Method for electrically connecting several solar cells and photovoltaic module

A technology for solar cells and photovoltaic modules, applied in electrical components, photovoltaic power generation, electrical solid devices, etc., can solve problems such as non-solderable welding and complexity, and achieve reliable electrical contact, metallization and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

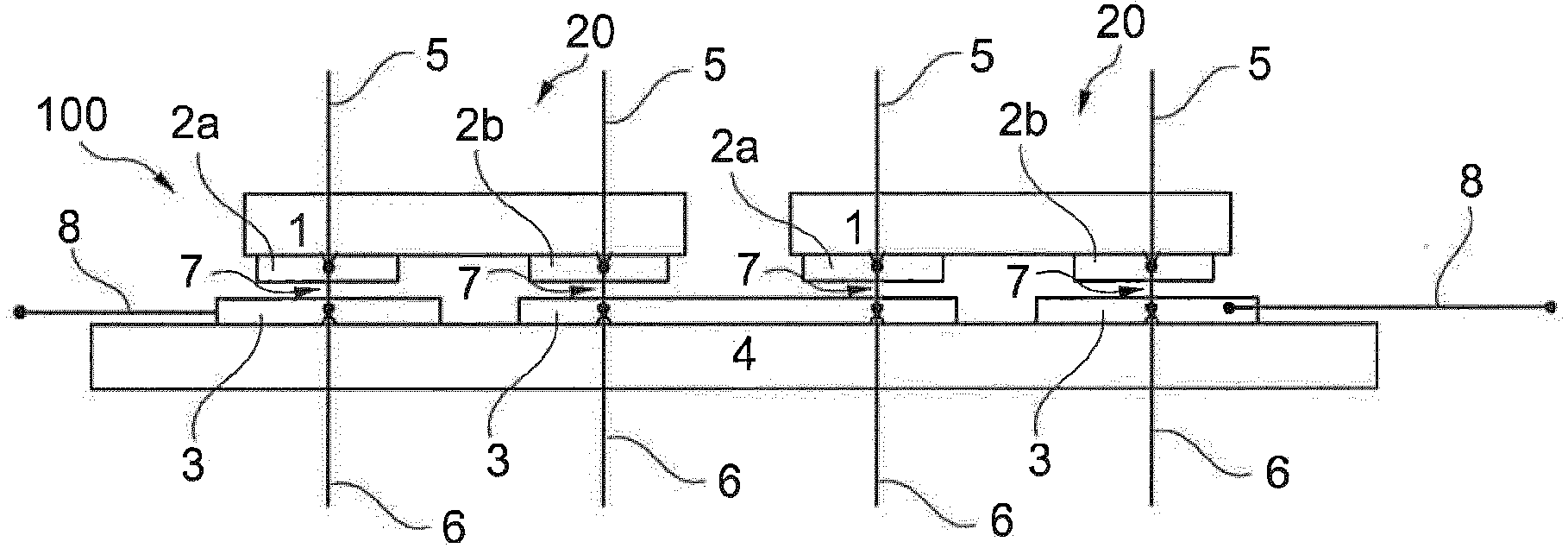

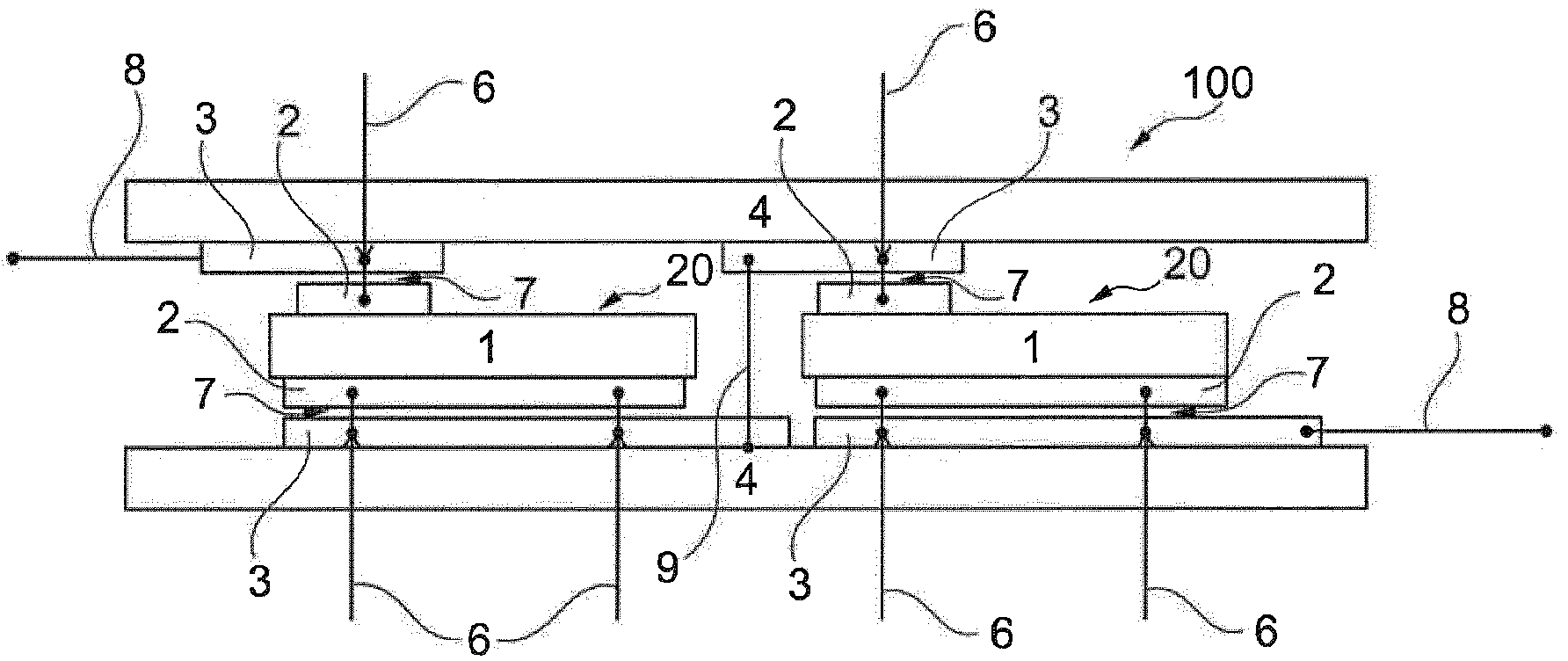

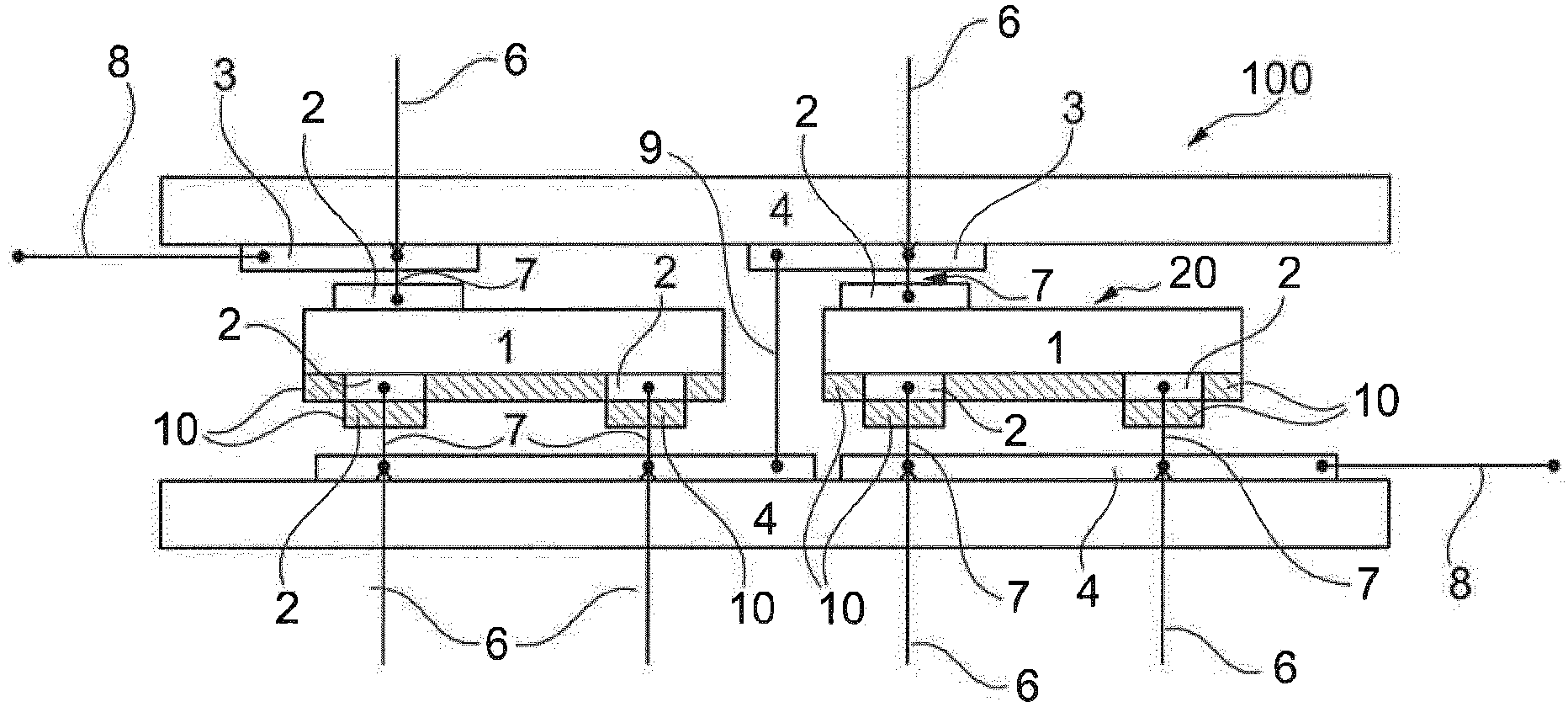

[0056]figure 1 A configuration of a plurality of metallized solar cells 20 electrically connected together and formed into a photovoltaic module 100 is shown. In the example shown, the solar cell 20 is a silicon wafer-based solar cell in which two types of contacts are provided on the back side of the solar cell substrate 1 . The emitter region of the solar cell is coated with an aluminum metal layer 2a forming a contact of the first type and the base region is coated with an aluminum metal layer 2b forming a contact of the second type.

[0057] Figure 5 A top view of a solar cell substrate 1 with metal layers 2a, 2b forming different types of contacts is shown.

[0058] For greater clarity, further details of the solar cell 20 are not shown in the figures, eg differently doped emitter and base regions, surface passivation layers, etc.

[0059] In preparation for the metallization process, the carrier substrate 4 is coated with a metal layer 3 which also consists of aluminu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com