Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "Dust removal is simple" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

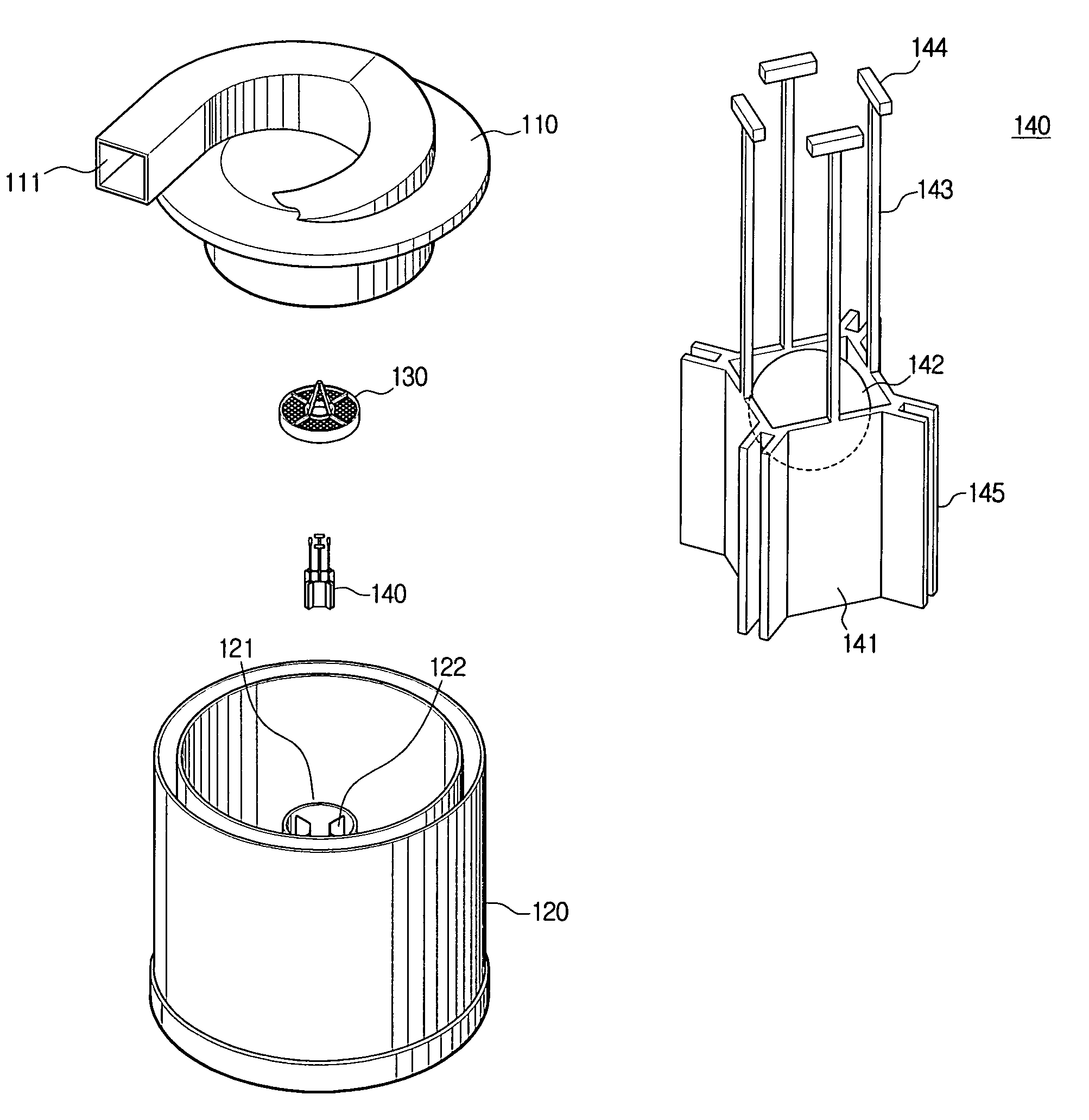

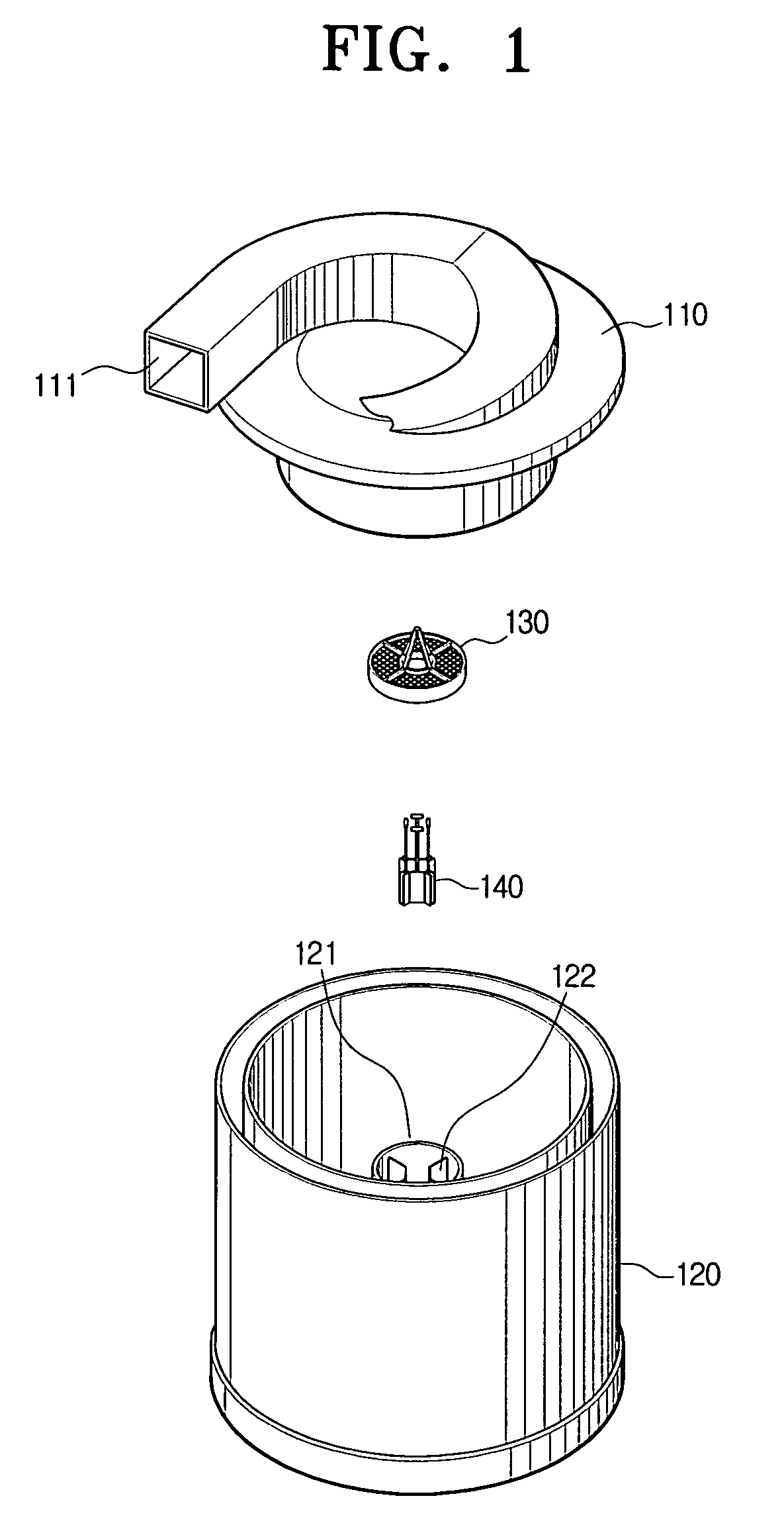

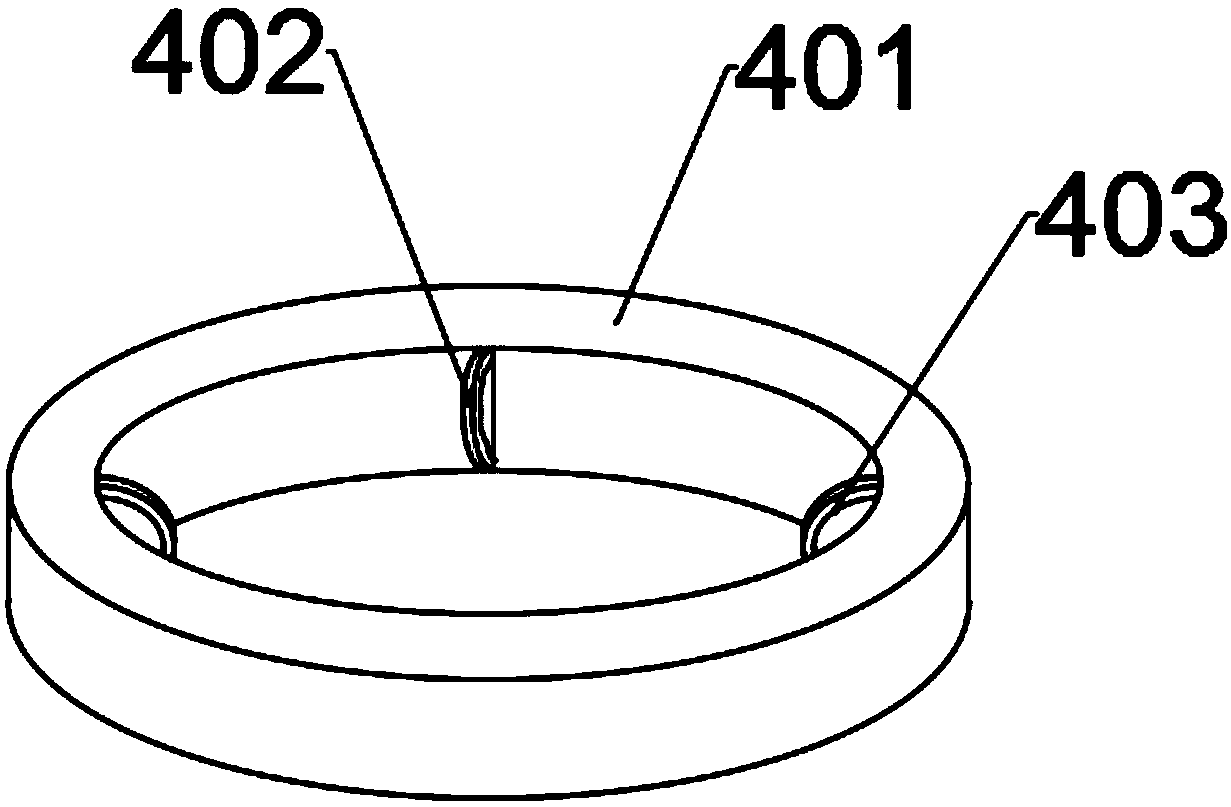

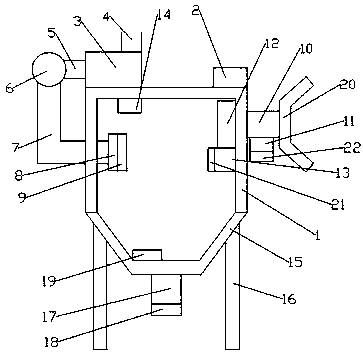

Cyclone dust collecting apparatus for vacuum cleaner

InactiveUS7704290B2Dust removal is simpleProblem and drawbackCleaning filter meansCombination devicesVacuum cleanerWaste management

A cyclone dust collecting apparatus for a vacuum cleaner according to the present disclosure includes a cover having a suction port forcing entering air to form a whirling air current; a cyclone body connected to the cover, the cyclone body having a discharging pipe discharging the entered air; a grill disposed at the discharging pipe; and a grill cleaning unit movably disposed at the discharging pipe so as to remove dust attached to the grill.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

Ink jet head, ink jet recording apparatus, and method for removing dust from the ink jet head

InactiveUS6851790B2Dust removal is simpleEasy and reliable removalOther printing apparatusEngineeringHead parts

An ink jet head has a substrate, partition walls disposed on a main surface of the substrate and spaced apart at a preselected interval to form channels for receiving ink. An ink chamber plate is connected to the substrate to define with the partition walls an ink chamber for supplying ink to the channels. A passage forming member is connected to the ink chamber plate and has an ink supply passage disposed in communication with the ink chamber for supplying ink contained in an ink storage device to the ink chamber and at least one ink discharge passage for discharging ink from the ink chamber. The ink discharge passage is independent from the ink supply passage so that ink is supplied directly to the ink chamber through the ink supply passage without passing through at least a portion of the ink discharge passage.

Owner:SEIKO INSTR INC

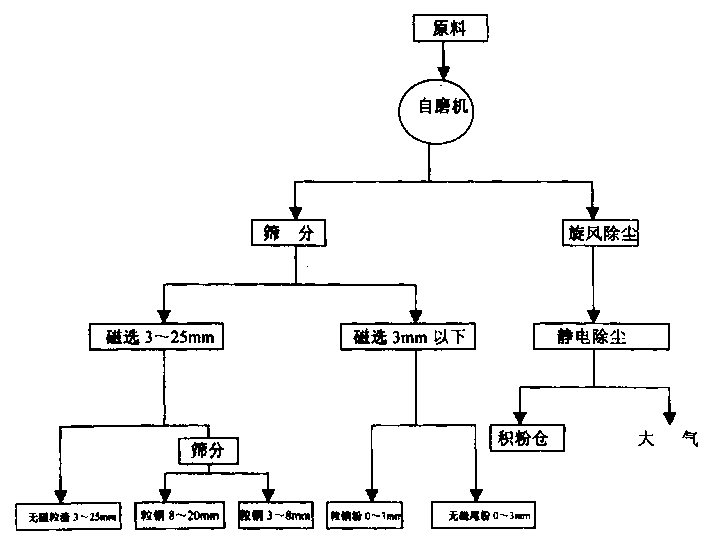

Process for treating steel slag by using self grinding technology

InactiveCN1492058AEfficient use ofImprove developmentBlast furnace detailsRecycling and recovery technologiesGranularitySlag

The grinding treatment process of the present invention is suitable for various kinds steel slag, such as electric furnace steel slag, converter steel slag, etc. It includes the following continuous technological steps: providing steel stag material of granularity up to 800 mm; pulverizing in dry pulverizing machine with pneumatic mechanism to discharge and electrostatic dust collection; sieving into different granularity components; and magnetic dressing to separate magnetic steel powder, granular steel and non-magnetic tail powder and granular slag. The present invention has continuous process, high production efficiency and other advantages.

Owner:庞慧鑫

Dust removal device

InactiveCN105477951AEasy to remove dustReduce labor intensityDispersed particle filtrationTransportation and packagingEngineeringDust fall

