Gradient induction heating based thermal deformation workpiece blank heating method and machining method

A technology of induction heating and heating method, used in metal processing equipment, heating/cooling equipment, manufacturing tools, etc., can solve the problems of harsh working environment, short mold life, difficult to quantify process parameters, etc., to increase comprehensive mechanical properties, guarantee Dimensional accuracy and the effect of improving service performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

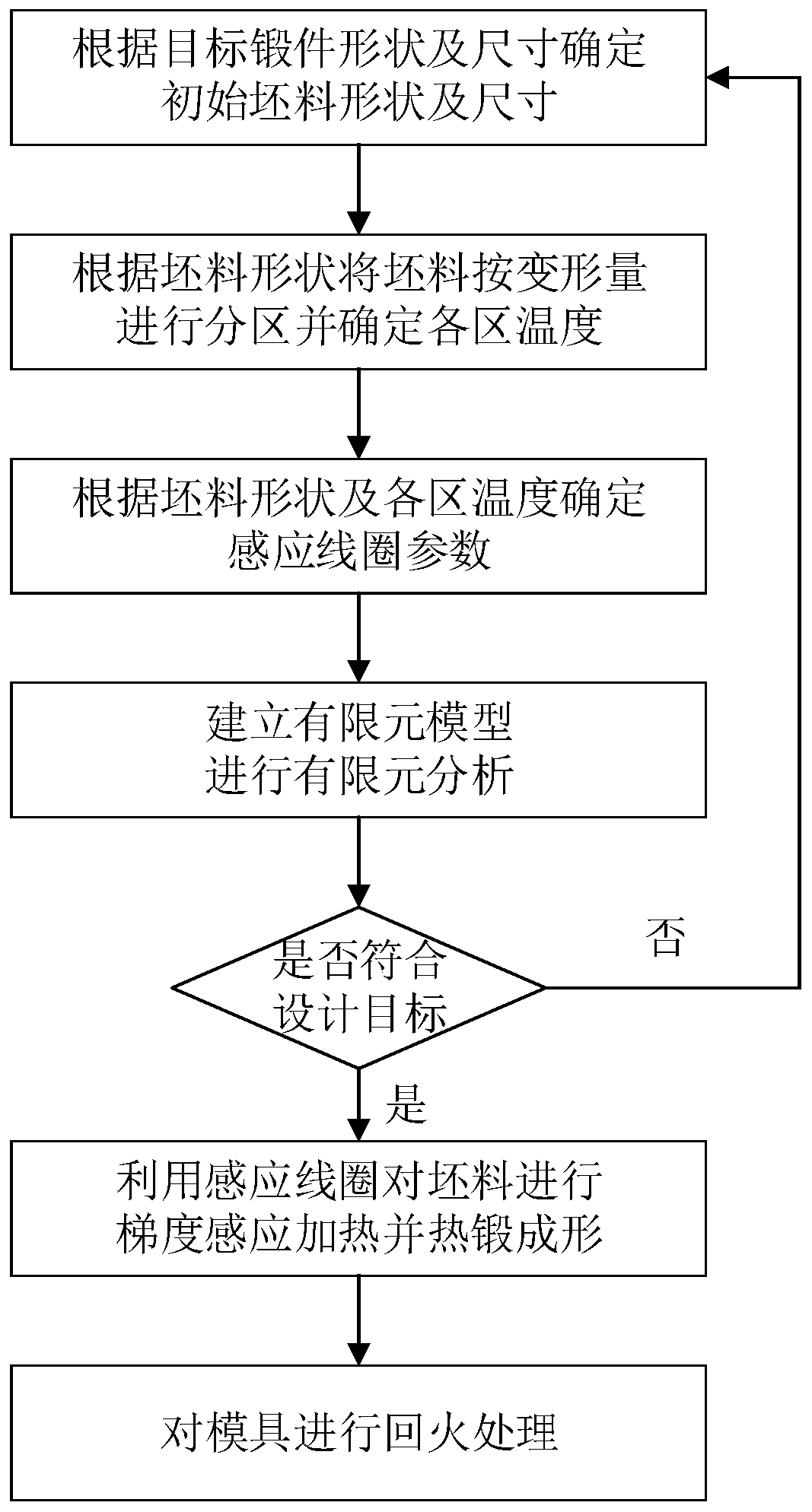

[0075] This embodiment illustrates the present invention by taking the forging process from the initial blank to the forging of the front landing gear outer cylinder of the aircraft as an example. The material of the forging is 300M steel. figure 1 Shown is a flow chart of a method for hot forging an aircraft nose landing gear outer cylinder based on gradient induction heating.

