Dedusting method based on electric spinning technique and dedusting device thereof

An electrospinning and technical technology, applied in the field of dust removal method and dust removal device based on electrospinning technology, dust removal method and dust removal device field, can solve the problems of inconvenience, increased use cost, use trouble, etc., and achieve convenient Efficiency, cost reduction, simple effect of dust removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

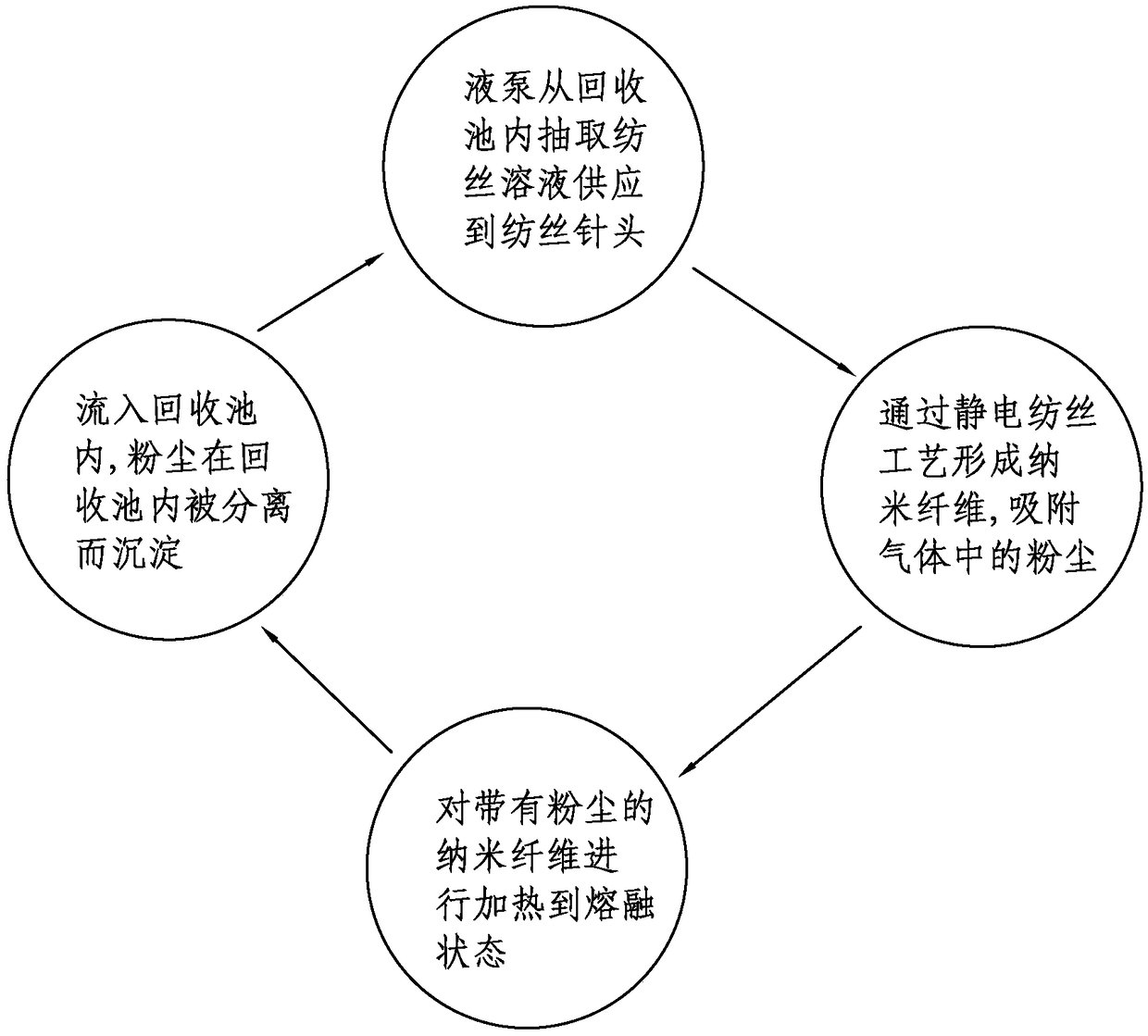

[0029] see figure 2 and image 3 , present embodiment relates to dedusting method, comprises the following steps:

