Preparation method of aluminium alloy semi-solid state blank for large size forging

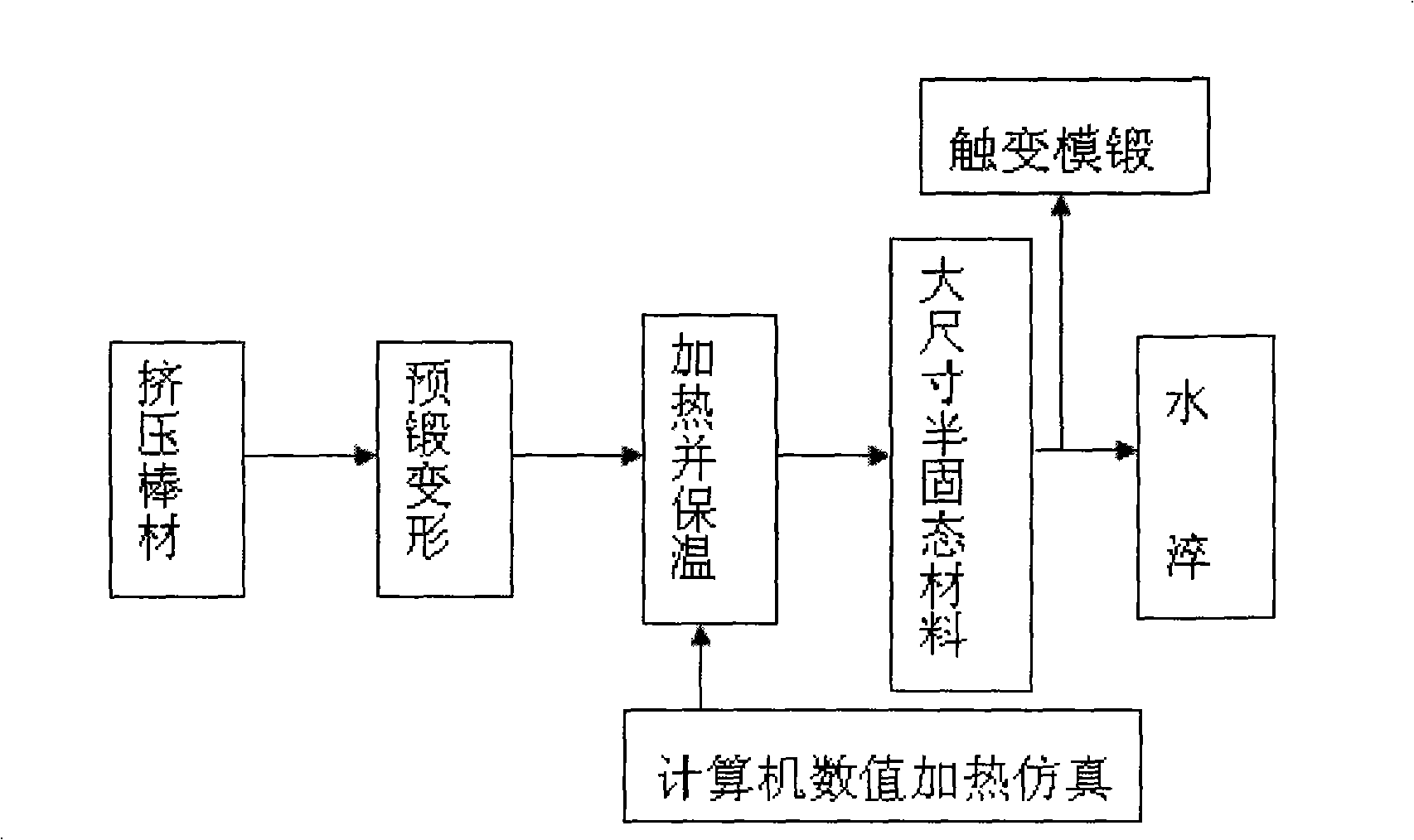

An aluminum alloy, large-size technology, applied in the field of preparation of aluminum alloy semi-solid billets, can solve the problems of uneven deformation, rapid heating of the billet, and the uniformity of the billet temperature cannot be well controlled, so as to achieve uniform temperature uniformity and shorten heating Unified effect of time and heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

