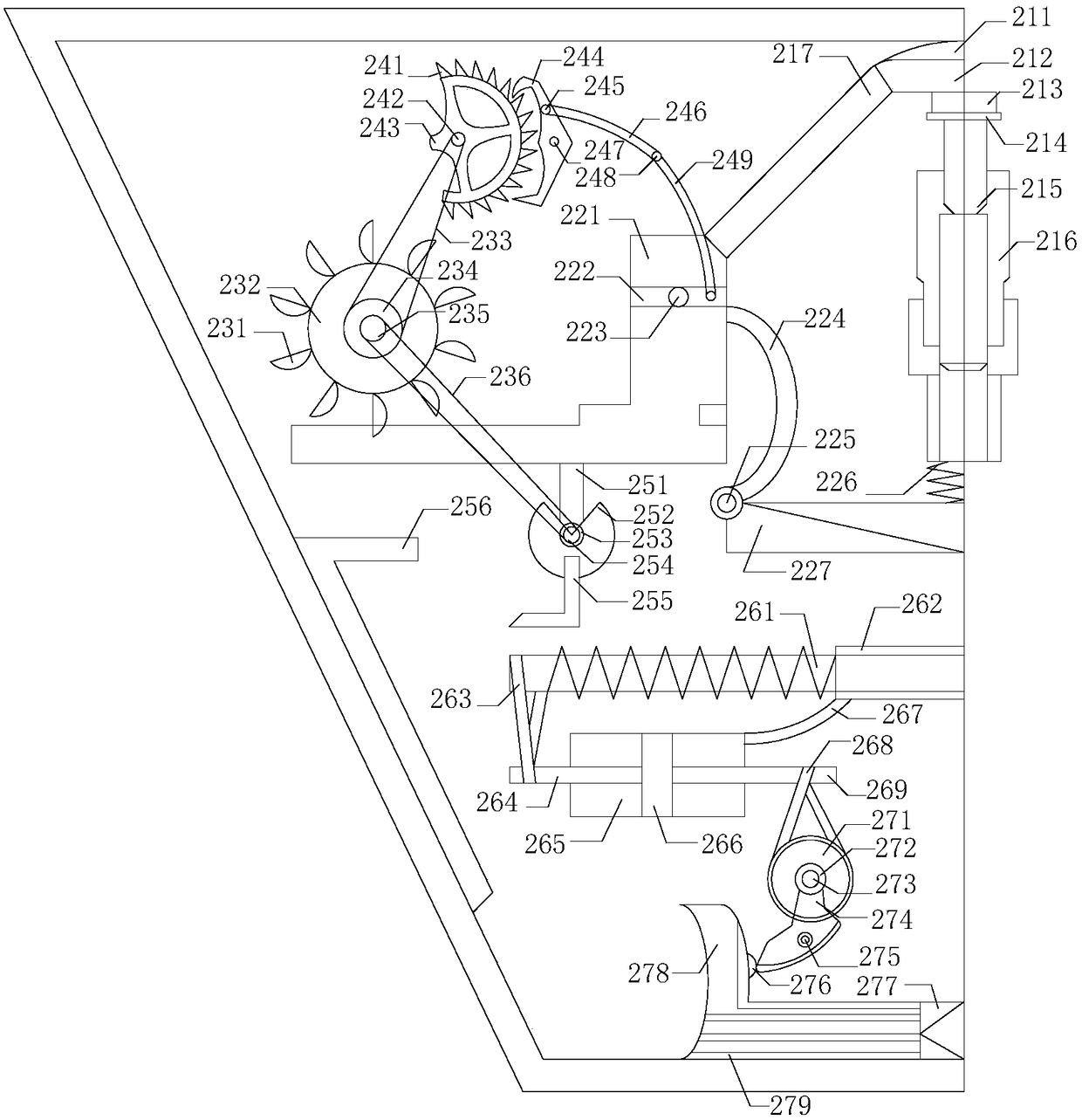

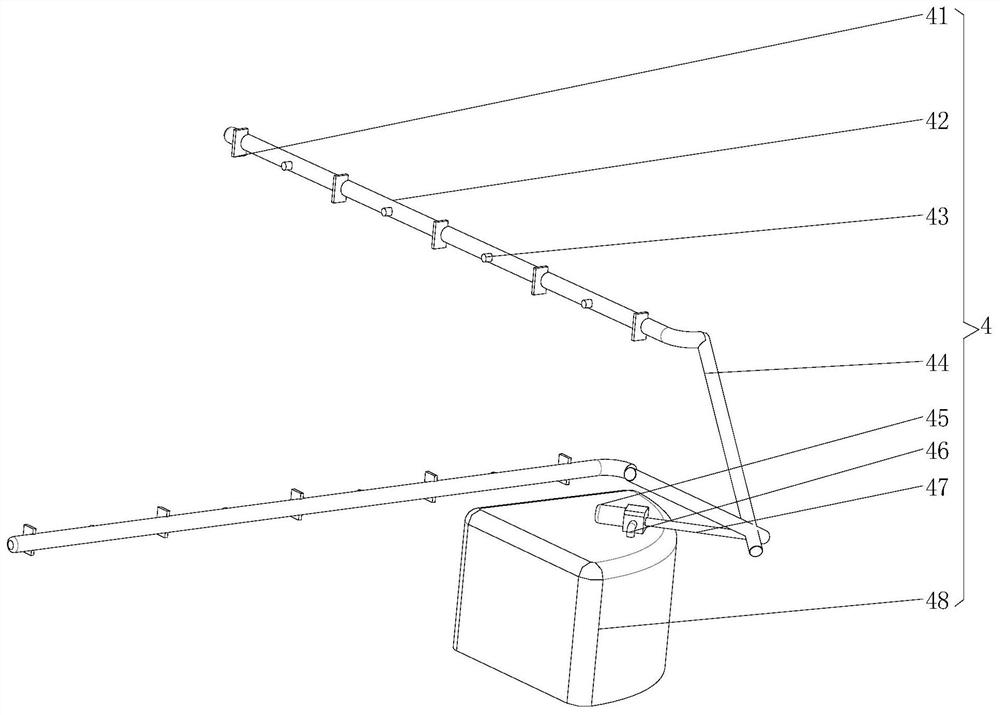