Owner:周桂灵

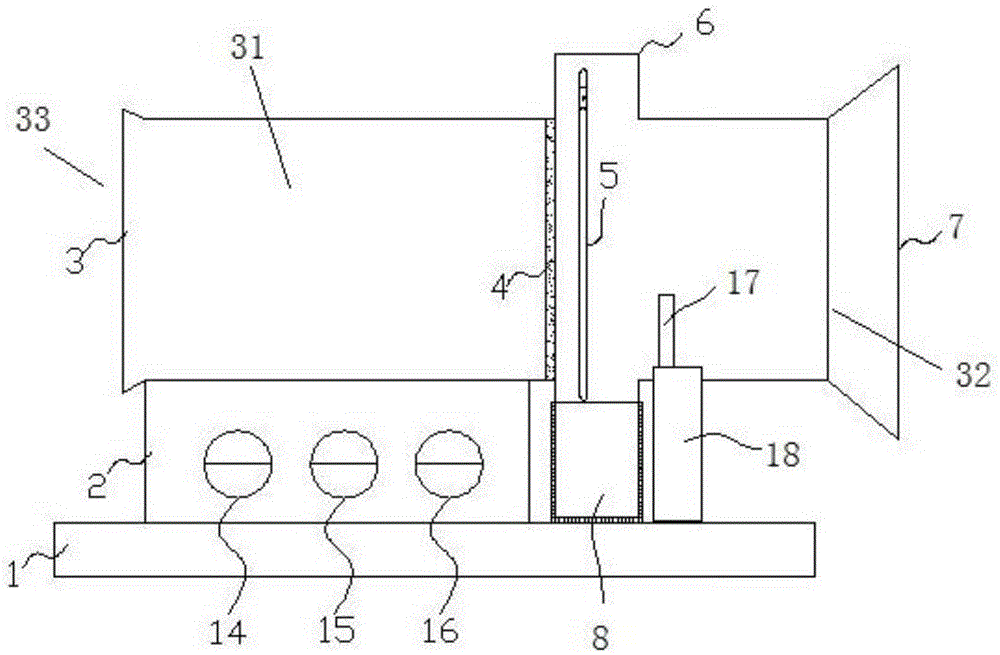

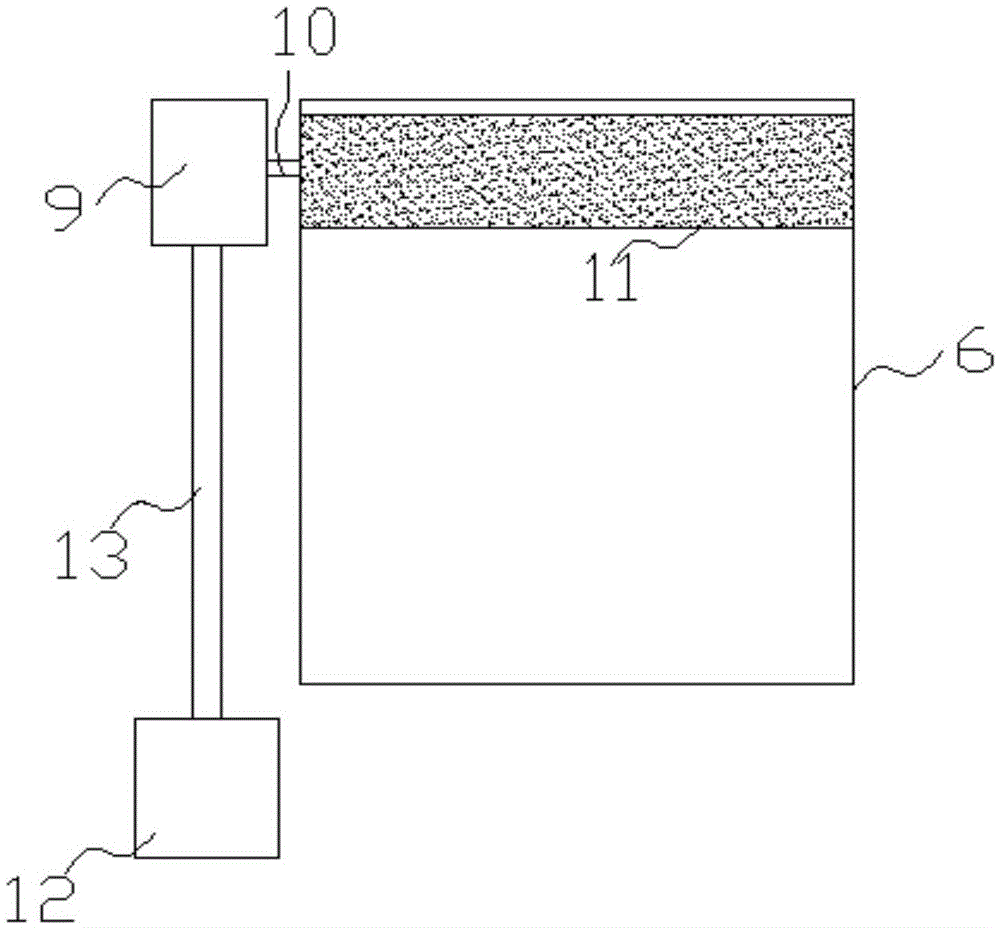

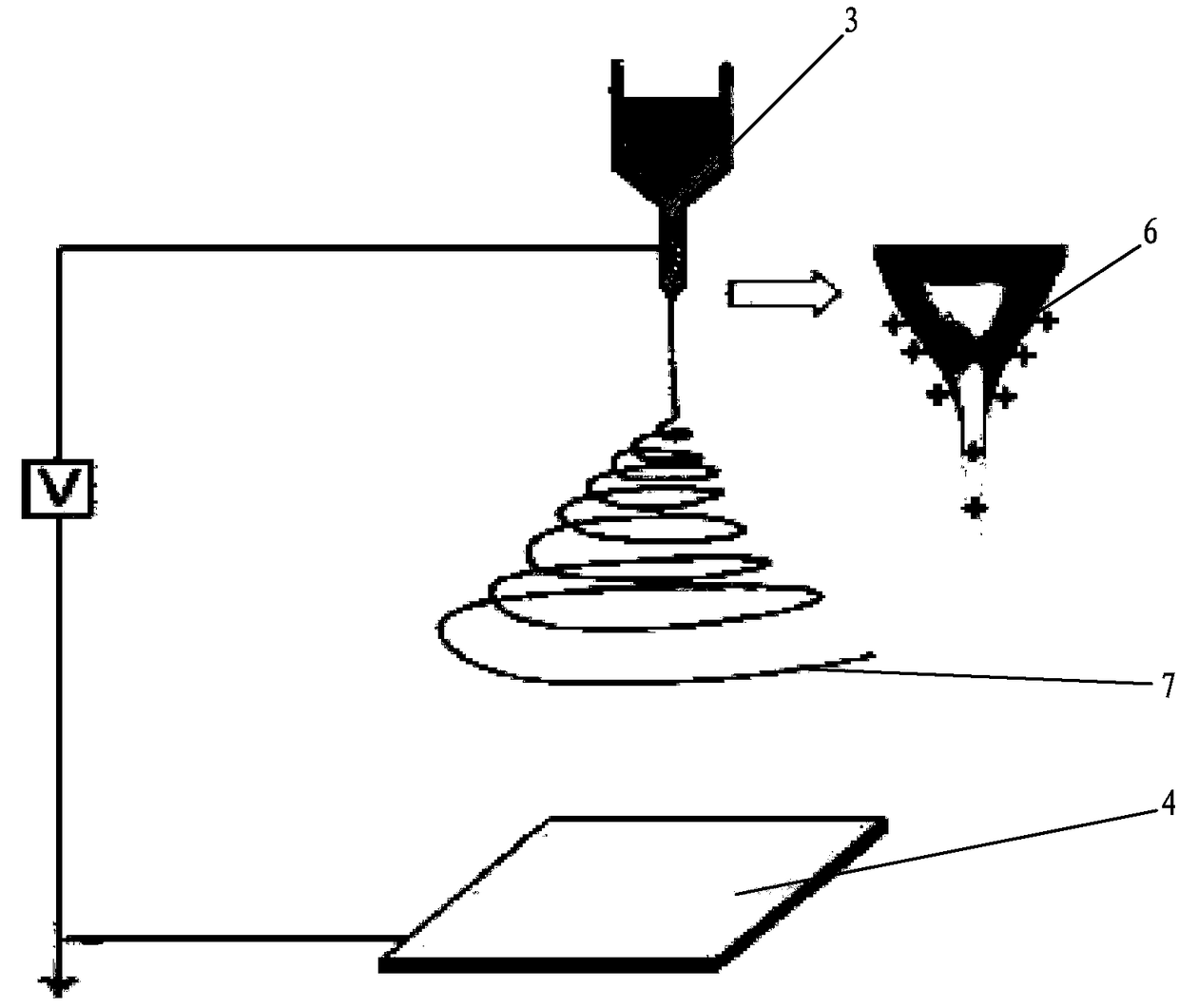

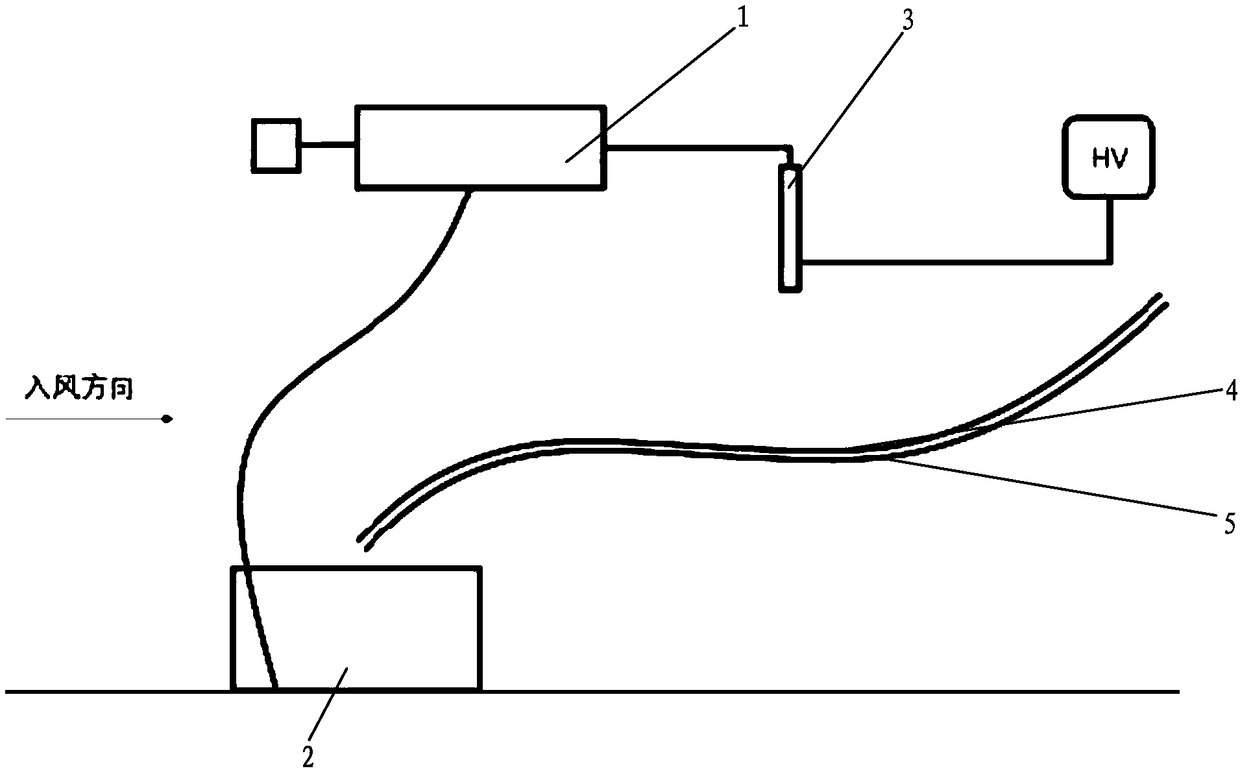

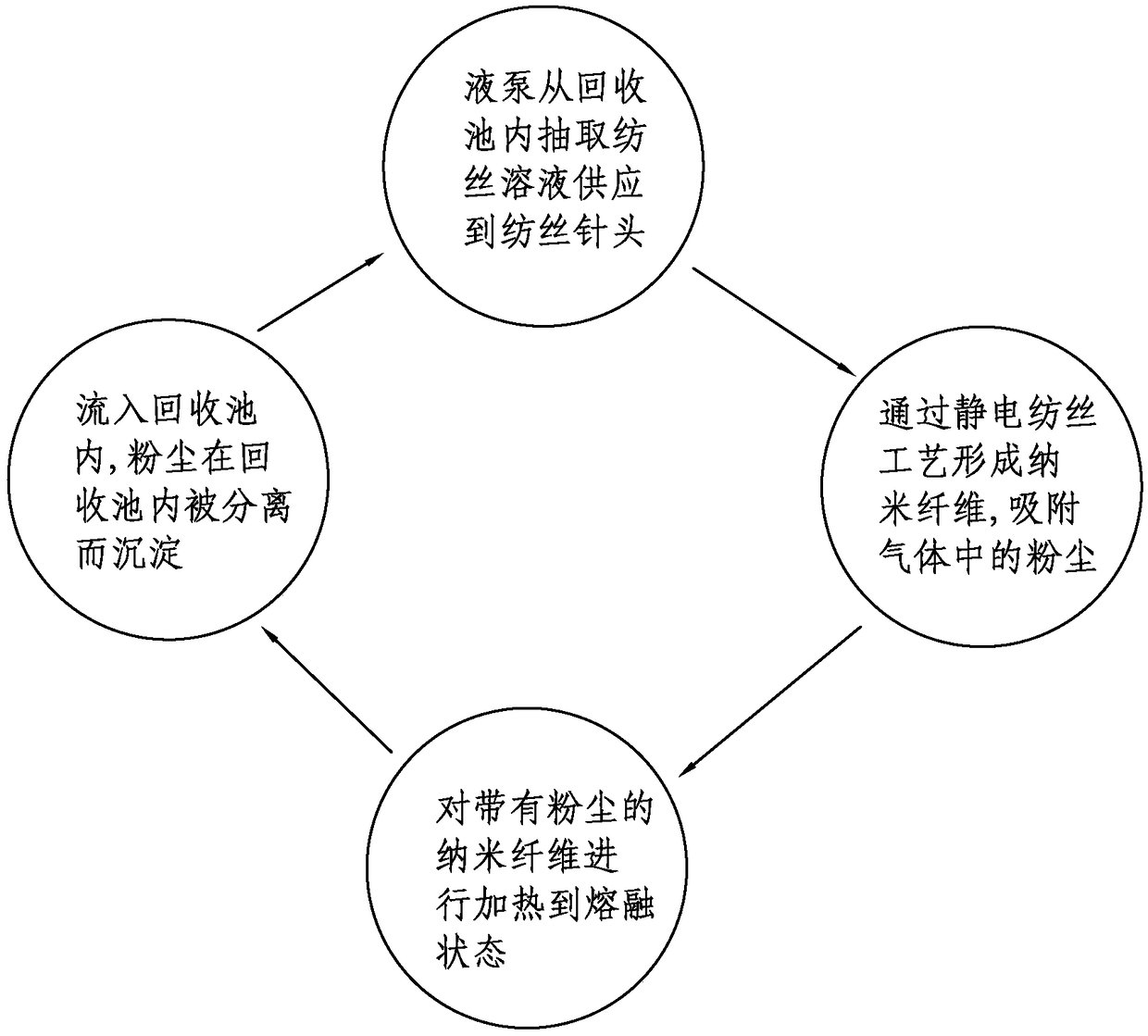

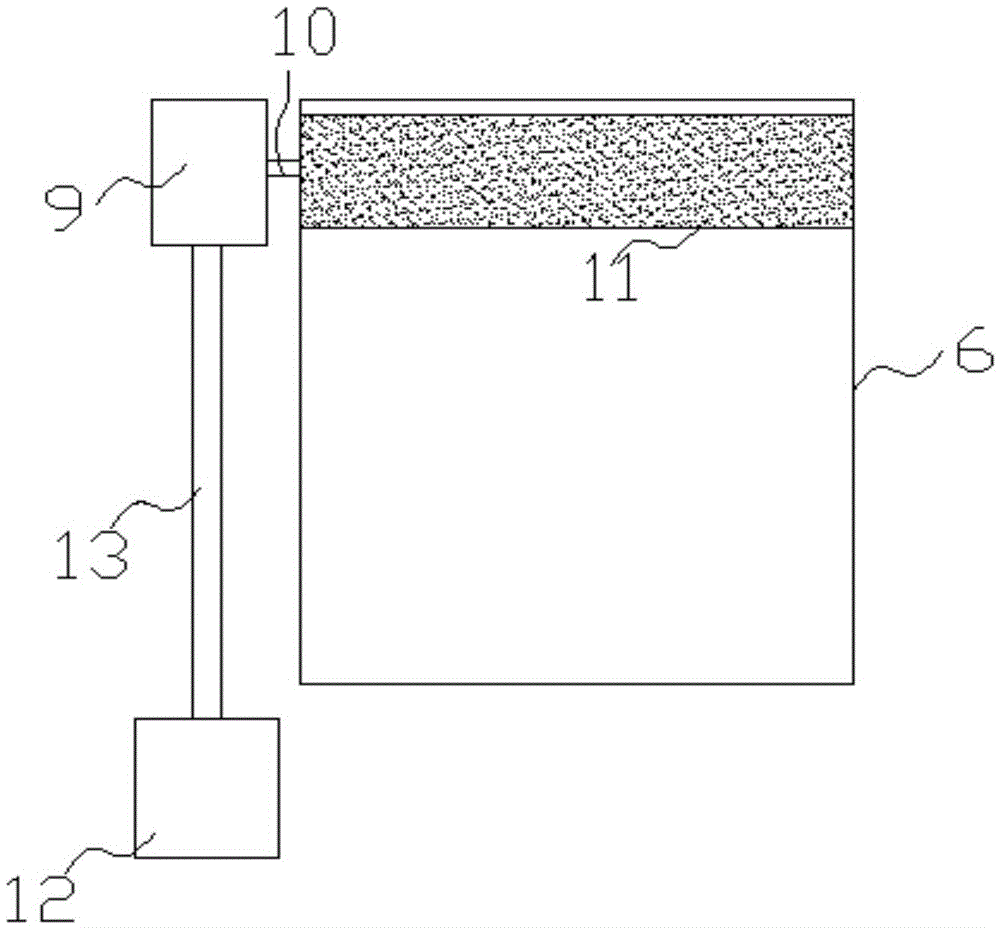

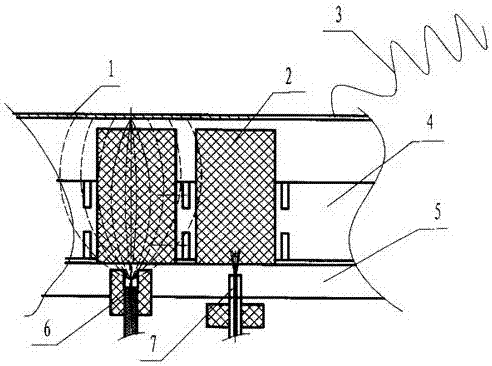

Dedusting method based on electric spinning technique and dedusting device thereof

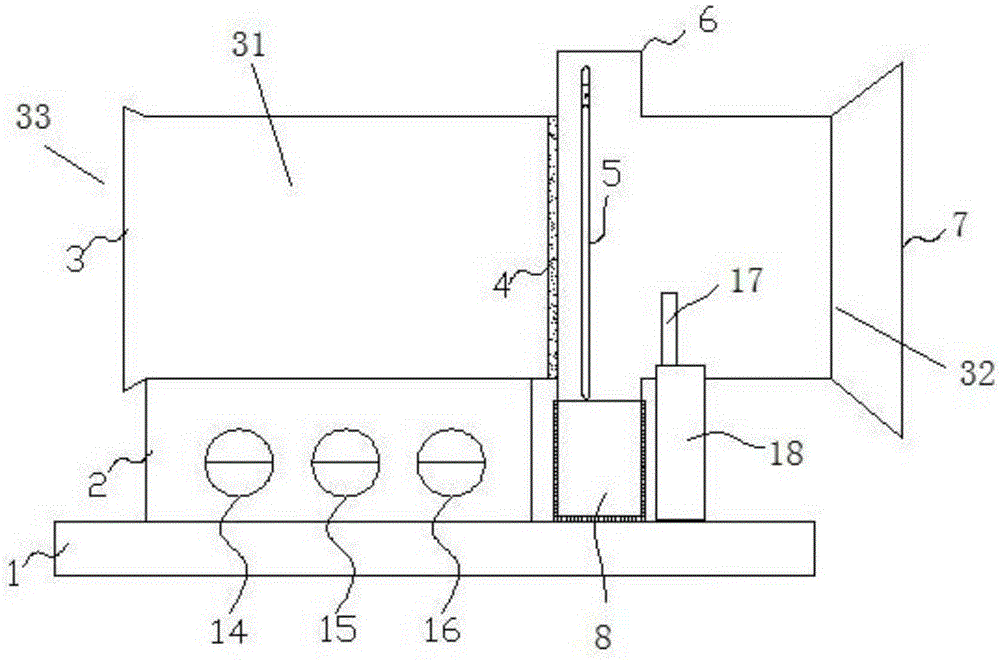

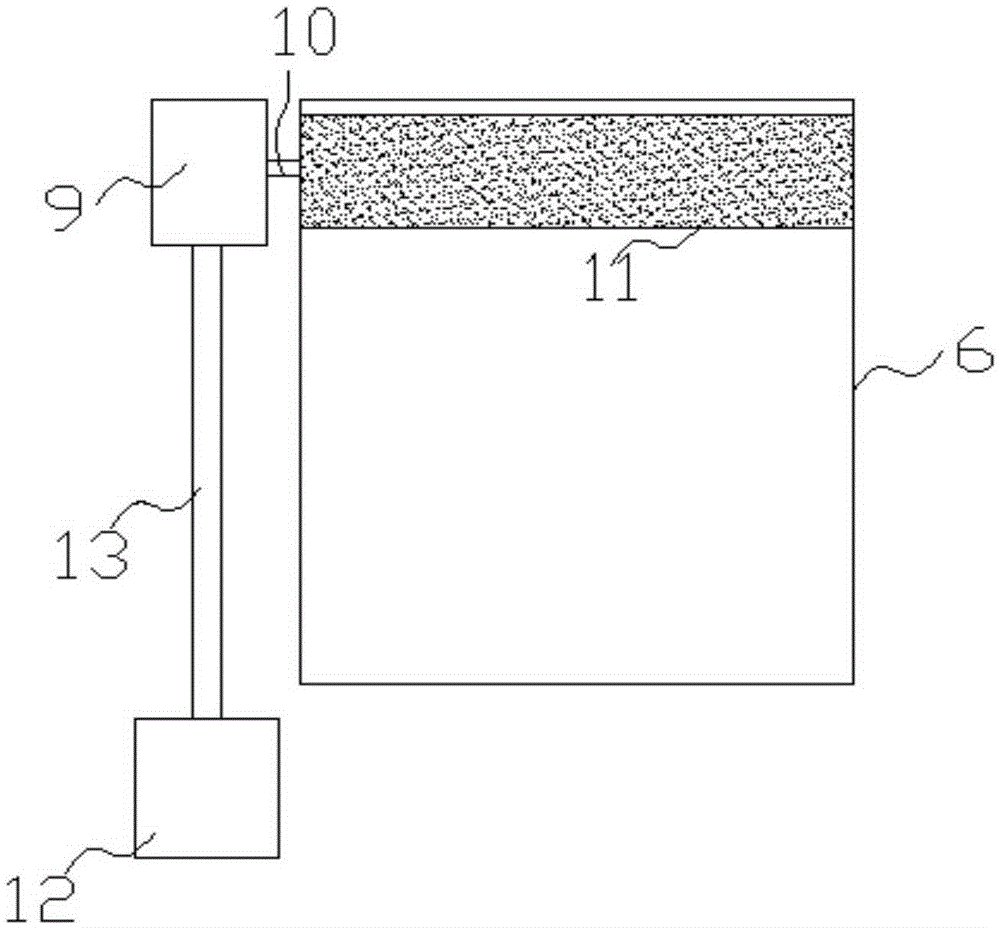

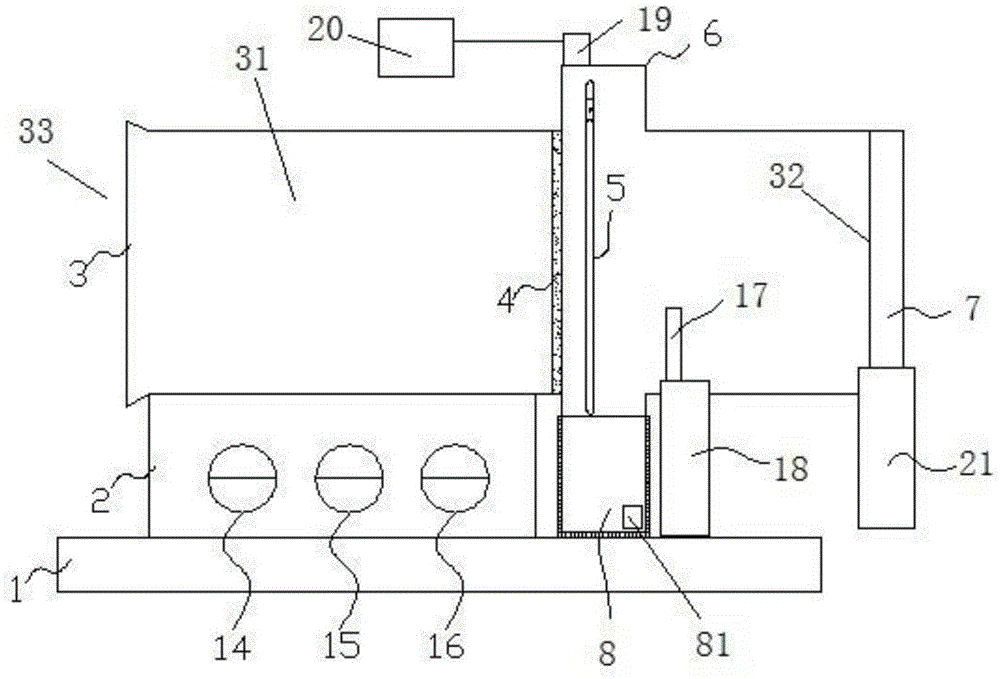

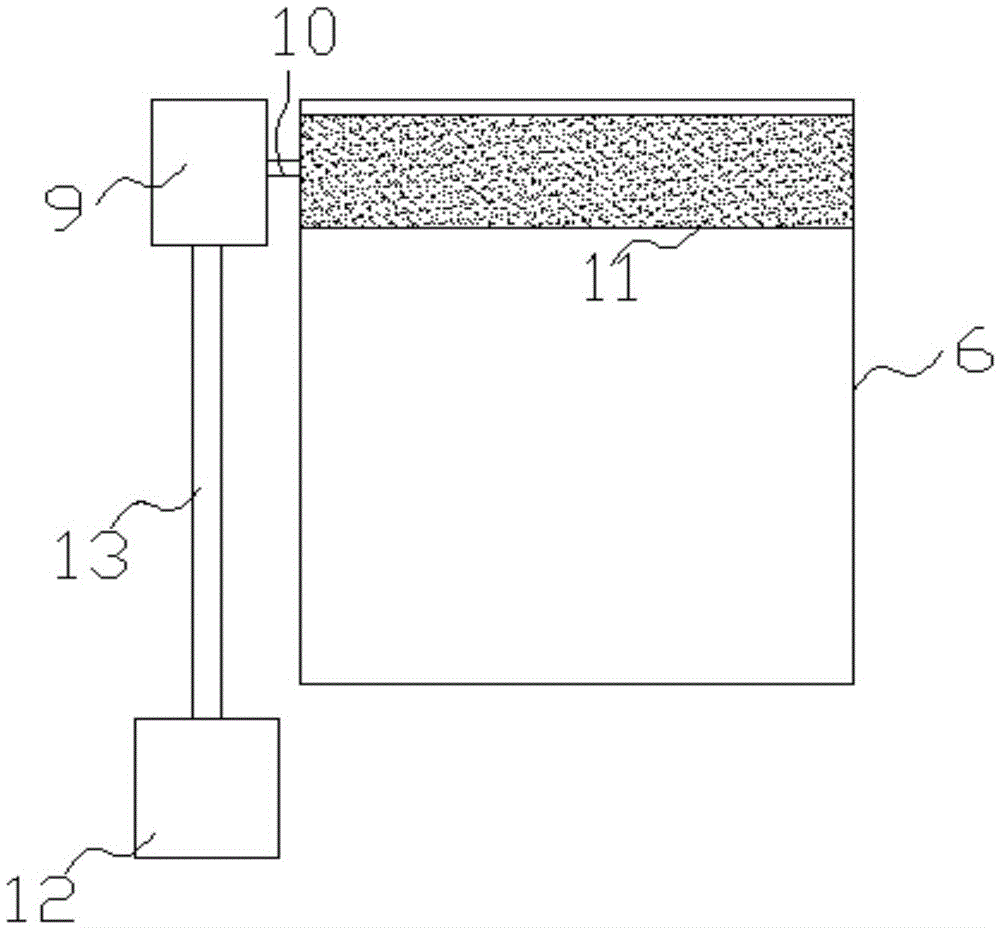

InactiveCN108914220ADust removal is simpleEasy to remove dustDispersed particle filtrationFilament/thread formingFiberElectrospinning

The invention discloses a dedusting method based on an electric spinning technique. The dedusting method comprises the following steps of S1, enabling a liquid pump to suck a spinning solution from arecycling tank and supply to a spinning needle head; S2, forming a nanometer fiber by an electrostatic spinning technique, and arranging the nanometer fiber on a flowing loop of the to-be-filtered gas; enabling the nanometer fiber to suck the dust in the air; S3, heating the dust-containing nanometer fiber to the melting state, enabling the dust-containing nanometer fiber to flow into the recycling tank, and separating and settling the dust in the recycling tank; S4, repeating the steps until the dust in the to-be-filtered gas is filtered out. The invention also discloses a dedusting device based on the electric spinning technique. The dedusting method has the advantages that the whole dedusting process is simple, convenient and efficient, and the gas can be cyclically dedusted; the use cost can be greatly reduced, and the green and environment-friendly effects are realized; the problems of long-time, fixed-time and frequent replacing of filtering membranes or filtering medium, troublesome and inconvenience in use, and higher cost in the existing dedusting method are solved.

Owner:GUANGDONG UNIV OF TECH

Air filter

InactiveCN105617784AWill not affect healthDust removal is simpleDispersed particle filtrationTransportation and packagingPhysical healthAir filter

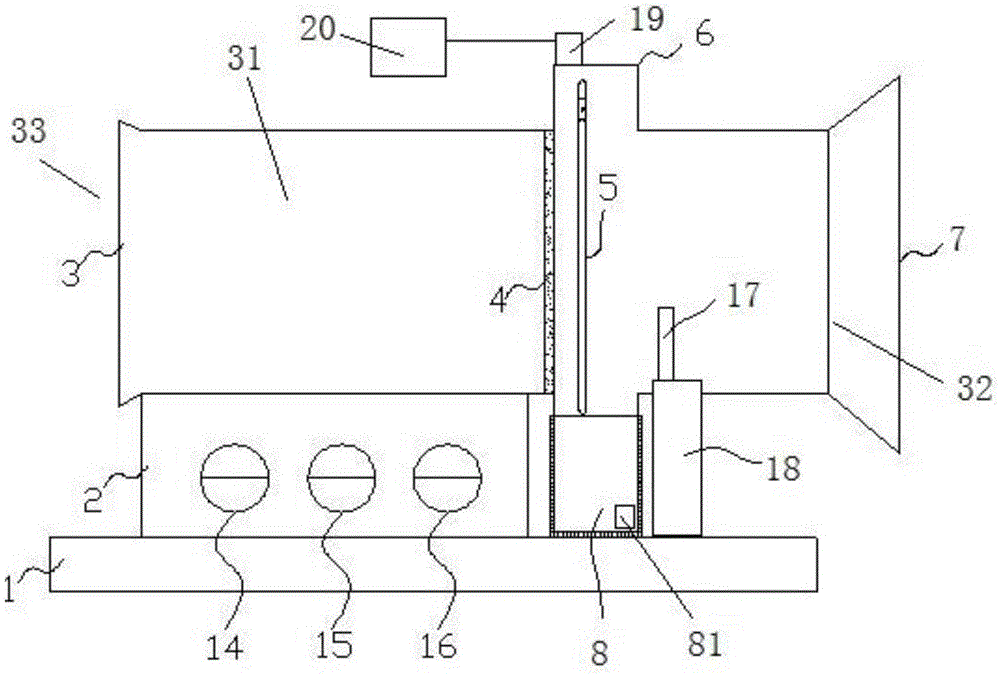

The invention provides an air filter. The air filter comprises a base, a fan bracket, a fan, a dust removing structure, a dust brushing structure, a rotary closing cover, a motor, a water drenching pipe and a water pump, wherein the fan comprises an air draught tube and fan blades, and the air draught tube has an air inlet and an air outlet; the dust removing structure is arranged at the middle part of the air draught tube and comprises a filter screen and a dust collecting chamber, and the dust collecting chamber is lower than the air draught tube in position; the dust brushing structure is used for brushing away dust attached to one side, facing to the air inlet, of the filter screen and enabling the dust to fall into the dust collecting chamber; the water drenching pipe is mounted above the dust brushing structure and is used for flushing the dust brushed away from the filter screen inside the dust collecting chamber; the water pump is used for supplying water to the water drenching pipe. According to the air filter provided by the invention, the dust removing structure is arranged at the middle part of the air draught tube, and the dust brushing structure is arranged, so that when the filter screen needs dust removal, the dust brushing structure is started up to clean the filter screen, and the dust removal can be carried out without detaching the filter screen, is easy and is low in labor intensity; the dust cannot fly around, cannot be inhaled by workers and cannot affect the physical health of the workers.

