Method for preparing tungsten copper alloy wire materials by using hot-swage technology

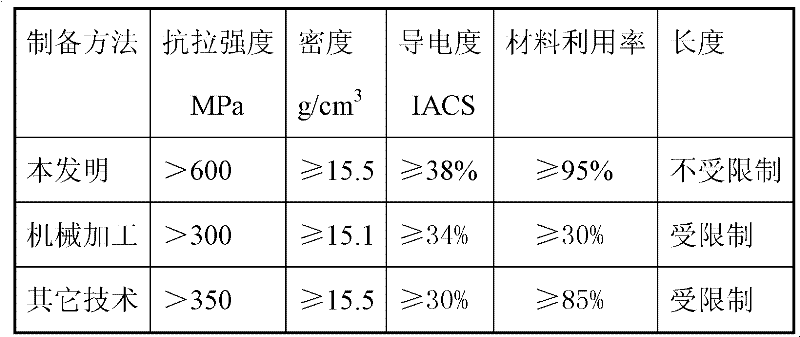

A tungsten-copper alloy and hot swaging technology, which is used in metal/alloy conductors, manufacturing tools, metal processing equipment, etc. The production cost is reduced and the preparation process is simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Wires of tungsten-copper alloy W70Cu30 with a diameter of 3 mm, a length of 300 mm, and a weight percentage of 70 and 30 were prepared.

[0018] This embodiment includes the following steps:

[0019] Step 1, ingredients: first weigh 20 grams of copper powder, 35 grams of tungsten powder, the particle size of the copper powder is 74 μm, and the particle size of the tungsten powder is 6 μm, and then add 6.05 ml of 11wt% of the total weight of the copper powder and the tungsten powder Glycerin was used as an additive, and the mixture was stirred mechanically for 6 hours;

[0020] Step 2, molding: put the viscous liquid mixed in step 1 with a certain fluidity into the cavity of a graphite mold with a diameter of 10 mm and a length of 200 mm at a high speed of 10 m / s;

[0021] Step 3, sintering: put the blank in step 2 together with the graphite mold in the vacuum sintering furnace, the vacuum degree is not more than 10 -2 Pa, temperature 1700±10°C, hold for 1.5 hours for ...

Embodiment 2

[0026] Wires of tungsten-copper alloy W85Cu15 with a diameter of 2 mm and a length of 400 mm and a weight percent of 85 and 15 were prepared.

[0027] This embodiment includes the following steps:

[0028] Step 1, ingredients: First weigh 11.25 grams of copper powder, 29.75 grams of tungsten powder, the particle size of the copper powder is 74 μm, and the particle size of the tungsten powder is 5 μm, and then add 4.92 ml of 12 wt% of the total weight of the copper powder and tungsten powder Glycerin is used as an additive, and the common stirring machine is mixed for 4 hours;

[0029] Step 2, molding: put the viscous liquid mixed in step 1 with a certain fluidity into the cavity of a graphite mold with a diameter of 10 mm and a length of 200 mm at a high speed of 10 m / s;

[0030] Step 3, sintering: put the blank in step 2 together with the graphite mold in the vacuum sintering furnace, the vacuum degree is not more than 10 -2 Pa, temperature 1800±10°C, hold for 2 hours for s...

Embodiment 3

[0035] A wire of tungsten-copper alloy W80Cu20 with a diameter of 3 mm and a length of 500 mm is prepared.

[0036] This embodiment includes the following steps:

[0037]Step 1, ingredients: first weigh 15 grams of copper powder, 40 grams of tungsten powder, the particle size of the copper powder is 74 μm, and the particle size of the tungsten powder is 4 μm, and then add 8.25 ml of 15wt% of the total weight of the copper powder and the tungsten powder Glycerol was used as an additive, and the stirring machine was mixed together for 5 hours;

[0038] Step 2, molding: put the viscous liquid mixed in step 1 with a certain fluidity into the cavity of a graphite mold with a diameter of 10 mm and a length of 200 mm at a high speed of 8 m / s;

[0039] Step 3, sintering: put the blank in step 2 together with the graphite mold in the vacuum sintering furnace, the vacuum degree is not more than 10 -2 Pa, temperature 1750±10°C, hold for 1.8 hours for sintering;

[0040] Step 4. Infilt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com