Transfer method of pattern and transfer paper

A technology of transfer printing paper and patterns, which is applied in the field of transfer printing method paper and transfer paper for printing patterns on the outer surface of products, and can solve the problems of high hot stamping temperature, insufficient pattern printing effect, and inability to hot stamp , to achieve the effect of low hot stamping temperature and fine and exquisite decorative patterns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

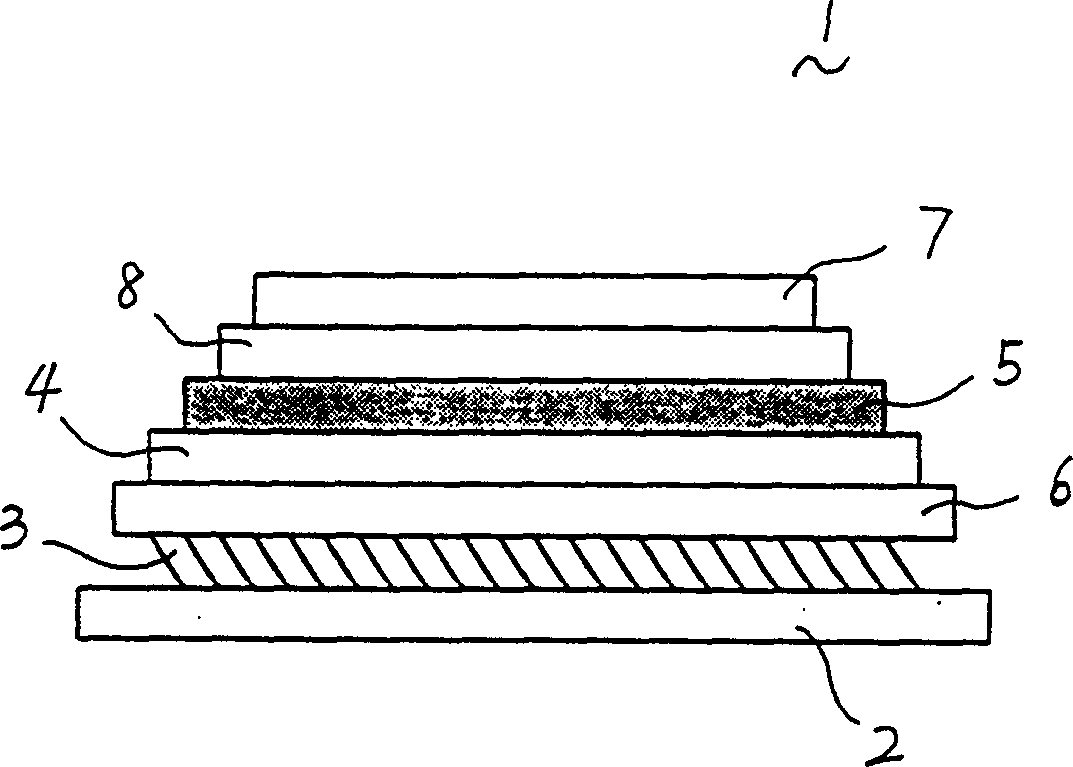

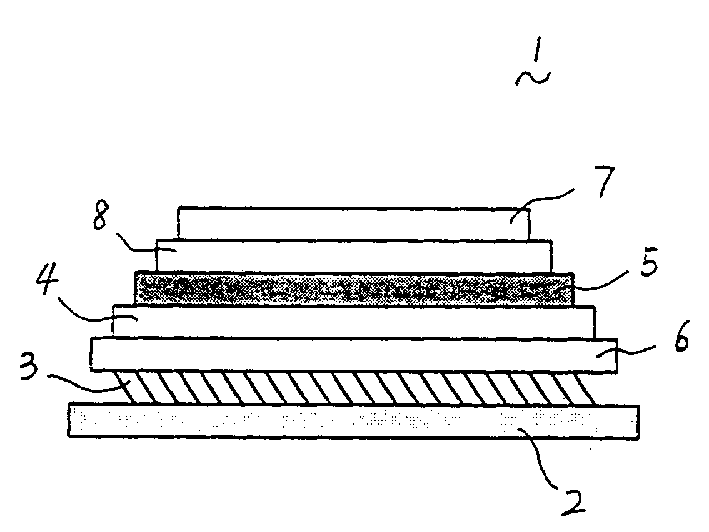

[0031] see figure 1 , the transfer printing method of pattern of the present invention comprises the following steps:

[0032] 1) making transfer paper 1, comprising the following steps:

[0033] a, on the backing paper 2 that is provided with one deck glue layer 3 in advance, adhere one to make with polyethylene (PE), polypropylene (PP) or the adhesive film 6 of the mixture of the two, and carry out electric shock on corona machine Halo treatment, the glue is a glue that has stronger viscosity to the backing paper 2 and weaker viscosity to the adhesive film 6, and its specific composition ratio is as follows:

[0034] Polyester resin 10~30%

[0035] Rubber 10~30%

[0036] Solvent 39~79.5%

[0037] Auxiliary 0.5~1.0%

[0038] B, screen printing a bottom ink layer 4 on the adhesive film 6, the composition ratio of this bottom ink is:

[0039] Polyester resin or alkyd resin 5~20%

[0040] Cellulose resin 5~40%

[0041] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com