Owner:周桂灵

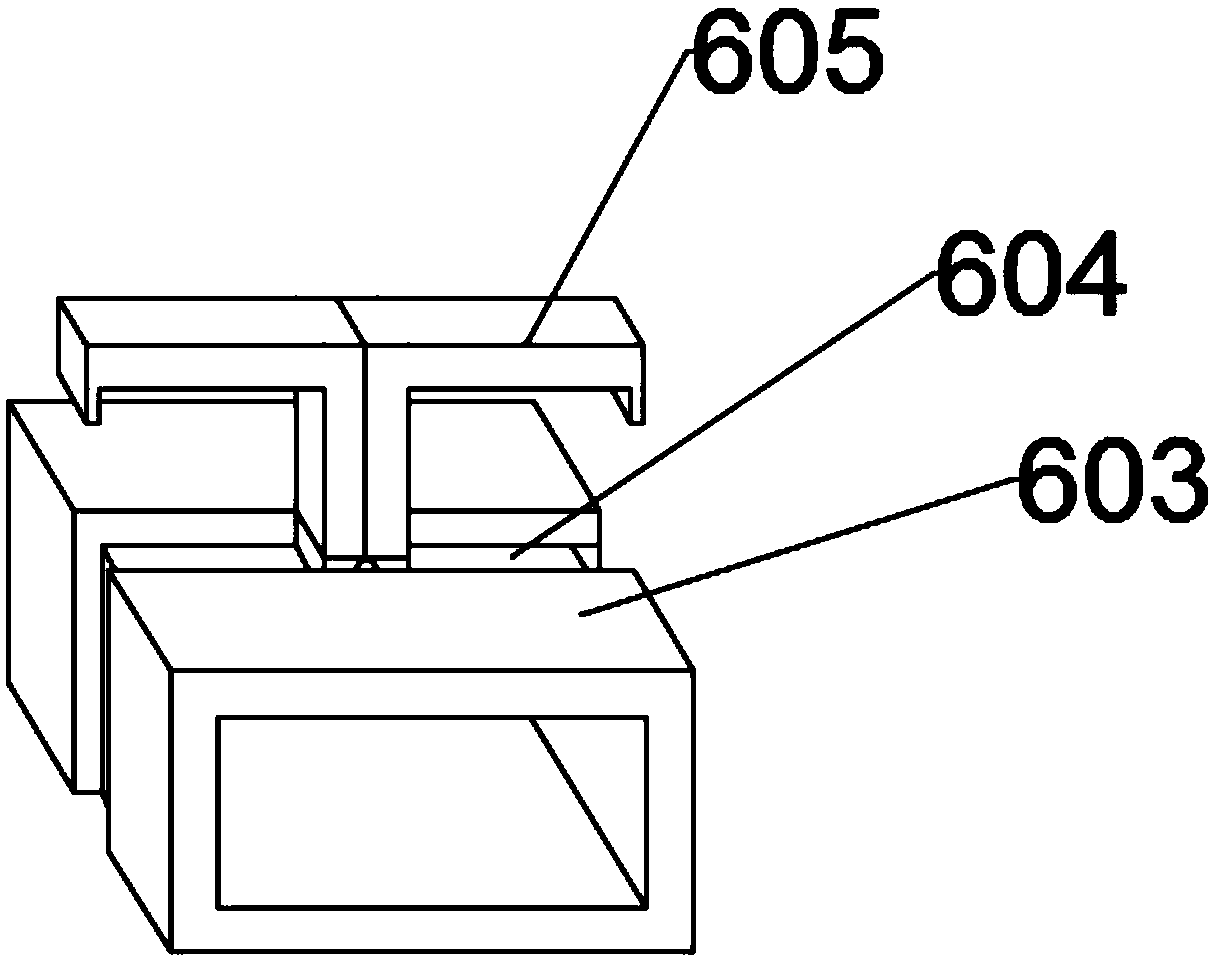

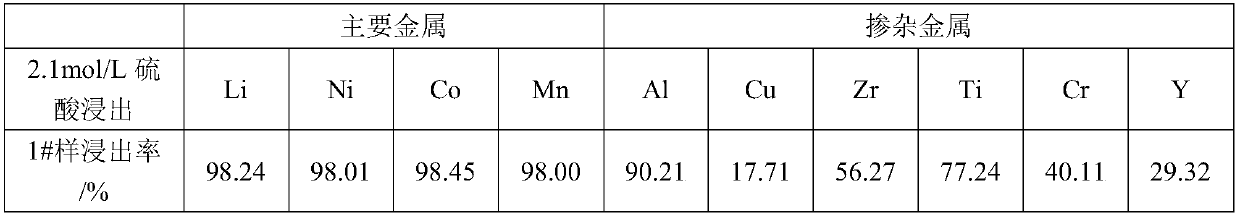

Filter dust collector

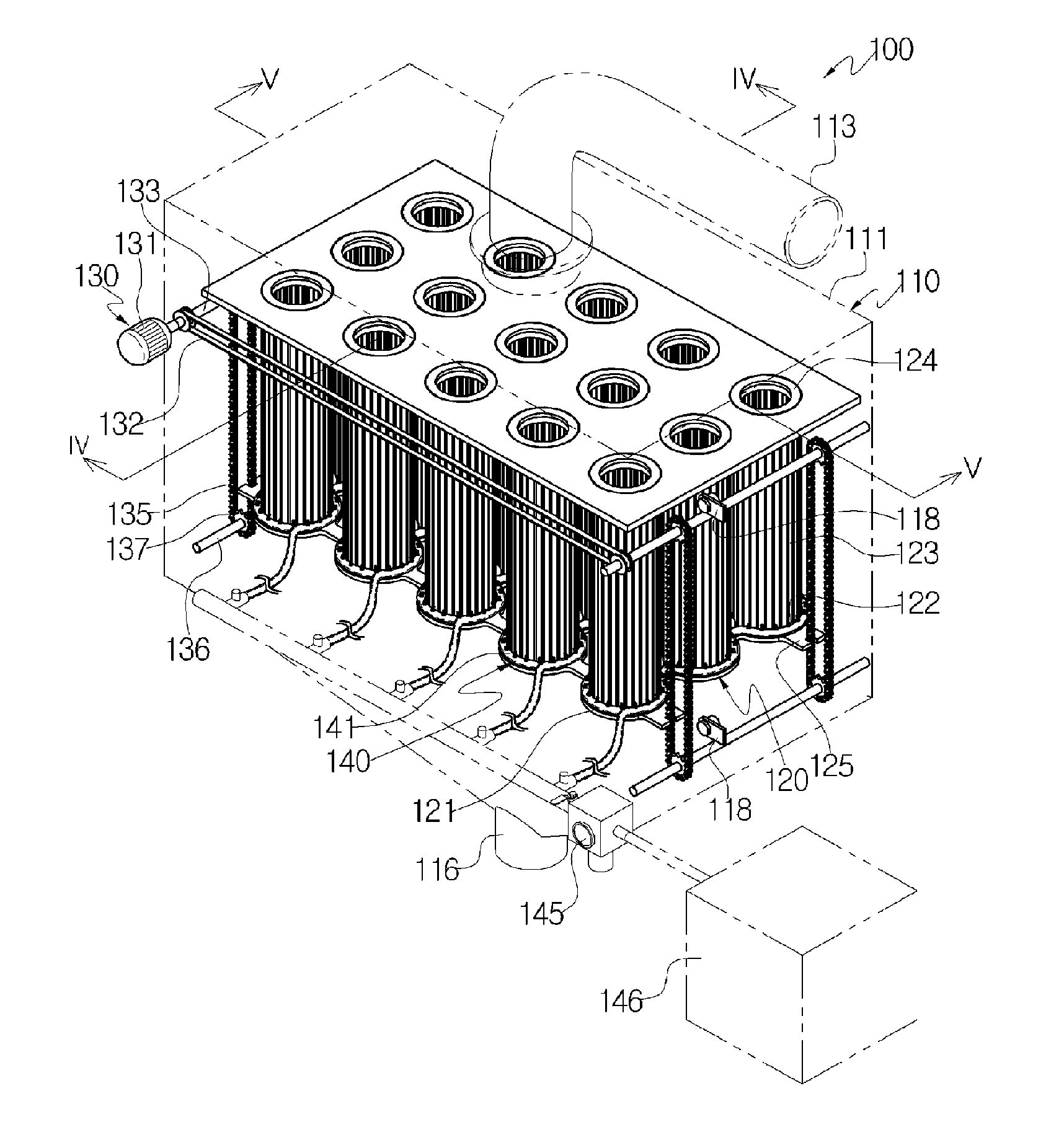

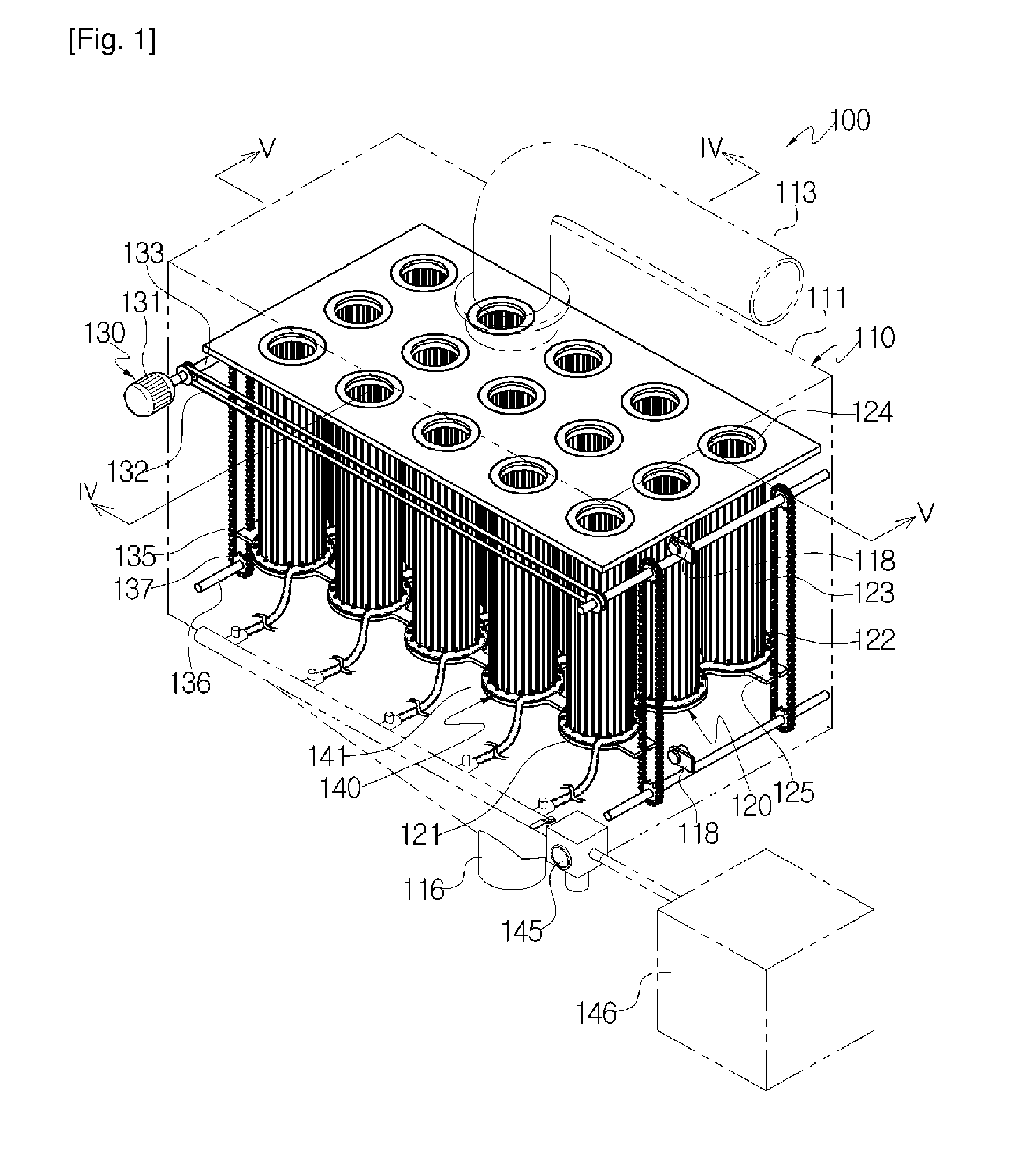

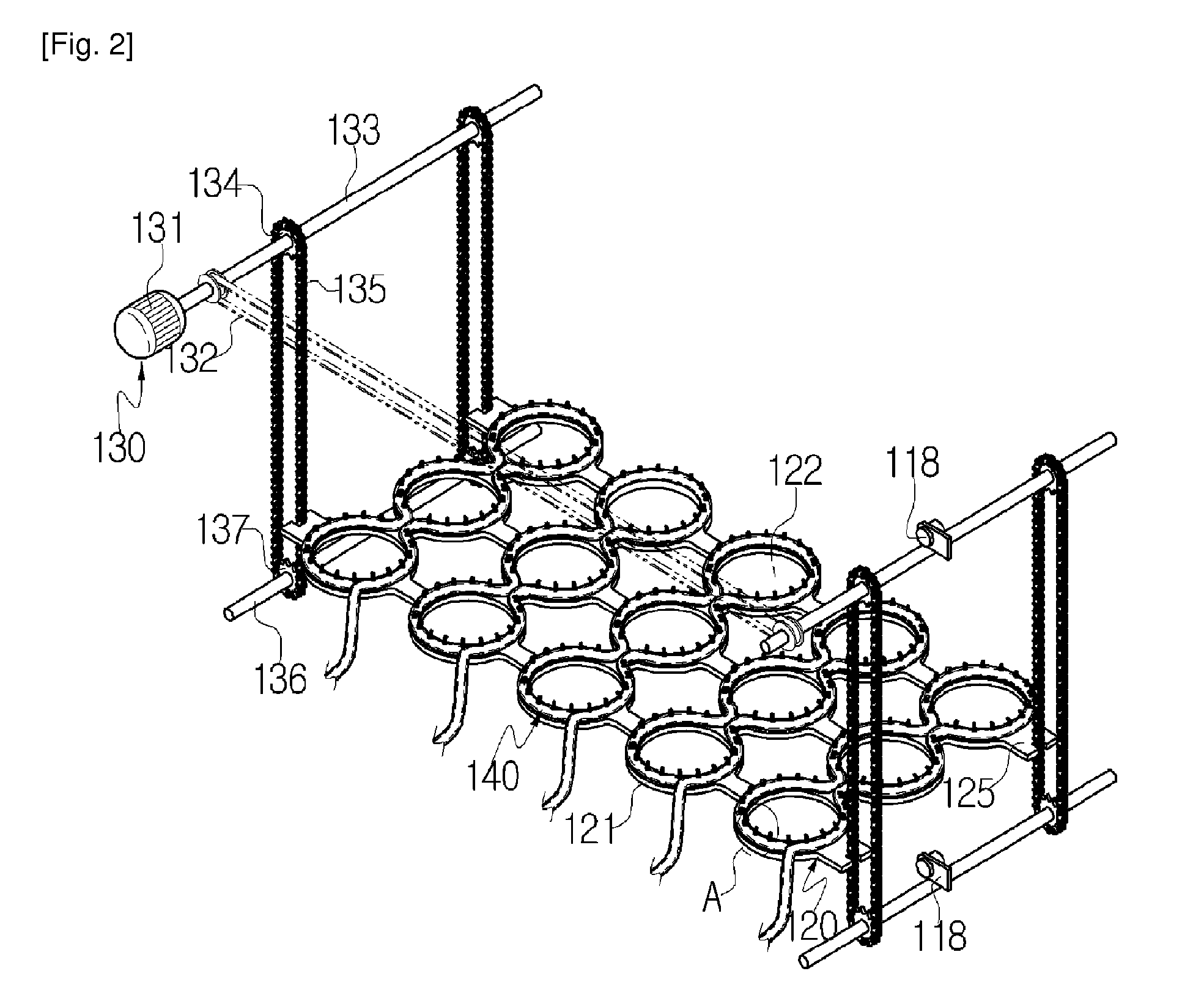

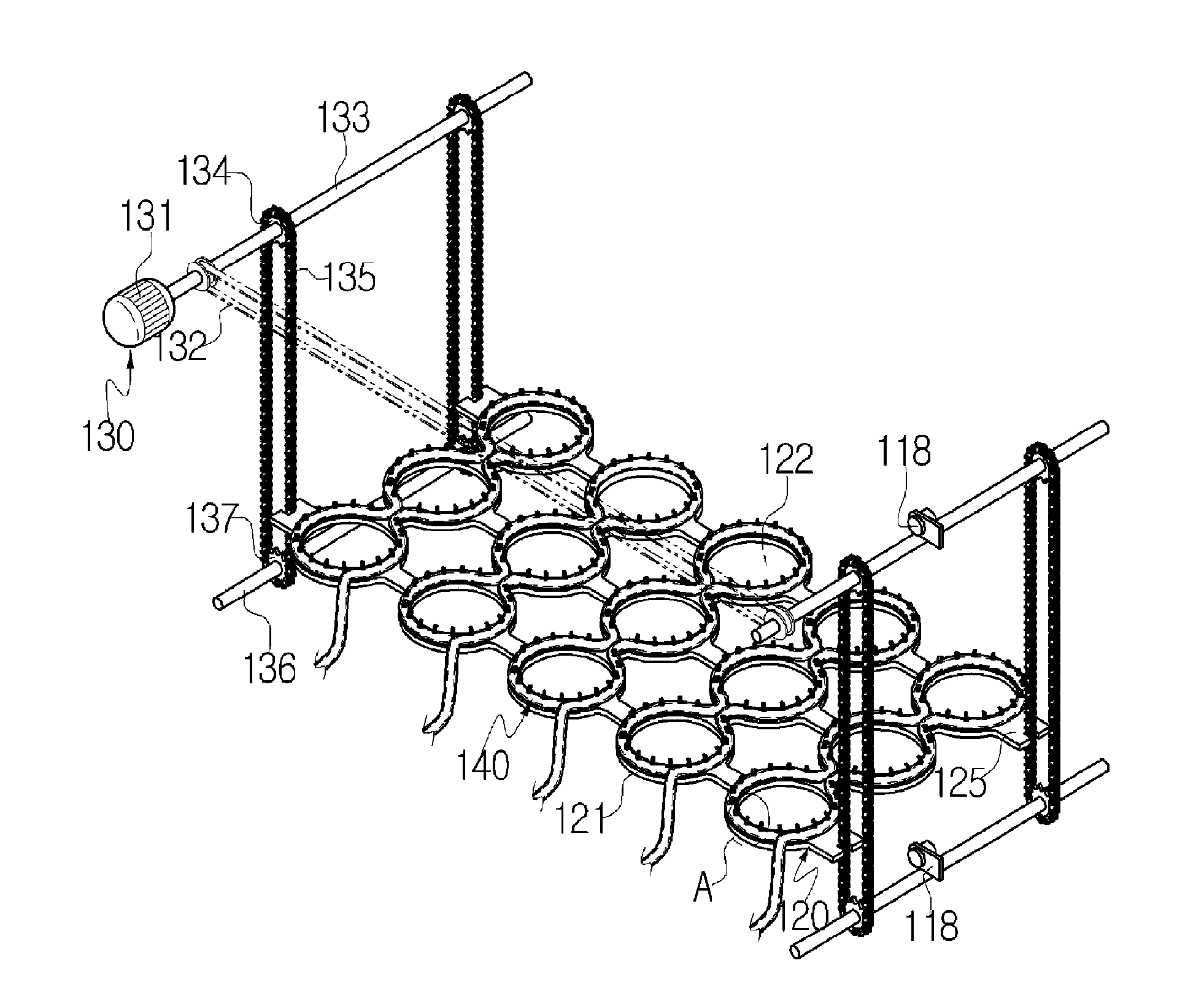

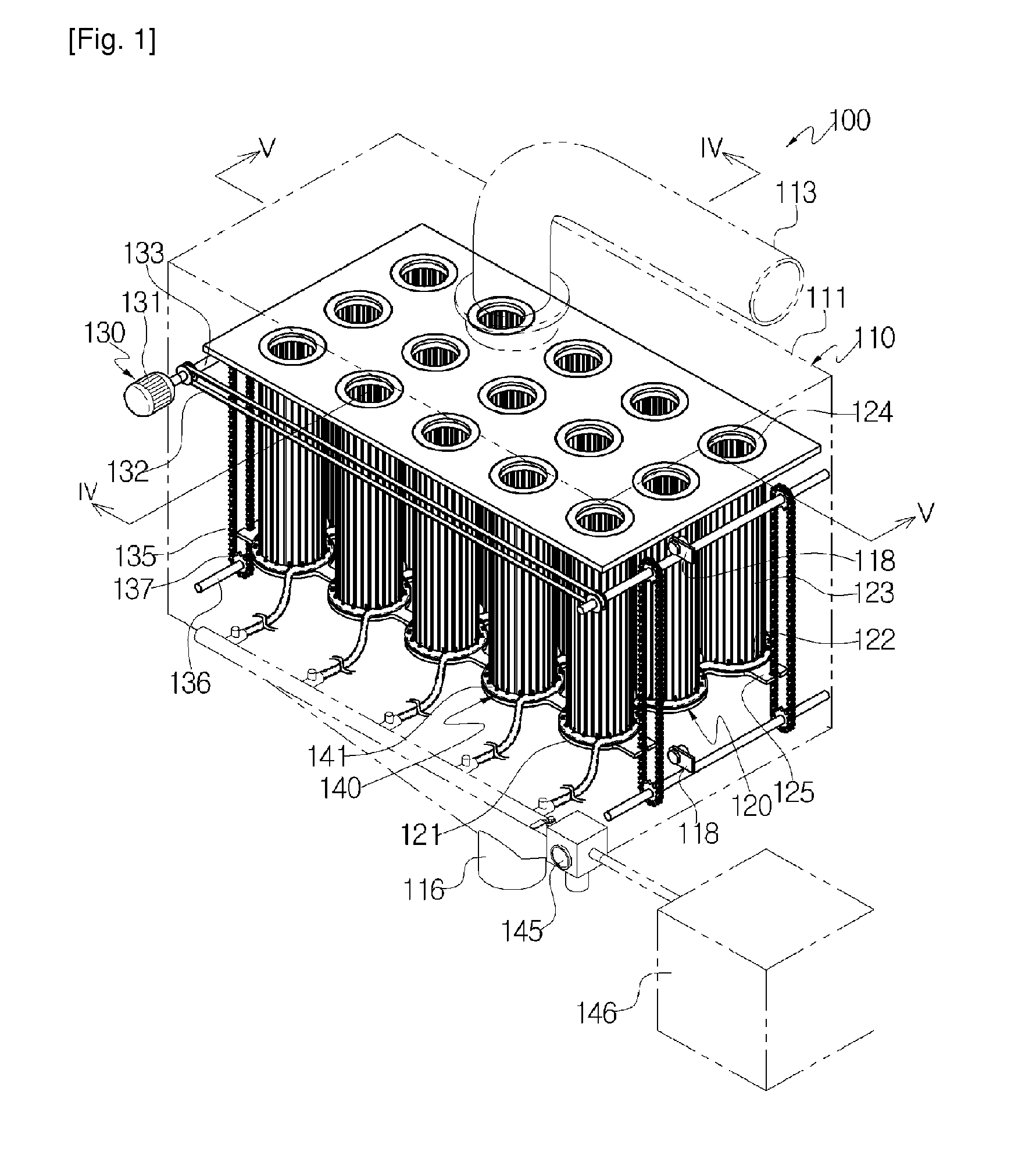

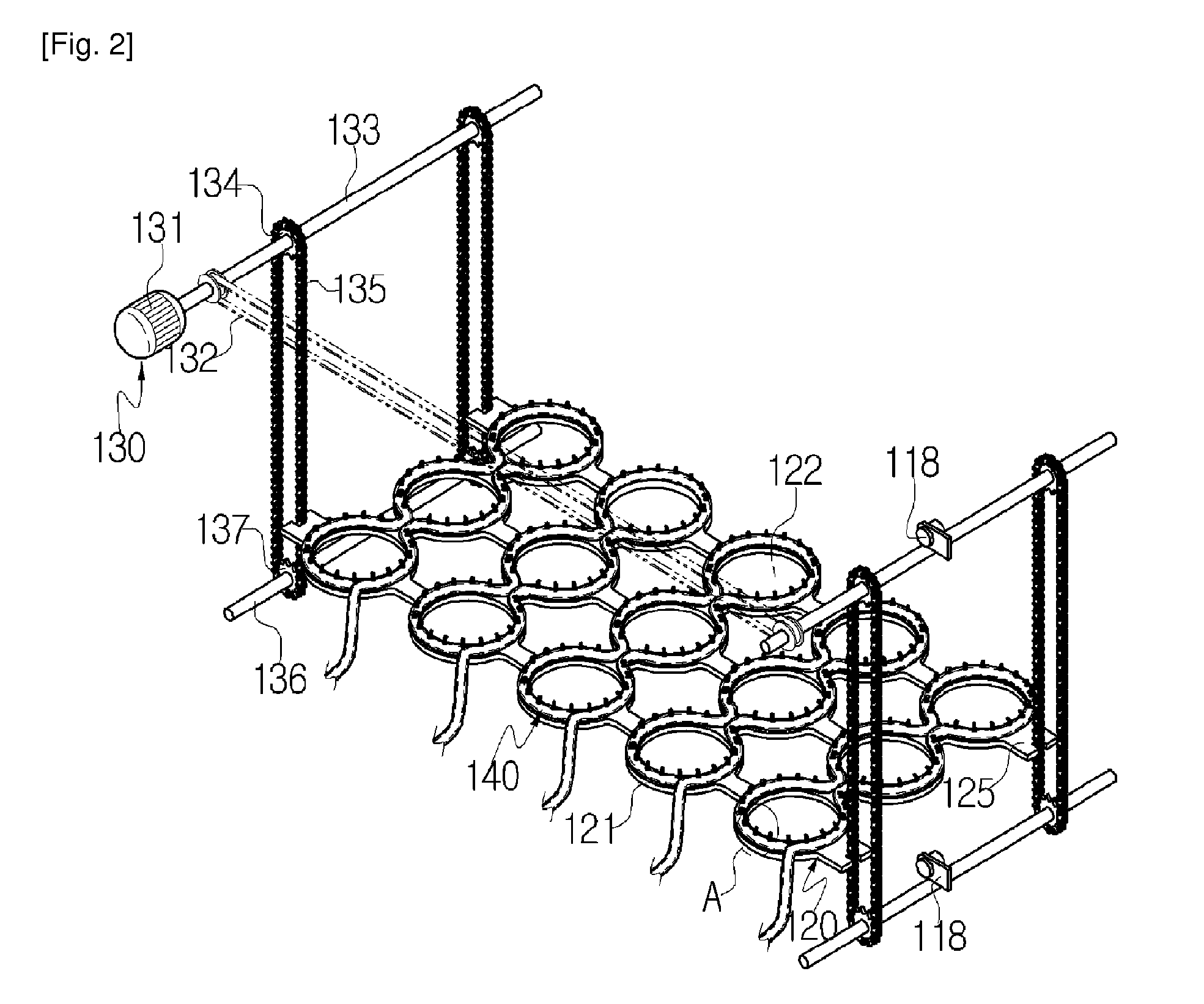

ActiveUS20100251676A1Improve removal efficiencyIncrease volumeCombination devicesDispersed particle filtrationDust collectorWaste management

A filter dust collector is disclosed. The filter dust collector includes a housing, filter cloths fixed to an inside of the housing, a filter body part disposed inside the housing and having filter insertion holes, a compressed air supply part coupled to peripheries of the filter insertion holes, a transfer part connected to the filter body part to move the filter body part and the compressed air supply part in a longitudinal direction, a duct suction port formed on a side surface of the housing to suck air to be filtered, a supply port formed on a side surface of the housing to discharge filtered air, and a dust discharge port formed on a side surface of the housing, wherein the filter cloths are positioned at the filter insertion holes, the filter body part and the compressed air supply part move in the longitudinal direction, and the compressed air supply part sprays compressed air to the filter cloths.

Owner:CHO YONG LAE

Filter dust collector

ActiveUS8277526B2Improve removal efficiencyIncrease volumeCombination devicesDispersed particle filtrationEngineeringDust collector

A filter dust collector is disclosed. The filter dust collector includes a housing, filter cloths fixed to an inside of the housing, a filter body part disposed inside the housing and having filter insertion holes, a compressed air supply part coupled to peripheries of the filter insertion holes, a transfer part connected to the filter body part to move the filter body part and the compressed air supply part in a longitudinal direction, a duct suction port formed on a side surface of the housing to suck air to be filtered, a supply port formed on a side surface of the housing to discharge filtered air, and a dust discharge port formed on a side surface of the housing, wherein the filter cloths are positioned at the filter insertion holes, the filter body part and the compressed air supply part move in the longitudinal direction, and the compressed air supply part sprays compressed air to the filter cloths.

Owner:CHO YONG LAE

Air purifying device

InactiveCN105413344AWill not affect healthDust removal is simpleDispersed particle filtrationTransportation and packagingEngineeringAir purification

The invention provides an air purifying device which comprises a base, a draught fan support, a draught fan, a dust removing structure, a dust brushing structure, a rotating sealing cover and a motor. The draught fan is fixedly installed on the draught fan support and comprises an air draft duct and fan blades installed in the air draft duct, the air draft duct is provided with an air inlet and an air outlet, and the bottom face of the air draft duct is a plane. The dust removing structure is arranged in the middle of the air draft duct and comprises a filter screen and a dust collecting box which is arranged on the side, close to the air inlet, of the filter screen, and the arrangement position of the dust collecting box is lower than that of the air draft duct. The dust brushing structure is used for brushing away dust attached to the side, facing the air inlet, of the filter screen and making the dust fall into the dust collecting box. According to the air purifying device, the dust removing structure is arranged in the middle of the air draft duct, the dust brushing structure is further arranged, when dust removal needs to be performed on the filter screen, the dust brushing structure is started to clean the filter screen, dust removal can be performed without detaching the filter screen, dust removal is easy, and labor intensity is low; dust will not be scattered in all directions or fly upwards and will not be inhaled by workers, and the body health of the workers will not be affected.

Owner:周桂灵

Air cleaning equipment

InactiveCN105582755AWill not affect healthDust removal is simpleDispersed particle filtrationTransportation and packagingAir cleaningEngineering

The invention provides air cleaning equipment. The air cleaning equipment comprises a base, a fan support, a fan, a dust removal structure, a dust brushing structure, a rotary seal cover, a motor, a water spraying pipe, a water pump, a dust cover and a rotating motor, wherein the fan comprises an air suction barrel and fan blades, and the air suction barrel has an air inlet and an air outlet; the dust removal structure is arranged in the middle of the air suction barrel and comprises a filter net and a dust collecting box; the dust brushing structure is used for brushing off dust which is attached on one side, facing the air inlet, of the filter net and enabling the dust to fall into the dust collecting box; the water spraying pipe is mounted above the dust brushing structure and used for flushing the dust brushed off the filter net into the dust collecting box; the water pump is used for supplying water to the water spraying pipe; the dust cover is rotationally mounted on the air suction barrel; the rotating motor drives the dust cover to rotate. According to the air cleaning equipment, the dust removal structure is arranged in the middle of the air suction barrel, the dust brushing structure is arranged and is started to clean the filter net when the dust on the filter net is required to be removed, the dust can be easily removed without dismounting the filter net, and the labor intensity is low; the dust cannot scatter or fly, and body health of workers cannot be affected.

