Novel micropore aluminum foil sound absorption acoustic screen

A sound insulation screen, aluminum foil technology, applied in the direction of noise absorption devices, buildings, etc., can solve the problems of only being used in interior decoration, increasing the use of support frames, and not being able to resist rainwater soaking, etc., to achieve a clear and novel concept, shorten the Construction time, strong natural texture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

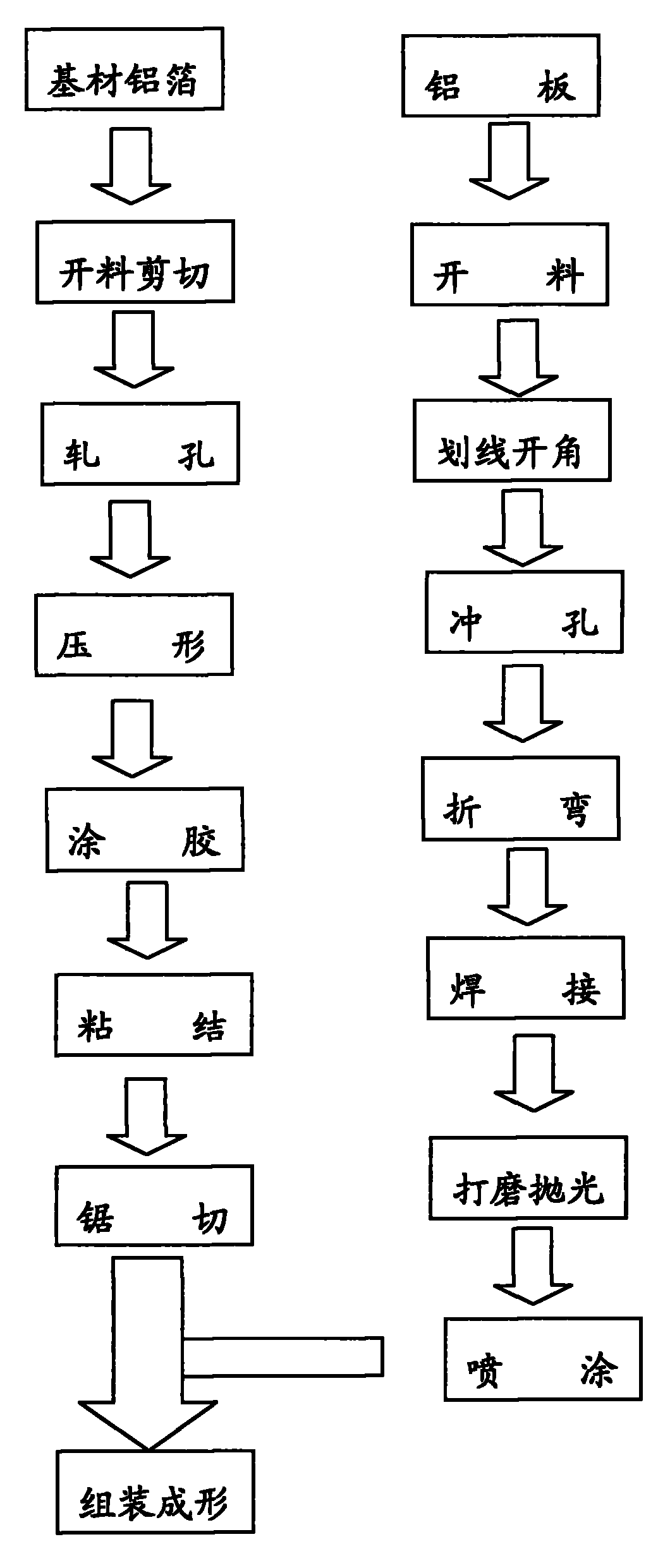

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings. As shown in the accompanying drawings:

[0028] A novel microporous aluminum foil sound-absorbing and sound-insulating screen, the production method of which is as follows:

[0029] ①. Production of microporous sound-absorbing aluminum foil: substrate aluminum foil→cutting and cutting→punching→pressing→gluing→bonding→sawing→make into microporous sound-absorbing aluminum foil for use;

[0030] ②, production of sound insulation screen: aluminum plate → material cutting → scribing and corner opening → punching → bending → welding → grinding and polishing → spraying → making into a sound insulation screen for use;

[0031] ③. Production of new microporous aluminum foil sound-absorbing and sound-insulating screen: Assemble the micro-porous aluminum foil and the sound-insulating screen together to make a new micro-porous aluminum foil sound-absorbing and sound-insulating sc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com