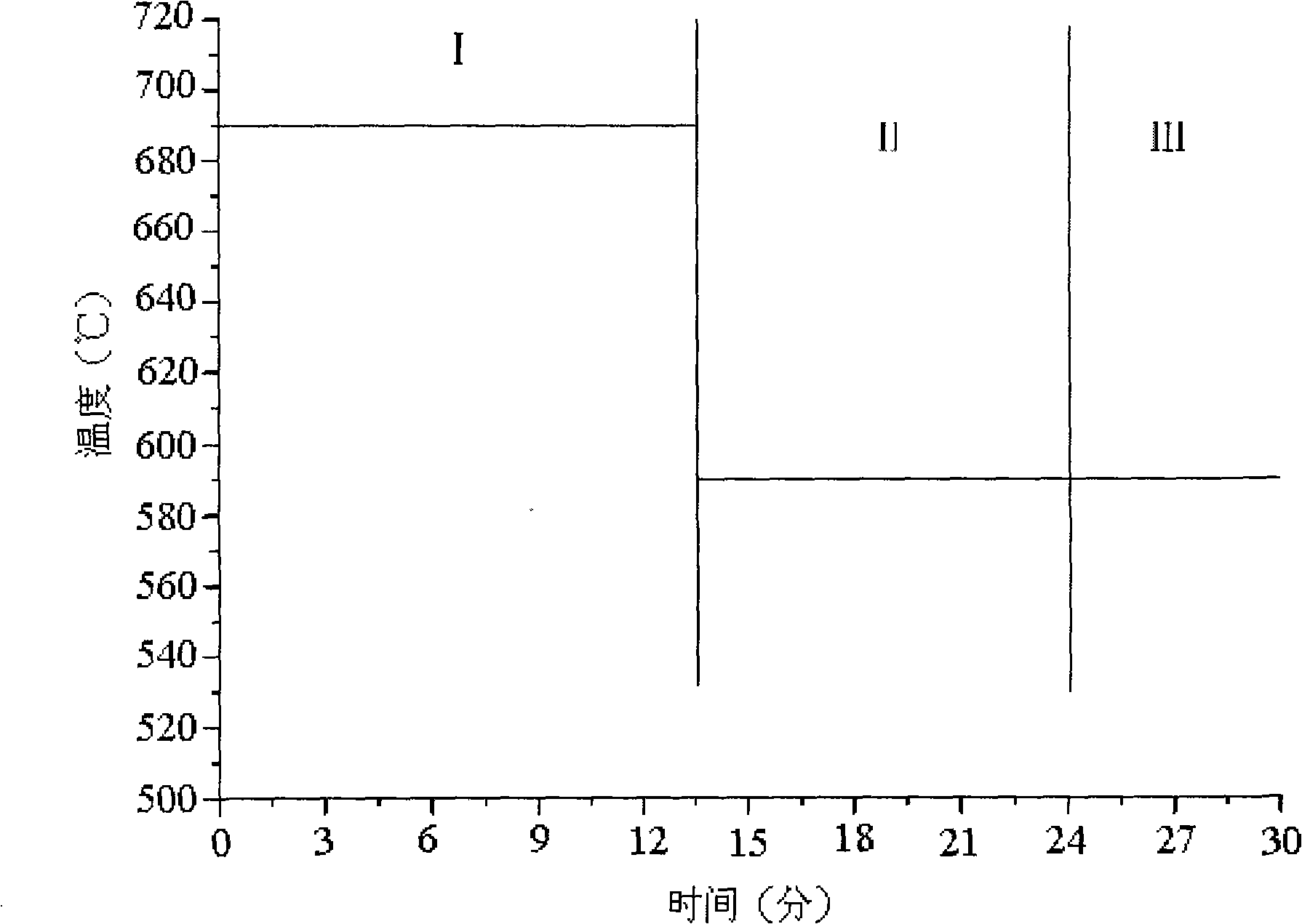

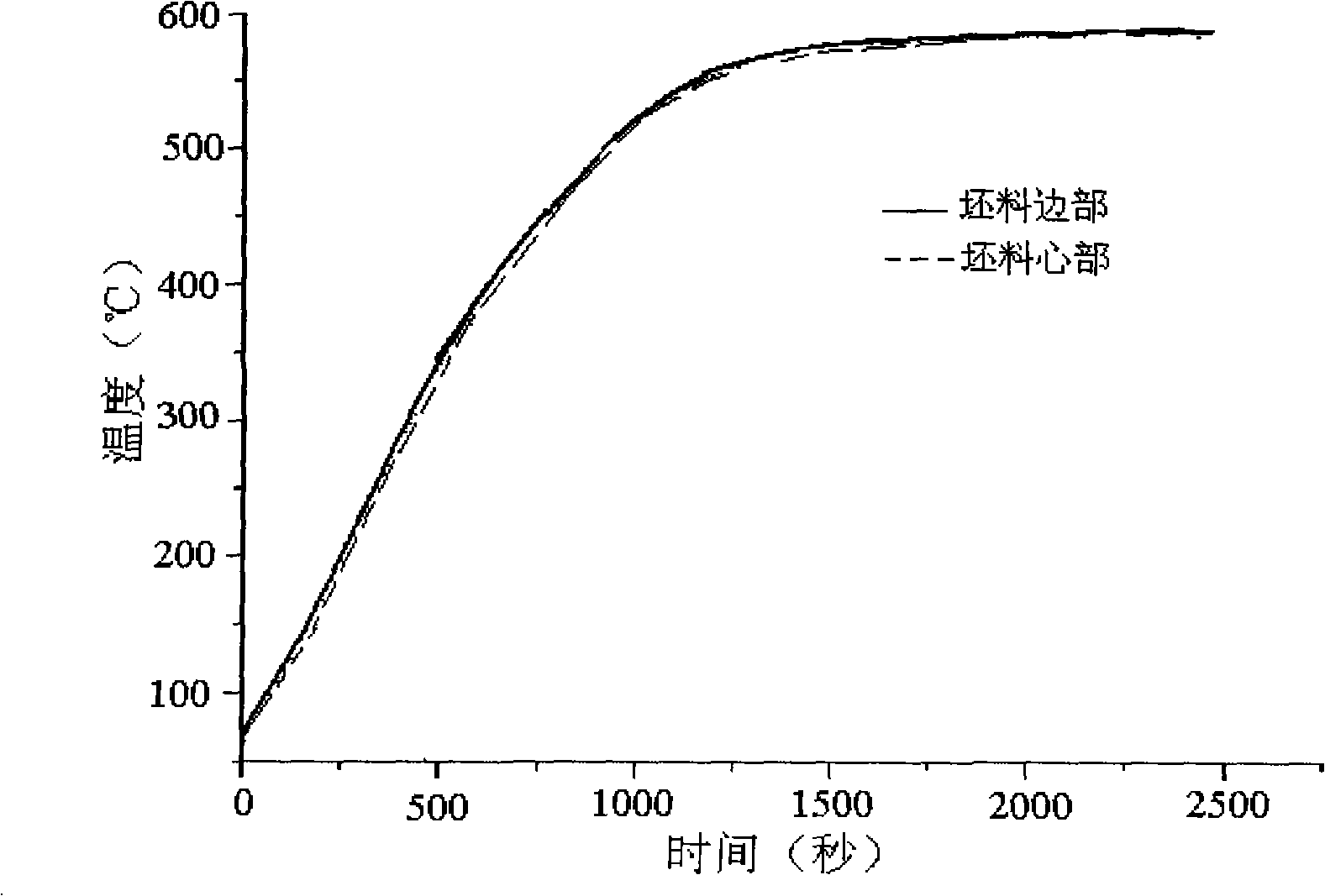

[0052] The commercially available 7A09 aluminum alloy extruded bar is cut off with a sawing machine and the two ends are flattened to make a round bar blank with a diameter of Φ90mm and a length of 150mm, and the round bar blank is placed in a resistance furnace , at a temperature of 400°C, keep warm for 1h for annealing, then cool with the furnace at a cooling rate of less than 30°C / h; forge the annealed round bar blank on a 500Kg air hammer, and the hammer anvil preheating temperature 100°C; forging follows the principle of "light-heavy-light", that is, light beating first, so that the end face of the billet and the hammer anvil are firmly attached, and the contact area between the end face of the round bar billet and the hammer anvil is less than 30% of the area of the end face of the round bar billet , and then hit again, each time hitting 1.5mm ~ 2mm. The diameter of the upper part of the round bar blank exceeds the diameter of the lower part by 4mm, and it is turned ar...

Embodiment 2

[0054] The commercially available 7A09 aluminum alloy extruded bar is cut off with a sawing machine and the two ends are flattened to make a round bar blank with a diameter of Φ140mm and a length of 225mm, and the round bar blank is placed in a resistance furnace , at a temperature of 420°C, keep warm for 3 hours for annealing, then cool with the furnace at a cooling rate of less than 30°C / h; forge the heat-treated round bar blank on a 750Kg air hammer, and the hammer anvil