Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38results about How to "Way to save energy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing high-quality gasoline from cracking biological oil

InactiveCN102676201ASimple methodWay to save energyLiquid hydrocarbon mixture productionBio-feedstockFuranCellulose

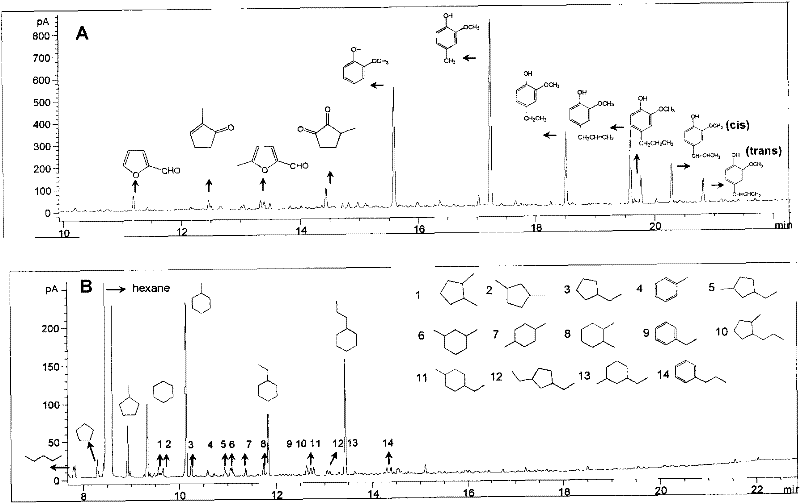

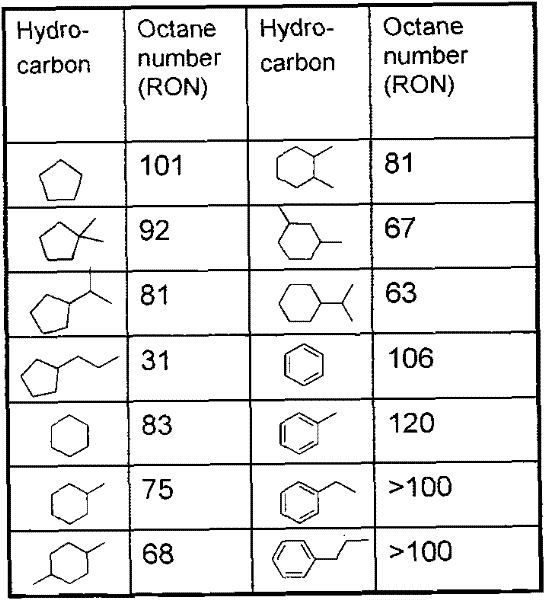

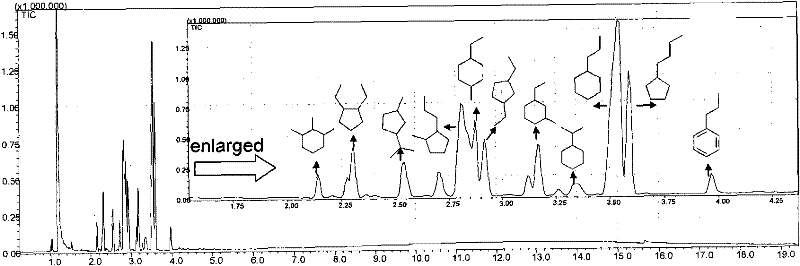

The invention discloses a method for preparing high-quality gasoline from cracking biological oil and relates to the technical field of hydrocarbon fuel preparation. According to the method, crude biological oil, lignocellulose, xylogen, phenolic monomer derived from the xylogen or / and lignin of the xylogen, cellulose, and a furan compound derived from the cellulose are used as raw materials. Under the catalytic action of Ni / HMFI catalyst, the hydrocarbon fuel is obtained through one-step hydrogenation deoxidizing conversion. Most of hydrocarbon products in obtained refined biological oil belong to the range of naphthenic hydrocarbon and aromatic hydrocarbon, does not contain sulphur and nitrogen, and belongs to high-octane high-quality clean gasoline fuel. The method has the advantage of being economical (source of the raw materials is wide and cost is low), simple in process, environment-friendly and easy to industrialize and the like. The catalyst is low in cost, efficient and easy in mass production, and products have significant application requirements. The method plays an important role in the field of replacement of fossil energy by biomass energy in the future, and is wide in application prospects.

Owner:赵晨

Positive electrode material for lithium ion battery and preparation method of positive electrode material

The invention discloses a positive electrode material for a lithium ion battery as well as a preparation method and application of the positive electrode material. Slurry prepared from the positive electrode material for the lithium ion battery is still stable after being arranged for a period of time and cannot be gelled, and therefore, a positive electrode piece can be prepared easily; meanwhile, the positive electrode material has excellent cycle performance at high temperature and under high voltage. According to the method for preparing the positive electrode material for the lithium ion battery, a microwave absorbent is added so that raw materials can be synthesized and subjected to coating reaction under a relatively high microwave power without secondary high-temperature annealing, and the added microwave absorbent which is taken as the raw material of the coating does not need to be removed, preparation operation is simple and industrial practicability is achieved.

Owner:TIANJIN GUOAN MGL NEW MATERIALS TECH CO LTD

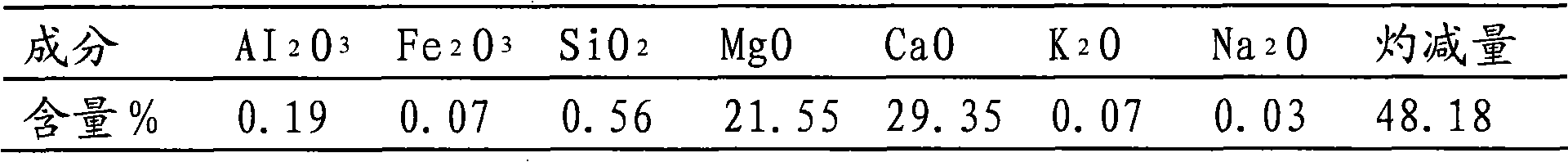

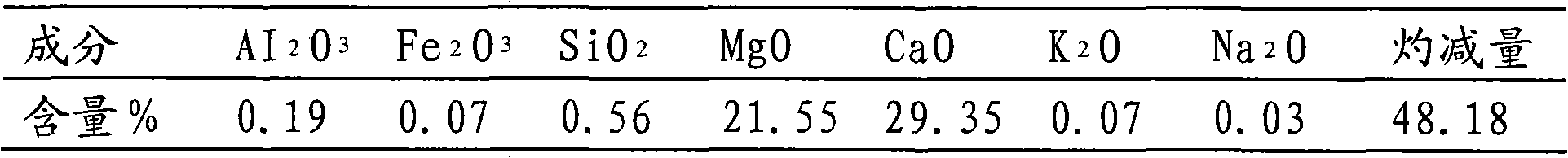

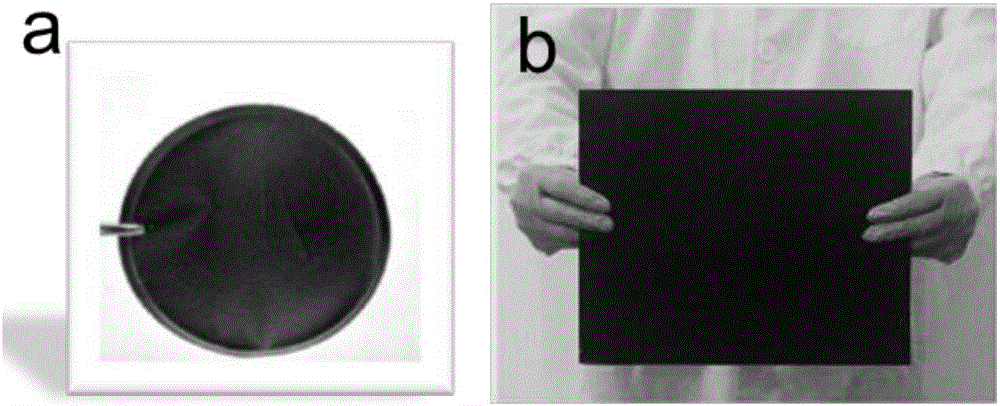

Method for preparing metal magnesium by using dolomite as raw material

The invention discloses a method for preparing metal magnesium by using dolomite as a raw material, and aims to solve the problems of low reducing efficiency, high energy consumption, long production period and serious pollution existing in the conventional method for preparing the metal magnesium. The method comprises the steps: crushing of dolomites, vacuum low-temperature light calcining and recycling of carbon dioxide, cooling and heat recovery, ball-milling of mixed materials, briquetting of mixed materials, vacuum high-temperature hot reduction, separation of magnesium blocks, and utilization of slag, wherein in the vacuum low-temperature light calcining, the crushed dolomites undergo light calcining in a continuous type vacuum calcining furnace for 1 to 3 hours at the calcining temperature of between 500 and 1,000 DEG C and under the furnace pressure of 10,000 to 60,000Pa, MgCO3 and CaCO3 in the dolomites are decomposed in sequence, the reaction expression is: CaMg(CO3)2=CaCO3+MgO+CO2(gas) and CaCO3=CaO+CO2(gas), and the mixture of carbon dioxide and magnesium oxide and calcium oxide is obtained; and the carbon dioxide which flows in the furnace and heats the dolomites is recycled.

