Polishing machine

A polishing machine and polishing mechanism technology, which is applied in the field of polishing machines, can solve problems such as poor flatness, lack of dust-proof and dust-removing devices, poor adaptability of oxide layers, etc., and achieve the effects of reasonable structure, improved polishing quality, and good polishing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

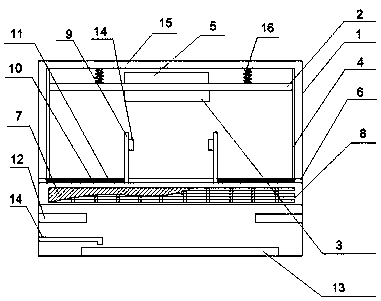

[0016] Such as figure 1 Shown, a kind of polishing machine comprises frame and polishing system, and frame is made of column 1 and crossbeam 2, is characterized in that: described polishing system 3 is composed of the polishing mechanism that contains polishing wheel and the rotary motor that controls the speed of polishing wheel , the polishing system 3 is installed on the crossbeam 2 of the frame through the polishing mechanism, and it is characterized in that: the first chute 4 is arranged on the left and right columns 1, and the crossbeam 2 is installed between the two first chute 4, The crossbeam 2 is made of metal, and a control cylinder 5 is also arranged on the crossbeam 2, and its power output shaft is connected with the polishing mechanism of the polishing system 3....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com