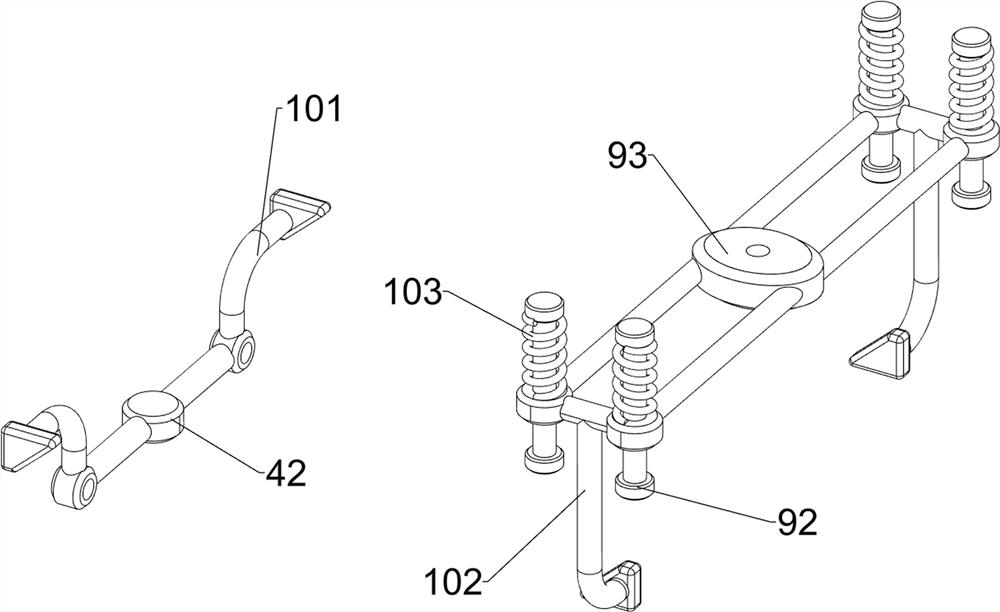

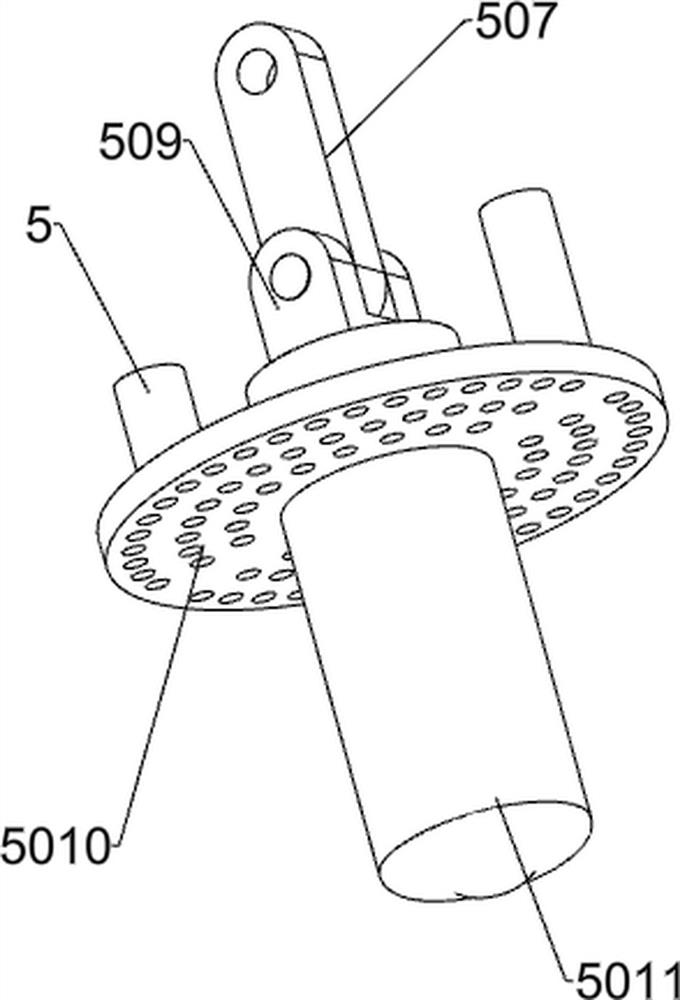

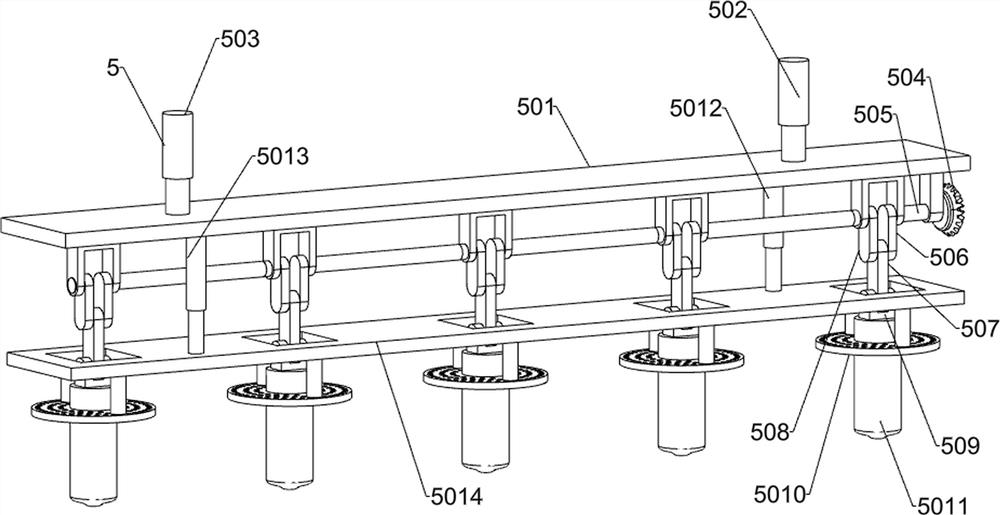

Sandwich moxa cone semi-forming pre-embedding production device and production method

