Flame-retardant nylon wire with corrosion resistance, aging resistance, low temperature resistance and high temperature resistance

A technology of flame-retardant nylon and low-temperature resistance, which is applied to circuits, insulated cables, electrical components, etc., to achieve the effects of high breakdown voltage resistance, corrosion resistance, and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

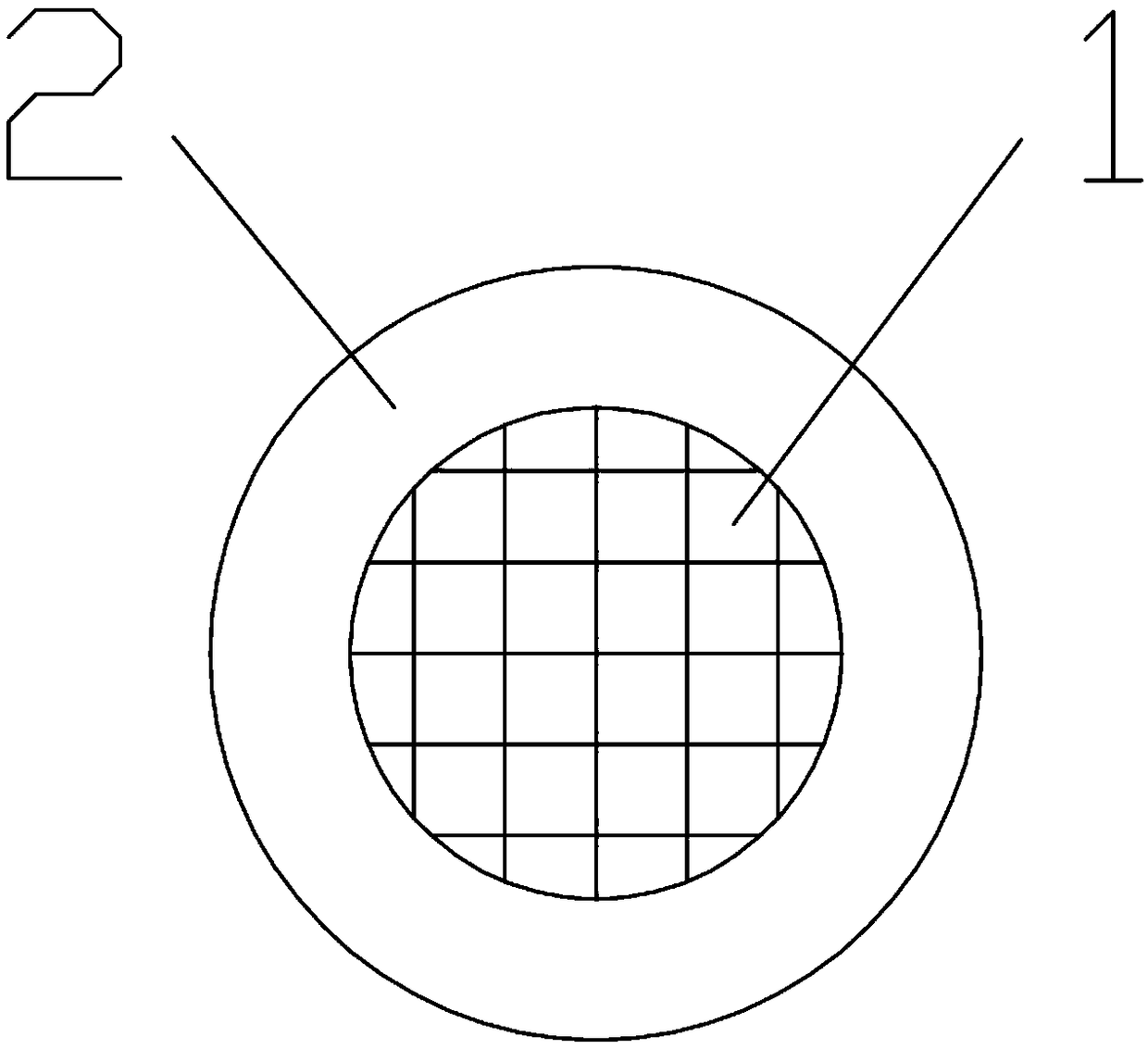

[0023] Such as figure 1 As shown, the corrosion-resistant, aging-resistant, low-temperature and high-temperature-resistant flame-retardant nylon wire is composed of a conductive core 1 and a wire protective layer 2. The conductive core 1 is composed of several copper conductors or tinned copper conductors. The wire The protective layer 2 is made of nylon material, and the wire protective layer 2 is directly wrapped on the outside of the conductive wire core 1 . There are plasticizers, low temperature resistant agents, antioxidants and flame retardants added in the wire protective layer 2.

[0024] According to the above, we selected nylon 6, nylon 11, nylon 12, nylon 1010, nylon 610, and nylon 612 as the nylon material of the wire protective layer to extrude the wire with an extruder for experiments, and obtained the following data:

[0025]

Embodiment 2

[0027] Such as figure 1 As shown, the corrosion-resistant, aging-resistant, low-temperature and high-temperature-resistant flame-retardant nylon wire is composed of a conductive core 1 and a wire protective layer 2. The conductive core 1 is composed of several copper conductors or tinned copper conductors. The wire The protective layer 2 is composed of a copolymer of nylon and thermoplastics or a copolymer of two different types of nylon. The wire protective layer 2 is directly wrapped on the outside of the conductive core 1. The wire protective layer In 2, plasticizers, antioxidants and flame retardants are added.

[0028] According to the above, we selected the copolymers of nylon and polyethylene, the copolymers of nylon 6 and nylon 66 as the nylon material of the wire protective layer, and used the extruder to extrude the wires for experiments, and obtained the following data:

[0029]

Embodiment 3

[0031]Corrosion-resistant, aging-resistant, low-temperature and high-temperature flame-retardant nylon wires, including several nylon insulated wires 5 and wire protective layers 2, nylon insulated wires 5 are composed of conductive core 1 and nylon insulating layer 3, conductive core 1 is composed of several copper conductors or tinned copper conductors, the nylon insulating layer 3 directly wraps the conductive wire core 1 to form a nylon insulated wire 5, and several nylon insulated wires 5 are wrapped by the wire protective layer 2. The nylon insulating layer 3 of the flame-retardant nylon wire is made of nylon material, and the nylon insulating layer 3 is filled with a plasticizer, a low temperature resistant agent, an antioxidant and a flame retardant. The wire protection layer 2 is also made of nylon material, and the wire protection layer 2 contains plasticizers, low temperature resistant agents, antioxidants and flame retardants. like figure 2 As shown, the flame-re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com