Cover film with low rebound force and preparation method of film

A cover film, low rebound technology, applied in the direction of film/sheet adhesive, epoxy adhesive, adhesive type, etc., can solve the problem of reducing product quality, low rebound force of regional protective layer, reducing production efficiency, etc. problems, to avoid the impact of product quality, reduce manual screen printing processes, and achieve the effect of mechanized production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

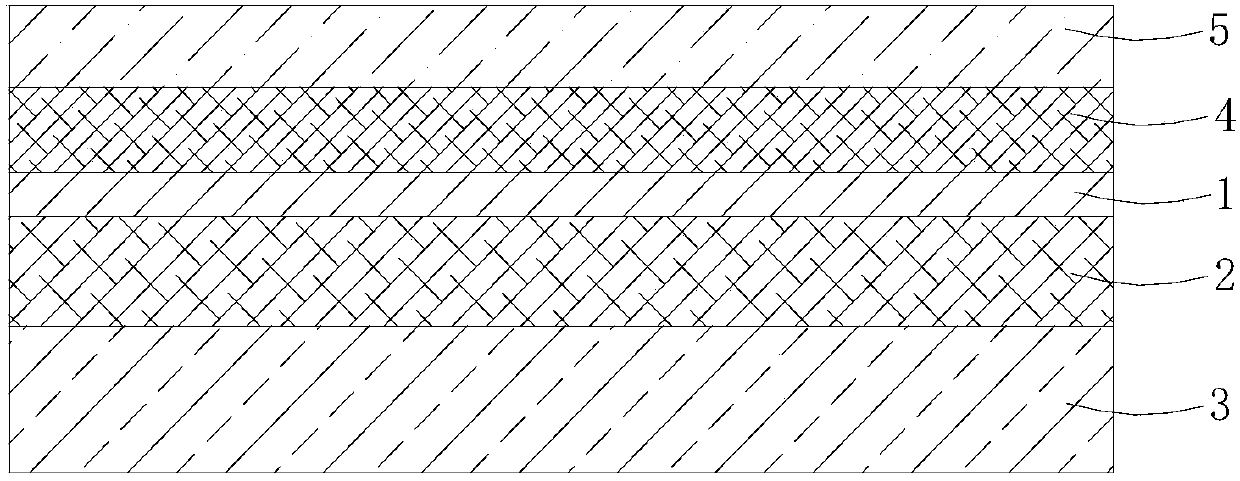

Image

Examples

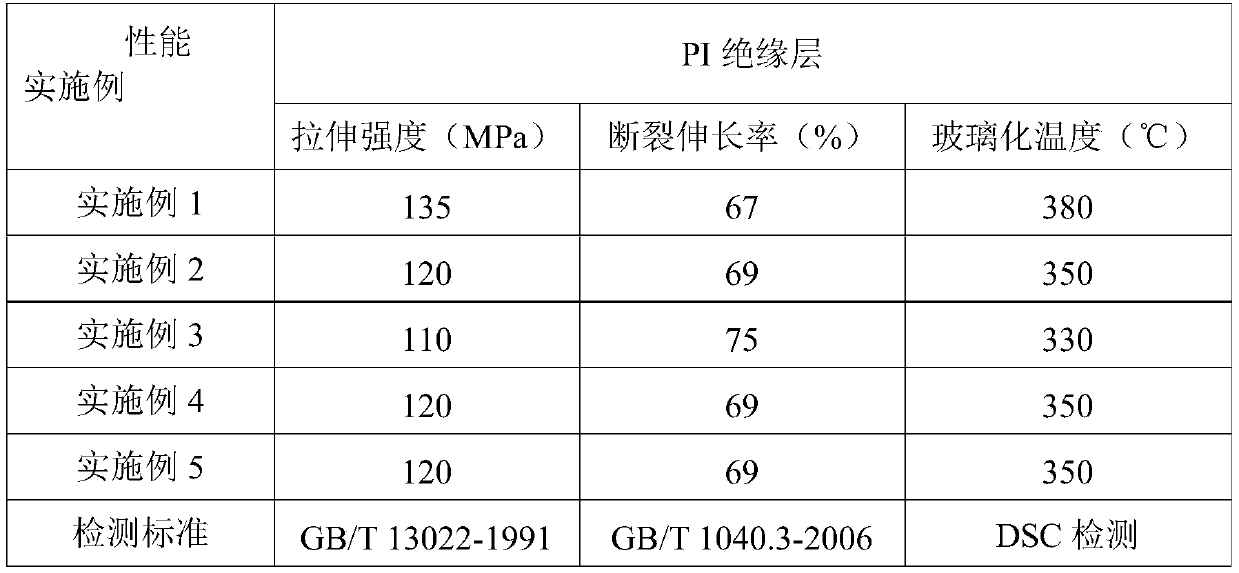

Embodiment 1

[0036] A preparation method for a low-rebound covering film, comprising the steps of:

[0037] Step 1, preparing PI film;

[0038] (1) Add 4,4-diaminodiphenyl ether (ODA for short) into N,N-dimethylacetamide to dissolve according to the molar ratio of 1:1;

[0039] (2) Adding pyromellitic dianhydride (PMDA for short) with a molar ratio of ODA in step 1 to the solution prepared above is 1:1, and synthetically obtains a polymer with a molecular weight greater than 100,000 and a solid content of less than 25%. Amic acid solution;

[0040] (3) Coat the above polyamic acid solution on the mirror steel strip, and the steel strip passes through a 160-380°C stepwise heating oven at a speed of 1-3m / min, and then peel off the polyimide film from the steel strip, and collect A 3 μm thick low-rebound PI film is obtained by rolling, the PI elongation at break is greater than 60%, the tensile strength is less than 150MPa, and the peeling temperature is lower than 390 degrees.

[0041] St...

Embodiment 2

[0046] A preparation method for a low-rebound covering film, comprising the steps of:

[0047] Step 1: preparing PI film;

[0048](1) According to the molar ratio of 1:1, 2,2'-diaminodiphenoxyethane (BAPE for short) is added to N,N-dimethylformamide for dissolution;

[0049] (2) Add pyromellitic dianhydride (PMDA for short) with a molar ratio of 1:1 to BAPE in the above-mentioned prepared solution, and synthetically obtain a polymer with a molecular weight greater than 100,000 and a solid content of less than 25%. Amic acid solution.

[0050] (3) Coat the above-mentioned polyamic acid solution on the mirror steel strip, and the steel strip passes through a 160-380-degree stepwise heating oven at a speed of 1-3m / min, and then peels off the polyimide film from the steel strip, and collects A PI film with a thickness of 1 μm and low rebound force can be obtained by rolling, the elongation at break of PI is greater than 60%, the tensile strength is less than 150MPa, and the peel...

Embodiment 3

[0058] The preparation method of the low-resilience covering film of this embodiment is basically the same as that of Example 1, the difference is that in step 1, triphenylbiether diamine (abbreviated as APB) replaces 4,4-diaminodiphenyl ether (abbreviated as ODA ), N-methylpyrrolidone instead of N,N-dimethylacetamide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com