Owner:JILIN UNIV

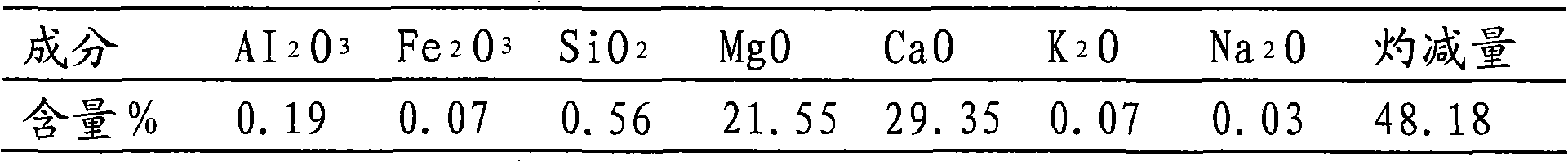

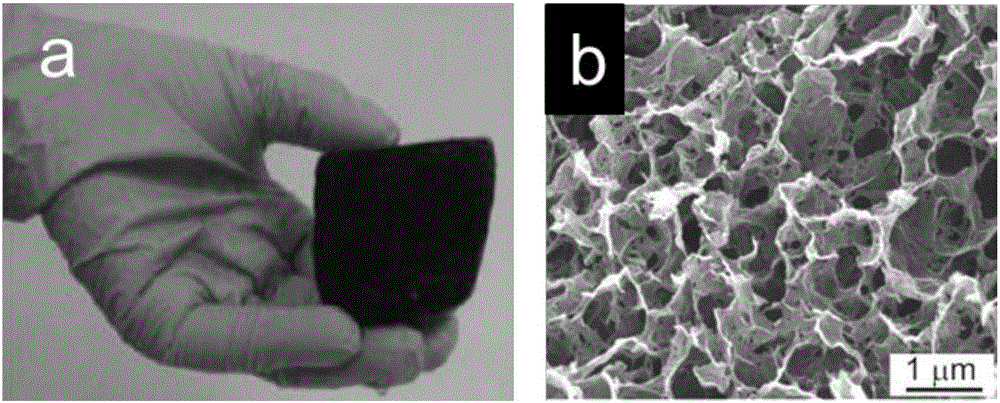

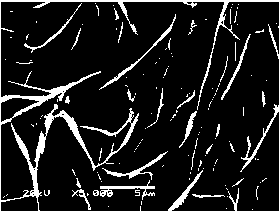

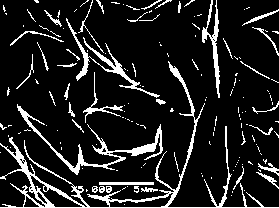

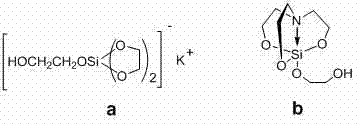

Preparation method of graphene foam-polydopamine composite membrane, product prepared with preparation method and application of product

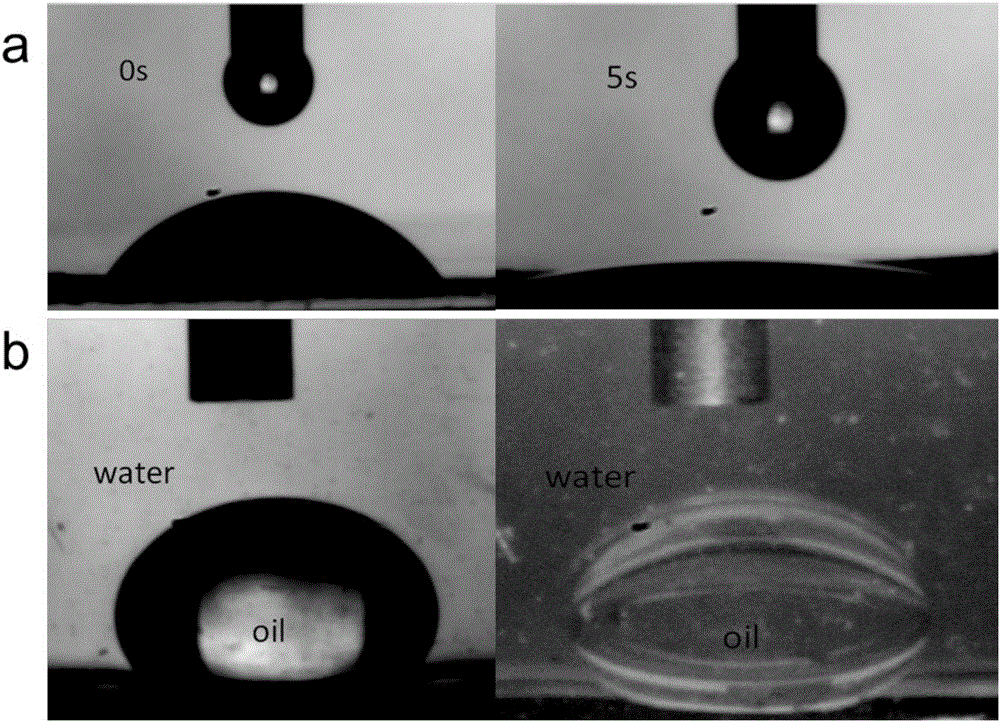

ActiveCN106422816AImprove mechanical propertiesRealize large-scale applicationSemi-permeable membranesFatty/oily/floating substances removal devicesMaterials scienceHydrochloride

The invention discloses a preparation method of a graphene foam-polydopamine composite membrane, a product prepared with the preparation method and an application of the product. The preparation method comprises steps as follows: (1) preparation of graphene foam-polydopamine: the pH value of a graphene oxide solution is adjusted, dopamine hydrochloride is added, a precursor solution is obtained and subjected to a hydrothermal reaction, and graphene foam-polydopamine is obtained; (2) preparation of the graphene foam-polydopamine composite membrane: graphene foam-polydopamine is added to N,N-dihydroxyethylglycine and mixed with a temperature-sensitive polymer, the mixture is stirred and subjected to vacuum filtration, and the temperature-sensitive graphene foam-polydopamine composite membrane is obtained. The graphene foam-polydopamine composite membrane prepared through improvement of overall process design, reaction conditions of steps and the like of a key preparation process has good temperature sensitivity and excellent super-hydrophilic property and underwater super-lipophobicity and is very applicable to oil-water separation.

Owner:HUAZHONG UNIV OF SCI & TECH

Efficient energy-saving reactive printing process

ActiveCN105088822AReduce processing stepsReduced color smearingSingeingMercerisingPhotochemistryEfficient energy use

The invention discloses an efficient energy-saving reactive printing process, which comprises the following steps: (1) pretreatment: performing body inspection, cloth arrangement, sewing, singeing, desizing, scouring, oxygen bleaching and mercerization on to-be-reactively printed cloth in sequence; (2) size mixing: melting colorants used for reactive printing under the condition of 70 to 90 DEG C, filtering and then adding the molten colorants to raw paste, and evenly stirring; (3) printing: during printing, arranging a printing screen of a dark colorant to be in front of a printing screen of a light colorant; (4) after the printing is finished, ageing, washing and setting to obtain a reactive printed product. According to the efficient energy-saving reactive printing process disclosed by the invention, through a chemical action between the dye colorants and the cloth, the color fading problem of reactive printing can be thoroughly solved, so that the product quality is greatly improved; meanwhile, compared with traditional reactive printing process, the efficient energy-saving reactive printing process has the advantages that processes are saved, the printing cost is reduced, and the production efficiency is increased.

Owner:江苏中诚印染股份有限公司

Method for purifying edible fungus polysaccharide by using enzyme pretreatment-microwave assisted extraction-chitosan flocculation technology

The invention relates to a method for purifying edible fungus polysaccharide by using an enzyme pretreatment-microwave assisted extraction-chitosan flocculation technology. The method comprises the following steps: adding enzyme into crushed edible fungi, mixing with water, stirring, and performing enzymolysis for a certain period of time; performing microwave radiation for a period of time, then cooling and performing suction filtration to obtain a polysaccharide extract; concentrating the extract, then adding chitosan to perform flocculation, and filtering to remove deposition after flocculation is finished, thus obtaining a purified polysaccharide solution; and drying to obtain relatively pure edible fungus polysaccharide which is tested to have good vitro antioxidation activity. According to the method provided by the invention, an enzymolysis technology is adopted to perform a certain degree of hydrolysis destruction on cell walls and intercellular substances of edible fungi at first, and then a 'body heating' characteristic of microwave is adopted to promote the dissolution of active ingredients. The method is efficient and energy-saving and can reduce the solvent consumption; and chitosan serving as a natural flocculating agent can well remove protein high polymer impurities, is good in impurity removal effect and low in cost, and cannot influence the product quality.

Owner:EAST CHINA UNIV OF SCI & TECH

Method of preparing cantharides capsule

InactiveCN1833717ALess quantityReduce doseCapsule deliveryAntineoplastic agentsMalignant lymphomaLung cancer

A Chinese medicine í«Compound telini fly capsuleí» for treating primary liver cancer, lung cancer, rectum cancer, lymph cancer, and gynecologic cancer is prepared from 10 Chinese-medicinal materials including ginseng, telini fly, astragalus root, etc. Its preparing process is also disclosed.

Owner:重庆希尔安药业有限公司

Method for decontaminating microorganisms on surface of fresh meat by performing ultrasonic treatment

The invention relates to a novel method for decontaminating microorganisms on the surface of fresh meat by performing ultrasonic treatment. The method comprises the following steps of: soaking fresh meat of which the surface contains a certain quantity of microorganisms (106cfu / g) into circularly flowing tap water (into which 20-100 ppm of sodium hypochlorite or chlorine dioxide can be added) which is subjected to ultrafiltration and degerming treatment by using the cavitation effect and mechanical effect of ultrasonic waves; and treating with an ultrasonic treatment device (of which the power range is 0-3,000w) under the constant-temperature condition (0-25 DEG C) in a certain frequency range (20-100 kHz) for a certain period of time (0-30 minutes), so that the aim of reducing the microorganisms on the surface of fresh meat to 102-103cfu / g is fulfilled. The treatment method is simple, environmentally friendly and sanitary; and according to the method, time is saved, and pollution of the microorganisms on the surface of fresh meat can be lowered effectively.

