Process and equipment for formation of low-plasticity nonferrous metal shaped wire

A non-ferrous metal and low plasticity technology, applied in metal processing equipment, other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of low operating cost, less quantity, high service life of equipment tools and molds, and achieve low operating cost and low deformation The effect of small force and uniform deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

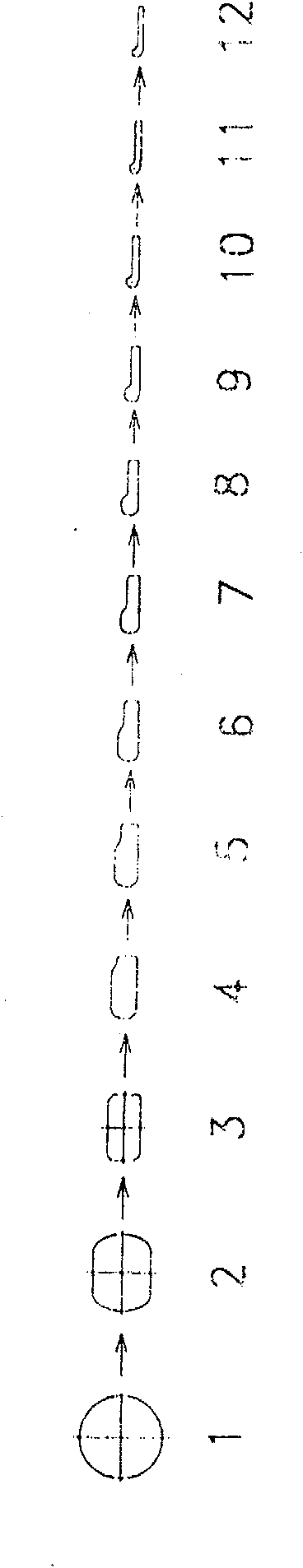

[0028] image 3 and Figure 4 , Figure 5 and Figure 6 They are respectively the processing flow chart and the envelope diagram of the processing section of two shapes of non-ferrous metal special-shaped materials. When swaging these two kinds of special-shaped materials, a lot of different special-shaped forging dies (14) should be made in advance according to the flow chart. During the processing process, special-shaped forging dies (14) of different specifications are assembled, and the special-shaped bar swaging process in the envelope diagram of the processing section is finally completed.