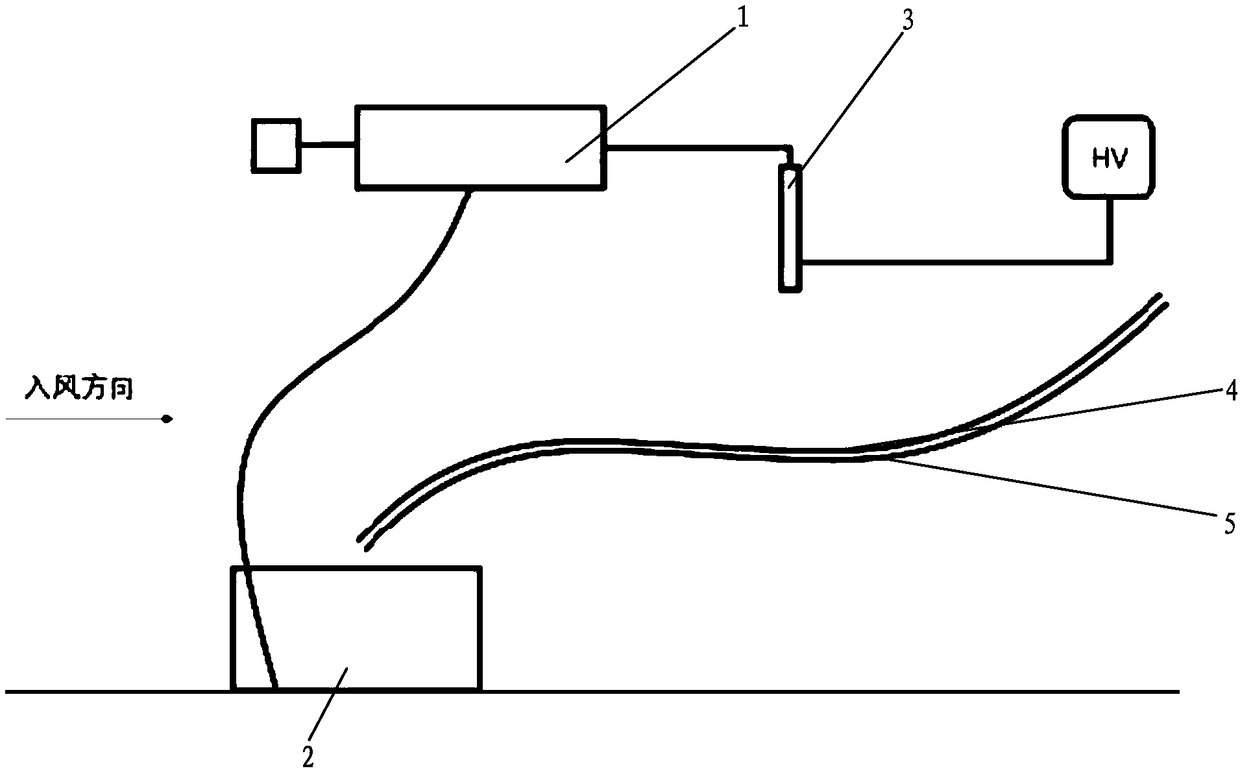

[0030] Step 1. The liquid pump 1 draws the spinning solution from the recovery tank 2 and supplies it to the spinning needle 3; the spinning solution is a PCL or PVA solution, and the mass fraction of the solution is 5%-20%.