InactiveCN113208907ANot prone to the problem of accumulation and hungerWon't fly aroundDevices for heating/cooling reflex pointsPharmaceutical product form changeProcess engineeringPharmaceutical Substances

The invention relates to the field of moxibustion, in particular to a sandwich moxa cone semi-forming pre-embedding production device and production method. The technical aim of the invention is to provide the sandwich moxa cone semi-forming pre-embedding production device and production method. According to the technical scheme, the sandwich moxa cone semi-forming pre-embedding production device comprises a bottom frame, a first supporting plate, a bearing and rotating mechanism, a control screen, a dust-free decompression semi-forming mechanism and a slicking mechanism; the bottom frame is fixedly connected with the first supporting plate; the bottom frame is connected with the bearing and rotating mechanism; the bearing and rotating mechanism is fixedly connected with the control screen; and the bearing and rotating mechanism is connected with the dust-free decompression semi-forming mechanism. According to the invention, molding and filling of spices and medicines are achieved for moxa cones, and batch production can be achieved; and during integral extrusion forming, folium artemisiae argyi powder, the spices and the medicines do not fly around, and the problem of dust accumulation of the device is not easily caused.

Owner:杨文连

Packaging material crushing and discharging device capable of controlling speed

The invention relates to the technical field of smashing and discharging devices, and discloses a speed-controllable packaging material smashing and discharging device which comprises a smashing device body, a dust removal box is fixedly connected to the bottom of the smashing device body, and a water pump is fixedly connected to the inner wall of a water tank. And one end of the spraying pipe is fixedly connected with a spraying head, the bottom of the support is fixedly connected with an air cylinder, and the inner wall of the sliding opening is slidably connected with a limiting plate. Compared with the prior art, the paper scrap crushing device has the following advantages and effects that a telescopic rod drives a limiting plate to slide in a sliding opening, so that the internal space of a discharging pipe can be controlled, the discharging speed of the crushing device body is adjusted, crushed paper scraps are wetted by water sprayed by a spray head in the falling process of falling into a dust removal box, the weight of the paper scraps is increased, and the dust removal effect is improved. The paper scraps are prevented from flying around when being discharged through the discharging opening in the bottom of the dust removal box, the dust removal effect is achieved, and the wetted paper scraps are convenient to collect.

