High-pressure separator and method for high-pressure separation

A technology of high-pressure separator and liquid separator, which is applied in the field of physical separation, can solve problems such as short operation period, achieve the effect of reducing equipment tonnage, reducing equipment investment cost, and eliminating physical factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

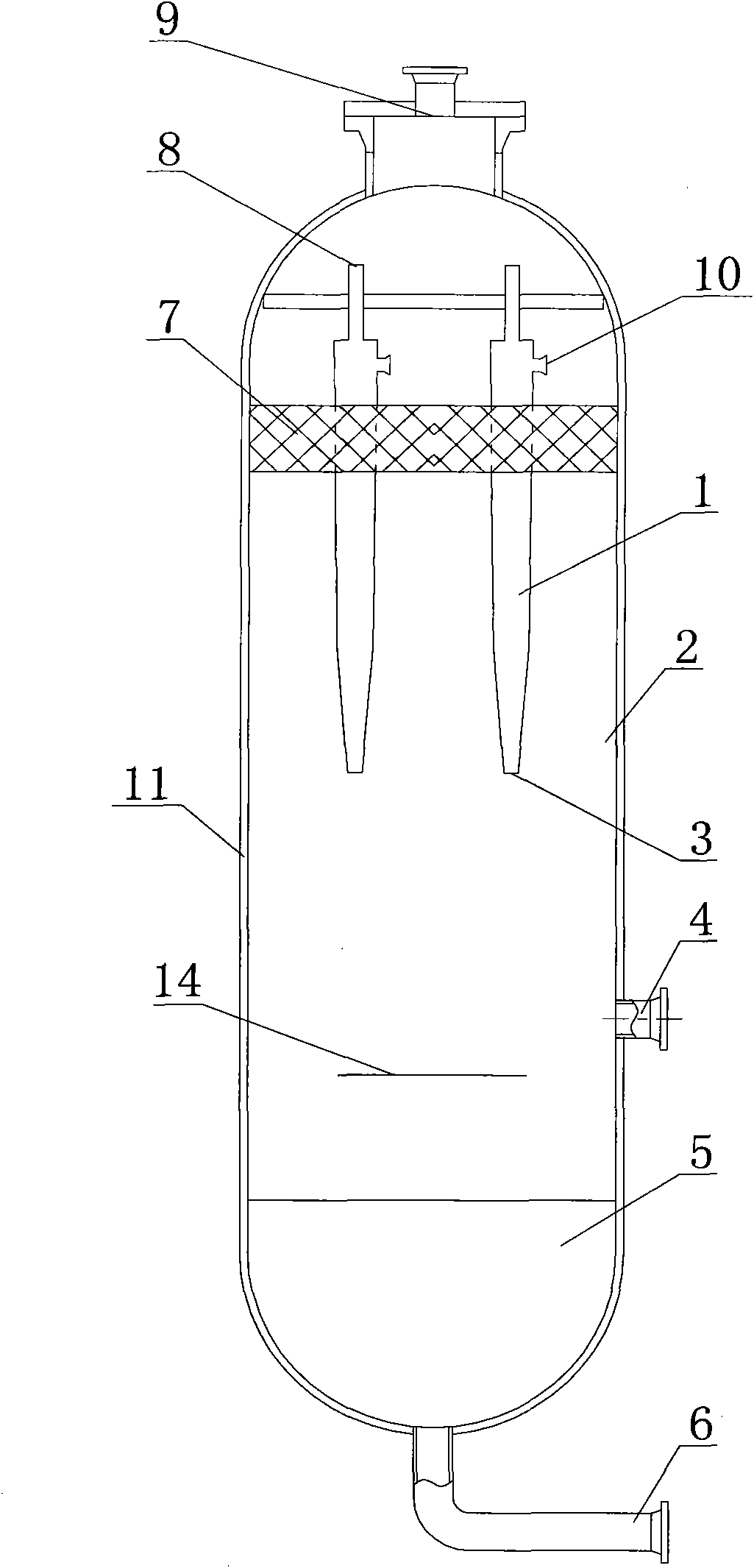

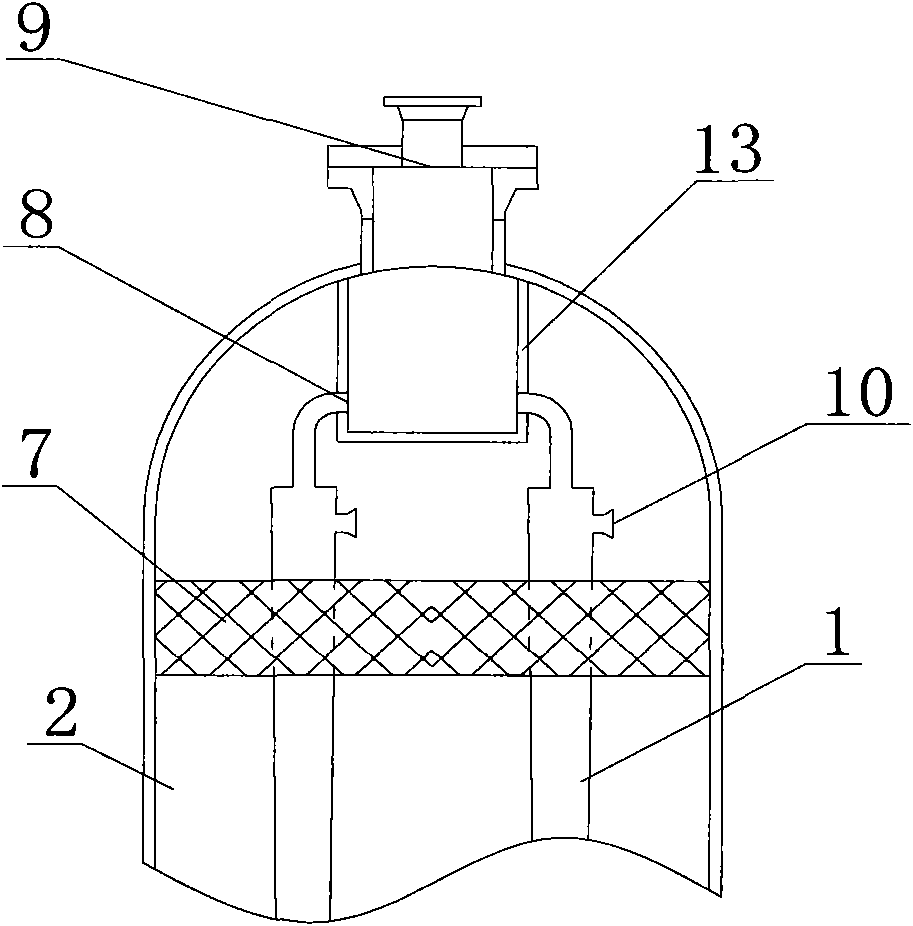

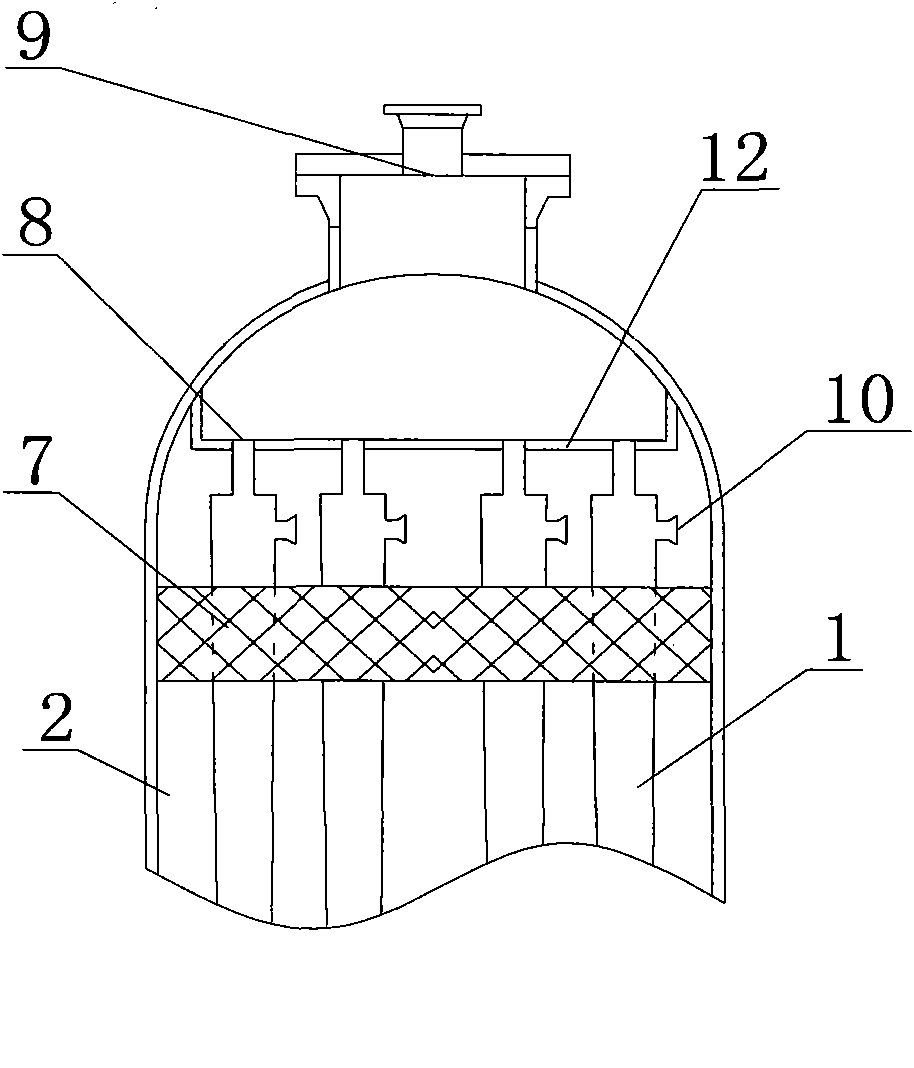

[0032] Such as figure 1 As shown, the high-pressure separator 2 includes a housing 11, a high-pressure separator inlet 4, a high-pressure separator liquid-solid phase outlet 6, and a high-pressure separator gas phase outlet 9, wherein the middle and upper part of the housing 11 is provided with a cyclone gas-liquid separator 1 , the cyclone gas-liquid separator 1 passes through the gas collector 13 (as figure 2 shown) or tray plate 12 (such as image 3 shown) is connected to the housing 11, the cyclone gas-liquid separator 1 includes a cyclone separation pipe, the upper part of the cyclone separation pipe is provided with a cyclone separator inlet 10, the top is provided with a cyclone separator overflow port 8, and the lower part There is a bottom flow port 3 of the cyclone separator.

[0033] figure 1 A soy-breaking net 7 is arranged radially below the inlet 10 of the cyclone separator in the high-pressure separator 2 .

[0034] The cyclone separation tube of the cyclon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com