Dust removal device

A technology of dust removal device and dust removal roller, applied in transportation and packaging, separation of dispersed particles, chemical instruments and methods, etc., can solve the problems of easy inhalation of dust, low efficiency, high labor intensity, etc., and achieve good dust removal effect, stable movement, The effect of low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

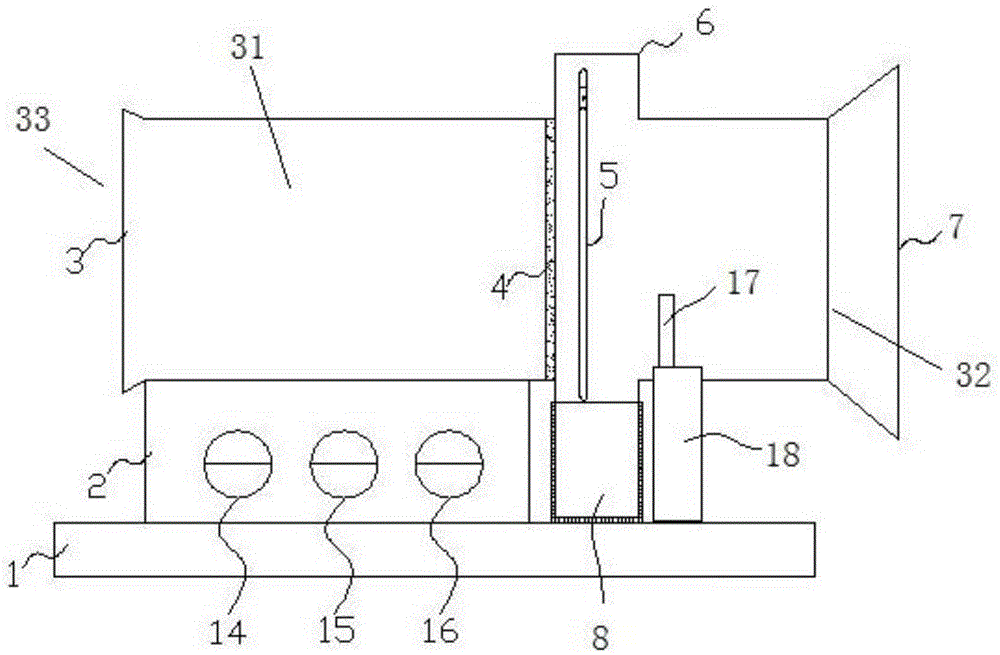

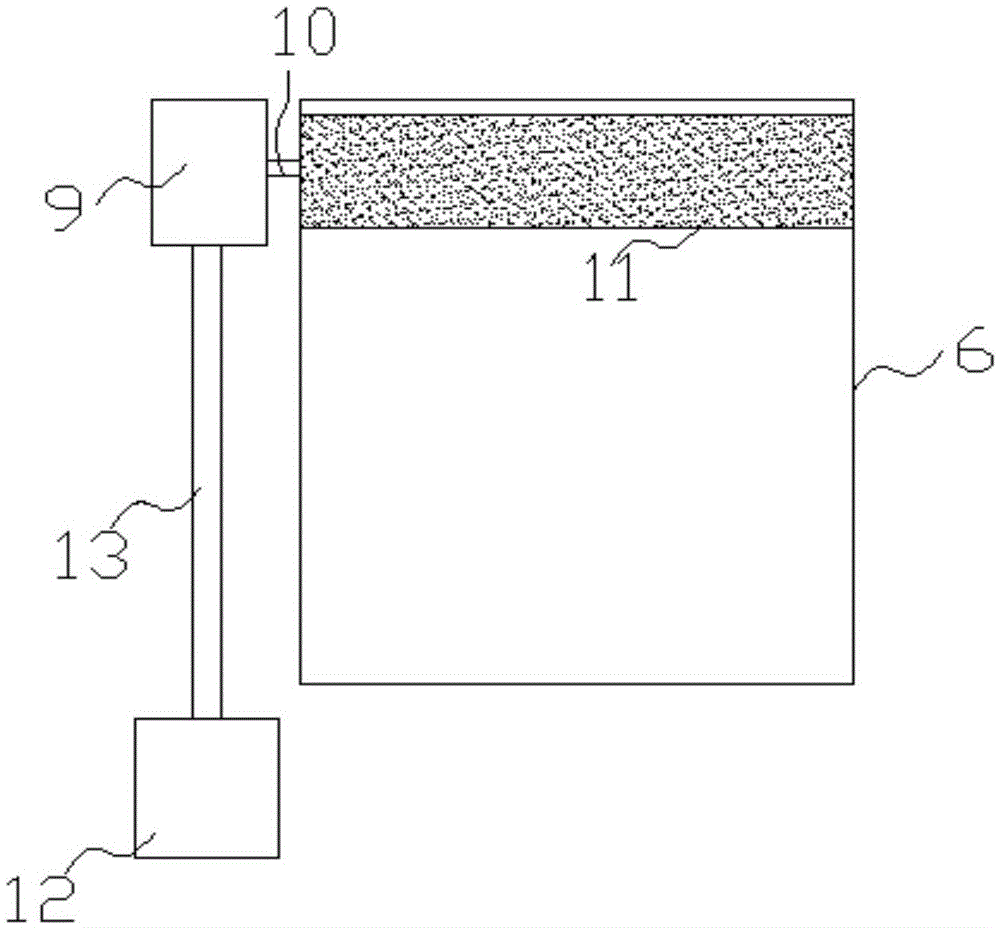

[0040] This embodiment provides a dust removal device, such as figure 1 As shown, it includes: a base 1, which is suitable for fixed installation; a fan bracket 2, which is fixedly installed on the base 1; a fan 3, which is fixedly installed on the fan bracket 2, includes an exhaust tube 31, and is installed on the exhaust fan. The fan blade inside the cylinder 31, the exhaust cylinder 31 has an air inlet 32 and an air outlet 33; the dust removal structure is arranged in the middle of the exhaust cylinder 31, including a filter screen 4, and is arranged on the filter screen 4 near the The dust collection box 8 on the side of the air inlet 32, the setting position of the dust collection box 8 is lower than the exhaust tube 31; The dust on the side is brushed away, and it falls into the dust box 8; the rotating cover 17 is rotatably installed inside the exhaust tube 31, and has a second opening covering the upper opening of the dust box 8. One position, and the second positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com