Owner:徐州瑞杰机械科技有限公司

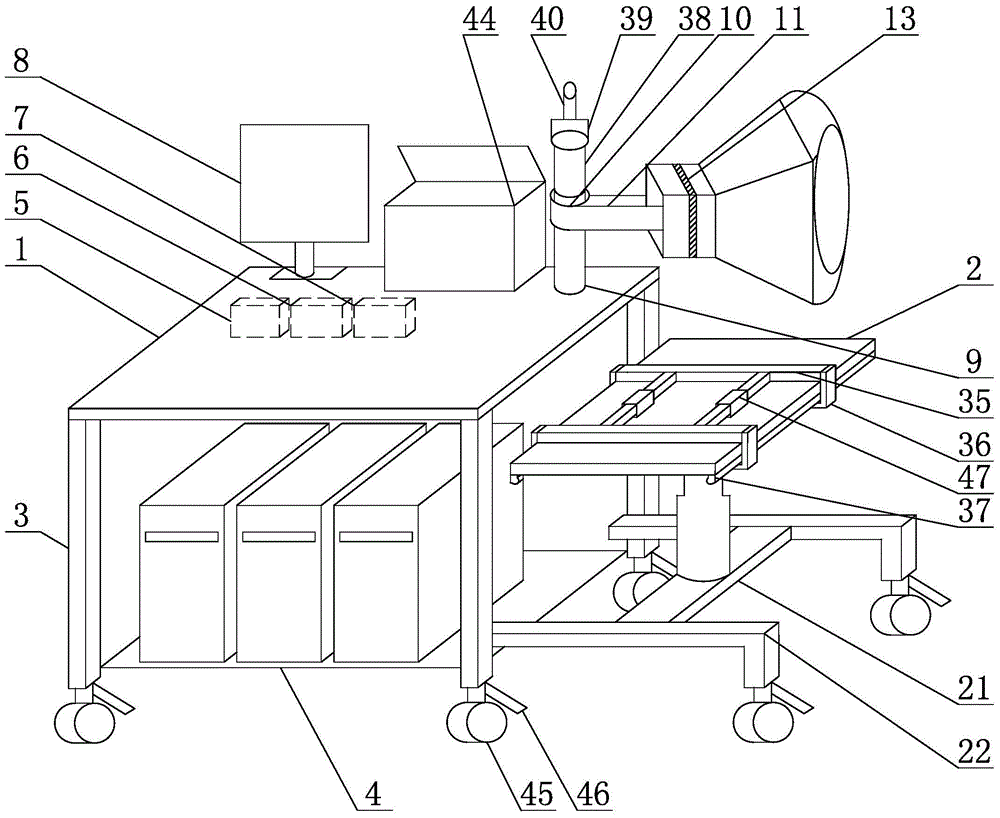

A multifunctional computer maintenance and repair platform

The invention discloses a multifunctional computer maintenance platform, which comprises a software maintenance platform and a hard maintenance platform, wherein desk legs, a video switcher, a switch and a loudspeaker are arranged at the bottom of the software maintenance platform; a display and a computer dust remover are arranged at the top of the software maintenance platform; a first supporting rod is arranged at the bottom of the hardware maintenance platform; a bearing and a fixed sleeve are arranged on the first supporting rod; a rotating locking device is arranged on the fixed sleeve; a hydraulic lifting rod is arranged at the bottom of the fixed sleeve; a fixed base is arranged at the bottom of the hydraulic lifting rod; second supporting rods are arranged at two ends of the fixed base; and the second supporting rods are connected to the desk legs in a sliding mode. The maintenance platform disclosed by the invention has the following beneficial effects that by virtue of the computer dust removal device, the maintenance platform can be used for preventing dust from flying everywhere when conducting dust removal on computers and can be used for removing dust of the computers in all directions cleanly and completely; the maintenance platform can be used for maintaining multiple computers simultaneously; and the hardware maintenance platform can rotate within 360 degrees and can regulate height, so that the hardware maintenance platform can conveniently conduct maintenance.

Owner:国网山东夏津县供电公司

A high-temperature flue gas dust removal cooling device

ActiveCN107715634BSave waterWon't fly aroundCombination devicesLighting and heating apparatusFlue gasHorizontal axis

The invention relates to the technical field of flue gas treatment, and specifically discloses a high-temperature flue gas dust removal cooling device, which includes a dust removal cooling mechanism and a receiving mechanism. The dust removal cooling mechanism includes a housing and a rotating shaft, and dust removal blades are installed on the rotating shaft; Air inlet pipe, the middle part of the air inlet pipe is provided with a one-way rotary intake valve, the upper end of the rotating shaft passes through the upper part of the housing and is threaded with the one-way rotary intake valve; the lower part of the housing is provided with an intercepting part, and a through hole is provided on the intercepting part , the lower end of the intercepting part is provided with a matching part, and an air outlet is provided on the matching part; the receiving mechanism is located at the lower end of the matching part, including a receiving pool and a horizontal shaft. The worm gear is connected, and the receiving pool is provided with a water outlet hole, and a water inlet pipe is connected between the water outlet hole and the rotating shaft. The device solves the problem of low adsorption of smoke and dust in the gas during the cooling process, which makes it difficult to collect the smoke and dust. In addition, the cooling water of the device can be recycled to save water resources.