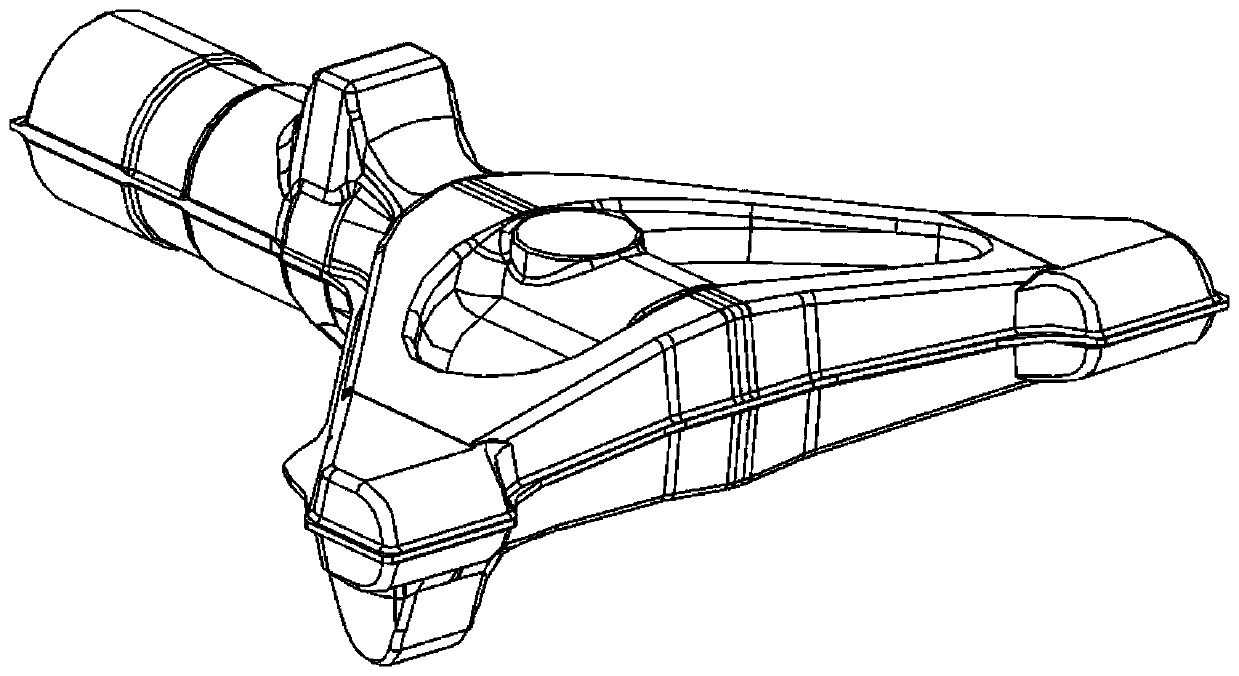

[0076] 1. The shape of the outer cylinder forging of the front landing gear of the aircraft is as follows: figure 2 shown. According to the theory of plastic deformation volume invariance, considering the flash size, combined with the existing blank design method, the design and processing are as follows: image 3 Initial blanks shown. And design the corresponding mold according to the target forging shape and size, and the mold material is 5CrMnMo. Since the method of designing the initial blank and mold according to the shape and size of the part is very mature, I will not repeat it here.

[00...

Embodiment 2

[0083] The present invention illustrates the present invention by taking the forming of cross rib-shaped forgings as an example, and the material is A100 high-strength steel. Forging target shape such as Figure 6 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com