Owner:周桂灵

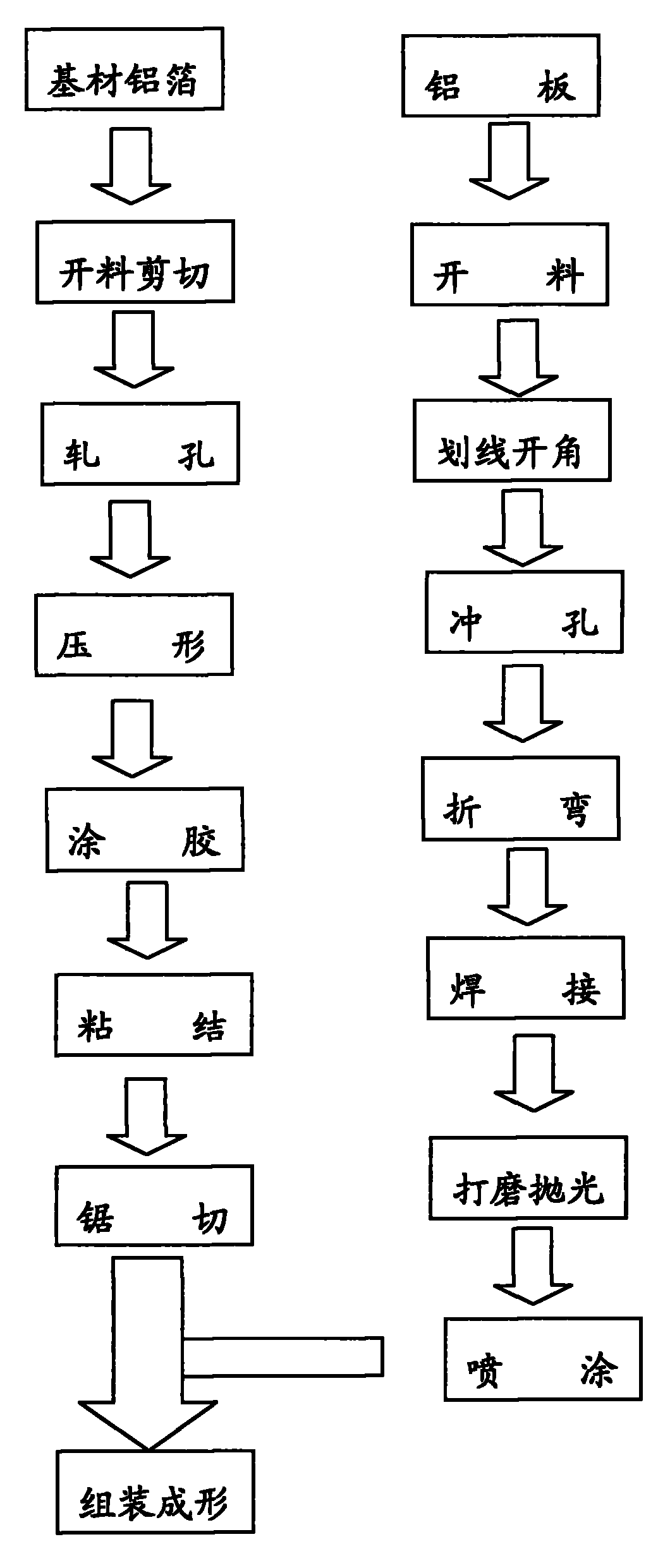

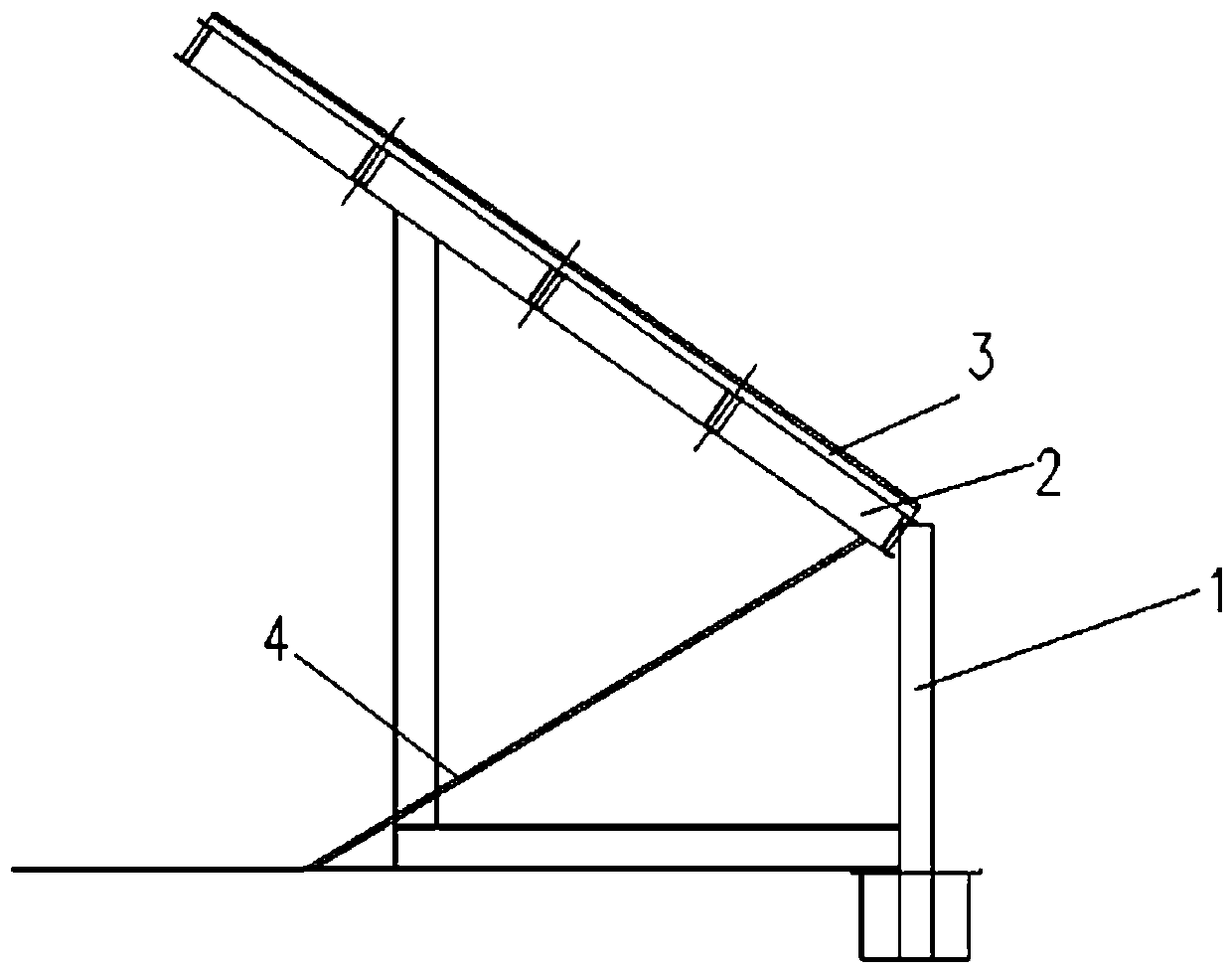

Novel micropore aluminum foil sound absorption acoustic screen

InactiveCN103397607AThe idea is clear and novelSimple and fast to makeNoise reduction constructionPunchingAluminum foil

The invention discloses a novel micropore aluminum foil sound absorption acoustic screen and relates to the technical field of building material decoration products. By adopting the key technology of 'using ultra-thin aluminum foil as a substrate micropore sound absorption structure', the manufacturing method comprises the following steps: the substrate aluminum foil is subjected to cutting, shearing, pricking, swaging, gluing, bonding and sawing to be manufactured into micropore sound absorption aluminum foil for use; an aluminum plate is subjected to cutting, scribing, angle opening, punching, bending, welding, polishing and spraying to be manufactured into an acoustic screen body for use; the micropore sound absorption aluminum foil and the acoustic screen body are assembled together to be manufactured into the finished product of the novel micropore aluminum foil sound absorption acoustic screen. The novel micropore aluminum foil sound absorption acoustic screen is used for sound absorption and insulation, and is ingenious in conception, reasonable in structure, good in sound absorption and insulation effect, resistant to impact, safe, reliable, retardant to flames, durable, convenient to install, use and maintain, attractive and elegant as a whole, easy to manufacture, low in cost, wide in application range, and beneficial to popularization and application.

Owner:唐海浩

Pulse bag type dust collection device and method thereof

InactiveCN105477966ASimple structureEasy to operateCombination devicesDispersed particle filtrationAir velocityAtmospheric air

The invention discloses a pulse bag type dust collection device and a method thereof. The dust collection device comprises a bracket, a box structure arranged on the bracket and a pulse bag type dust collection device arranged in the box structure, wherein an air inlet is formed at the bottom of the box structure, an air outlet is formed at the upper part of the box structure, the air inlet is connected with an inlet of the pulse bag type dust collection device, and the air outlet is connected with the outlet of the pulse bag type dust collection device. According to the invention, by arranging the pulse bag type dust collection device to dispose dust in a factory workshop, dust in the workshop can be adsorbed by utilizing match of a tapered suction port with reasonable air speed, then an induced draft fan is used for providing power so that the dust enters the pulse bag type dust collection device, the dust is captured by the inner surface of a filter bag, and purified gas is discharged to the atmosphere via the air outlet of the pulse bag type dust collection device; the whole dust collection process is simple and rapid, dust in the air can be collected and disposed in time, and an effect of quickly removing dust can be achieved.

Owner:GUANGDONG JUNFENGHUA TECH CO LTD

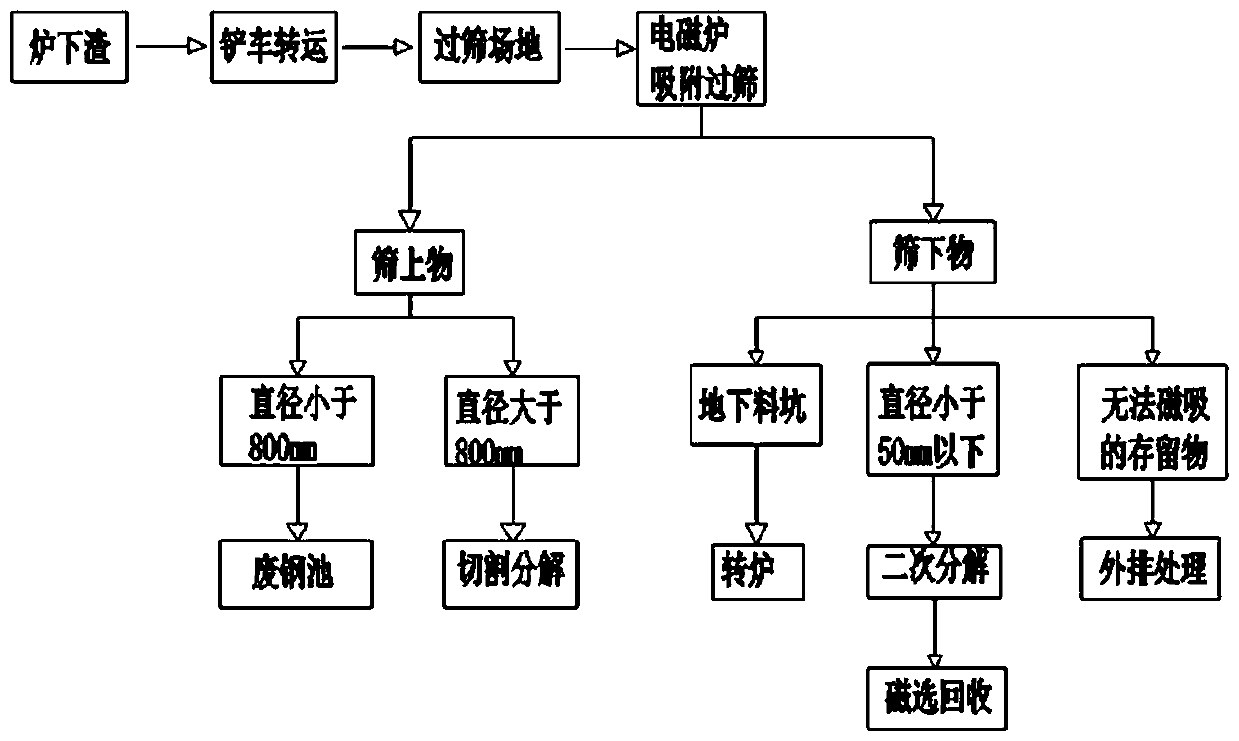

Recovery device and method of furnace bottom steel slag of steel-making furnace

The invention relates to the technical field of steel-making furnace steel slag treatment, and more specifically, relates to a recovery device and method of furnace bottom steel slag of a steel-makingfurnace. According to the technical scheme, the recovery device is characterized by comprising four supports which are vertically arranged on the ground in a rectangular mode. The horizontal heightsof the two supports located on one side are larger than those of the two supports located on the other side. A screen frame is installed on the tops of the supports, and an opening is formed in the middle of the surface of the screen frame. A screen mesh is laid on the screen frame. The invention further provides a recovery technology process of utilizing the recovery device to recover the steel slag. The recovery device and method of the furnace bottom steel slag of the steel-making furnace have the advantages that the technology is continuous, the facility is simple and is centralized, and the smelting cost is reduced.

Owner:SGIS SONGSHAN CO LTD

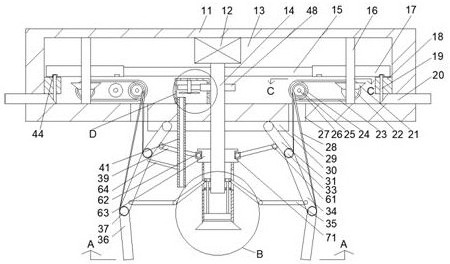

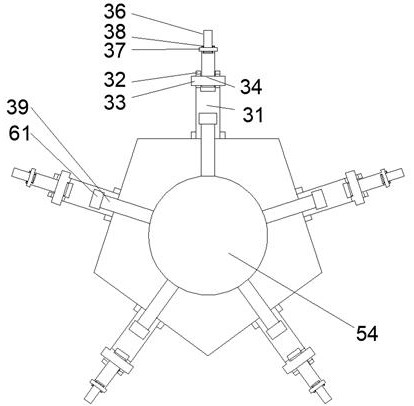

Tea dust-removal device with air separation structure

ActiveCN109013323ADust removal is simpleDust completelySievingPre-extraction tea treatmentPrimary screeningAir separation

The invention discloses a tea dust-removal device with an air separation structure. The tea dust-removal device comprises a table-shaped base, the upper portion of the table-shaped base is provided with a primary screening device, and the top of the primary screening device is provided with a material input mouth, the primary screening device is internally provided with a drying device, the innerbottom of the primary screening device is provided with a pumping direction motor, the side surface of the bottom of the primary screening device is provided with a dust collecting device, the primaryscreening device is connected with an air separation device through a hopper sliding passage, and the side surface of the table-shaped base is provided with a dust collecting drawer group. By means of the tea dust-removal device with the air separation structure, a two-segment type dust-removal method is realized, and by means of the primary screening device, most impurities in tea are rapidly and effectively separated.