Owner:GUIZHOU HUANKE ENVIRONMENT ECOLOGICAL RES & DEV CO LTD

A metal pipe cutting device

Owner:DONGQING TECH

Disc cutting device

InactiveCN112643111AWon't fly aroundNo pollutionShearing machinesMaintainance and safety accessoriesCircular discThermodynamics

The invention discloses a disc cutting device which structurally comprises a base, a cutting device body, a purifying device, a fixing device, sliding rails and a cutting rail. A cutting cavity is formed in the base, the cutting cavity and the base are integrally formed, the cutting device body is connected to the sliding rails in a sliding mode, the purifying device is located on one side of the upper portion of the base, the fixing device is located on one side of the cutting cavity, the two sliding rails are located on the two sides of the base, the cutting rail is located on the cutting cavity, and the cutting rail and the cutting cavity are integrally formed. Chippings generated in the working process can be blocked by a protective cover, so that the chippings are prevented from flying around, the protective cover is made of a transparent material, the situation in the protective cover can be seen in the working process, the chippings blocked by the protective cover can be sucked away by a dust suction pump, waste gas exhausted in the working process of the dust suction pump can be purified by an air purifier and then exhausted, and therefore environmental pollution cannot be caused.

Owner:郭献进

Single-head woodworking engraving machine

InactiveCN112440344AQuick fixWon't fly aroundProfiling/shaping machinesCleaning using toolsWorkbenchWoodworking

The invention provides a single-head woodworking engraving machine. The single-head woodworking engraving machine comprises a workbench, a pressing mechanism, a wiping mechanism, a locking mechanism and a shielding mechanism, a first driving frame is fixedly mounted at the top of the workbench, a second driving frame is fixedly mounted on the side wall of the first driving frame, an engraving mechanism is mounted on the side wall of the second driving frame, and a drive is slidably connected to the side wall of the second driving frame. An engraving head push rod is fixedly mounted at the output end of the drive, a sliding rod is fixedly mounted on the edge of the top of the workbench, a pressing plate is slidably connected to the rod wall of the sliding rod, a first spring is connected tothe rod wall of the sliding rod in series, the wiping mechanism is mounted on the second driving frame, the locking mechanism is mounted on the side wall of the workbench, and the shielding mechanismis mounted on the push rod. The single-head woodworking engraving machine provided by the invention has the advantages that a plate can be quickly fixed, time is saved, and engraved wood chips cannotfly to the ground.

Owner:郑禅禅

Electrostatic adsorption blackboard eraser for smart classroom and control system thereof

InactiveCN112677682AImprove adsorption capacityEasy to scrape outBoard cleaning devicesControl systemElectric machine

The invention discloses an electrostatic adsorption blackboard eraser for a smart classroom and a control system thereof, and relates to the technical field of electrostatic adsorption blackboard erasers. The electrostatic adsorption blackboard eraser comprises an outer box body, a rectangular annular plate, a wiping plate and a linkage mechanism, wherein the linkage mechanism comprises a fixed pulley, a pull rope and a first spring, conductive cloth is mounted on the inner side surface of a rectangular annular plate and is in electric signal connection with an electrostatic generator, a pressure sensor is installed between the two side walls of the vertical sliding hole, a control panel is mounted on the inner bottom surface of the outer box body, and the control panel is in electric signal connection with the pressure sensor and the electrostatic generator. According to the electrostatic adsorption blackboard eraser, after the pressure sensor detects a pressure signal and transmits the pressure signal to the control panel, the control panel controls a positive and negative rotation motor to rotate reversely to drive a horizontal scraping plate to contract into a supporting annular plate and controls the conductive cloth to be powered on, it is guaranteed that chalk powder falling from the eraser enters the outer box body through an annular channel between the supporting plate and the rectangular annular plate, and the conductive cloth can adsorb chalk powder conveniently.

Owner:安徽文香信息技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com