Forging method of soliding fork

A sliding fork and forging technology, which is used in the manufacture of tools, forging/pressing/hammer devices, forging/pressing/hammering machinery, etc. The effect of reducing repair costs, reducing mold repair costs and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0015] Below in conjunction with accompanying drawing, the present invention will be further described:

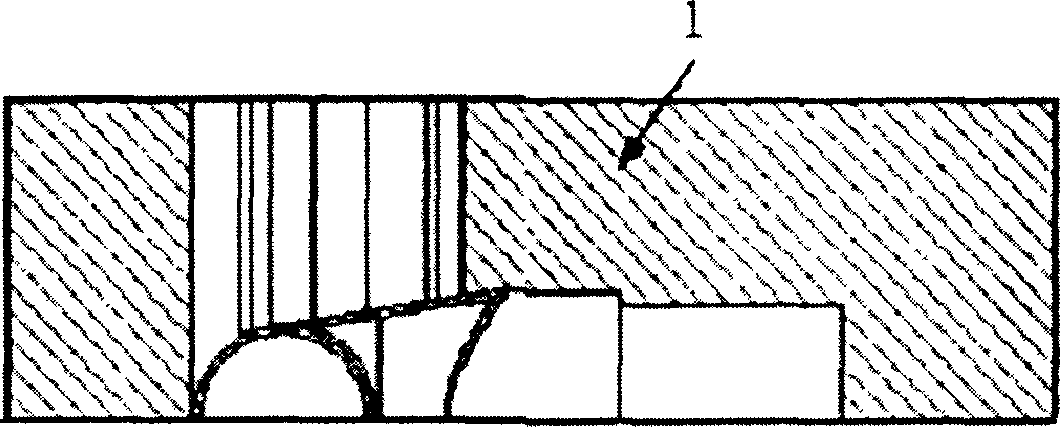

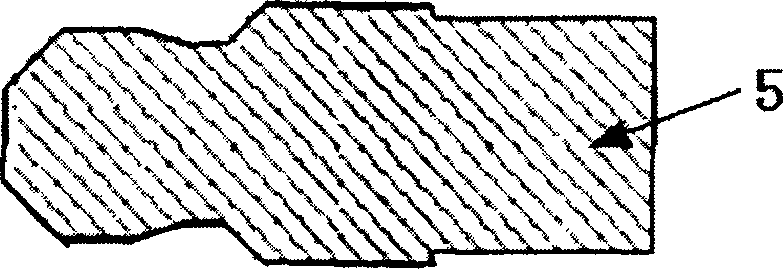

[0016] The invention consists of Figure 1 to Figure 6 As shown, first design the hot forging diagram according to the product parts diagram, and make the law of the distribution of the volume of each part of the forging along the axial direction of the forging according to the hot forging diagram, and design the blank that should be made by cross wedge rolling; then according to the method of the present invention Principles and methods design the final forging die diagram; according to the hot forging diagram and the final forging die diagram, calculate the energy parameters (extrusion force and die force, etc.) during deformation, and select the die force loading mode and equipment type; Design the cross-wedge rolling die, final forging die and cut-off fork continuous skin die according to the principle; finally select the appropriate die material and heat treatment met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com