Owner:QINGDAO AGRI UNIV +1

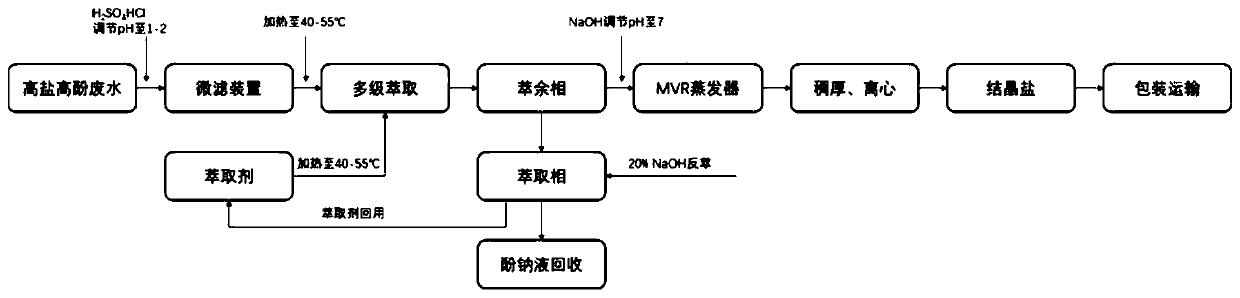

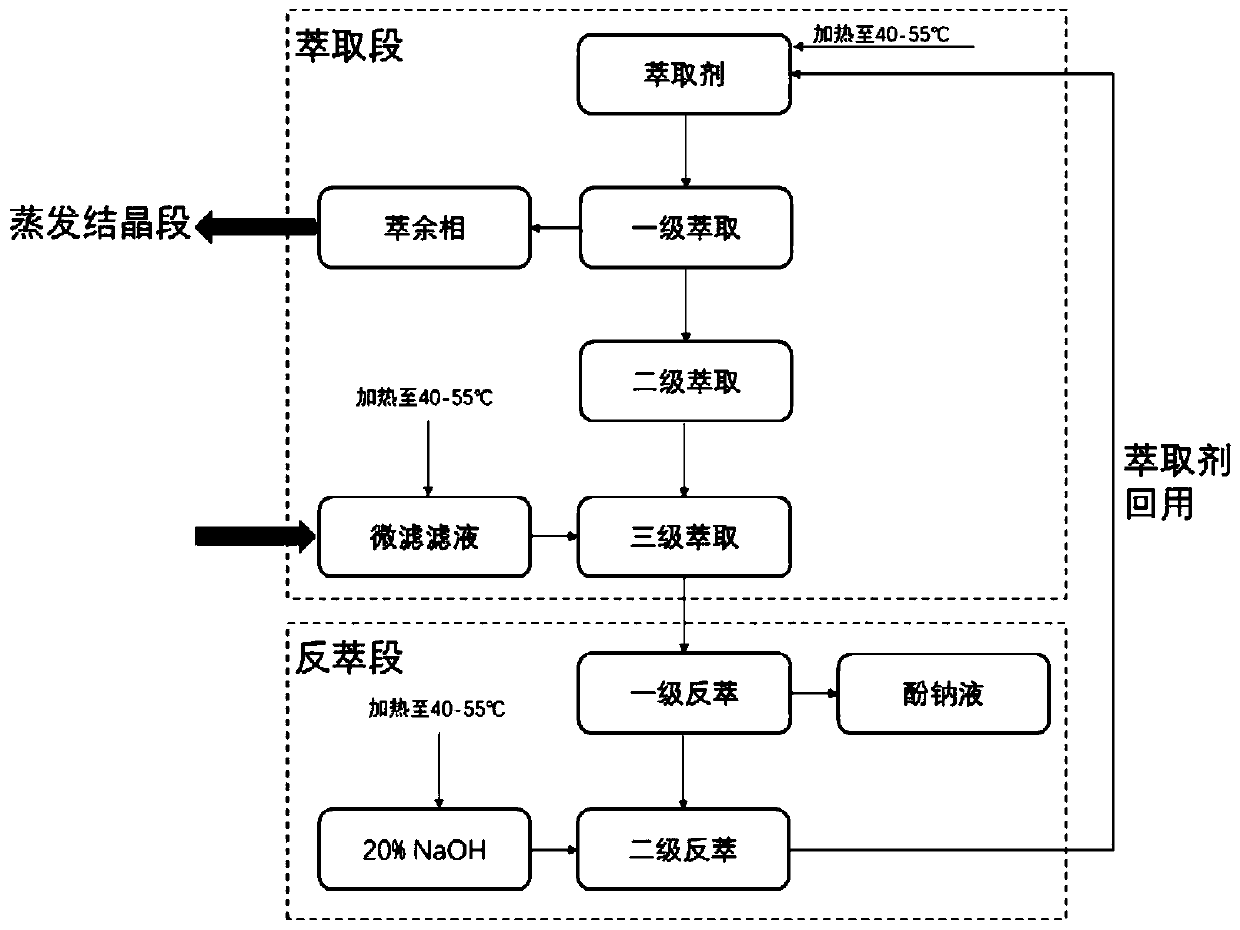

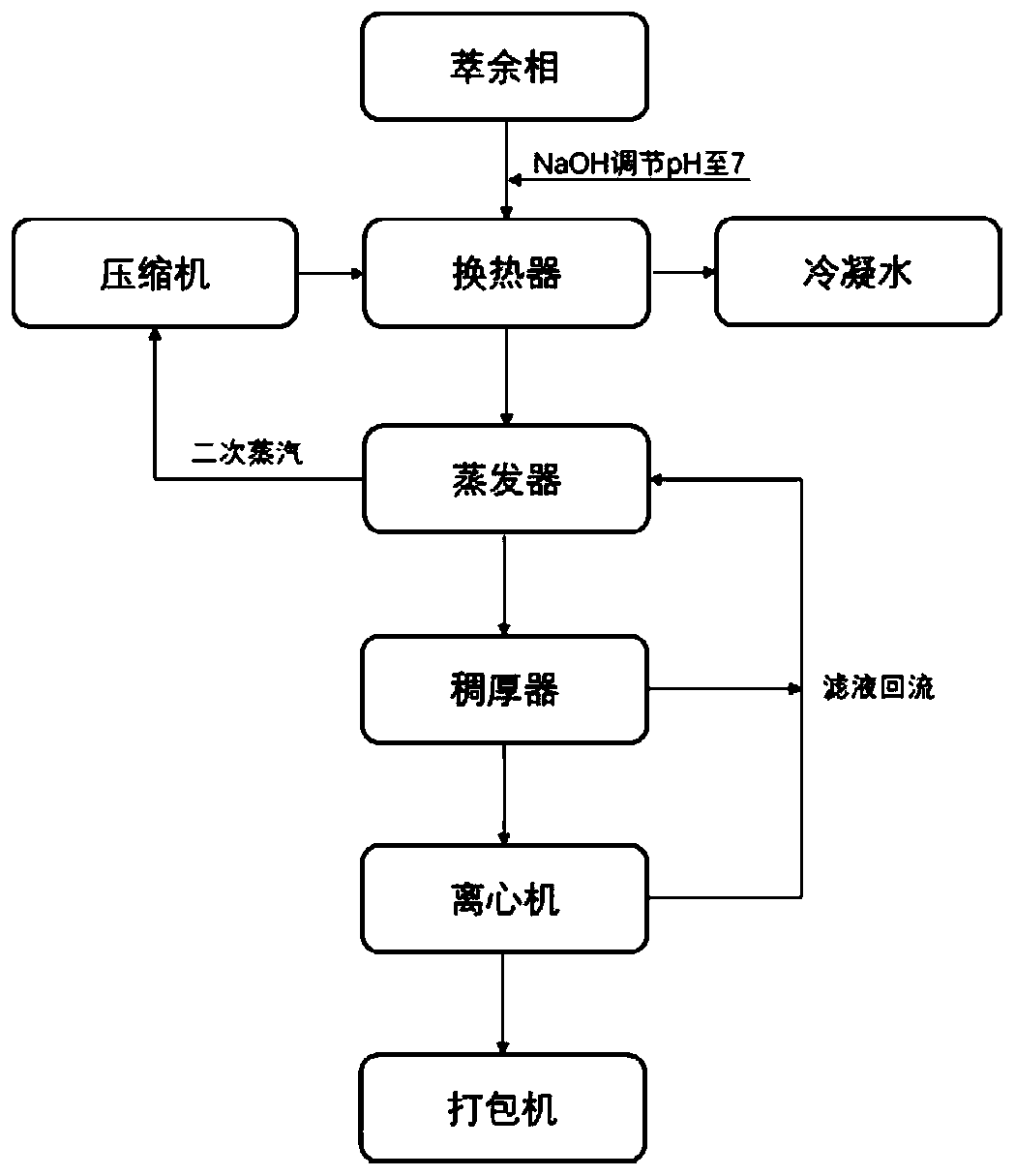

Extraction agent and treatment method of high-salt and high-phenol wastewater

InactiveCN110294561AEasy extractionGuaranteed treatment effectWater contaminantsMultistage water/sewage treatmentKeroseneEvaporation

The invention relates to the field of wastewater treatment, and in particular relates to an extraction agent and a treatment method of high-salt and high-phenol wastewater. The extraction agent comprises 40-90 parts of sulfonated kerosene, 5-70 parts of a phosphotriester compound and 10-80 parts of a tertiary amine compound. The extraction agent can effectively carry out multi-stage extraction onthe high-salt and high-phenol wastewater and improves the treatment effect of the high-salt and high-phenol wastewater. The total phenol content of the wastewater after extraction by the treatment method can be reduced to below 150 ppm, the dephenolization efficiency can reach 99%, and the extraction agent can be reused after back extraction and regeneration; salts in water after evaporation and crystallization are collected, and the resource application of the salts can be realized. The extraction agent can greatly reduce the treatment cost of the high-salt and high-phenol wastewater and improves the treatment efficiency.