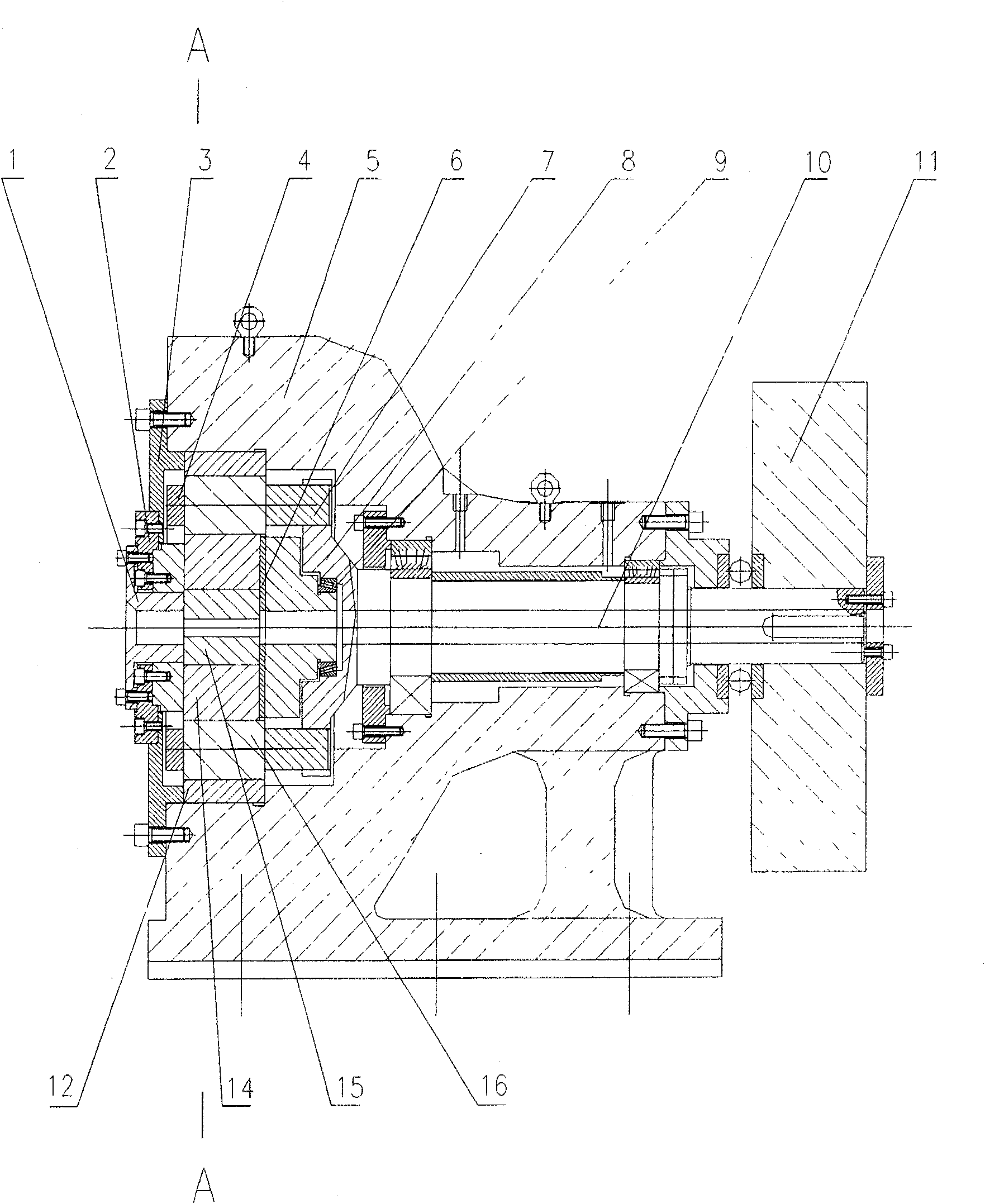

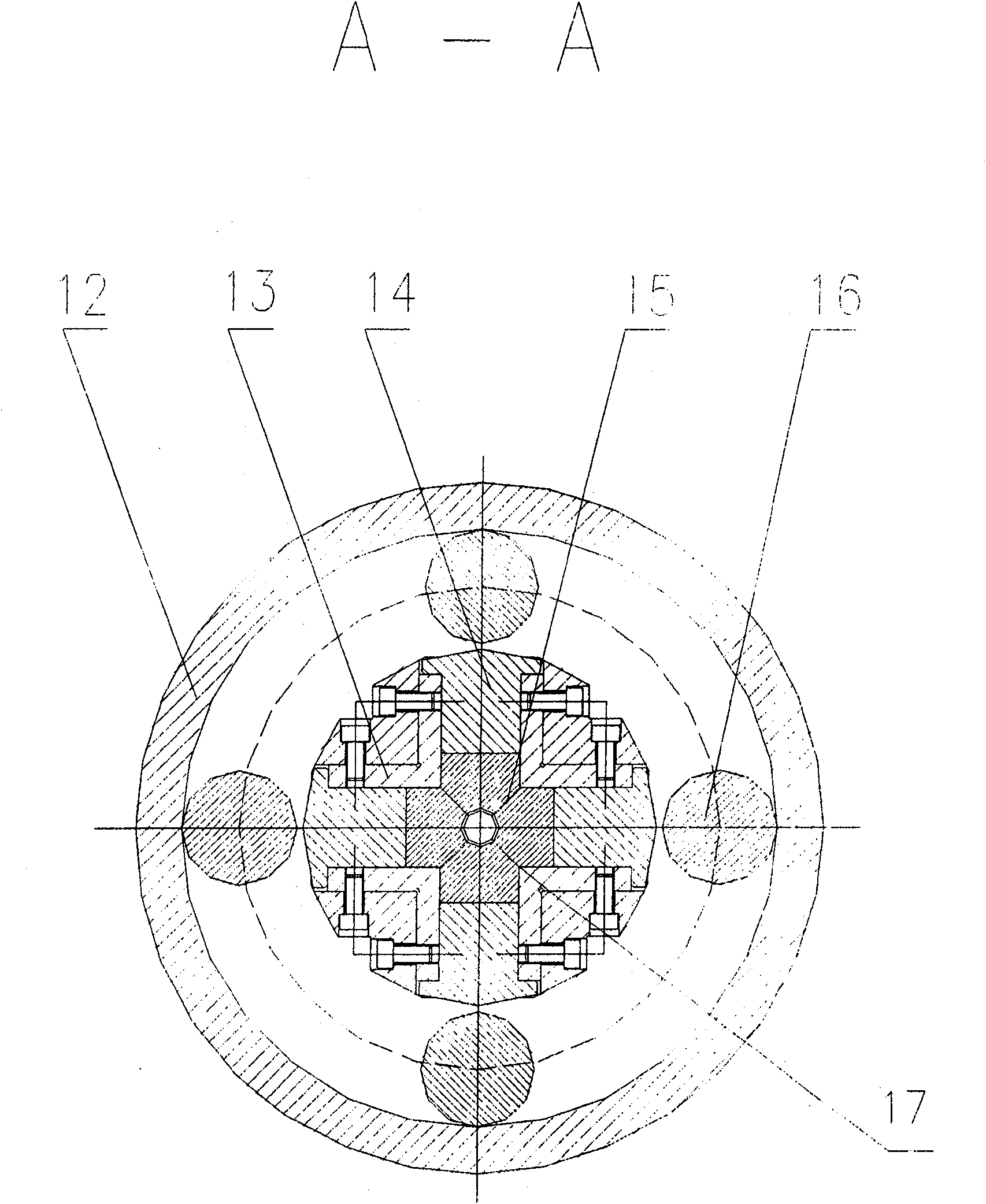

[0029] The structure of rotary forging processing equipment is as follows: figure 1 and figure 2 as shown, figure 1 From figure 2 Sectional view of the axial direction. In the figure, the hammer head (14) is placed in the cross fork shaft (8), but the cross fork shaft (8) does not rotate with the main transmission shaft (10), so neither the hammer head (14) nor the special-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com