Passive air sac pressure controlled flexible furbisher

A flexible polishing and passive technology, applied in manufacturing tools, grinding/polishing equipment, metal processing, etc., can solve the problems of low polishing quality, inability to carry out online control, and low polishing efficiency of polishing tools, so as to achieve high polishing quality and realize Automated, normal polishing force for stable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

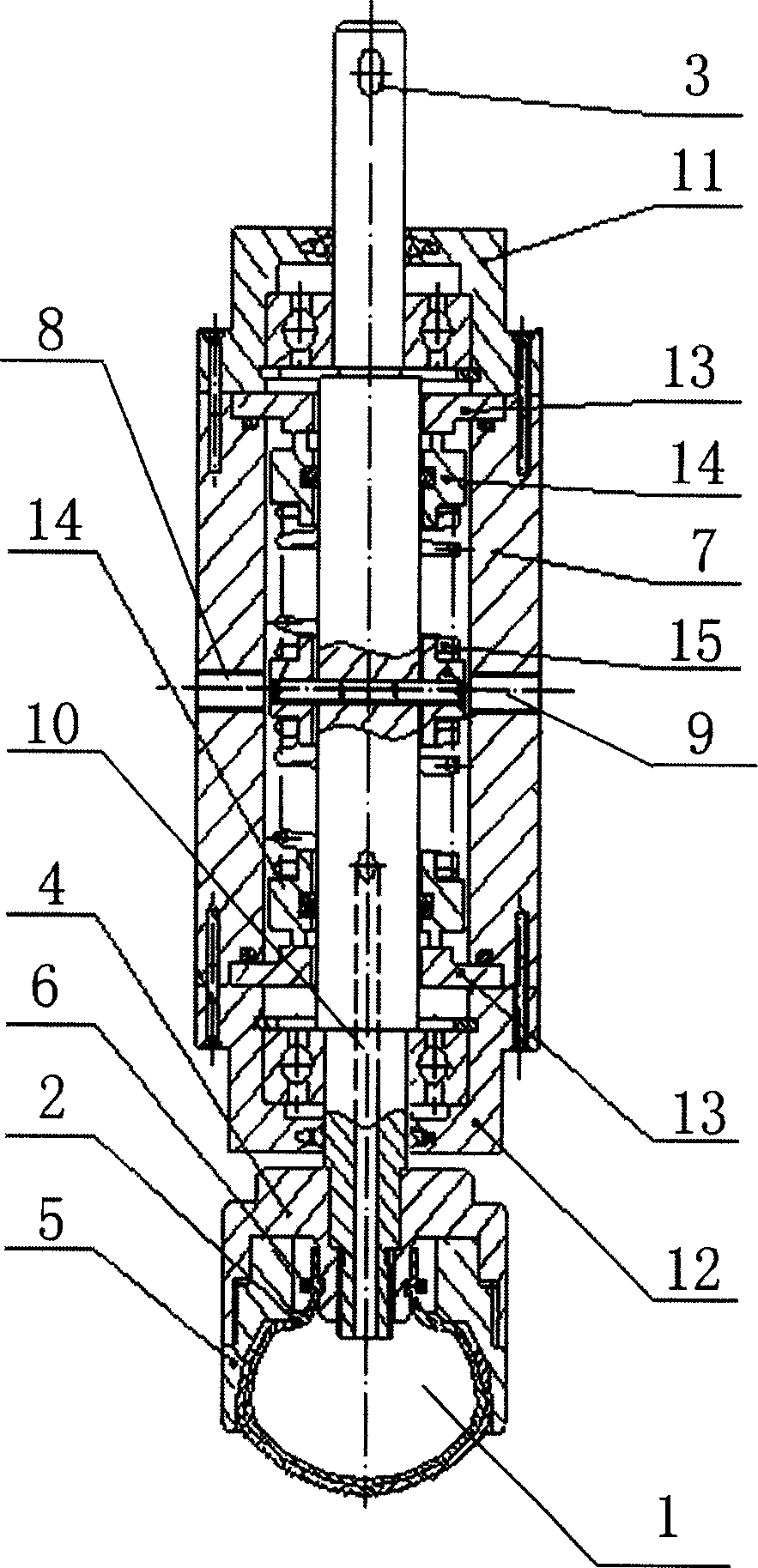

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

[0019] Refer to figure 1 , A passive airbag pressure-controlled flexible polishing tool, the polishing tool includes an airbag 1, the front end of the airbag 1 has a polishing cloth 2 as a working surface, the airbag 1 is installed in a holder, and the holder is installed On a rotating shaft 3 that can drive the holder to rotate, the holder includes a polishing head outer cover 4, a polishing head inner cover 5, and the polishing head outer cover 4 is connected to the rotating shaft 3 through threads, and the polishing cloth 2 is connected to the polishing cloth 2 with resin. The head cover 4 is bonded into one body and reinforced with a circlip 6. The polishing head inner cover 5 is a part of the polishing cloth 2 for shape determination and shaping. It is connected with the polishing head cover 4 through threads. After the polishing cloth 2 is inflated, The contact part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com