Owner:BEIJING GUODIAN FUTONG SCI & TECH DEV

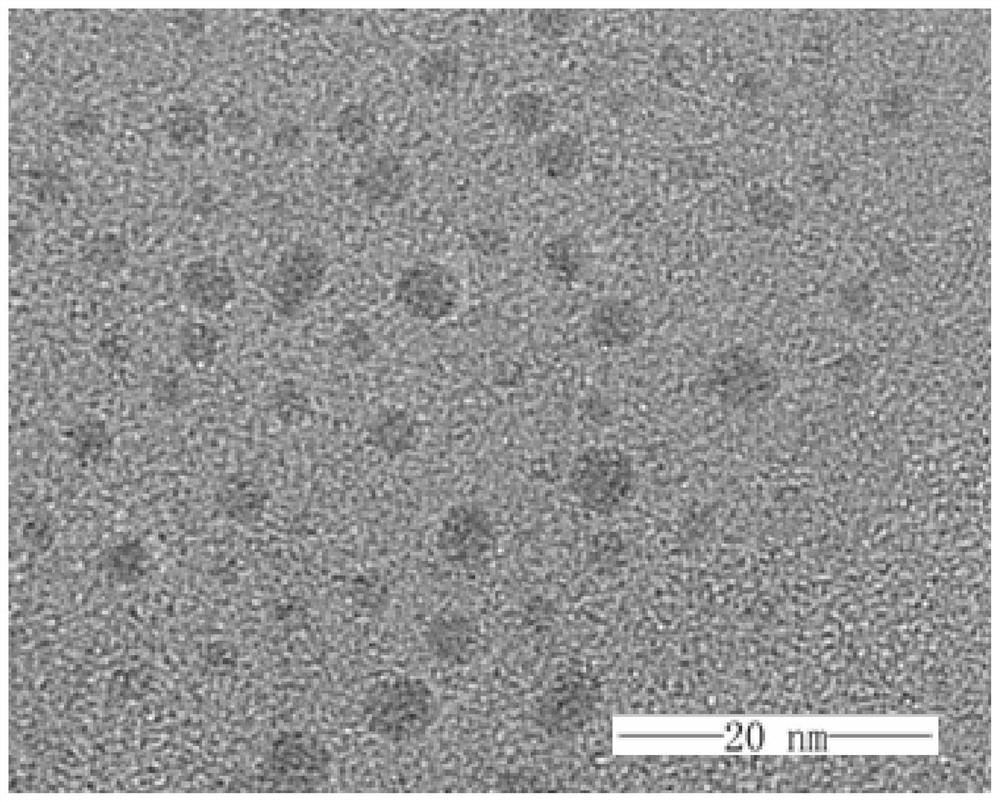

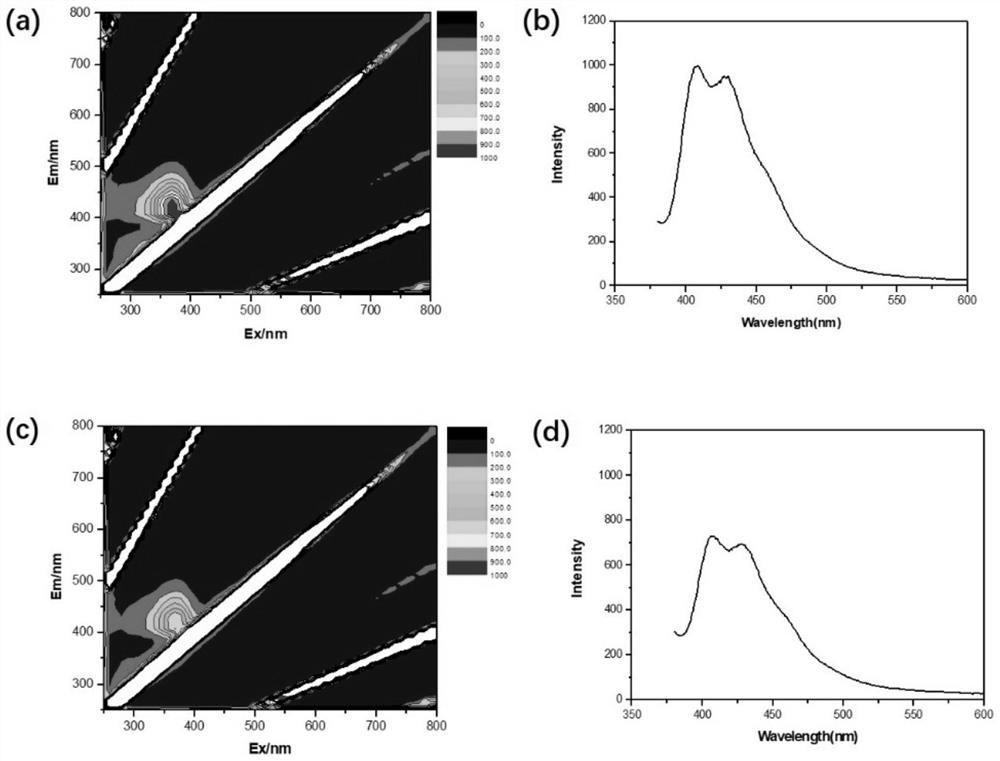

Preparation method of silicon dioxide coated fluorescent carbon quantum dot composite microspheres

InactiveCN111635758ALow equipment requirementsWay to save energyNanoopticsLuminescent compositionsEthyl esterOrganosolv

The invention belongs to the technical field of luminescent materials, and particularly relates to a preparation method of silicon dioxide coated fluorescent carbon quantum dot composite microspheres.The method comprises the following steps: preparing carbon quantum dots by using a microwave reactor through a hydrothermal method, transferring the carbon quantum dots into an organic solvent through an extraction method, then adding ethanol, dispersing the carbon quantum dots into the ethanol solvent through solvent replacement, finally, adding carbon quantum dots in hydrolysis reaction of tetraethoxysilane under ammonia-alkali conditions, and coating the carbon quantum dots in situ in the growth process of silicon dioxide to obtain the silicon dioxide coated carbon quantum dot fluorescentcomposite microsphere. The preparation method is energy-saving, rapid, efficient and high in quantum dot coating rate, and the prepared fluorescent composite microsphere is regular in shape, uniform and adjustable in particle size, good in light-emitting stability and long in service life.

Owner:QINGDAO UNIV OF SCI & TECH

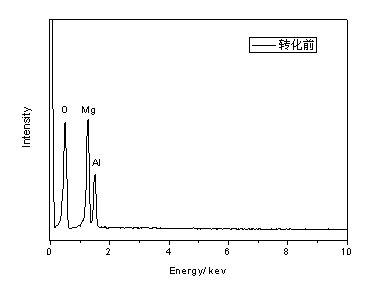

Aluminum and aluminum alloy surface self-repairing and corrosion-resisting conversion coating and preparation method thereof

ActiveCN103184447ANovel methodEasy to operateMetallic material coating processesHydrotalciteCorrosion current density

The invention belongs to the field of corrosion protection application of coating. An aluminum and aluminum alloy self-repairing and corrosion-resisting composite conversion coating is prepared by that a magnalium hydrotalcite layered structure is grown on an aluminum and aluminum alloy basal body, 8-chinosol for conversion is adopted for conversion, the molar concentration of 8-chinosol is 0.01 to 0.03 mol / L, PH ranges between 10.5 and 12.5, and conversion for 12 to 48 hours is performed at a room temperature. The coating ensures that the corrosion resisting performance of a metal basal body can be remarkably improved, the density of corrosion current is lowered by one order of magnitude, meanwhile, the coating has an excellent self-repairing and corrosion-resisting performance, after being soaked in 3.5 percent of NaCl for 7 days, the impedance of the converted coating is increased by one order of magnitude by compared with a coating not converted. The method adopting the scheme is simple to operate, the cost is low, the energy consumption is small, mass production can be carried out, a chromate process coating layer on an aluminum alloy surface can be replaced, and the coating and the method have a favorable application prospect.