preheating temperature 250°C; forging follows the principle of "light-heavy-light", that is, at the beginning of hammering, hit lightly so that the end face of the billet and the hammer anvil are firmly attached, and the contact area between the end face of the round bar billet and the hammer anvil is smaller than that of the end face of the round bar billet 30% of the area, and then hit again, each time 1.5mm ~ 2mm, the diameter of the upper part exceeds the diameter of the lower part by 4mm, turn around fo...

Embodiment 3

[0056] The commercially available 7A09 aluminum alloy extruded bar is cut off with a sawing machine and the two ends are flattened to make a round bar blank with a diameter of Φ110mm and a length of 188mm, and the round bar blank is placed in a resistance furnace , at a temperature of 410°C, keep warm for 2 hours for annealing, and then cool with the furnace at a cooling rate of less than 30°C / h; forge the heat-treated round bar blank on a 750Kg air hammer, and the hammer anvil preheats the temperature The temperature is 175°C; forging follows the principle of "light-heavy-light", that is, at the beginning of hammering, hit lightly so that the end face of the billet and the hammer anvil are firmly attached, and the contact area between the end face of the round bar billet and the hammer anvil is smaller than that of the end face of the round bar billet 30% of the area, and then hit again, each time 1.5mm ~ 2mm, the diameter of the upper part exceeds the diameter of the lower pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com