Manufacturing method for austenitic stainless steel bar used for nuclear power reactor

An austenitic stainless steel and reactor technology, which is applied in the field of the preparation of austenitic stainless steel bars for nuclear power reactors, can solve problems such as coarse structure, die adhesion, and influence on mechanical properties, and achieve uniform deformation and ensure product specifications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

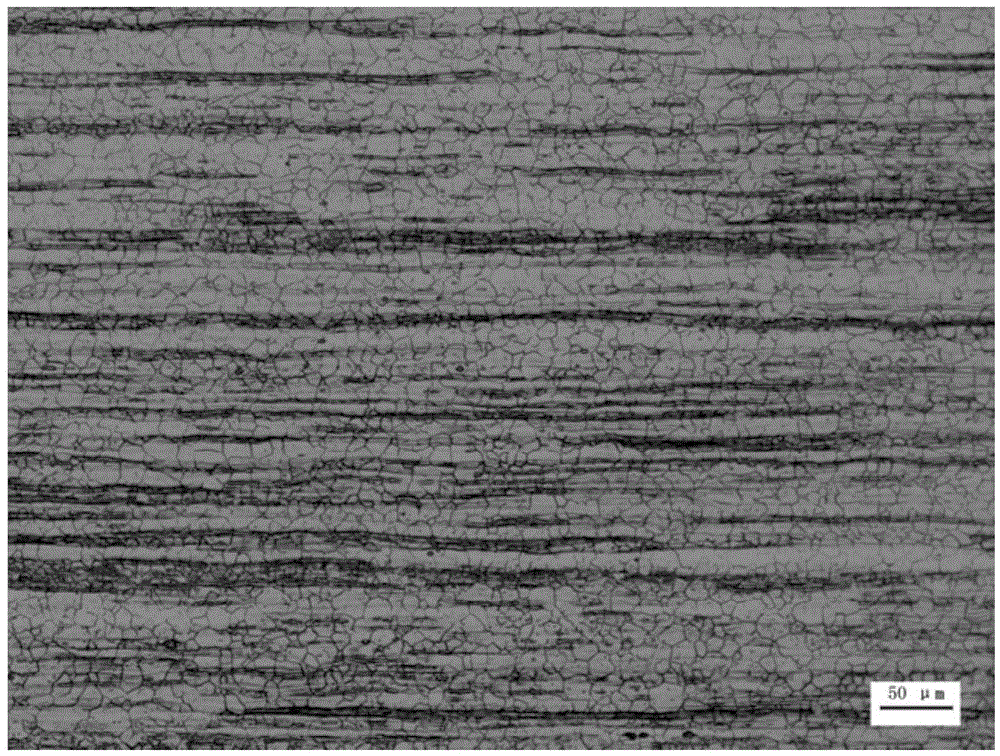

Image

Examples

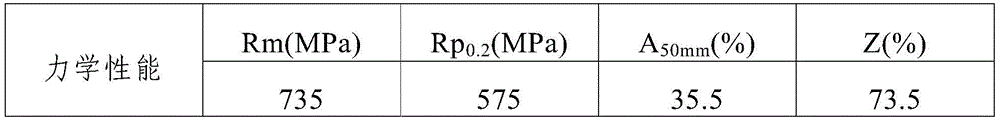

Embodiment 1

[0030] The preparation method of the austenitic stainless steel rod for nuclear power reactor of the present embodiment comprises the following steps:

[0031] Step 1. Select an austenitic stainless steel billet with a cylindrical shape and a cross-sectional diameter of 30 mm, and then use a roller die drawing machine to perform first roll die drawing on the austenitic stainless steel billet to obtain the first drawn billet The drawing of the first roll die is cold drawing, and the processing rate of the drawing of the first roll die is 75%; the cross-sectional shape of the first drawn bar blank is nearly circular, and the average size of the cross-sectional diameter is 15mm;

[0032] Step 2: Heating the first drawn billet described in step 1 by means of electrification, and simultaneously using an infrared thermometer to monitor the temperature of the first drawn billet in real time, and conducting current monitoring according to the measured temperature. Adjust the temperat...

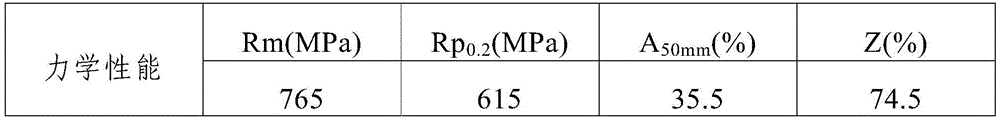

Embodiment 2

[0042]The preparation method of the austenitic stainless steel rod for nuclear power reactor of the present embodiment comprises the following steps:

[0043] Step 1. Select an austenitic stainless steel billet with a cylindrical shape and a cross-sectional diameter of 35 mm, and then use a roller die drawing machine to perform first roll die drawing on the austenitic stainless steel billet to obtain the first drawn billet The drawing of the first roll die is cold drawing, and the processing rate of the drawing of the first roll die is 80%; the cross-sectional shape of the first drawn bar blank is nearly circular, and the average size of the cross-sectional diameter is 15.65mm;

[0044] Step 2: Heating the first drawn billet described in step 1 by means of electrification, and simultaneously using an infrared thermometer to monitor the temperature of the first drawn billet in real time, and conducting current monitoring according to the measured temperature. Adjust the temper...

Embodiment 3

[0054] The preparation method of the austenitic stainless steel rod for nuclear power reactor of the present embodiment comprises the following steps:

[0055] Step 1. Select an austenitic stainless steel billet with a cylindrical shape and a cross-sectional diameter of 30 mm, and then use a roller die drawing machine to perform first roll die drawing on the austenitic stainless steel billet to obtain the first drawn billet The drawing of the first roll die is cold drawing, and the processing rate of the drawing of the first roll die is 75%; the cross-sectional shape of the first drawn bar blank is nearly circular, and the average size of the cross-sectional diameter is 15mm;

[0056] Step 2: Heating the first drawn billet described in step 1 by means of electrification, and simultaneously using an infrared thermometer to monitor the temperature of the first drawn billet in real time, and conducting current monitoring according to the measured temperature. Adjust the temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com