Owner:DALIAN UNIV OF TECH

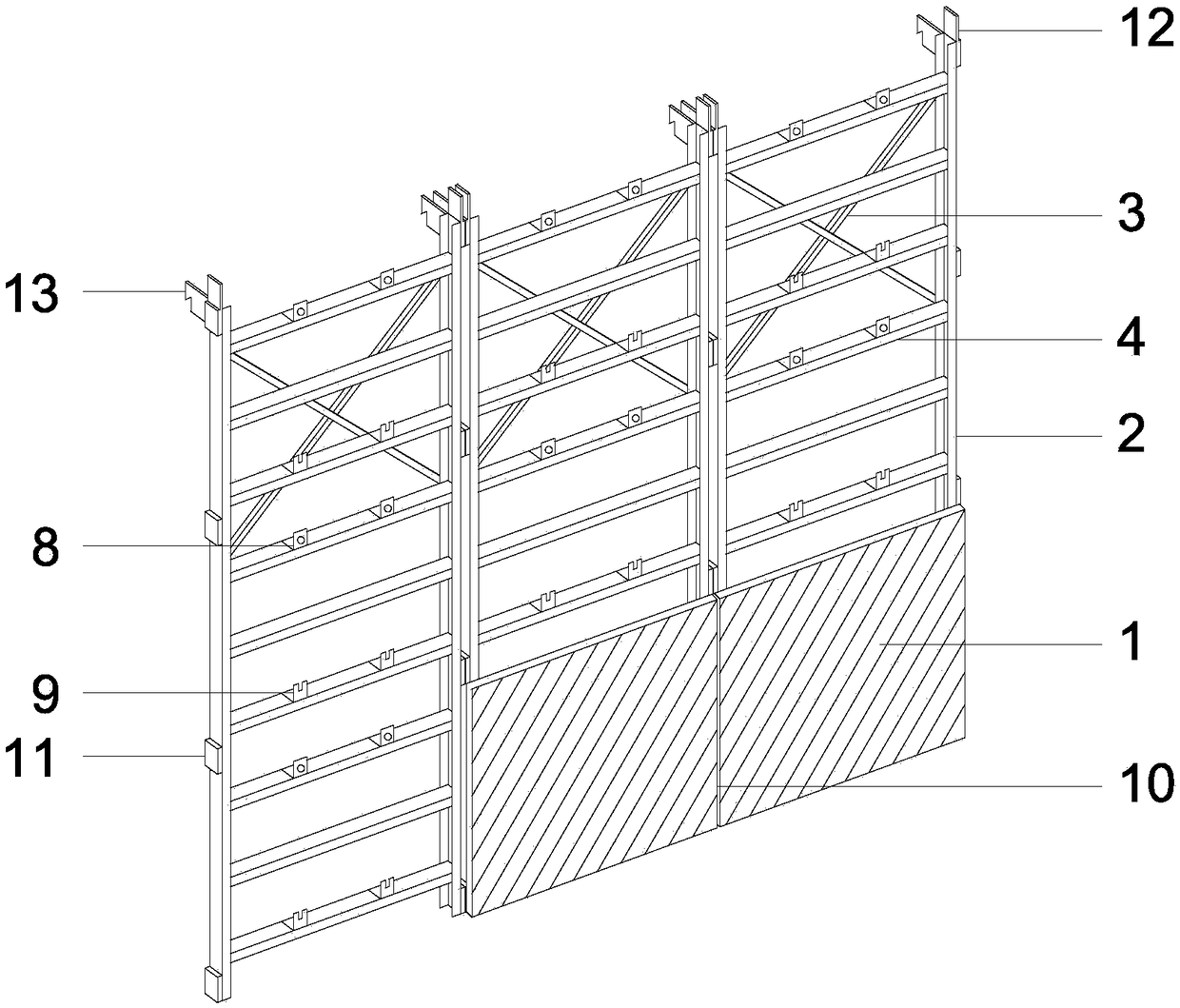

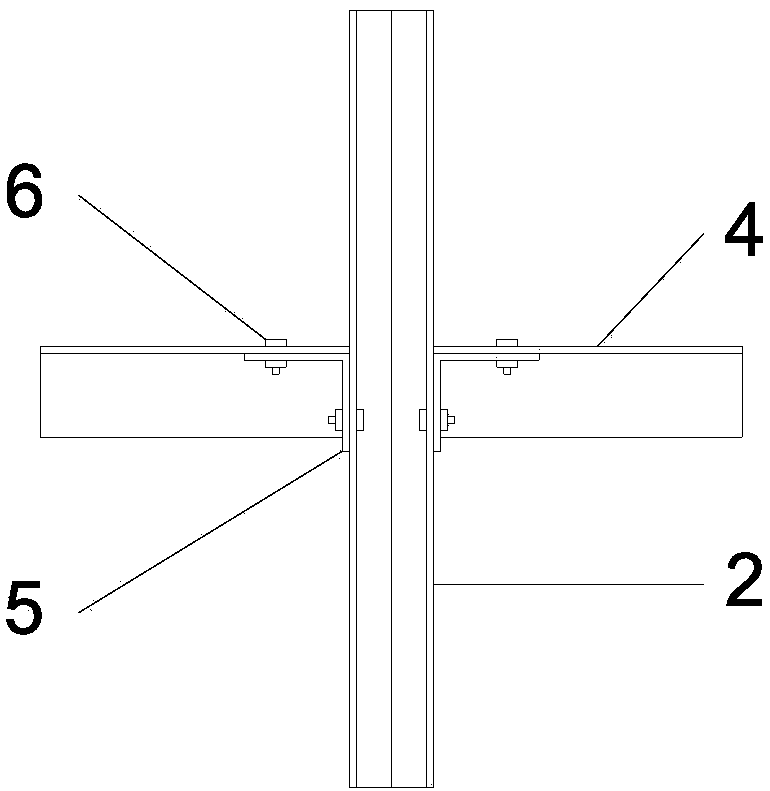

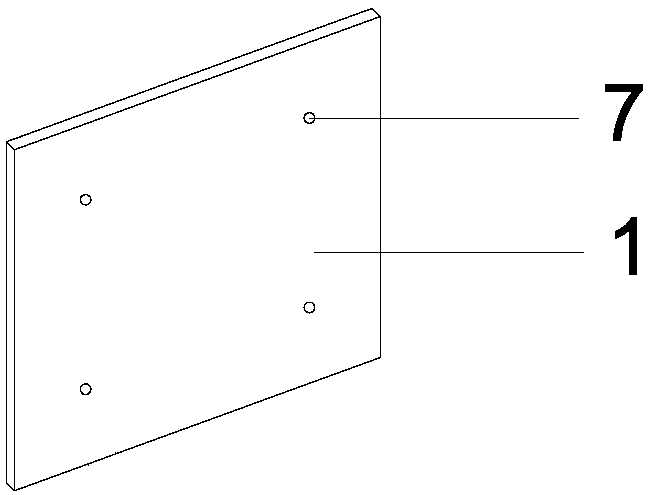

Bedding face stone or artificial board curtain wall structure and method

The invention discloses a bedding face stone or artificial board curtain wall structure and method. The bedding face stone or artificial board curtain wall structure and method solves the problem thatin the prior art, a curtain wall structure needs to be cut on-site and welded and assembled on-site, and has the beneficial effects that factory production is realized, prefabrication or assembly onsite can be realized, the dependence on skilled workers is reduced and the quality of assembly is ensured. According to the scheme, the bedding face stone or artificial board curtain wall structure comprises at least one set of curtain wall unit, and the curtain wall units each comprises at least two stand columns. A plurality of cross beams are connected between every two adjacent stand columns by bolts, and the cross beams are arranged in parallel with each other. The cross beams are provided with connecting pieces, and the bolts pass through the connecting pieces to be connected with the back side of a stone or an artificial board. Structural hanging pieces for hanging and connecting the curtain wall units to building wall embedded parts are arranged on the inner sides of the tops of the stand columns.

Owner:济南历下控股集团有限公司

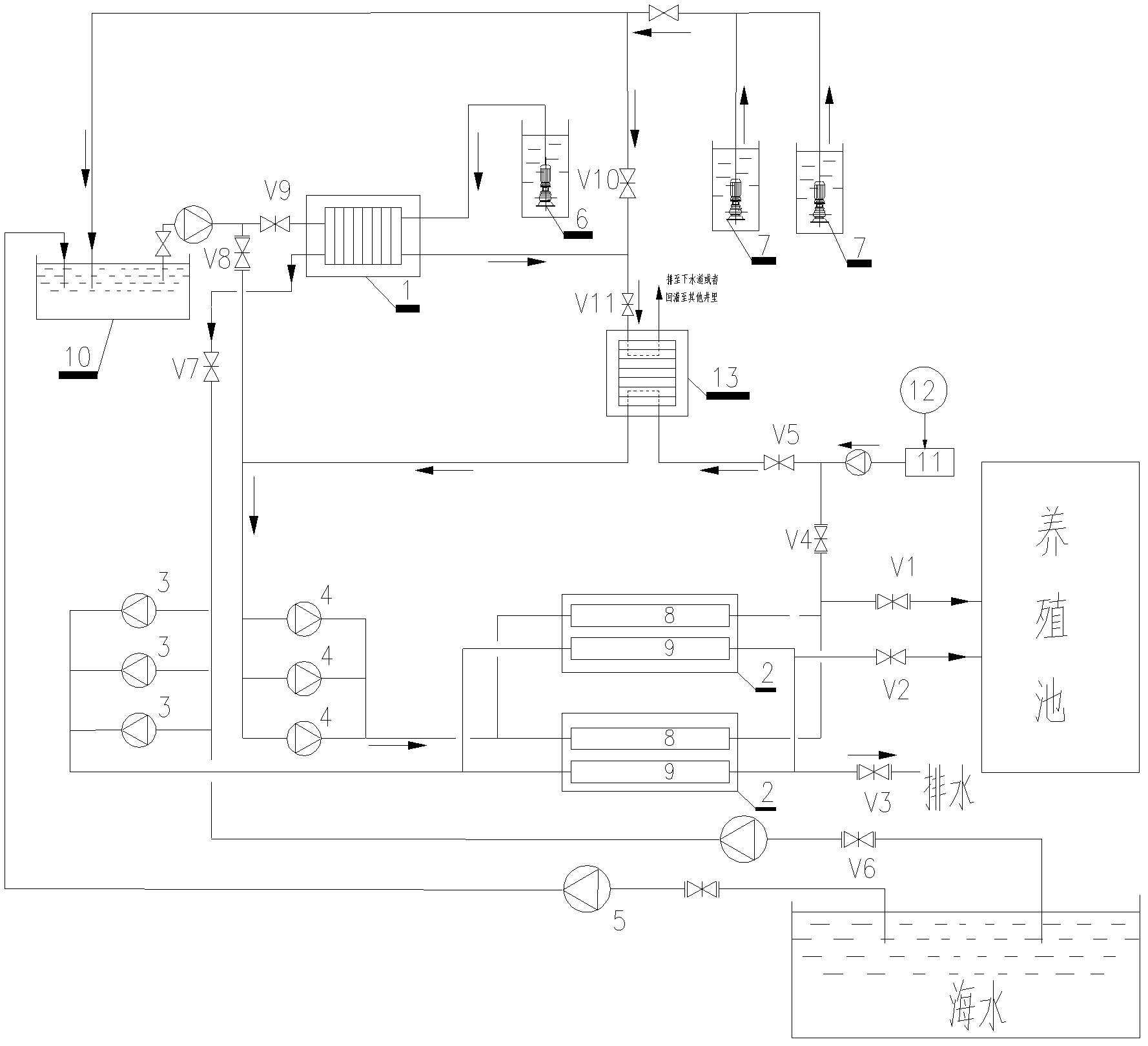

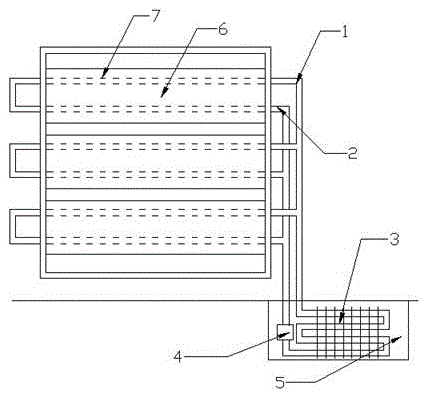

Summer and winter cold and hot water supply method for cultivation farm

InactiveCN102506521ASatisfy with salty waterSatisfies light, coldHeat pumpsWater source heat pumpWater source

The invention discloses a summer and winter cold and hot water supply method for a cultivation farm. In winter, firstly, acquired seawater and fresh water pumped from a fresh water well are mixed into mixed water; and secondly, after heat exchange, mixed water flows into condensers of two single-screw water source heat pump units in parallel and is turned into cultivation hot water after absorbing heat, after waste water formed by high-temperature water after heat exchange is mixed with fresh water pumped from the fresh water well, mixture of the waste water and the fresh water flows into a heat exchanger to indirectly exchange heat with water on evaporator sides of the two heat pump units, and circulating water in independent water systems of the evaporator sides flows into evaporators of the heat pump units in parallel after heat exchange to discharge heat. In summer, acquired seawater is mixed with fresh water pumped from the fresh water well, and then flows into the evaporators of the two heat pump units in parallel, and required cultivation cold water can be obtained after mixture of the seawater and the fresh water realizes heat discharge and is cooled; and a second channel of seawater directly flows into the condensers of the two heat pump units in parallel after being pressurized by a cooling water circulating water pump, and is drained after heat is absorbed. The method is efficient and energy-saving and is low in running expense.