Owner:陕西安康山川秀美农业有限公司

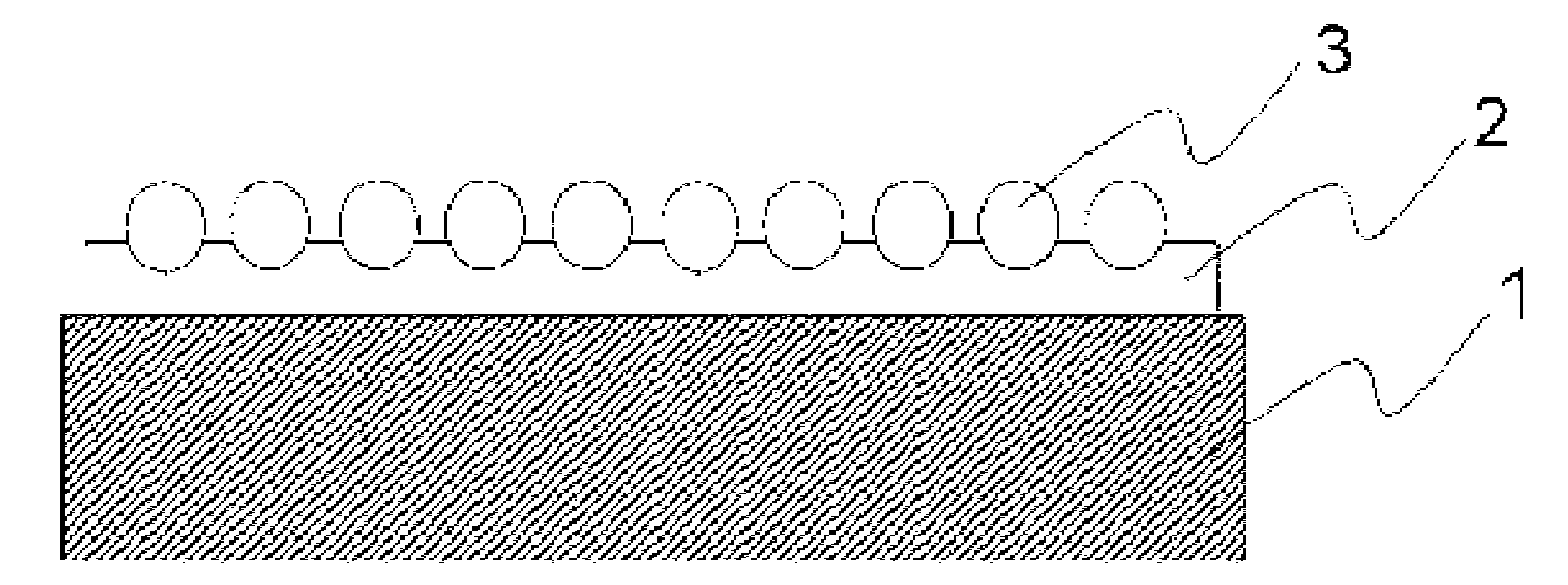

Structure of Preventing Sticking and Method of Preparing the Same

InactiveUS20080305699A1Reduce contact areaInhibition of attachmentCovering/liningsWallsCoated surfaceWeather resistance

The present invention provides an anti-adhesion mechanism and a method of producing it and more particularly, it provides an anti-adhesion mechanism comprising a structure body, a resin binder layer comprising a resin binder coated on all or part of the surface of the structure body and a bead layer comprising a plurality of beads bond to the upper side of the coated resin binder layer and being salient outside, and a method of producing an anti-adhesion mechanism comprising coating a resin binder on the surface to be coated, spraying beads on the upper portion of the resin binder before the coated resin binder is hardened and hardening them to form bead protrusions. The anti-adhesion mechanism prepared in accordance with the invention can prevent the adhesion of attachments such as stickers, posters and dusts to the coated surface and easily remove the attachments even though they are adhered, can be readily formed and can improve such properties as weather resistance, contamination resistance, scratch resistance, chemical resistance and impact resistance of the surfaces coated therewith.

Owner:KWAK SANG WOON +4

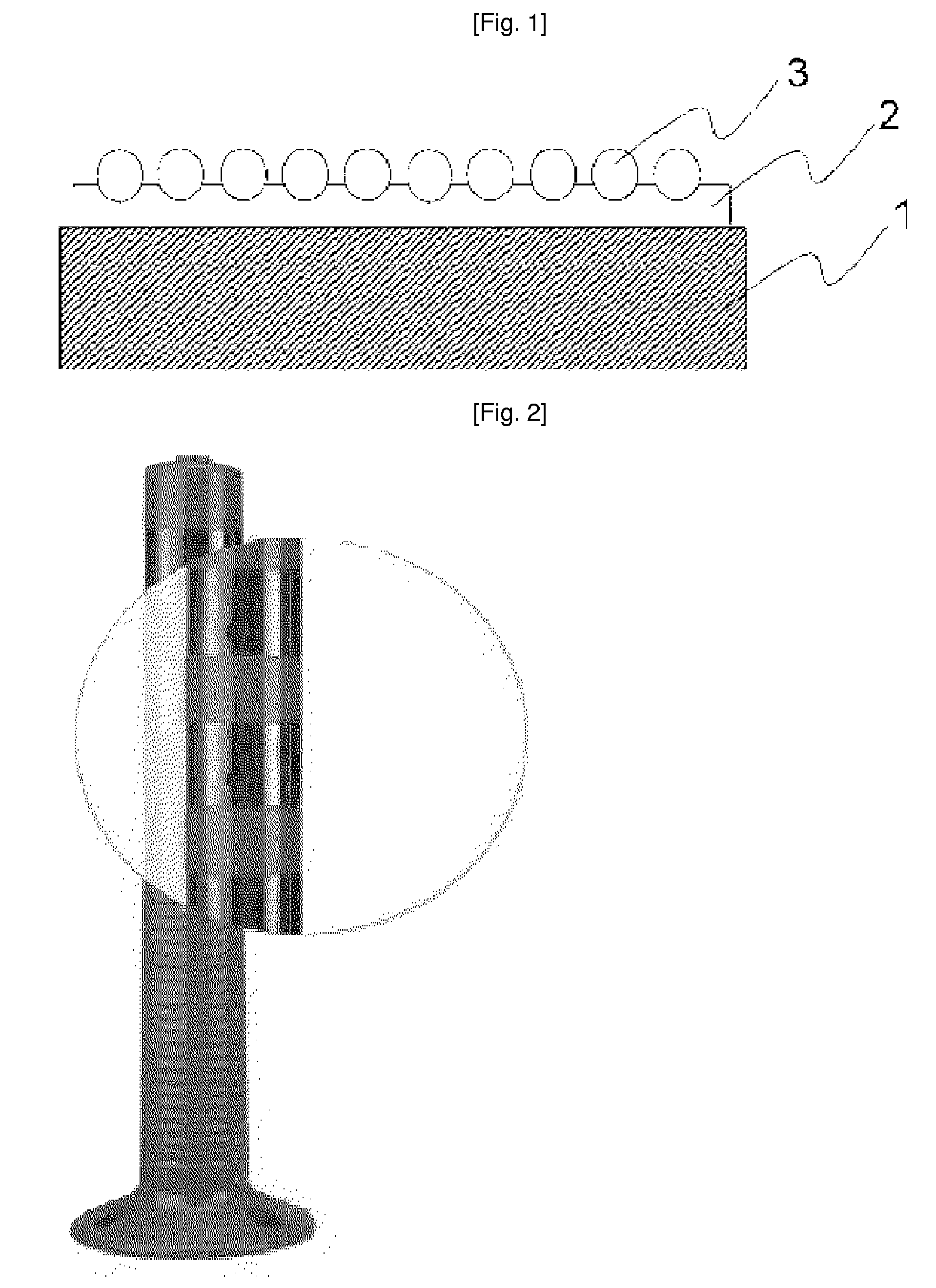

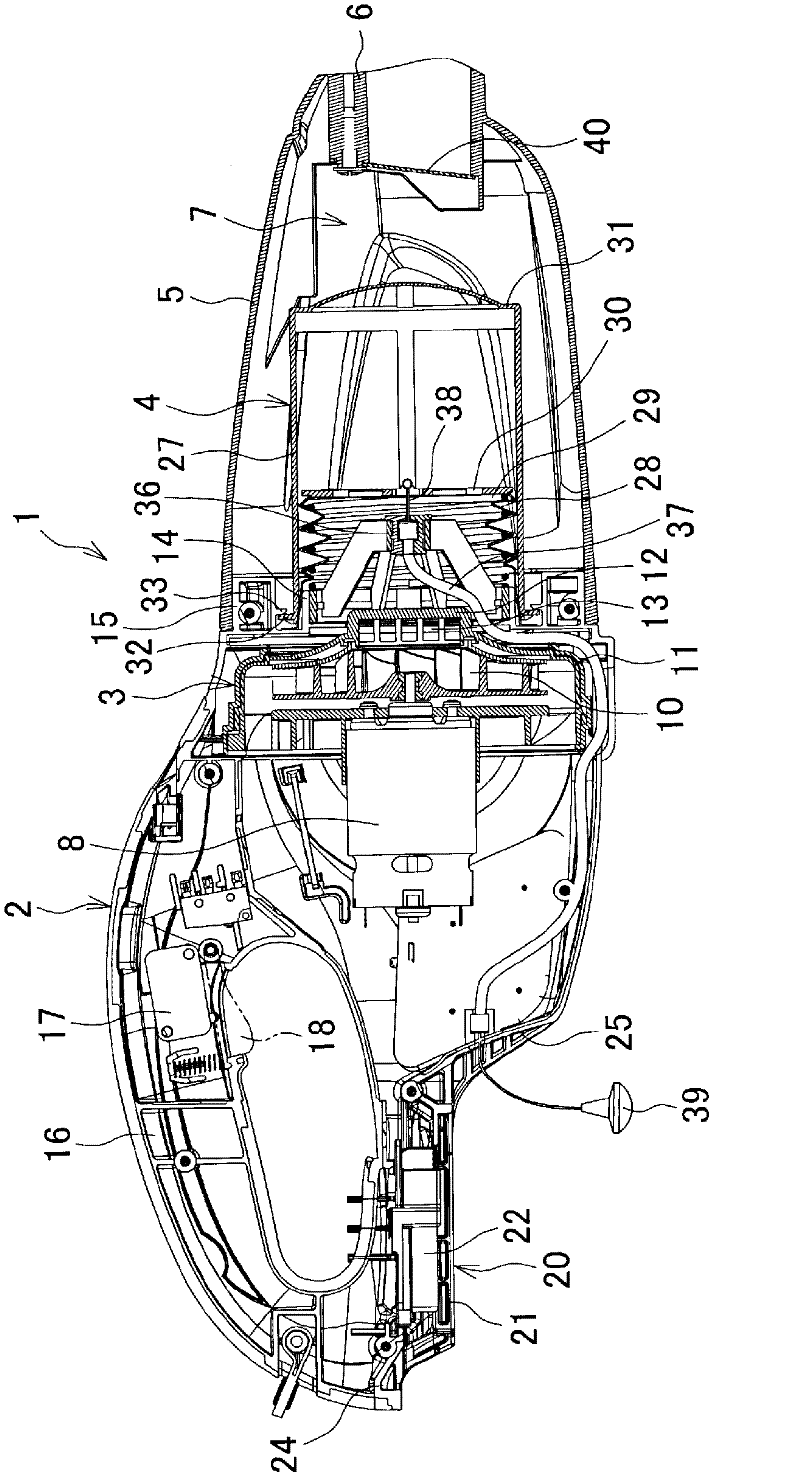

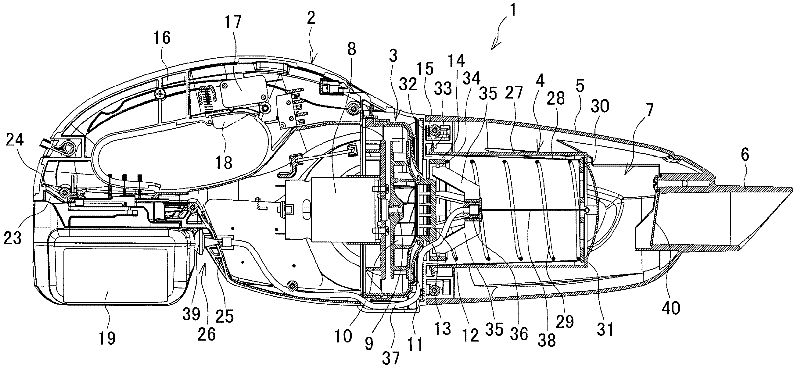

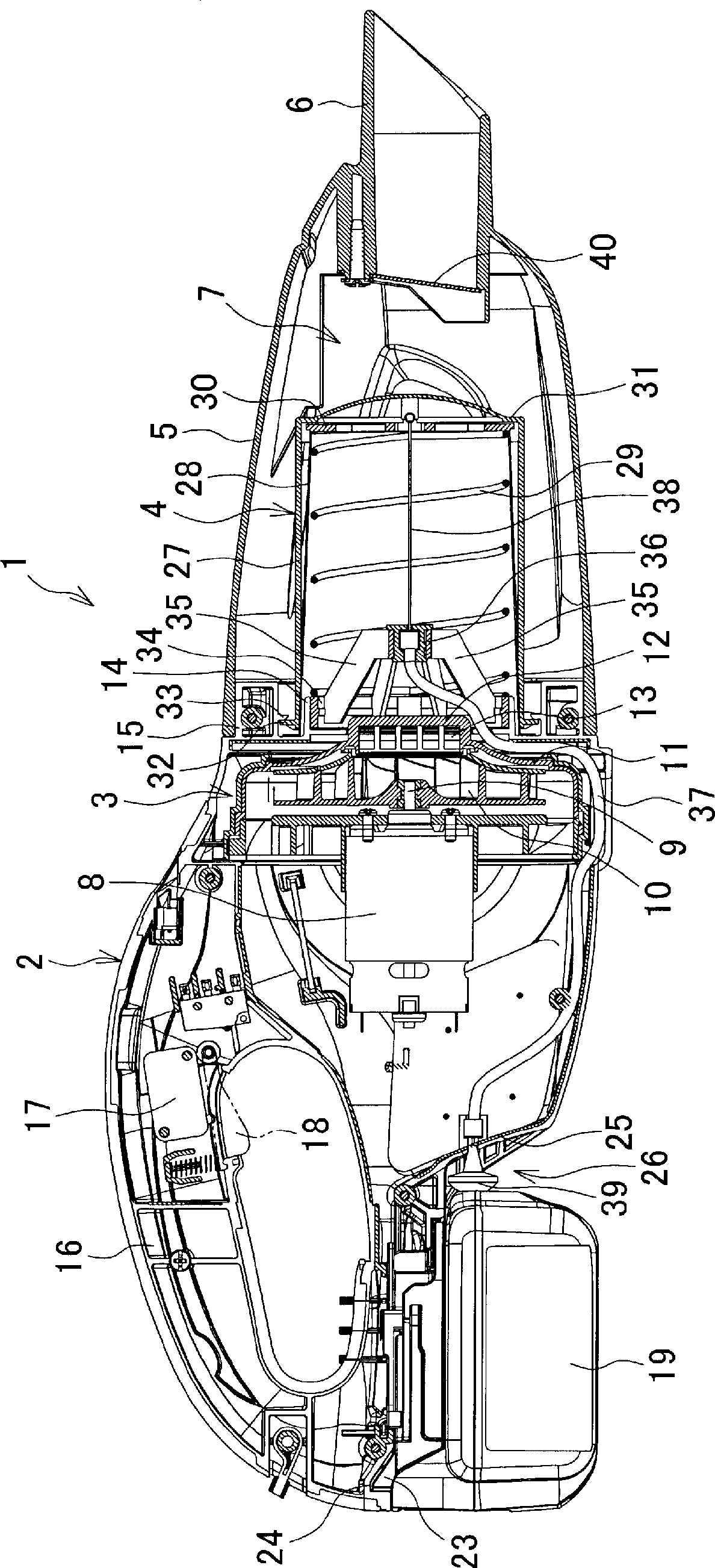

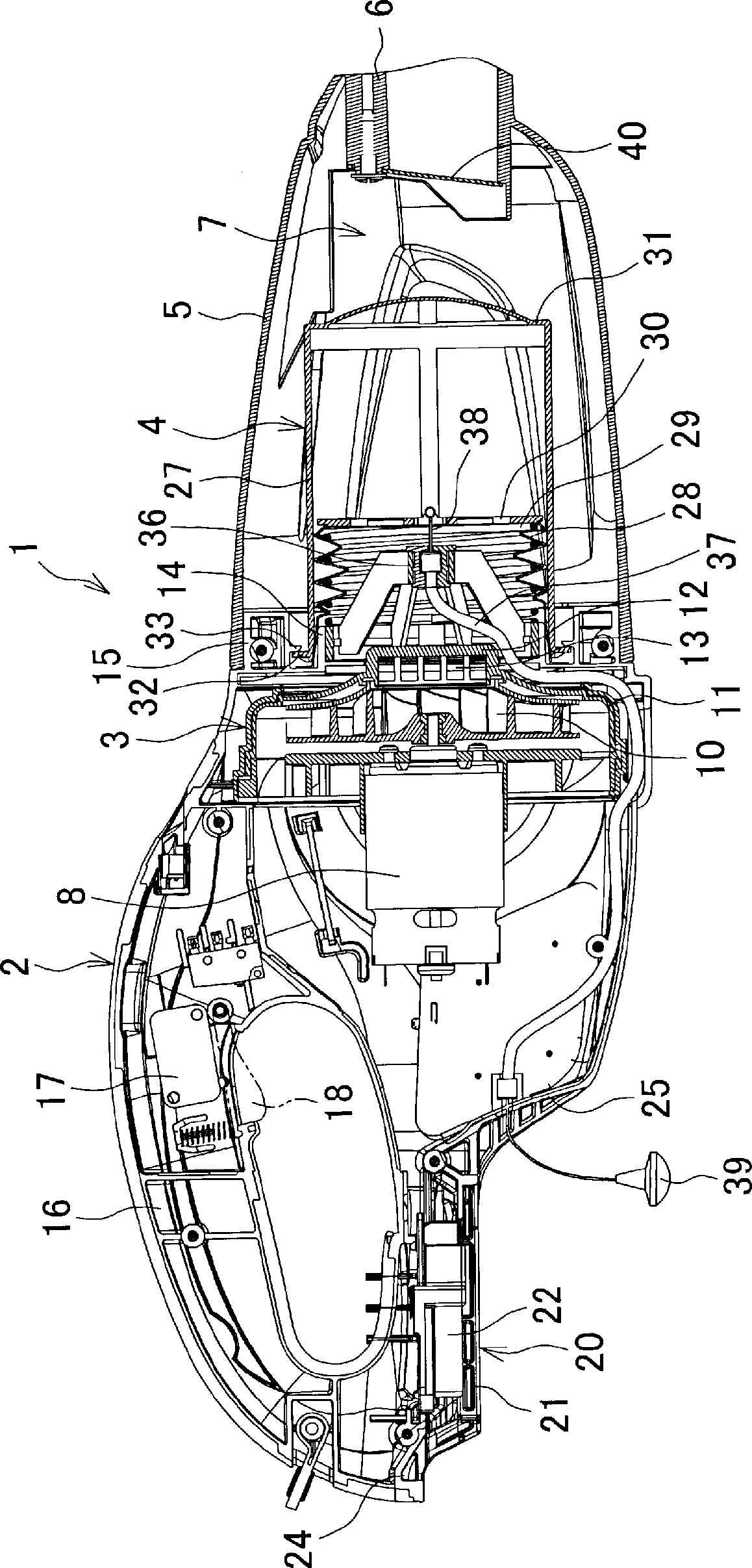

Cleaner

A cleaner configured in such a manner that dust removal operation can be optimally performed without the removal of a front housing, without the entry of dust into the filter due to the dust removal operation, and without a decrease in the suction force. A cleaner (1), wherein a coiled spring (29) for pressing a filter (28) so that the filter is retained in an extended attitude is provided within the filter (28) of a filter unit (4), a mounting plate (30) is secured to the front end of the filter (28), one end of a wire (38) is connected to the mounting plate (30), and the other end of the wire (38) is led out of the inside of the filter (28) to the outside at the rear of the body housing after being made to pass through the body housing (2). The filter (28) can be arbitrarily contracted by causing, through pulling operation of the other end of the wire (38), the mounting plate (30) to recede against the pressing force of the coiled spring (29).

Owner:MAKITA CORP

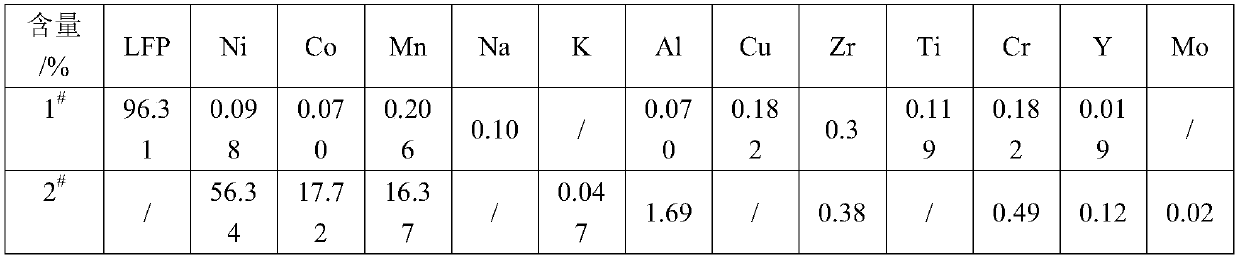

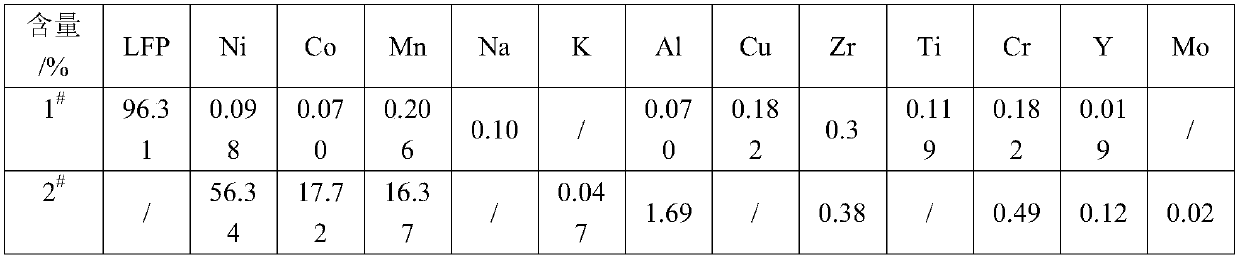

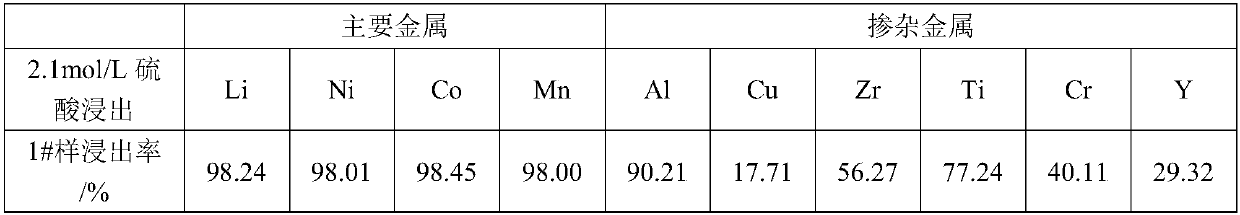

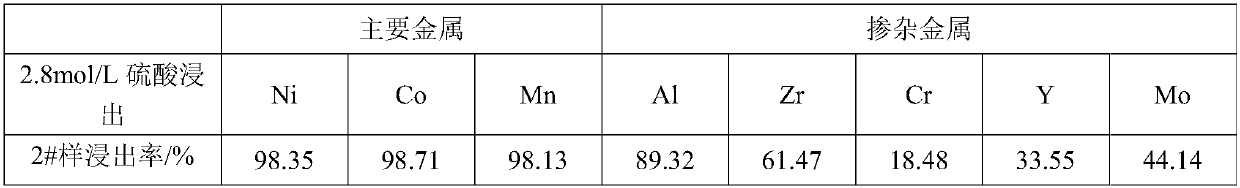

A sodium salt roasting method for recovering metals in positive electrode powder of waste lithium batteries

ActiveCN107586960BHigh recovery rateIncrease profitWaste accumulators reclaimingProcess efficiency improvementIndiumManganese

The invention discloses a sodium salt added roasting method of metal in recycled waste lithium battery cathode powder. The method comprises steps as follows: a waste lithium battery cathode powder andsodium salt mixture is added to a mixing machine, and a mixed material is obtained; the mixed material is sent into a hydraulic ball press for ball preparation, and material balls are obtained; the material balls are roasted, crushed, ground and subjected to acid leaching treatment, and an acid leaching solution is obtained. The method capable of effectively damaging the lattice structure of a cathode material, improving the leaching activity of target metals and reducing the acid amount in the following acid leaching procedure is provided, so that the production condition is optimized, the recovery rate of main metals such as lithium, nickel, cobalt, manganese and the like and the conversion rate of doped metals such as titanium, chromium, zirconium, yttrium, indium, tin, molybdenum, vanadium and the like are increased, and the production efficiency of the roasting and leaching sections is finally improved. Besides, resourceful utilization of the main metals and the doped metals in the waste lithium battery cathode powder is realized.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Bottle cap cleaning machine

InactiveCN101190437ANo electrostatic attractionEliminate static electricityCleaning using gasesElectrostatic chargesHigh pressureBottle cap

The invention relates to a bottle cover cleaning machine with electrostatic dedusting. The lower part of an insulated feeding disc in the dedusting area of the bottle cover cleaning machine is provided with an insulated bracket and a grounding wire connected with a height adjusting cover plate; blowing nozzles are intermittently separated from high-voltage acusector tip; furthermore, the upper end of the blowing nozzle and the upper end of the high-voltage acusector tip are arranged in the internal space of the insulated bracket. Owning to the insulated bracket, original anode plate can be replaced by the height adjusting cover plate, thus leading a electric field to be generated between the height adjusting cover plate and the high-voltage acusector tip, leading the bottle cover to fully pass through the electric field, eliminating static through grounding the height adjusting cover plate and being easier to dedust. Furthermore, the upper end of the blowing nozzle is arranged in the internal space of the insulated bracket, which is closer to the bottle cover, thus reinforcing dust blowing function by strong airflow which is generated.

