UV offset printing frosted ink, and preparation method thereof

A matte ink and offset printing technology, used in inks, household appliances, applications, etc., can solve the problems of improper control of the amount of sandy materials added, improper selection of the main resin for offset printing, and difficulty in adapting to the printing requirements of UV offset printing inks. Printing effect, reduction of silk screen printing process, and the effect of strong printability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

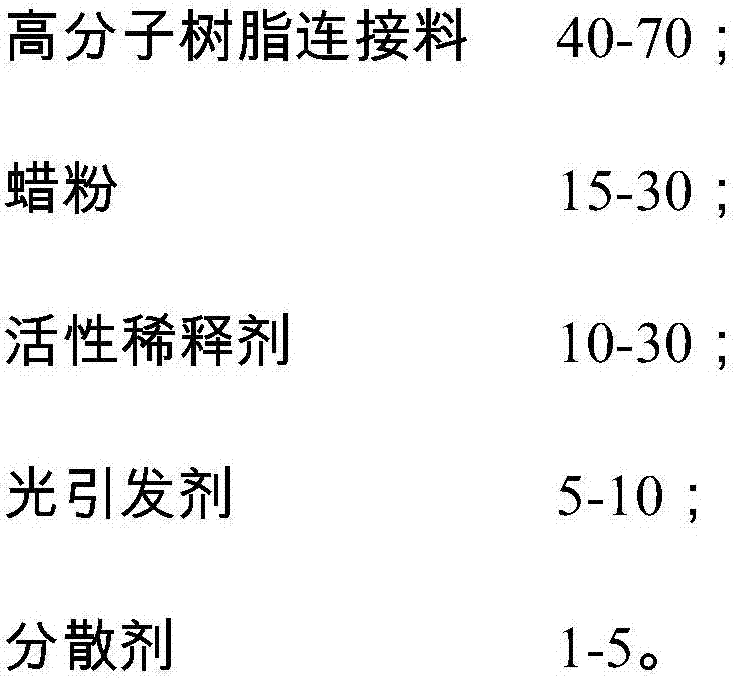

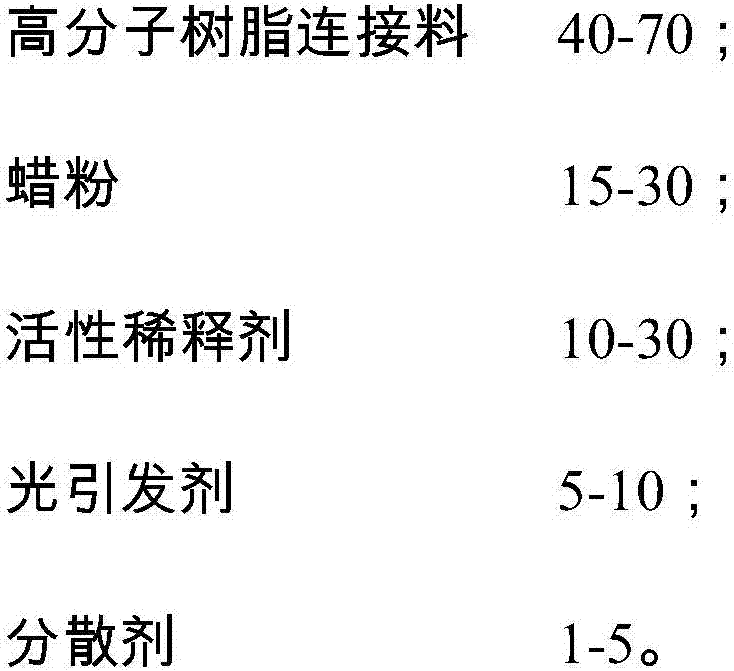

[0030] Add 45 parts of modified rosin resin, 20 parts of PE wax powder, 10 parts of PMMA micropowder, 25 parts of trimethylolpropane triacrylate reactive diluent, and 3 parts of photoinitiator in a certain volume of agitable open cylinder according to the weight ratio. ITX, 3 parts of photoinitiator 379 and 5 parts of dispersant; start stirring, disperse at low speed, the speed of rotation is suitable for the material not to splash, and disperse for 5-10 minutes, so that every solid is wrapped by liquid and pre-dispersed Then grind the pre-dispersion on a three-roll machine for three times, and check the ink fluidity, viscosity, fineness, etc. before discharging, and the qualified product is a qualified product.

Embodiment 2

[0032] In a stirring open cylinder with a certain volume, according to the weight ratio, add 55 parts of modified rosin resin, 25 parts of PE wax powder, 5 parts of PMMA micropowder, 25 parts of trimethylolpropane triacrylate reactive diluent, 3 parts of photoinitiator ITX, 2 parts of photoinitiator 379 and 5 parts of dispersant; start stirring, disperse at low speed, the speed of rotation is suitable for the material not to splash, and disperse for 5-10 minutes, so that every solid is wrapped by liquid and pre-dispersed Then grind the pre-dispersion on a three-roll machine for three times, and check the ink fluidity, viscosity, fineness, etc. before discharging, and the qualified product is a qualified product.

Embodiment 3

[0034] Add 70 parts of modified rosin resin, 15 parts of PE wax powder, 10 parts of PMMA micropowder, 15 parts of trimethylolpropane triacrylate reactive diluent, and 3 parts of photoinitiator in a certain volume of agitable open cylinder according to the weight ratio. ITX, 2 parts of photoinitiator 379 and 3 parts of dispersant; start stirring, disperse at low speed, the speed of rotation is suitable for the material not to splash, and disperse for 5-10 minutes, so that every solid is wrapped by liquid and pre-dispersed Then grind the pre-dispersion on a three-roll machine for three times, and check the ink fluidity, viscosity, fineness, etc. before discharging, and the qualified product is a qualified product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com