Owner:TIANJIN UNIV

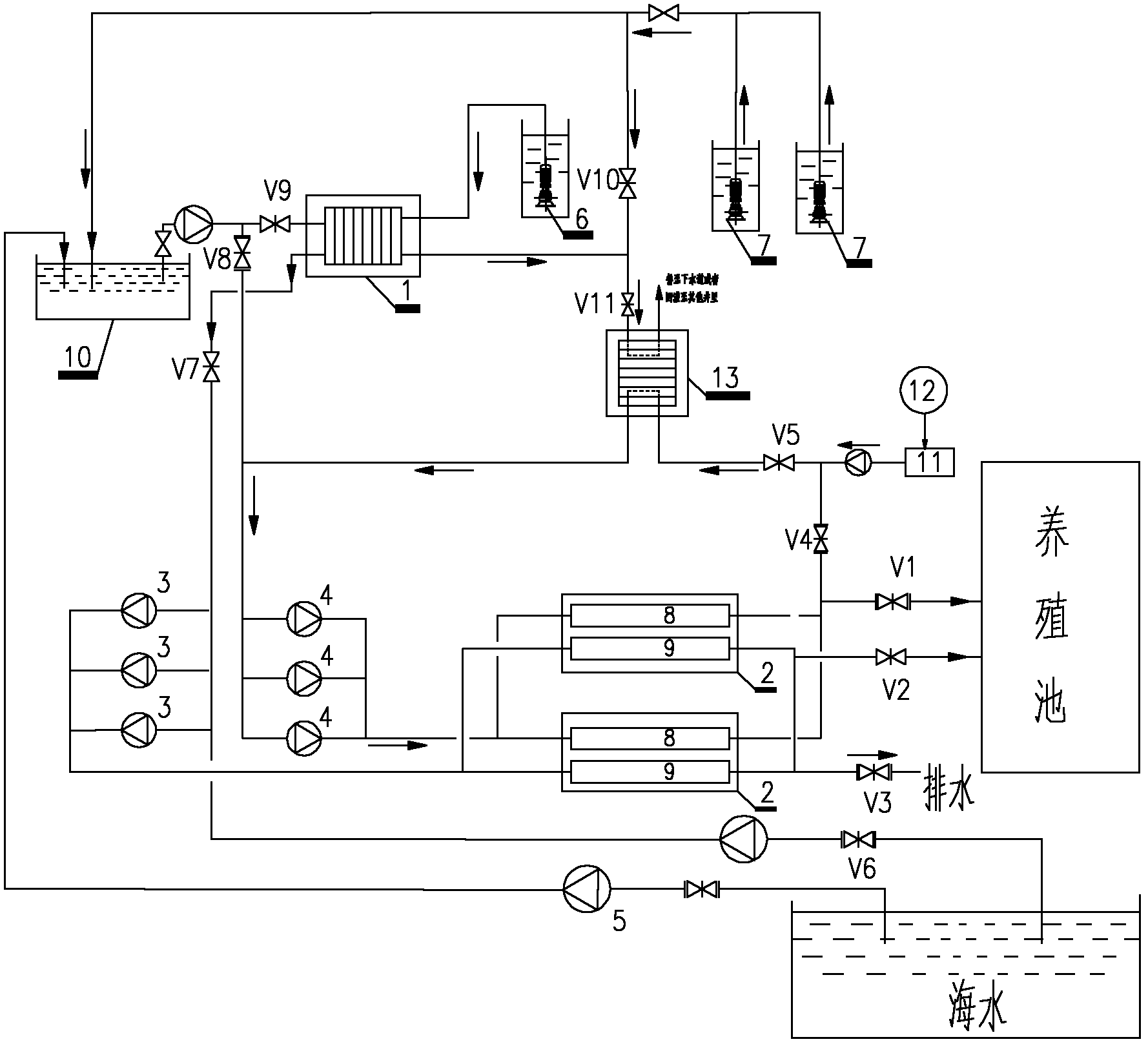

Electrochemical method for synthesizing organic silicon based polymer

InactiveCN104120442AEfficient synthesisSolve problems such as high energy consumption and high carbon dioxide emissionsElectrolysis componentsElectrolytic organic productionElectrochemical responseAlcohol

The invention relates to the field of organic chemistry. In order to solve the problems that at present, an electrochemical reaction needs relatively high temperature, reflux and complicated after-treatment processes, and an organic silicon based polymer necessary for synthesizing an organic silicon material can be hardly prepared from compounds, the invention provides an electrochemical method for synthesizing the organic silicon based polymer. The organic silicon based polymer is synthesized by enabling silicon dioxide and alcohol compounds to directly react. According to the electrochemical method provided by the invention, the electrochemical reaction is adopted, the organic silicon based polymer can be prepared by enabling rich SiO2 (more than 99%) such as sand and quartz in nature to react with alcohol, environment-friendly synthesis of the organic silicon material is realized, and the aims of saving energy and reducing emission.

Owner:HANGZHOU NORMAL UNIVERSITY

Method for enhanced treatment of heavy metal complex wastewater

ActiveCN113735323AAchieving Simultaneous AchievementImprove processing efficiencyWater/sewage treatment by irradiationWater treatment compoundsFenton reactionOrganic matter

The invention discloses a method for enhanced treatment of heavy metal complex wastewater, and belongs to the field of wastewater treatment. According to the method, the ferric iron generated after the Fenton reaction and the residual hydrogen peroxide are utilized to destroy and remove heavy metal complexes in the wastewater under the effect of visible light enhancement; meanwhile, the degradation of organic substances is enhanced, so that the target of rapidly and efficiently removing heavy metals and COD is achieved. The treatment method has the advantages of rapidness, high efficiency, simplicity in operation and easiness in realizing engineering application.

Owner:NANJING UNIV +1

Manufacturing method for prolonging service life of KR stirrer

The invention discloses a manufacturing method for prolonging the service life of a KR stirrer, specifically comprising the steps of: selecting a steel core, removing impurities on the surface of the steel core, washing and cleaning the steel core, and airing; welding a group of riveting pieces with different heights ranging from 30mm to 80mm on the surface of the steel core; covering a refractory fiber material layer with the thickness of 0-50mm on the surface of the steel core, coating a castable layer with the thickness of 60-120mm on the refractory fiber material layer, and baking the entire device for 36-60h at the temperature of 80-100 DEG C; and continuously heating the baked device to ensure that the temperature reaches 320-350 DEG C, and maintaining the temperature for 8-16h. The method is simple and energy-saving, and the used materials are not molten at high temperature and can stop the heat from being transmitted to the steel core, therefore, not only is the expansion degree of the steel core alleviated, but also the extrusion stress generated due to the expansion of the steel core can be effectively buffered so that the quantity of the cracks generated after the KR stirrer is baked can be reduced to the minimum.

Owner:宜兴市瑞华工业炉科技有限公司

Fabricated type curtain wall decorative column structure and method

The invention discloses a fabricated type curtain wall decorative column structure and method which solves the problem in the prior art that the decorative column needs to be mounted in a welded modeby a scaffold on the spot and has the beneficial effects that factory-like production can be achieved, assembly can be carried out in a factory, and dependence on skilled workers is reduced. Accordingto the technical scheme, the fabricated type curtain wall decorative column structure comprises a plurality of vertical stand columns forming a rectangular column body. Beams are arranged between every two stand columns in the rectangular column body to connect the columns. A wall baffle panel is fixed on one side of the rectangular column body. Decoration boards are fixed on the sides without the wall baffle panel of the rectangular column body. Structural hanging pieces for enabling the rectangular column body to be hanged to the curtain wall structure pre-embedded parts are arranged in theinner side of the wall baffle panel. Bolted connections are correspondingly carried out between the beams and the stand columns, the wall baffle panel and the stand columns, the decoration boards andthe stand columns or the beams.

Owner:济南历下控股集团有限公司

Multi-element mineral fertilizer taking copper smelting slag as raw material and preparation method of multi-element mineral fertilizer

InactiveCN104909962ASolve the problem of resource utilizationImprove qualityFertilizer mixturesMetallurgical slagResource utilization

The invention relates to multi-element mineral fertilizer taking copper smelting slag as a raw material and a preparation method of the multi-element mineral fertilizer, belonging to the technical field of utilization of metallurgical slag. The multi-element mineral fertilizer consists of the following components: the mass ratio of the copper smelting slag to available phosphorus substances is (1-20):1. The crushed copper smelting slag and the available phosphorus substances are mixed according to the mass ratio of (1-20):1, and the available phosphorus content of the mixture is 2.73-15%, so that the multi-element mineral fertilizer is obtained. The multi-element mineral fertilizer has various nutrients needed by crops for growth, so that the quality of the crops is improved. The multi-element mineral fertilizer can improve soil and achieves the effects of retaining fertilizer, saving fertilizer, increasing yield, improving color, improving the quality of the crops, improving the soil, retaining water and retaining soil moisture. According to the invention, the problem of the resource utilization of the copper smelting slag is solved, the resource utilization rate is increased, and the method is economical, energy-saving and environmentally friendly.