Owner:周捷明

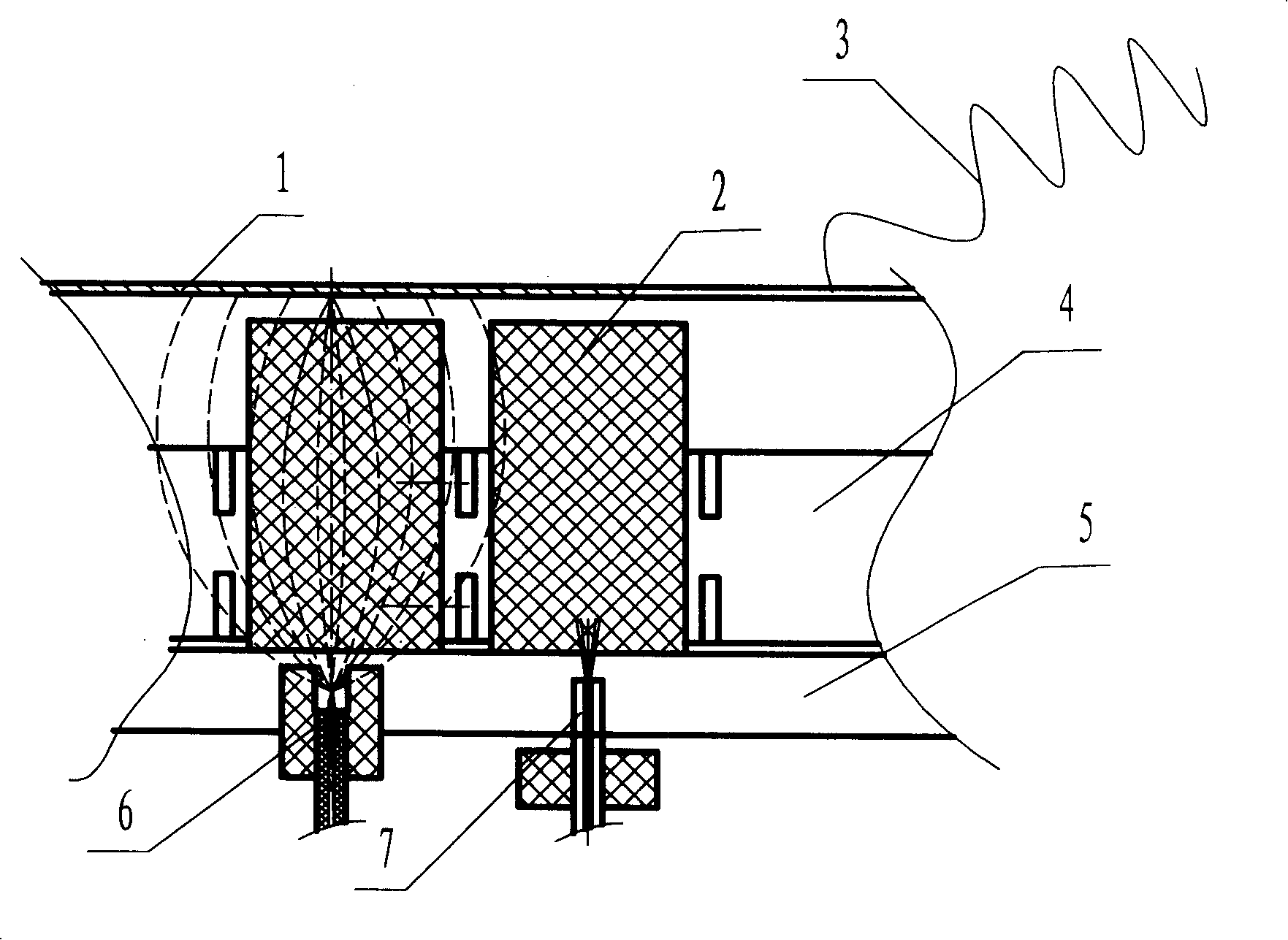

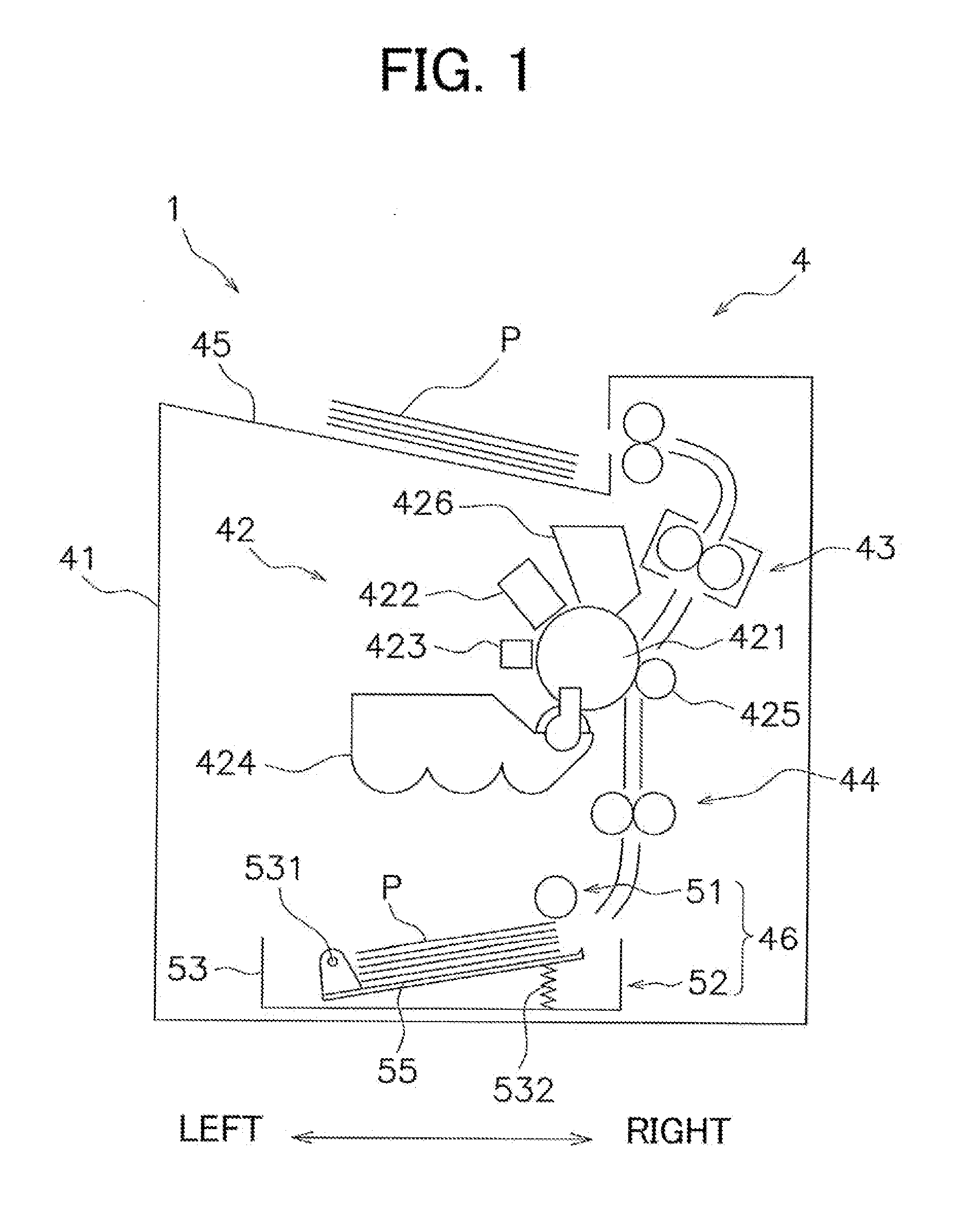

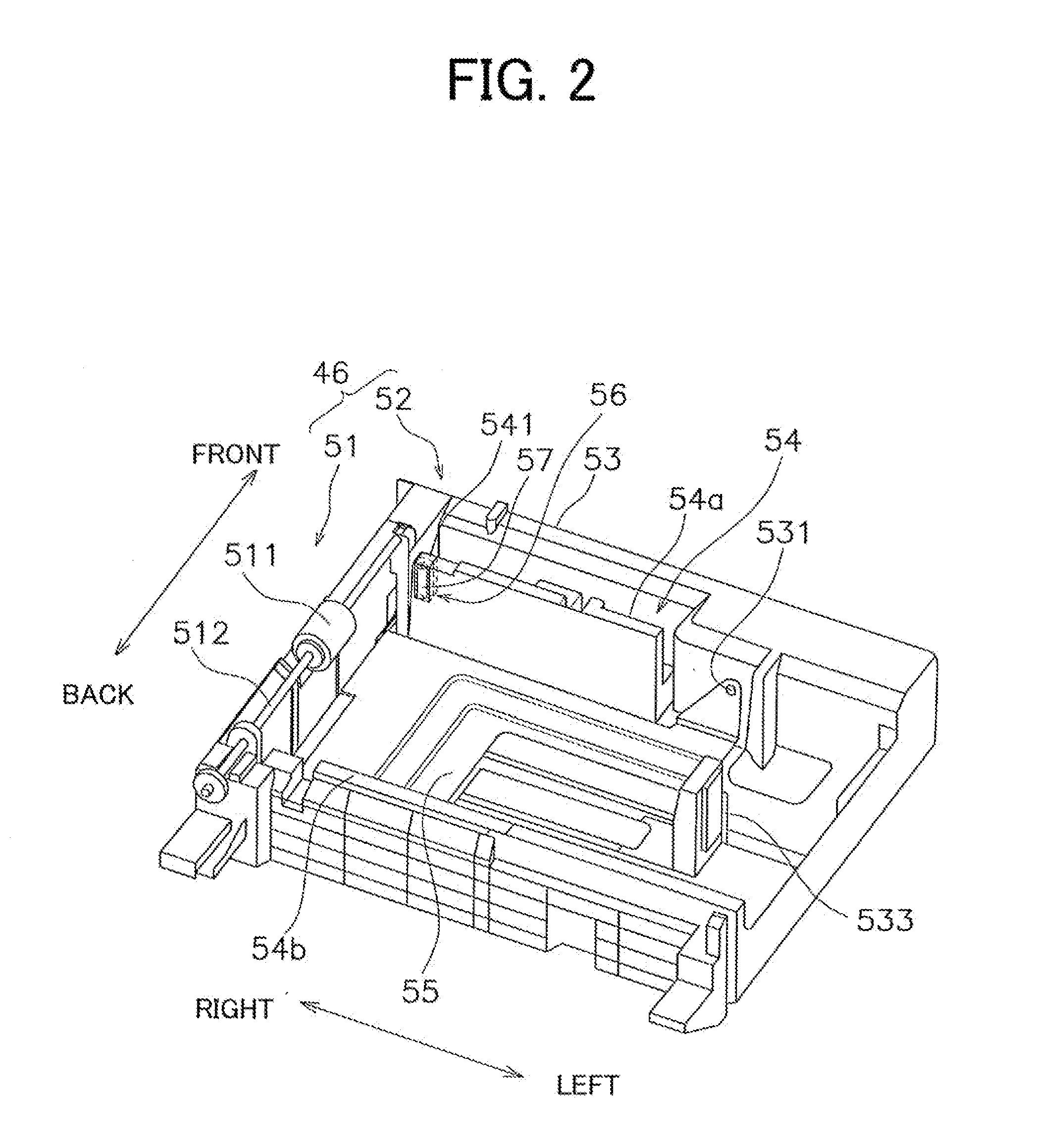

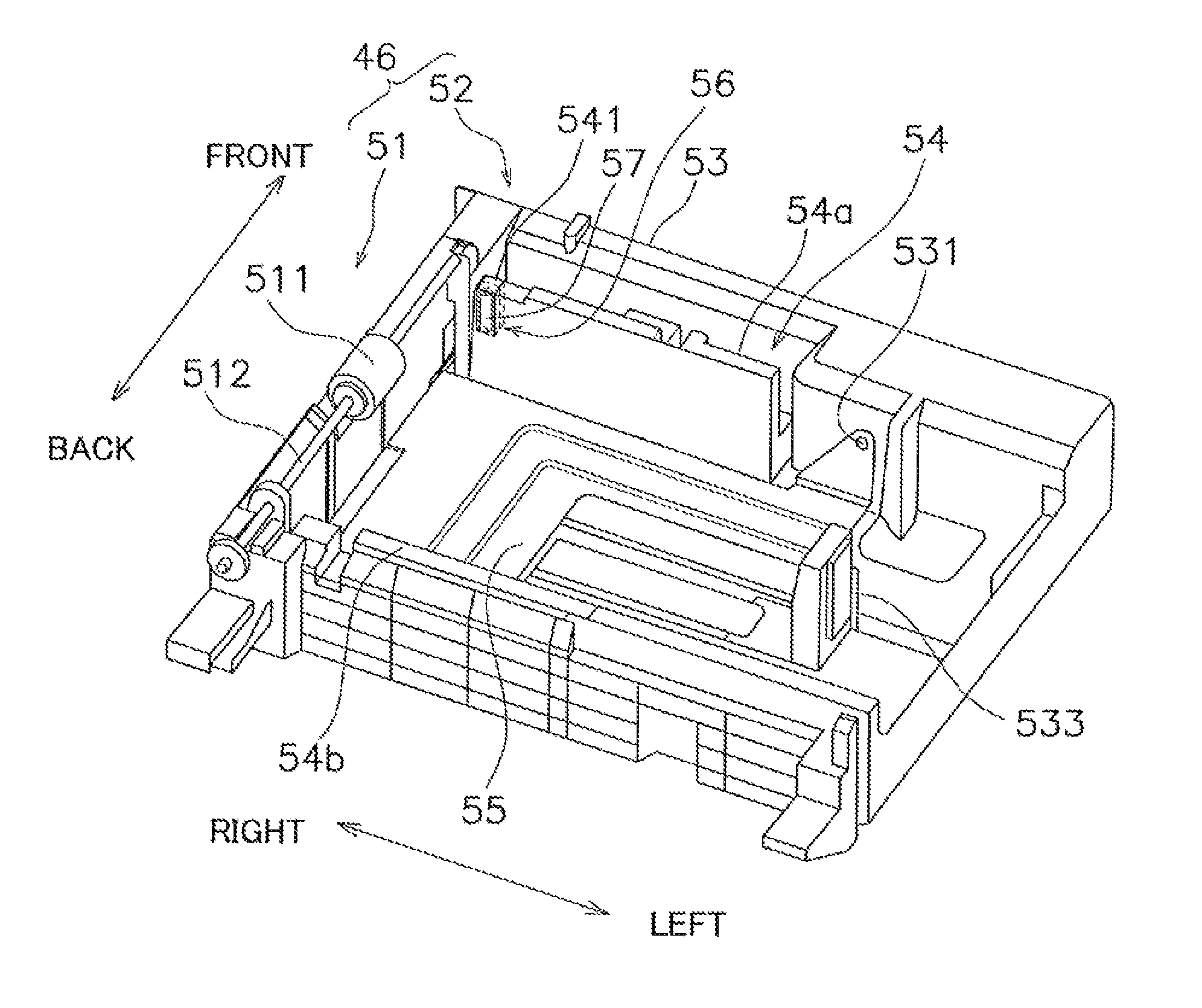

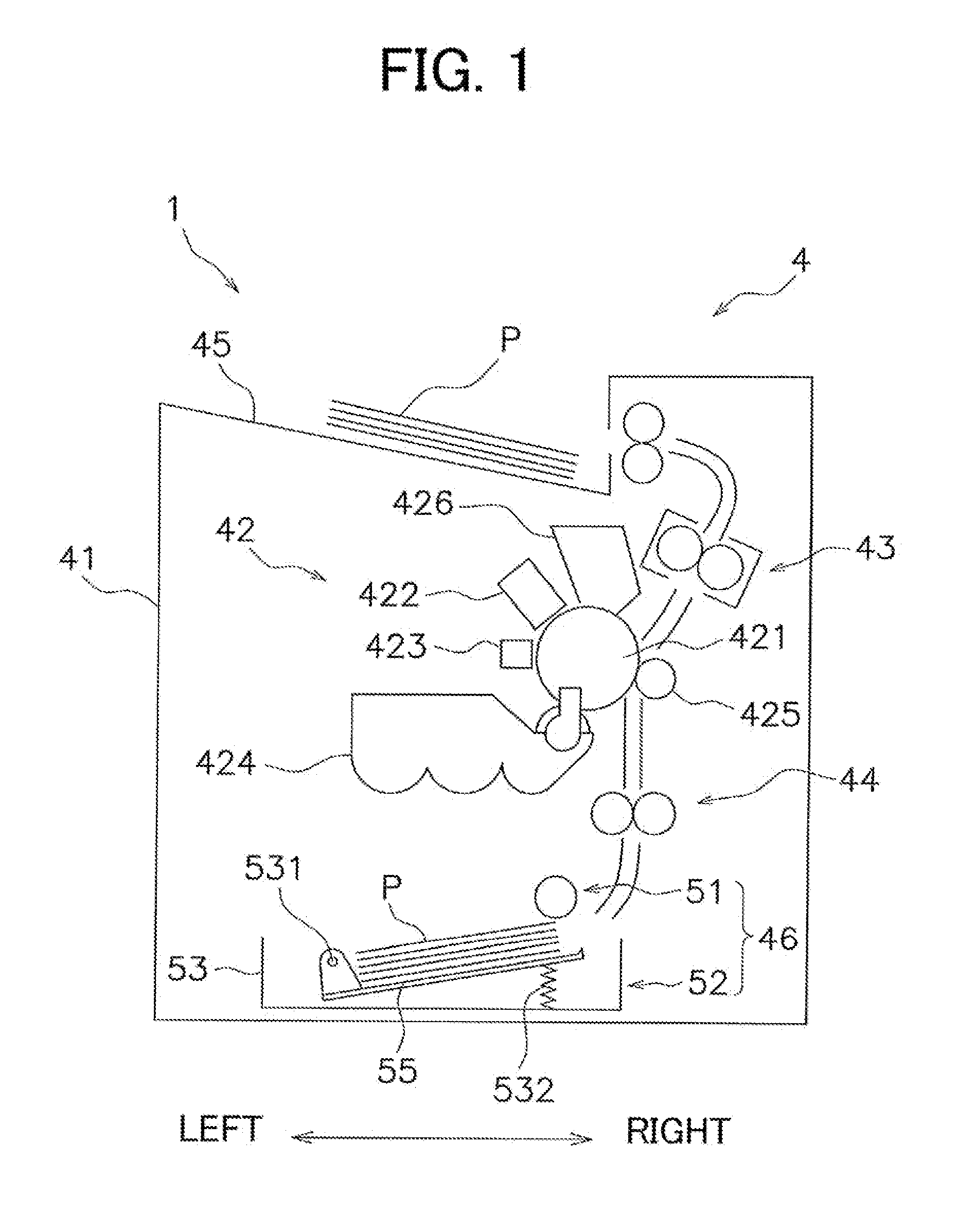

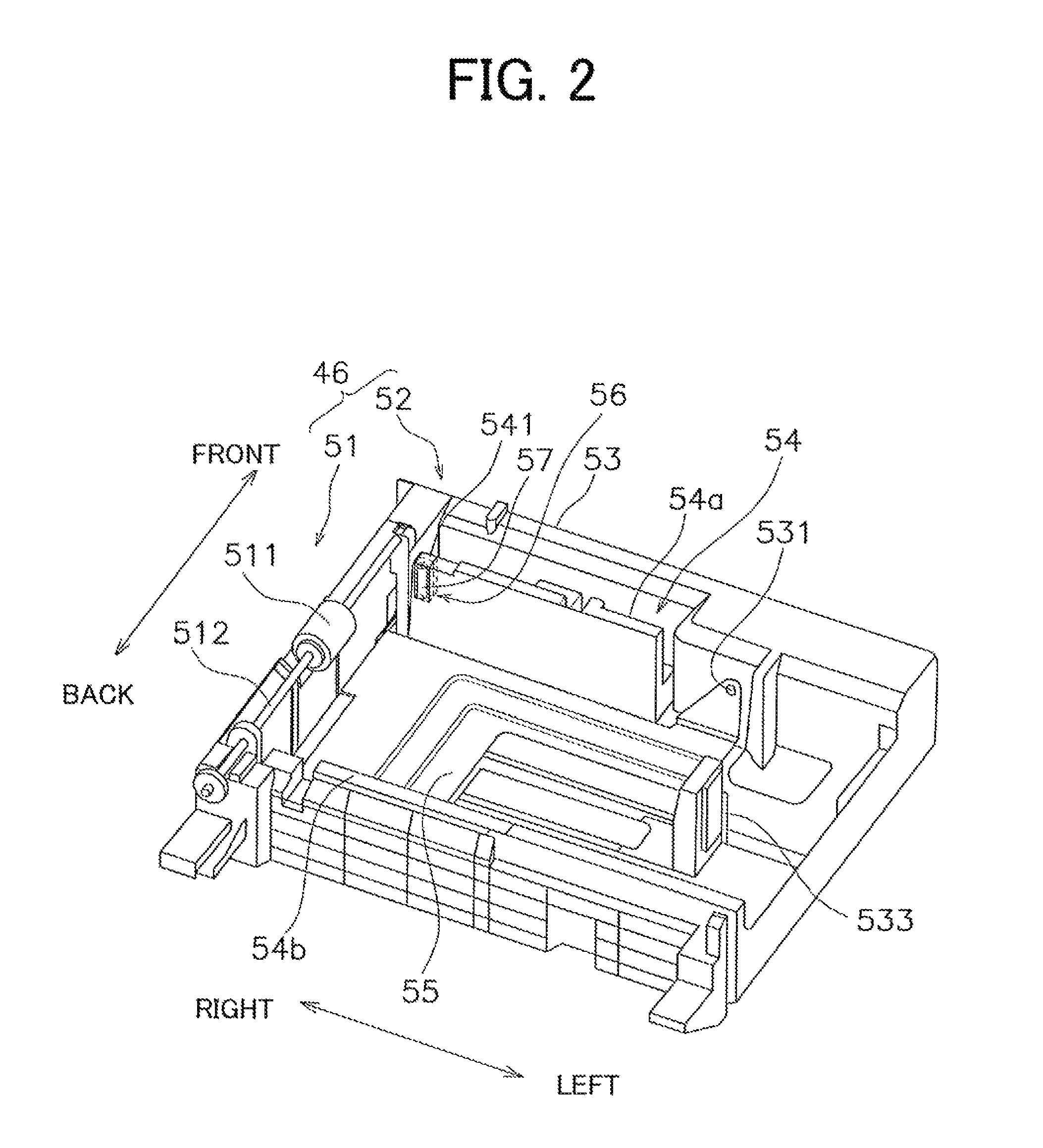

Paper feeding apparatus and image forming apparatus

InactiveUS20110204559A1Fully removedEfficient removalRegistering devicesElectrographic process apparatusPulp and paper industryEngineering