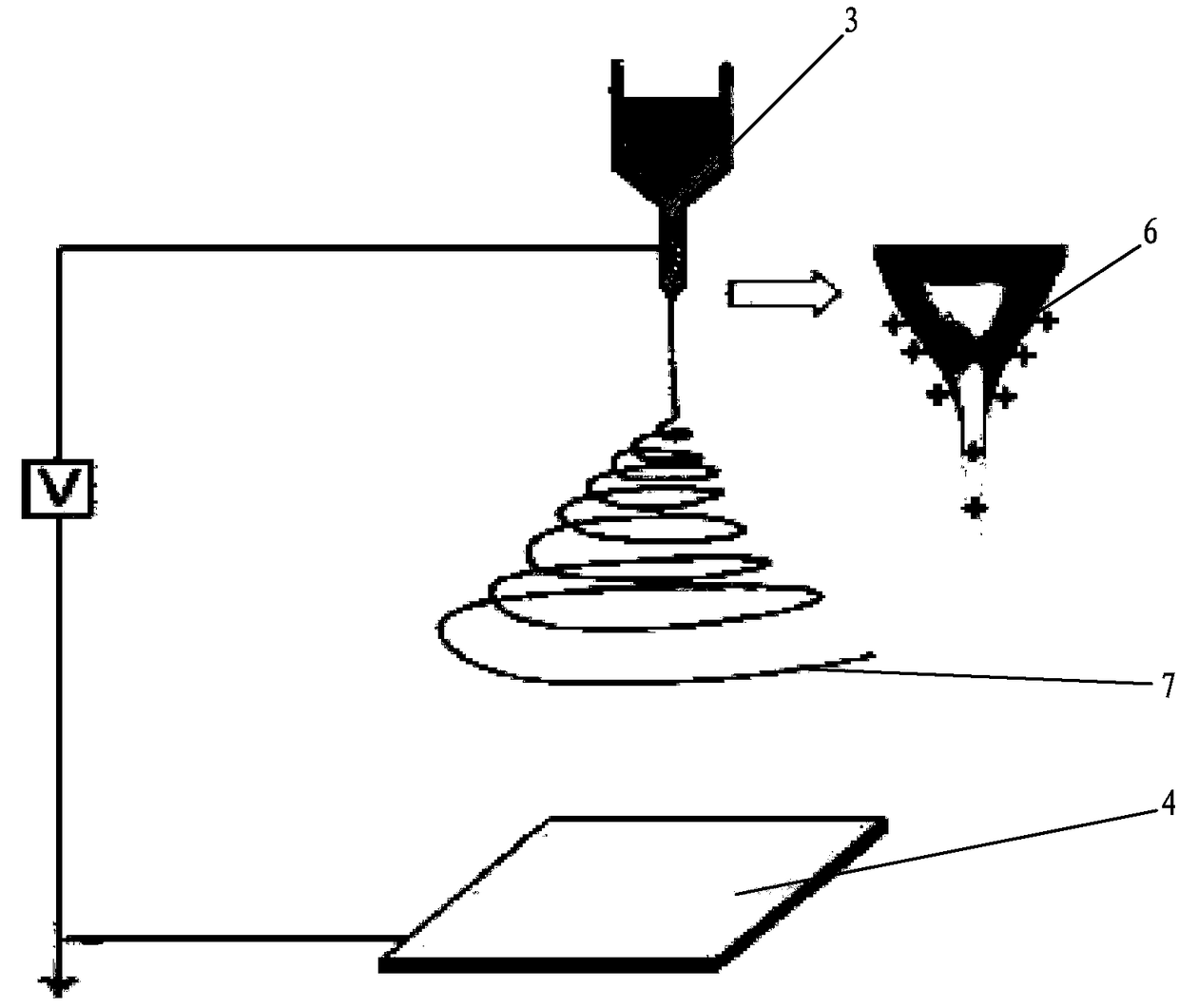

[0031] Step 2. Nanofibers are formed through the electrospinning process, and the nanofibers are arranged on the flow circuit of the gas to be filtered; the nanofibers absorb the dust in the gas; a 2-30KV high-voltage electrostatic field is attached to the spinning needle 3, and the spinning needle 3Through electric field traction and thinning, between the spinning needle 3 and the collecting plate 4, spray to form electrospun nanofibers; form nanofibers.

[0032] Step 3, heat the nanofibers with dust to a molten state, and flow into the recovery tank 2, where the dust is separated and precipitated in the recovery tank 2; The nanofiber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com