Owner:KUNMING YITANGCHUN TECH CO LTD

Chemical-additive-free and safe preparation method of graphene oxide

The invention discloses a chemical-additive-free and safe preparation method of graphene oxide, and belongs to the field of graphene preparation. Graphite processed products such as graphite coiled materials, strips and blocks are used as a raw material, andundergo two processes of liquid-phase electrochemical treatment and mechanical treatment, oxidation and stripping to prepare thethe graphene oxide. The electrochemical process is characterized in that in a water system without addition of any acid, alkali, salt or other electrolytes, a graphite material is taken as an anode, is electrifiedwith direct current under a soaking condition, and participates in oxidation and intercalation of graphite under the driving of an electric field to form a graphite oxide intermediate material; and inthe mechanical treatment, graphite oxide is subjected to low-intensity mechanical stripping, such as ultrasonic treatment to obtain the graphene oxide. According to the method, post-treatment processes such as washing are not needed, and energy consumption is greatly reduced; the obtained product does not contain any impurity such as metal ions, and has the advantages of controllable graphene oxidation degree, safe process, no pollution and the like.

Owner:BEIJING UNIV OF TECH

Preparation method for styrene-acrylic polyester resin

ActiveCN107163195ACharged stabilityGood compatibilityDevelopersBulk chemical productionPolymer scienceXerography

The invention relates to a preparation method for styrene-acrylic polyester resin, and belongs to the technical field of preparation of colorful powders for laser printing / xerography. The method comprises performing swelling polymerization reaction on styrene, an acrylate, polyester resin and an initiator under a supercritical condition, so as to prepare the styrene-acrylic polyester resin. The method is energy-saving, green and friendly to environment. Additionally, the styrene-acrylic polyester resin prepared by employing the method is electrically stable under high temperature and high humidity conditions, is low in photographic fixing temperature, and has good compatibility with a demolding agent.

Owner:邯郸汉光办公自动化耗材有限公司

Production method for increasing yield of xylose

The invention discloses a production method for increasing a yield of xylose, and relates to the technical field of functional sugar production. The production method comprises the following steps of raw material pretreatment, hydrolysis, primary purification, primary concentration, glucose removal with yeast, secondary purification, condensation crystallization, and crystallized xylose mother solution utilization. According to the production method, the active yeast is added for removing glucose, so that the purity of the xylose is improved; batch treatment is performed, so that the yield of the xylose in a first batch is increased; when a feed solution in a second batch is treated, a mother solution recycling method is adopted, so that the purity of the xylose keeps in a xylose crystallization range; and partial xylose is extracted from a mother solution, so that a purpose of entirely increasing the yield of the xylose is achieved. The production method replaces a primary ion exchange resin method with an electrodialysis desalination method, so that pH (potential of hydrogen) of a sugar solution is effectively increased; and the sugar solution suitable for removing the glucose with the yeast can be obtained without value adjustment. The method is high-efficiency, energy-saving and convenient to operate, and effectively increases the yield of the xylose.

Owner:FUTASTE PHARM CO LTD

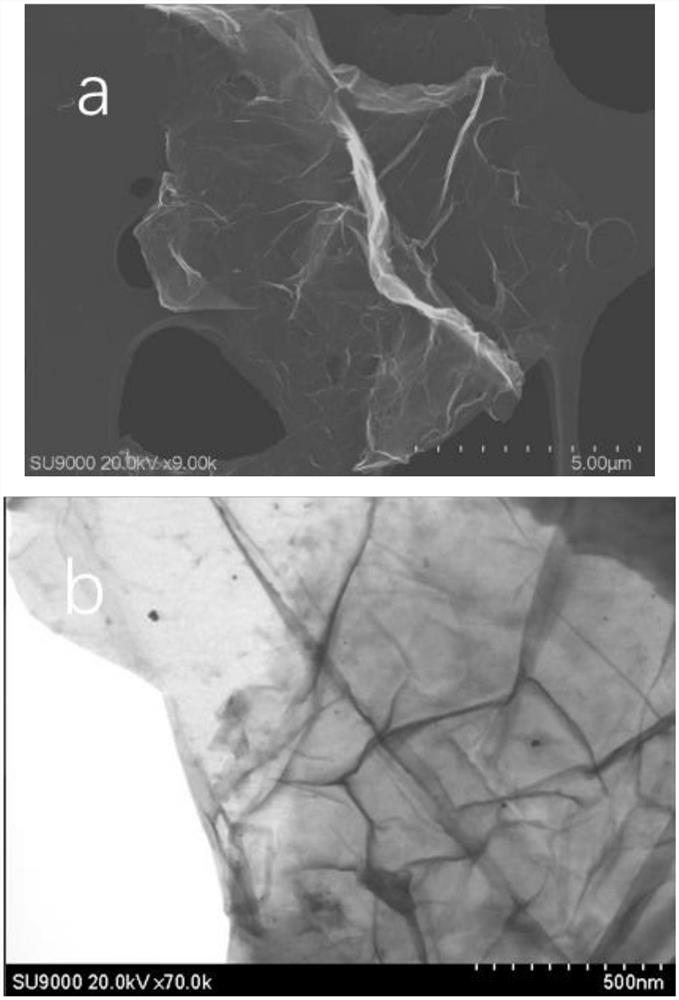

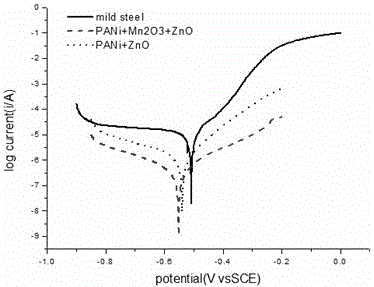

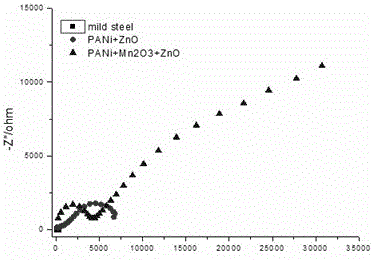

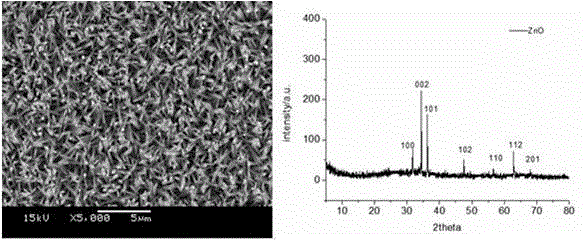

A conductive polymer polyaniline/manganese trioxide composite coating with strong adhesion and its preparation method

ActiveCN102942840BImprove bindingImprove anti-corrosion performanceAnti-corrosive paintsSolid/suspension decomposition chemical coatingConductive polymerOxide composite

The invention relates to a novel preparation method of a conductive polymeric material polyaniline and preparation of its composite material, belonging to the field of material synthesis and high performance anticorrosion materials. The conducting polymer polyaniline / manganic oxide composite coating having strong adhesiveness is prepared by growing zinc oxide nanorod on a metal matrix, then coating a polyaniline / manganic oxide composite coating on the metal matrix to embed the film in the zinc oxide nanorod, wherein the polyaniline / manganic oxide composite coating is prepared by mixing polyaniline with spherical manganic oxide according to the weight ratio of 99:1-90:10; putting the mixed material in N-methyl pyrrolidone solution, conducting ultrasonic vibration, and conducting magnetic stirring reaction for 6-48h. According to the invention, the prepared material can obviously improve the corrosion resistance of the metal matrix, compared with a bare carbon steel, the corrosion rate is reduced 25 times, and the anticorrosion performance is excellent. The method has the advantages of novel method, simple operation, low cost, and low energy consumption, and is suitable for practical application and large scale production.

Owner:DALIAN UNIV OF TECH

Method for absorbing nitrogen oxide tail gas and generating by-product p-phenylenediamine by using aniline

ActiveCN102731320BReduce manufacturing costReduce harmPreparation by N-O/N-N bondsP-NitroanilineP-Aminoazobenzene

The invention discloses a method for absorbing nitrogen oxide tail gas and generating by-product p-phenylenediamine by using aniline. The method comprises the following steps of: reacting part aniline with NOx to obtain diazonium salt; reacting the diazonium salt with the non-reacted aniline to obtain 1,3-diphenyltriazene, wherein the reaction products contain less p-nitroaniline and o-nitroaniline; making the 1,3-diphenyltriazene in a rearrangement reactor generate the rearrangement reaction at 30 DEG C-120 DEG C to convert into p-aminoazobenzene, wherein 90% of the 1,3-diphenyltriazene is converted into the p-aminoazobenzene and the remaining 1,3-diphenyltriazene is converted into o-aminoazobenzene and few impurities after the rearrangement reaction; separating the low distillates from the rearranged materials; and carrying out the hydrogenation reaction: using Raney nickel as a catalyst, continuously inputting hydrogen gas and controlling the pressure and the temperature to be 0.2MPa-4MPa and 25 DEG C-150 DEG C respectively to synthesize the p-phenylenediamine. The method provided by the invention reduces the production cost of the p-phenylenediamine and also reduces environmental pollution. A DCS (distributed control system) computer control system is used so that the automation of the whole system is realized and meanwhile the production efficiency is high.

Owner:HANGZHOU LONGSHAN CHEM CO LTD

A distribution box mounting plate

InactiveCN103326262BRealize heat dissipationImprove cooling effectSubstation/switching arrangement cooling/ventilationSocial benefitsHeat conducting

The invention discloses a power distribution box mounting plate. According to the power distribution box mounting plate, through the combination of a heat conducting tube and a mounting guide rail of an electrical component in a power distribution box, circulating pump liquid cooling is used, and the heat radiation of the electrical component is realized. Compared with a forced convection type passive cooling method such as a fan, the cooling method of the invention is more suitable for the working environment with high heat flow density of the electrical component, the heat radiation is more stable, there is no heat radiation dead corner, the structure is simple, the reconstruction of an ordinary power distribution box can be realized, and the power distribution box mounting plate has good social benefits.

