Bottle cap cleaning machine

A cleaning machine and bottle cap technology, applied in cleaning methods and utensils, cleaning methods using gas flow, static electricity, etc., can solve the problem that the design of the discharge needle tip air blowing nozzle is not completely reasonable, the diameter of the air column is increased, and the dust removal effect is not good. good question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

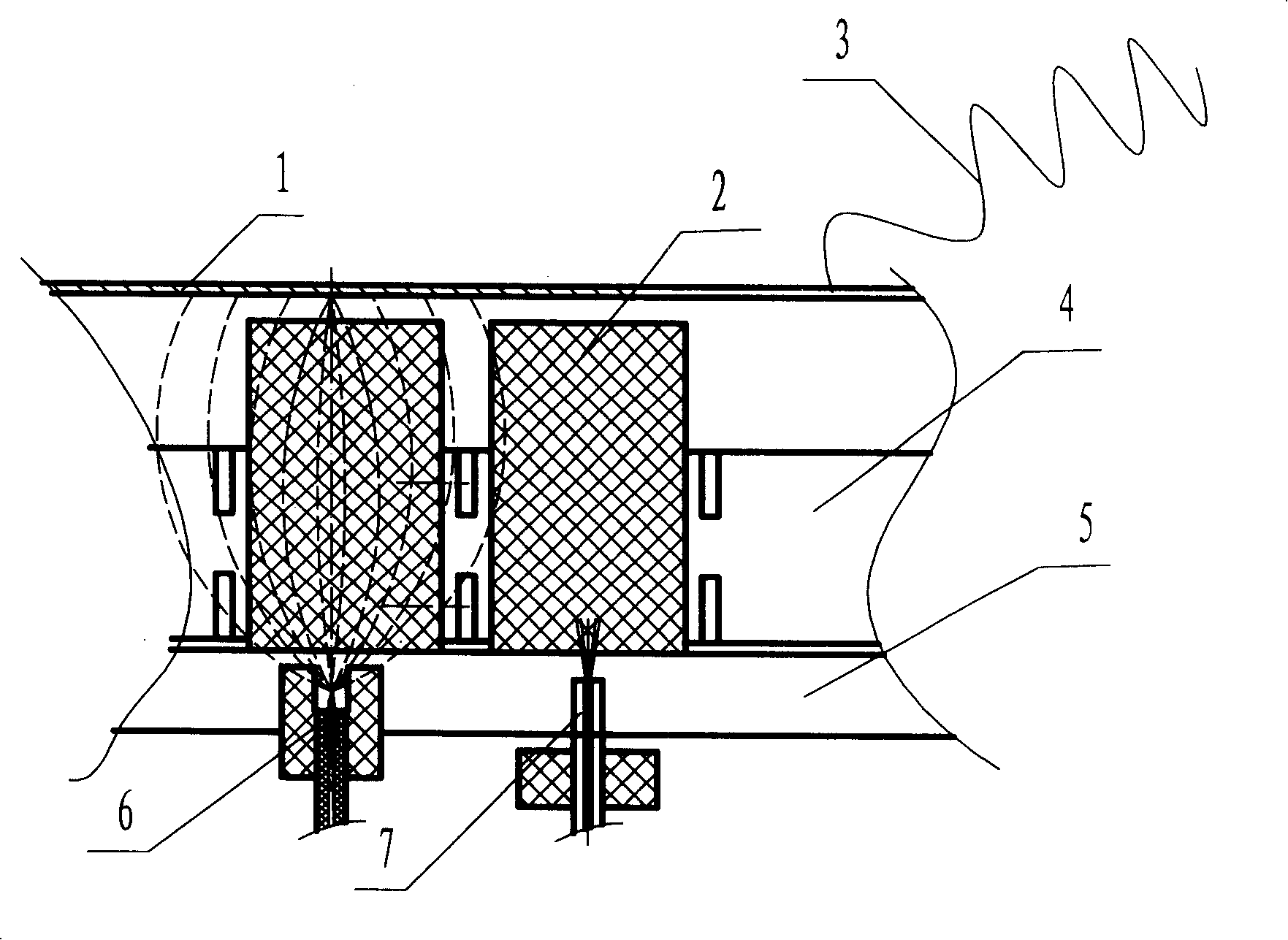

[0010] refer to figure 1 , the dust removal area of the bottle cap cleaning machine includes blowing nozzle 7, high-voltage electric needle tip 6, height adjustment cover 1, insulation bracket 5, insulation feeding tray 4, grounding wire 3, etc.; height adjustment cover 1 is located in the insulation feeding The upper part of the tray 4; the blowing nozzle 7 and the high-voltage electric needle tip 6 are spaced apart, and are separately arranged at the lower part of the insulating feeding tray 4; the lower part of the insulating feeding tray 4 is also provided with an insulating bracket 5, a grounding wire 3 and a height adjustment cover The board 1 is connected; and the upper end of the air blowing nozzle 7 and the upper end of the high voltage electric needle point 6 are located at the inner space of the insulating bracket 5; or only the upper end of the air blowing nozzle 7 is located at the inner space of the insulating bracket 5.

[0011] When in use, when the bottle ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com