Owner:MURATA MASCH LTD

Sodium salt added roasting method of metal in recycled waste lithium battery cathode powder

ActiveCN107586960AHigh recovery rateIncrease profitProcess efficiency improvementBattery recyclingIndiumManganese

The invention discloses a sodium salt added roasting method of metal in recycled waste lithium battery cathode powder. The method comprises steps as follows: a waste lithium battery cathode powder andsodium salt mixture is added to a mixing machine, and a mixed material is obtained; the mixed material is sent into a hydraulic ball press for ball preparation, and material balls are obtained; the material balls are roasted, crushed, ground and subjected to acid leaching treatment, and an acid leaching solution is obtained. The method capable of effectively damaging the lattice structure of a cathode material, improving the leaching activity of target metals and reducing the acid amount in the following acid leaching procedure is provided, so that the production condition is optimized, the recovery rate of main metals such as lithium, nickel, cobalt, manganese and the like and the conversion rate of doped metals such as titanium, chromium, zirconium, yttrium, indium, tin, molybdenum, vanadium and the like are increased, and the production efficiency of the roasting and leaching sections is finally improved. Besides, resourceful utilization of the main metals and the doped metals in the waste lithium battery cathode powder is realized.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

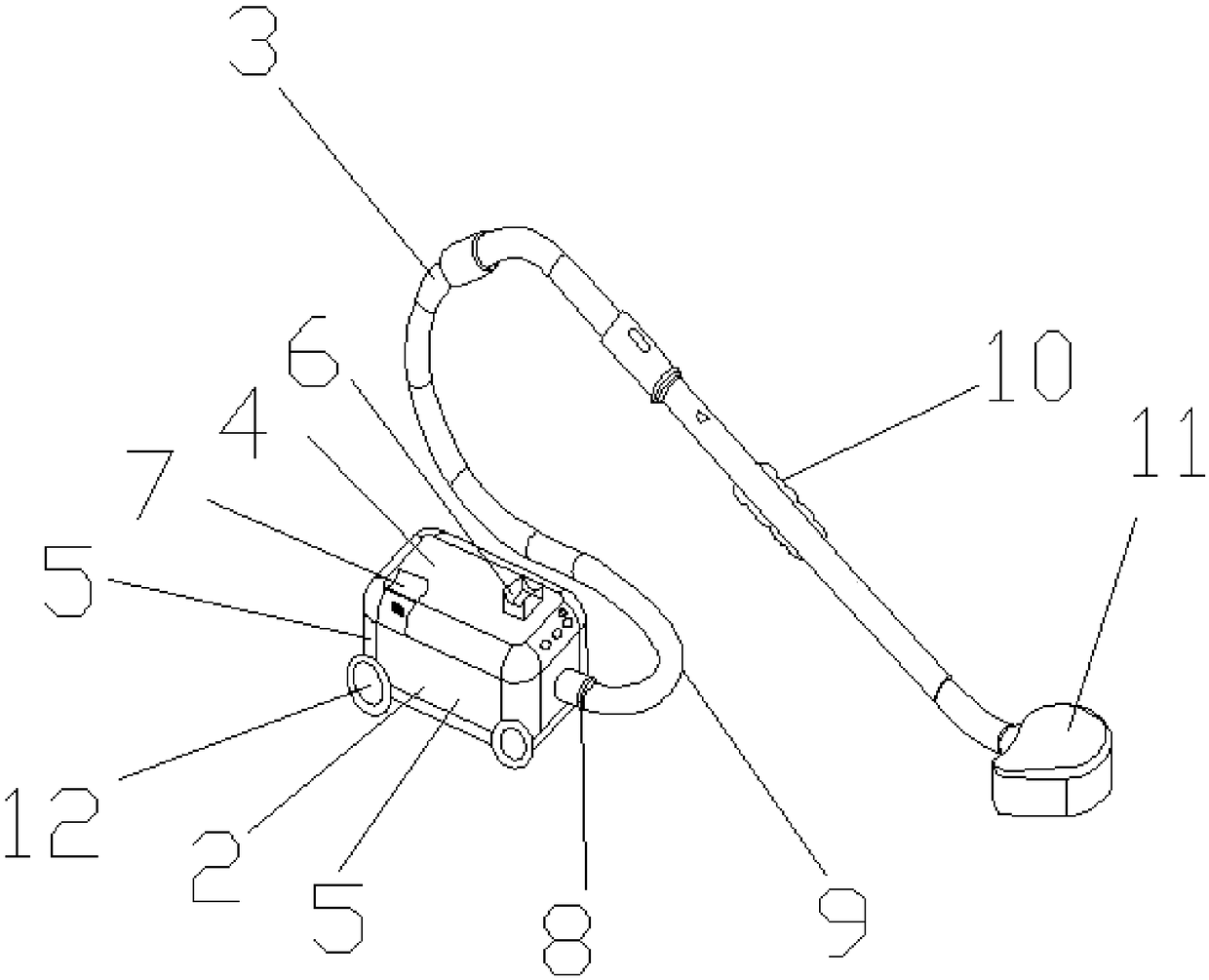

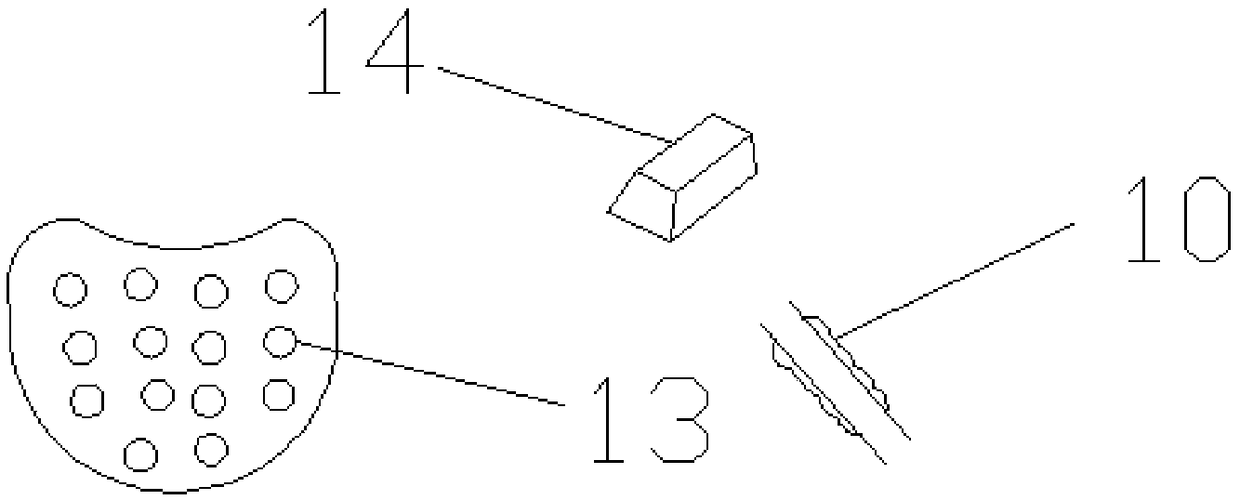

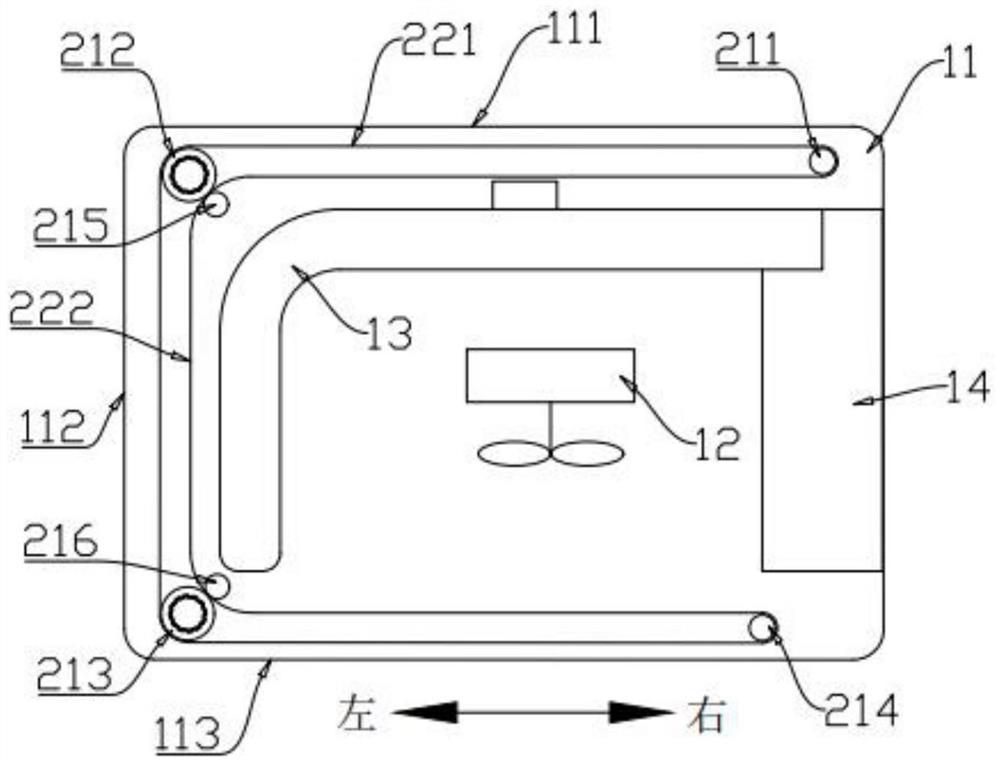

Dust removal machine

The invention discloses a dust removal machine. The dust removal machine comprises a rack, a dust removal box device and a dust removal pipe device, wherein the dust removal box device is connected with the dust removal pipe device; the rack, the dust removal box device and the dust removal pipe device are connected two by two; the dust removal box device comprises a motor noise reduction sheet, adust removal box, a closable small plate and a small clamping groove capable of being placed, wherein the motor noise reduction sheet is connected with the dust removal box through an inner clampingseam; the closable small plate is connected with the dust removal box through a small rotary shaft; the small clamping groove capable of being placed is connected with the dust removal box; a light-weight soft hose is connected with a handle; the light-weight soft hose is connected with a dust removal head. After the machine is improved, the handle can be held by a hand to carry out dust removal in a dust removal process and dust removal is simple; dragging type dust removal is adopted so that large-area dust removal can be realized; the time is greatly shortened and labor is saved; the dust removal box is arranged in the machine and can be used for loading a lot of dust removal substances; the dust can be directly poured off and other complicated operation is not needed.

Owner:陈超

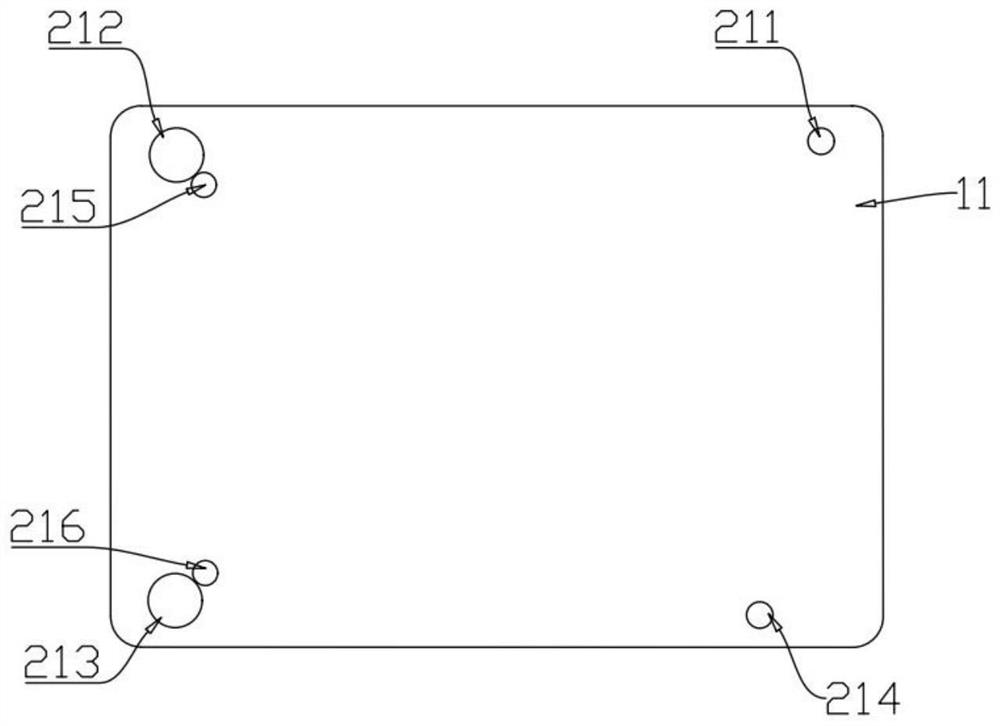

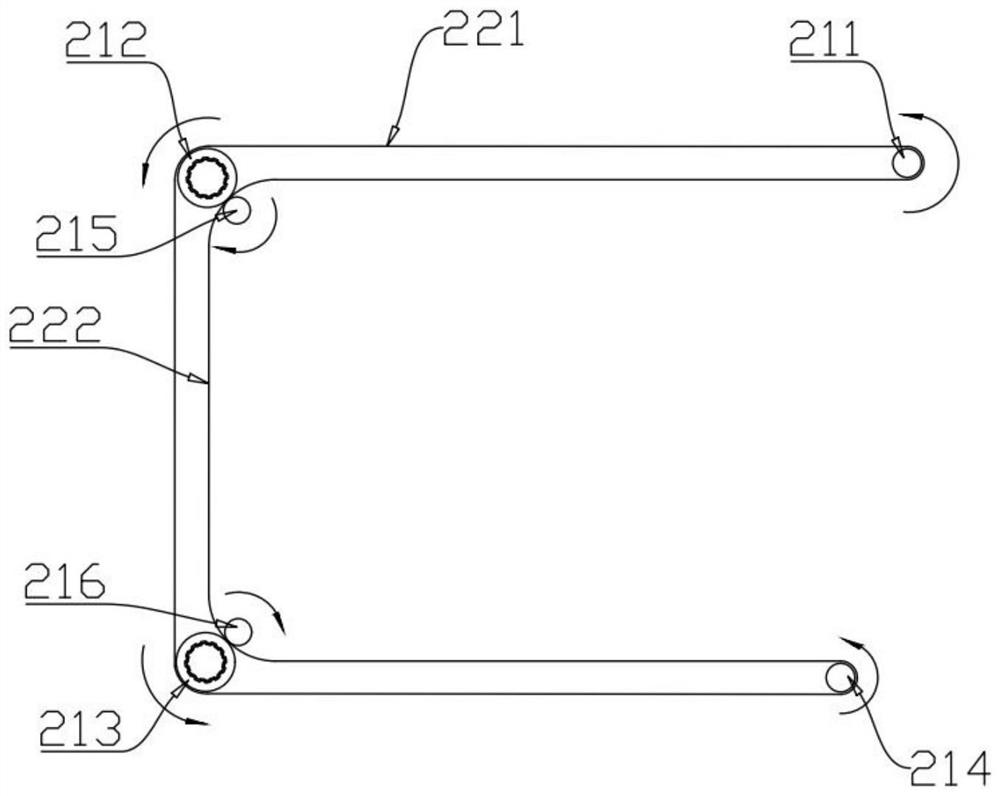

Filter screen assembly for air conditioner outdoor unit, air conditioner and control method

ActiveCN114110893AGuaranteed uptimeLarge coverageMechanical apparatusLighting and heating apparatusDust controlControl room

The invention provides a filter screen assembly for an air conditioner outdoor unit, an air conditioner and a control method, the air conditioner outdoor unit comprises a shell and an outdoor fan, and an air inlet and an air outlet are formed in the first side wall and the third side wall of the shell correspondingly; the filter screen assembly comprises a supporting structure, a filter screen and a driving mechanism; the supporting structure comprises a plurality of supporting columns which are arranged in the shell and are sequentially arranged at intervals; the driving mechanism drives the filter screen to annularly move between the air inlet and the air outlet, so that the outdoor fan cleans dust on the filter screen; the structure is simple, the coverage area of the filter screen is large, the condenser can be protected in real time, the dedusting effect and the filtering effect are guaranteed, the dedusting process is simplified, and the dedusting efficiency is high; the invention further provides a control method of the air conditioner. The control method comprises the steps that the accumulative operation duration and the preset duration of the air conditioner outdoor unit are compared, the filth blockage degree of the filter screen is judged, the driving mechanism is controlled to drive the filter screen to move, and the outdoor fan is controlled to clean dust on the filter screen; the automation degree is high and the user experience is improved.

