Forming method of spatial curved surface protective plate with internal and external bidirectional stiffener

A technology of reinforcing ribs and protective plates, which is applied in the field of forming technology of the protective structure of the traveler, to achieve the effect of improving the forming quality, improving the overall rigidity and anti-stability ability, and suppressing various defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

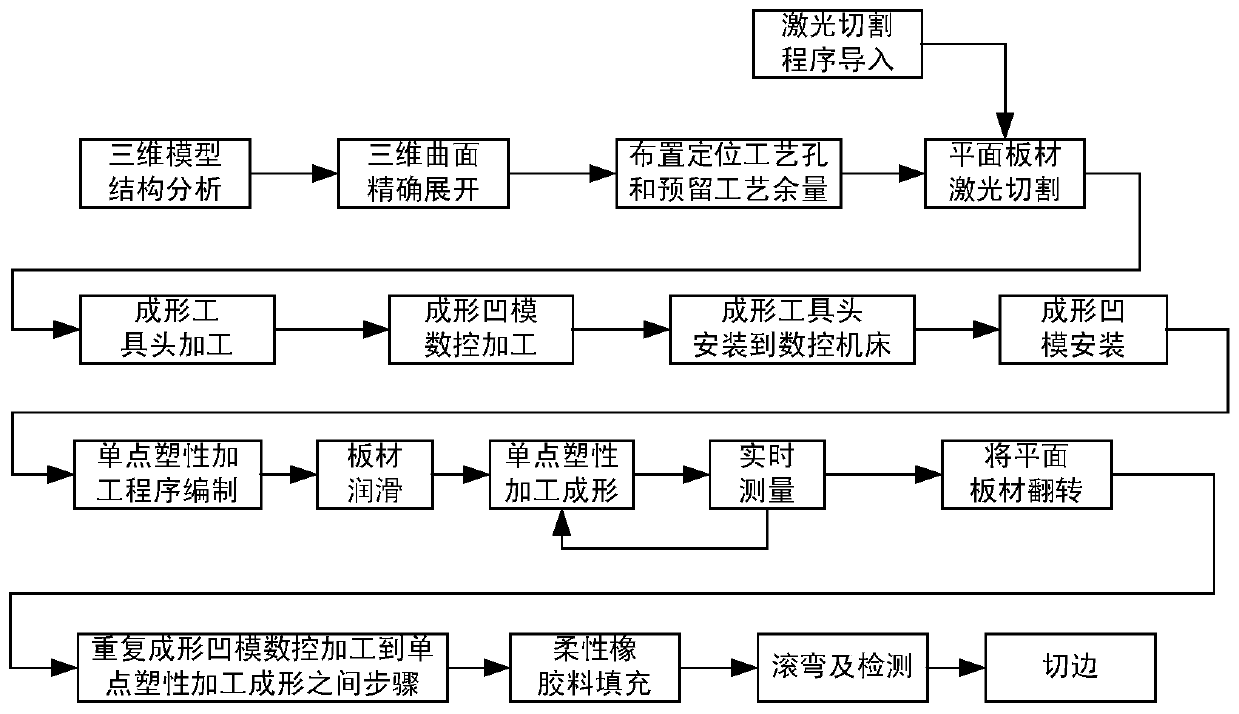

[0057] The present invention overcomes the shortcomings of the prior art, and provides a complex, high-efficiency, complex internal and external bidirectional reinforcing ribs with internal and external bidirectional reinforcing ribs, which is simple in operation and easy to realize, for the insufficiency of the formation of such a complex aluminum alloy space curved protective plate with internal and external bidirectional reinforcing ribs. The forming method of the aluminum alloy space curved protective plate solves the problems of high production cost, relatively difficult to control springback, and easy cracking at the excessive fillet of the reinforcing rib in the traditional forming process of the space curved protective plate. The present invention will be described in detail below with reference to the drawings and specific embodiments, such as figure 1 Shown is a schematic diagram of the process flow of the present invention. The method of the present invention includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com