Owner:GREE ELECTRIC APPLIANCES INC

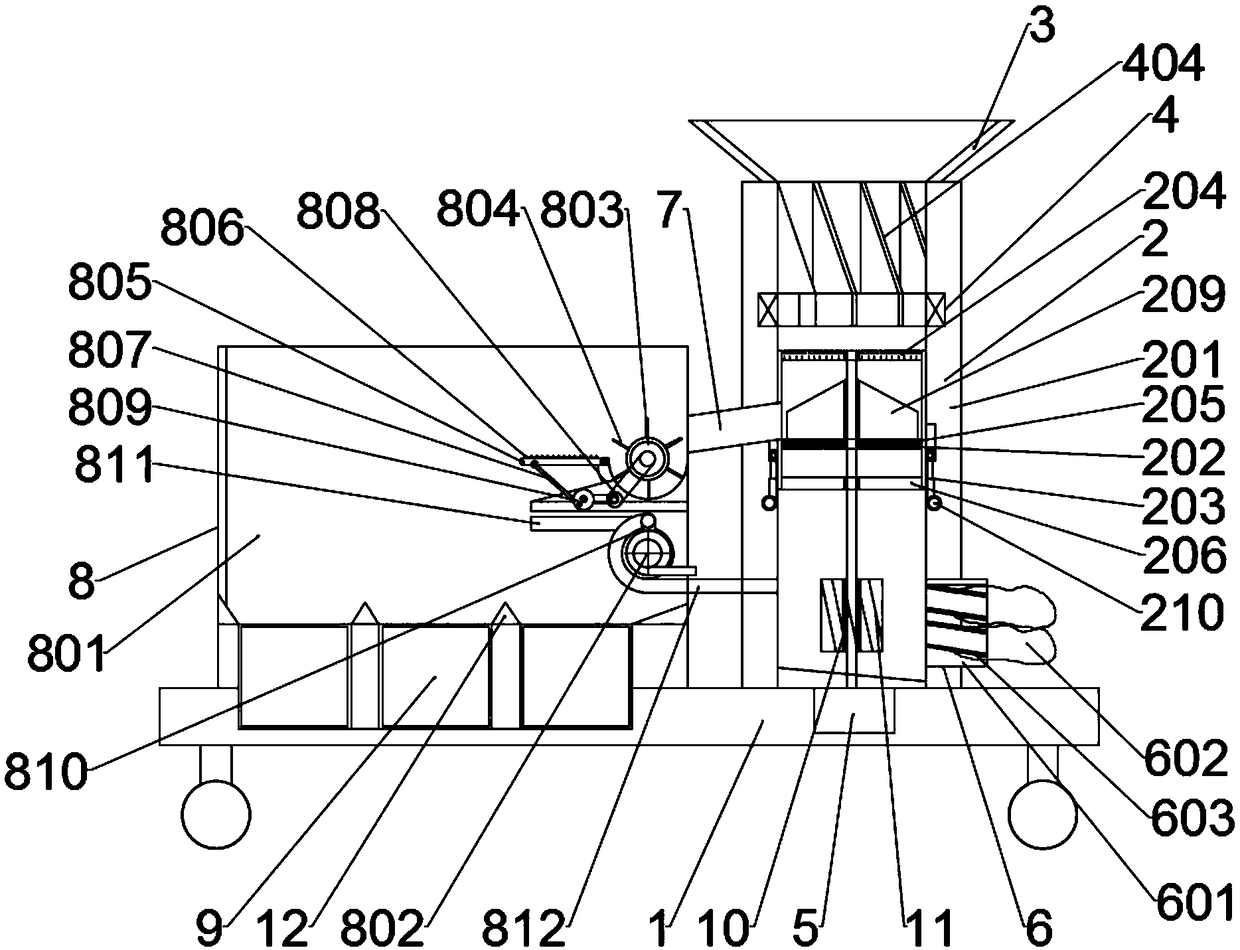

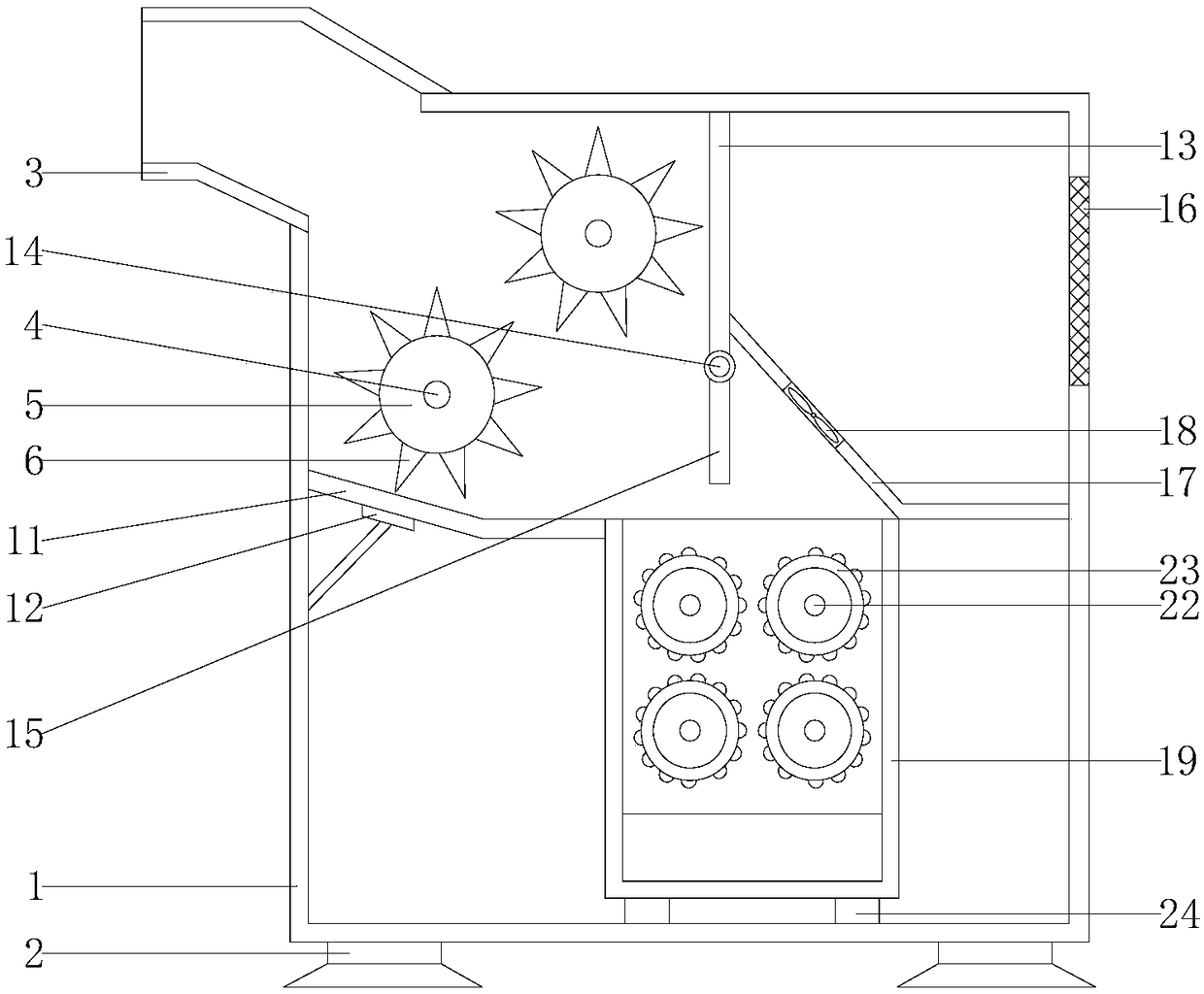

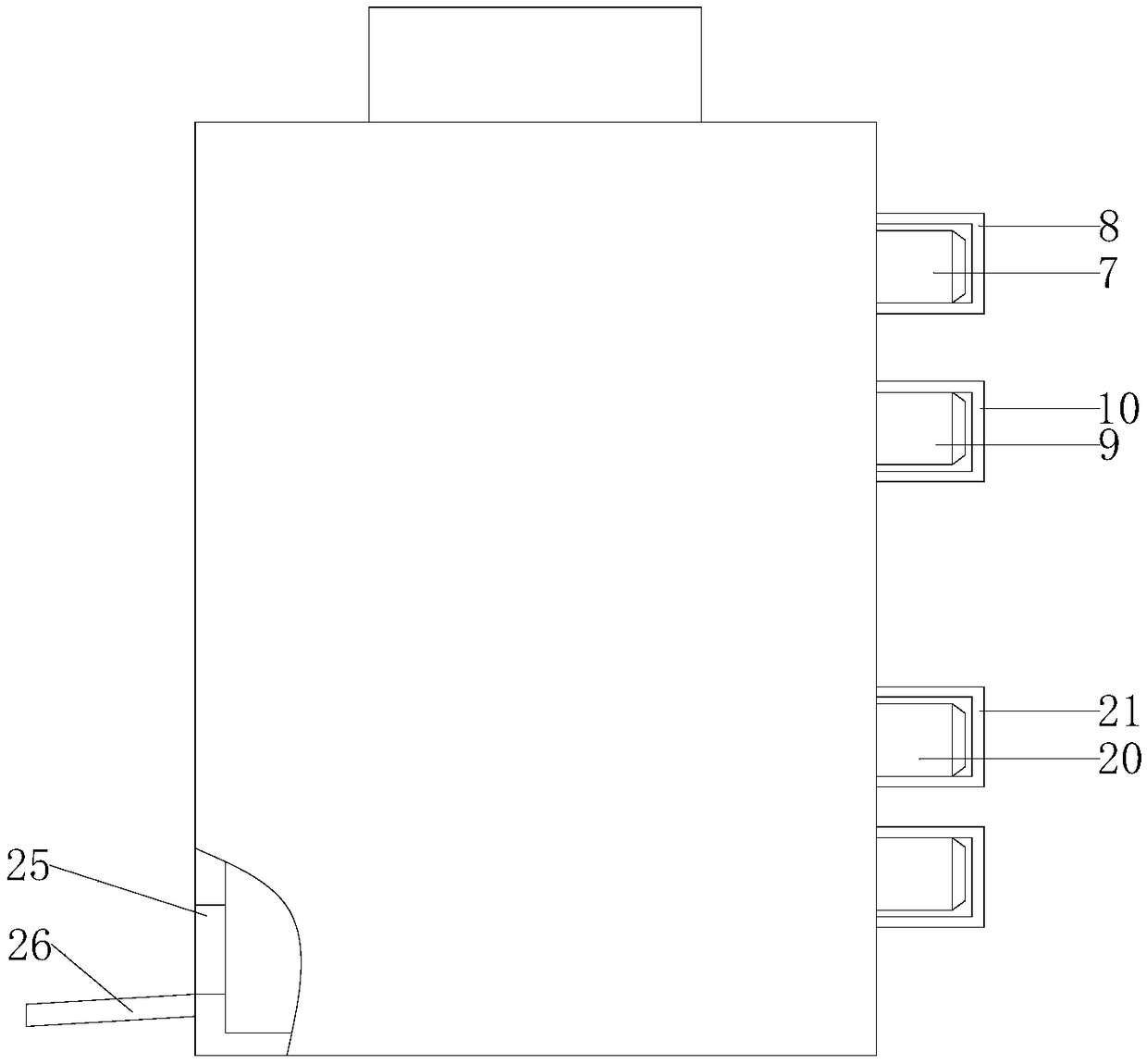

Efficient dust-absorption multistage coal mine stone crushing device

The invention relates to an efficient dust-absorption multistage coal mine stone crushing device, and belongs to the technical field of coal mine stone crushing equipment. The efficient dust-absorption multistage coal mine stone crushing device comprises a box body, a first-stage crushing chamber, a second-stage crushing chamber and a dust removal chamber; the first-stage crushing chamber and thedust removal chamber are arranged at the upper part in the box body, the second-stage crushing chamber is arranged at the lower part in the box body, and a coal mine stone inlet is formed in the upperpart of the box body; the coal mine stone inlet is in communication with the first-stage crushing chamber, an outlet of the first-stage crushing chamber is in communication with an inlet of the second-stage crushing chamber, so that the preliminarily crushed coal mine stone enters the second-stage crushing chamber; and an opening is formed in the lower part of the side wall of the second-stage crushing chamber, the opening is in communication with a discharge port of the box body, and the crushed finished coal mine stone is discharged. According to the efficient dust-absorption multistage coal mine stone crushing device, the crushing speed fast, the efficiency is high, dust can be absorbed in the crushing process, so that pollution is prevented, the multistage crushing of the coal mine stone is realized, meanwhile, an air curtain is used for collecting the dust, finally a filter screen is combined to remove the dust, and the crushing and the dust removal efficiency are high.

Owner:LIAONING TECHNICAL UNIVERSITY

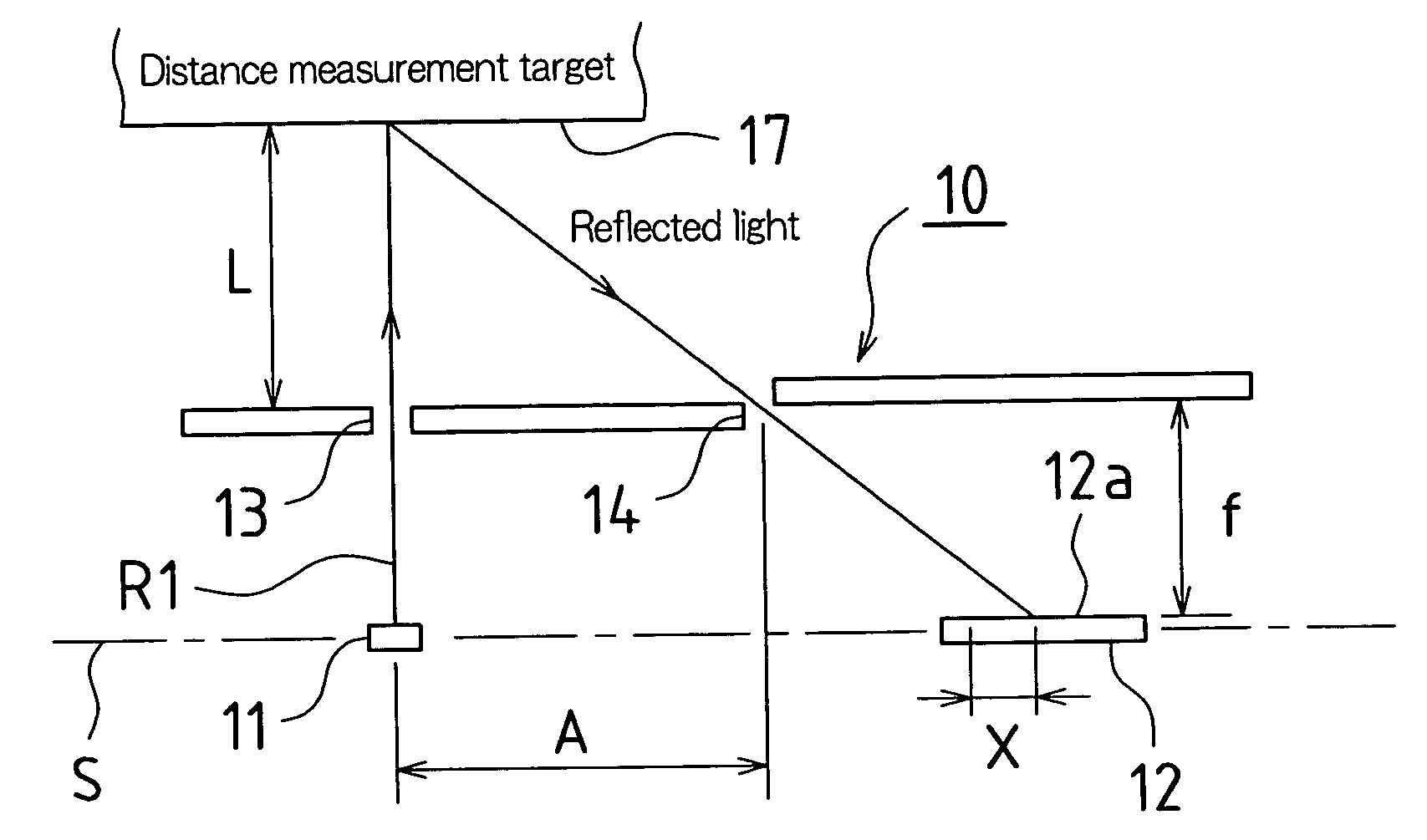

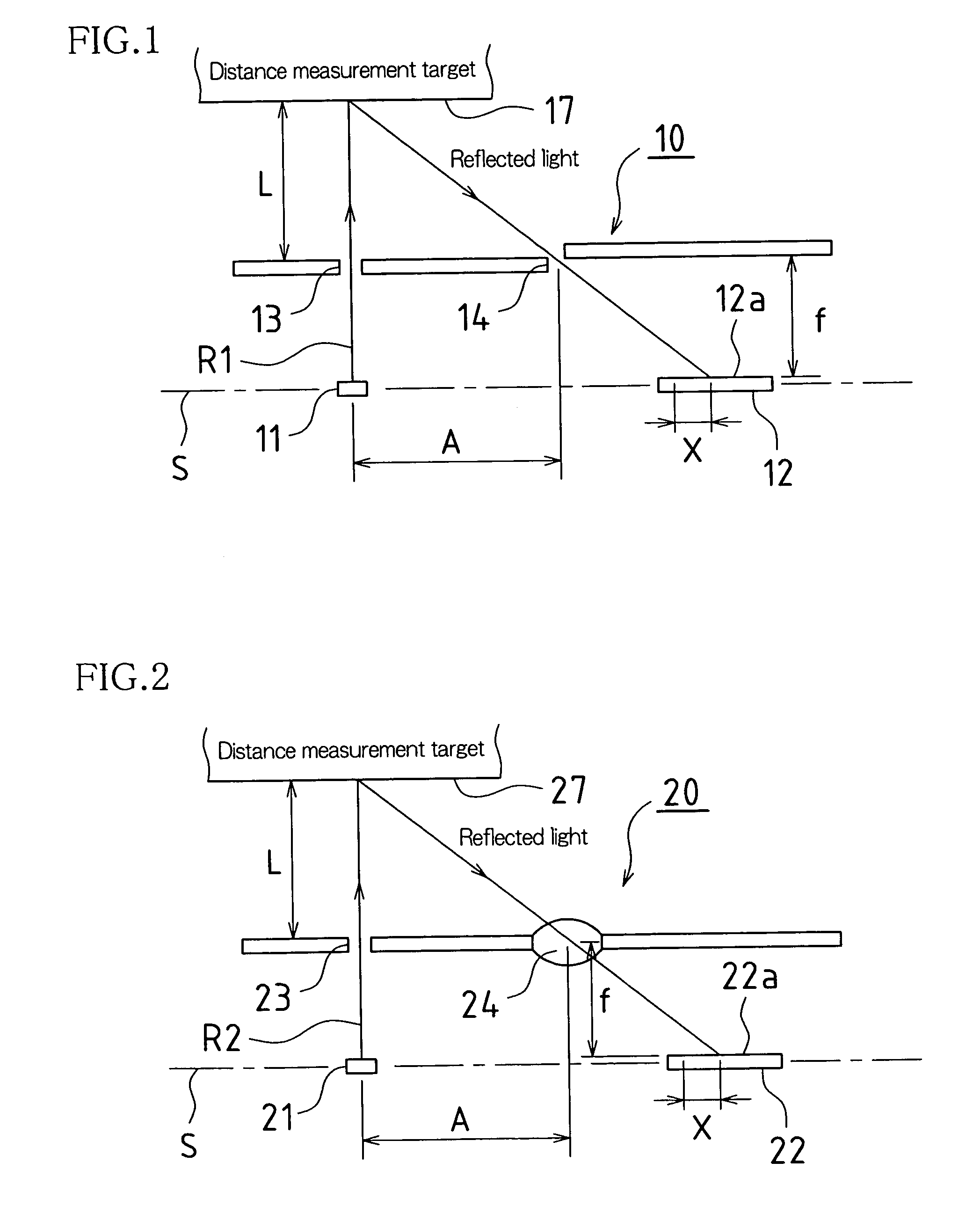

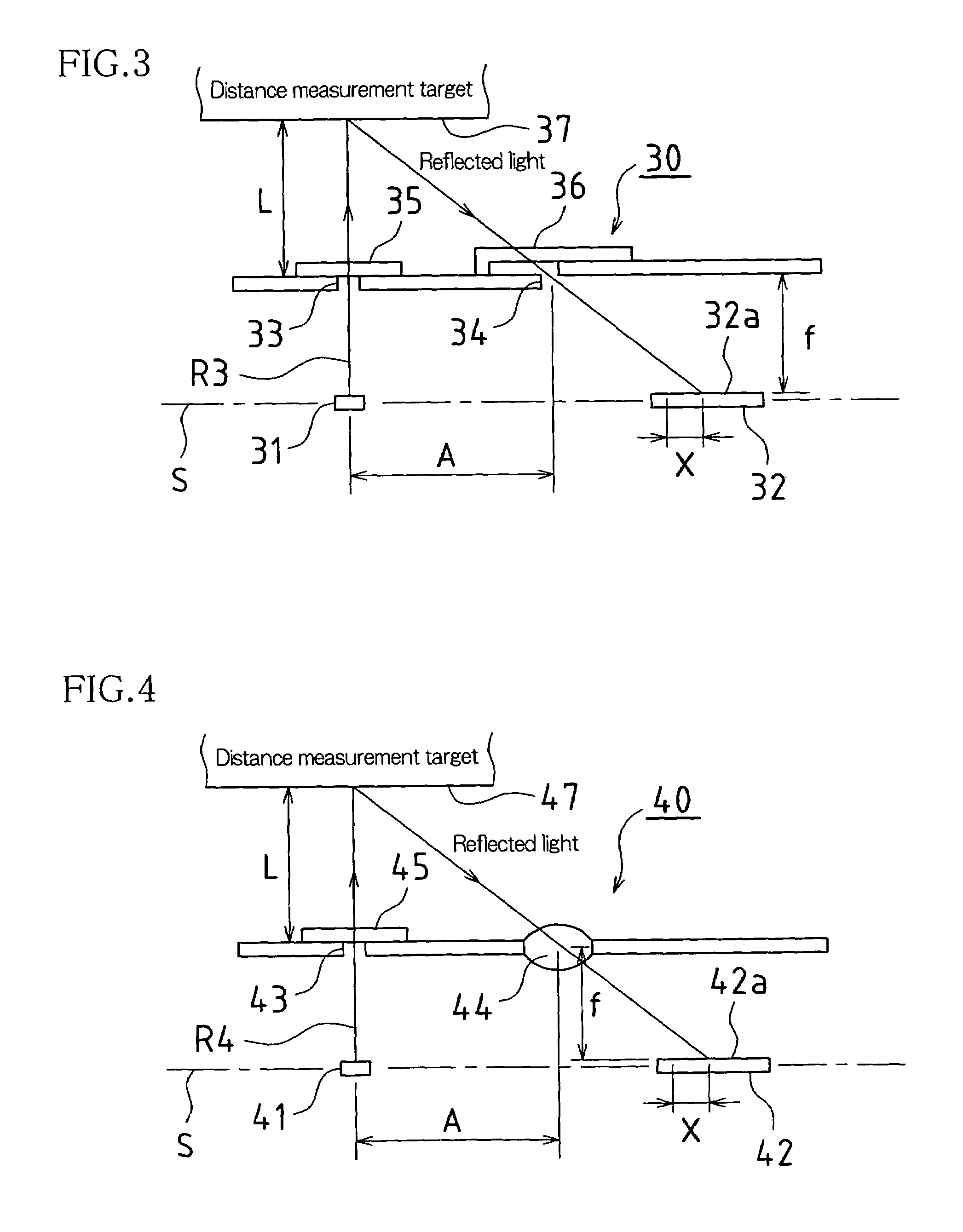

Optical displacement sensor

InactiveUS7193731B2Dust removal is simplePrevent impairing detection capabilityOptical rangefindersMaterial analysis by optical meansOptical axisLight beam

Optical displacement sensor may possess light-emitting element(s) for projecting light onto distance measurement target(s), and light-receiving element(s) capable of receiving light reflected from distance measurement target(s) and disposed such that light-receiving surface(s) thereof is or are substantially perpendicular to optical axis or axes R1 of projected light. Furthermore, such optical displacement sensor(s) may be equipped with slit(s) capable of narrowing light beam(s) projected toward distance measurement target(s), and slit(s) capable of narrowing light reflected from distance measurement target(s).

Owner:WISCONSIN ALUMNI RES FOUNDATON +1

Paper feeding apparatus and image forming apparatus

InactiveUS8256763B2Efficient removalDust removal is simpleElectrographic process apparatusArticle separationPulp and paper industryPaper sheet

Owner:MURATA MASCH LTD

Bottle cap washing device with disinfection effect

InactiveCN107486446ANo electrostatic attractionEliminate static electricityElectrostatic cleaningElectrostatic chargesSpray nozzleEngineering

The invention relates to a bottle cap washing device with a disinfection effect. According to the bottle cap washing device with the disinfection effect, an insulation bracket is arranged on the lower portion of an insulation feeding disc of a dust removal area, and a grounding wire is arranged to be connected with a height adjusting cover plate; an air blowing spray nozzle and a high voltage needle tip are separated in a spaced mode; and the upper end of the air blowing spray nozzle and the upper end of the high voltage needle tip are both located in the inner space of the insulation bracket. The insulation bracket is arranged so that an original positive plate can be replaced by the height adjusting cover plate to enable an electric field to be generated between the height adjusting cover plate and the high voltage needle tip, a bottle cap is made to completely pass through the electric field area, and the height adjusting cover plate makes contact with the ground to eliminate static electricity, so that dust removal is easier; and additionally, the upper end of the air blowing spray nozzle is located in the inner space of the insulation bracket and is closer to the bottle cap, and an generated strong air flow can improve the dust blowing effect.

Owner:NANTONG MUYE MACHINERY

Industrial automatic dust removing device

InactiveCN108905445AAvoid dust accumulationEasy to removeUsing liquid separation agentEngineeringInductor

The invention discloses an industrial automatic dust removing device, comprising a dust removing box. One side of the top of the dust removing box is provided with an alarm, and the other side of thetop of the dust removing box is provided with a water tank; one side of the top of the water tank is provided with a water injection port; one side of the water tank is provided with a water pipe; oneend, away from the water tank, of the water pipe is provided with a water pump; the bottom of the water pump is provided with an L-shaped water pipe; one end, away from the water pump, of the L-shaped water pipe penetrates one side of the dust removing box and is provided with a spraying unit; one side, away from the L-shaped water pipe, of the spraying unit is provided with an inductor I; and the top of one side, away from the L-shaped water pipe, of the dust removing box a dust inlet pipe, and the dust inlet pipe penetrates the dust removing box. The industrial automatic dust removing device has the beneficial effects that dust removal process is simple; workload can be greatly reduced; and dust removal efficiency is high.

Owner:HEFEI CANGMIN AUTOMATION CO LTD

Cleaner

A cleaner configured in such a manner that dust removal operation can be optimally performed without the removal of a front housing, without the entry of dust into the filter due to the dust removal operation, and without a decrease in the suction force. A cleaner (1), wherein a coiled spring (29) for pressing a filter (28) so that the filter is retained in an extended attitude is provided within the filter (28) of a filter unit (4), a mounting plate (30) is secured to the front end of the filter (28), one end of a wire (38) is connected to the mounting plate (30), and the other end of the wire (38) is led out of the inside of the filter (28) to the outside at the rear of the body housing after being made to pass through the body housing (2). The filter (28) can be arbitrarily contracted by causing, through pulling operation of the other end of the wire (38), the mounting plate (30) to recede against the pressing force of the coiled spring (29).

Owner:MAKITA CORP

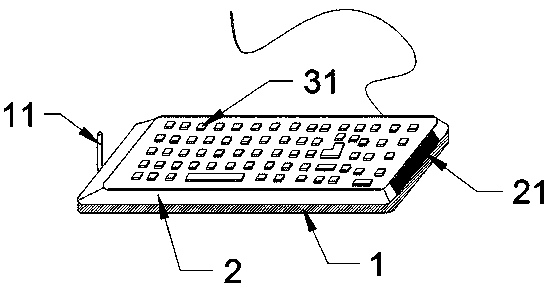

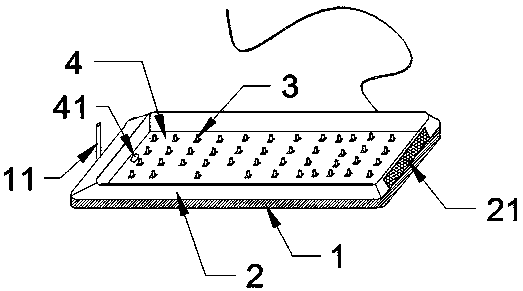

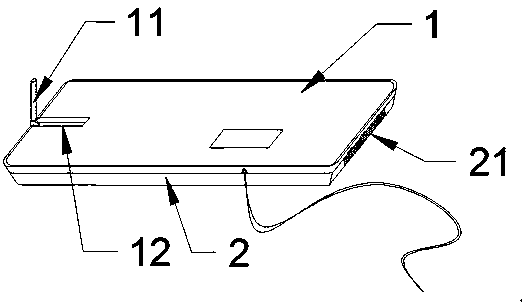

Novel keyboard convenient for dust removal

InactiveCN108536305AEasy to remove dustEasy to cleanInput/output for user-computer interactionCleaning using gasesPeripheralEngineering

The invention belongs to the technical field of computer peripherals, and particularly relates to a novel keyboard convenient for dust removal. The keyboard comprises a bottom plate, a cover plate anda key cap. The circuit board is located inside the bottom plate, and a cavity is formed between the cover plate and the bottom plate, and a key position electrically connected to the circuit board isarranged in the cavity. The key cap is fastened to the key position, and the blower tube connected to the hinge of the bottom plate is arranged on one side of the bottom plate, and the air blowing hose is arranged in the blown hard tube. The air blowing hose is connected to the cavity through the through hole in the bottom plate, and the storage groove is arranged in the lower surface of the bottom plate corresponding to the position of the blowing hard tube, and the air blowing hard tube is collected into the receiving groove by folding. The other side of the cover plate corresponding to theblow pipe is provided with an openable dust-removing door; when in use, the user can remove and clean the dust by blowing air into the blow pipe. The dust-proof computer host is provided with a goodcleaning effect, simple and beautiful keyboard structure, low manufacturing cost, which is convenient for popularization and application.

Owner:HEFEI MINZHONGYIXING SOFTWARE DEV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com