Owner:国网山东省电力公司沂源县供电公司

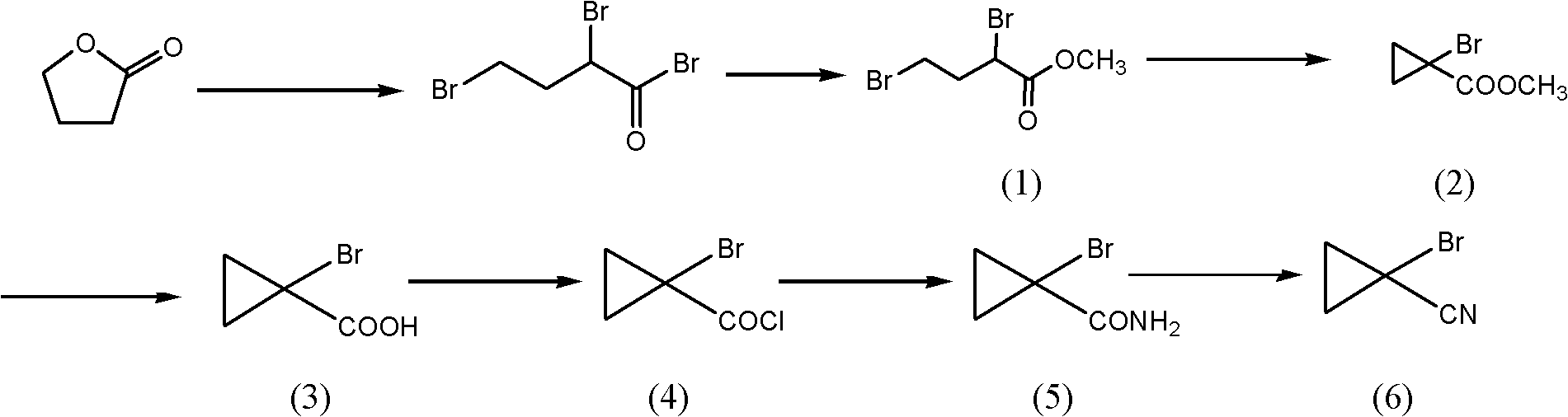

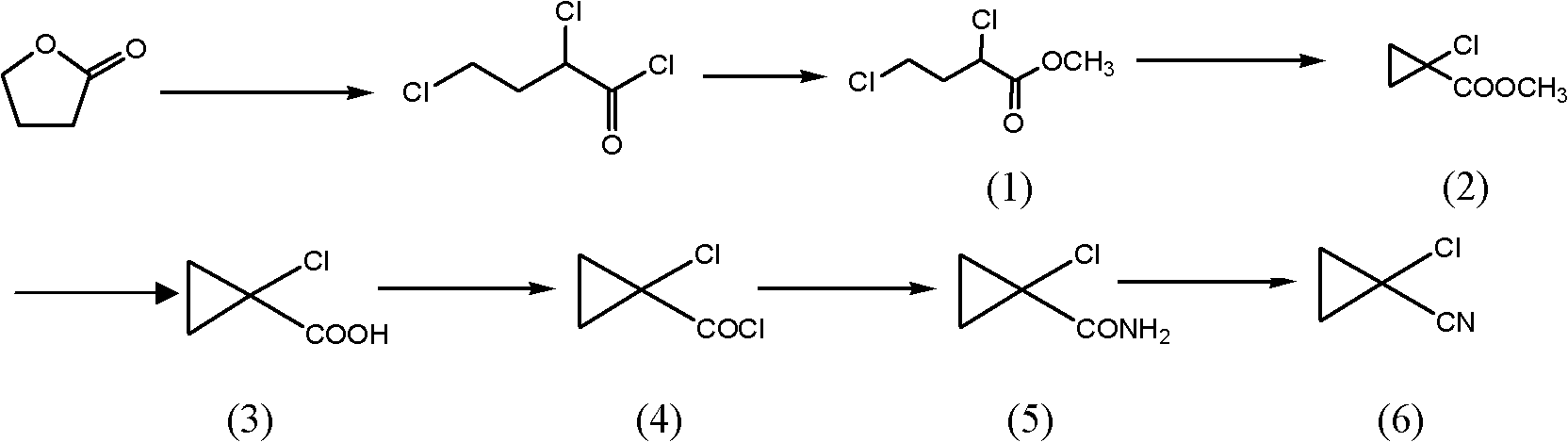

Preparation method of cyclopropyl fenpropathin derivative

ActiveCN102249949BReduce dosageRaise the reaction temperaturePreparation by carboxylic acid amide dehydrationBiochemical engineeringCombinatorial chemistry

The invention relates to a preparation method of a cyclopropyl fenpropathin derivative. The preparation method comprises the following steps: synthesizing a cyclopropyl carboxylic acid derivative by taking gamma-butylrolactone as a raw material; and then carrying out acylation, amination and dewatering reactions so as to prepare the cyclopropyl fenpropathin derivative. The method provided by the invention can be used for large-scale industrial production, has the advantages of low energy consumption, less side reactions, high yield, high product purity and the like, and is an ideal safe and efficient energy-saving consumption-reducing process for preparing the cyclopropyl fenpropathin derivative.

Owner:DALIAN QIKAI MEDICAL TECH +1

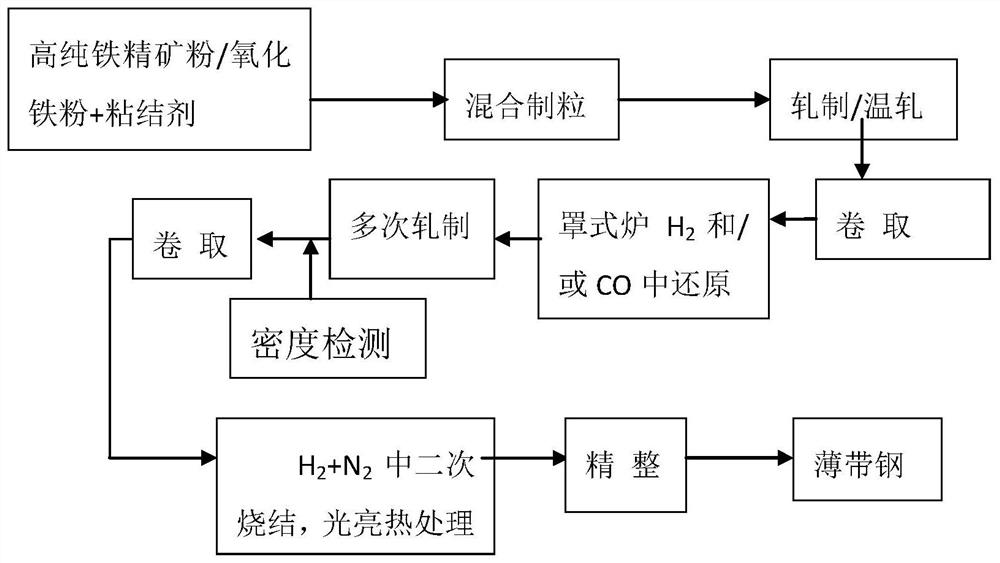

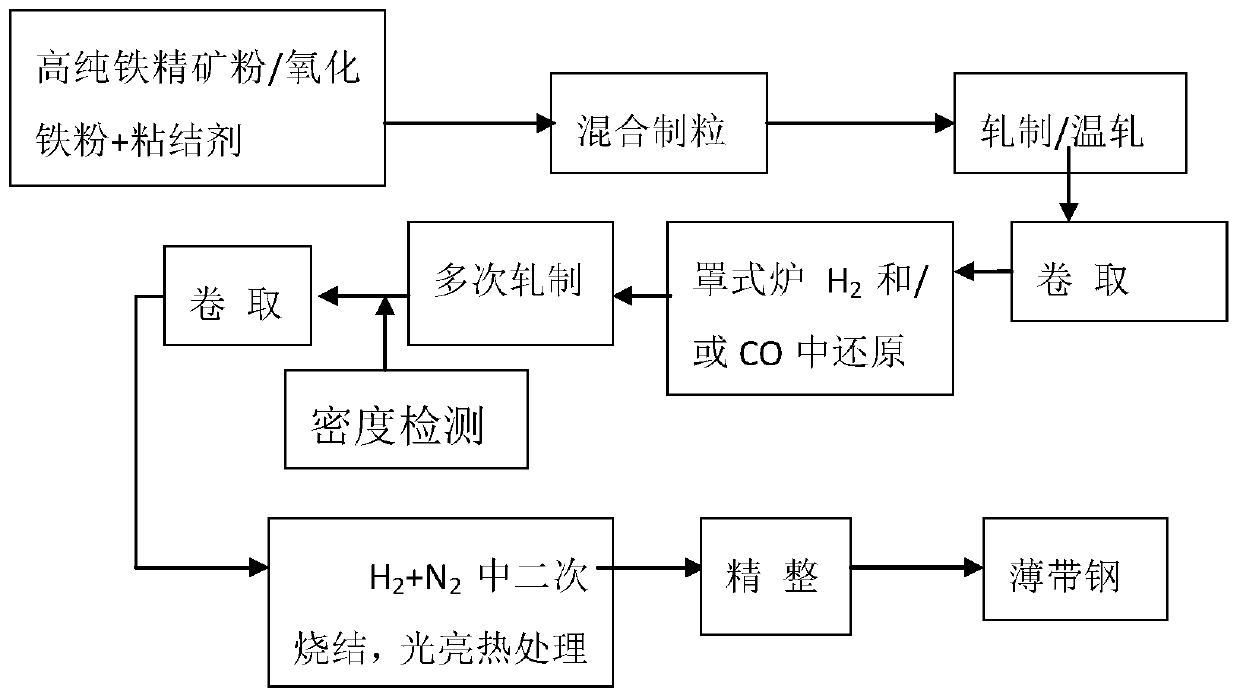

A method for directly preparing thin strip steel from iron oxide

ActiveCN110699588BLengthy processIncrease investmentMetal rolling arrangementsSteelmakingStrip steel

The invention relates to a method for directly preparing a thin strip from ferric oxide. The method comprises the following steps of weighing super iron concentrate powder / iron oxide powder with the content larger than 71.5% and an organic binder according to the proportion, mixing in a mixing machine for 30-60 min, pelletizing, sequentially performing preliminary rolling and winding, reducing, rolling and winding for multiple times, and finally sequentially performing secondary sintering, bright heat treatment, finishing and winding, thereby obtaining the thin strip. During the whole production process, ironmaking, steelmaking, hot steel rolling, pickling and alkaline cleaning are not needed, as is known to all, the ironmaking and steelmaking and other processes are performed at the temperature of about 1600 DEG C, and pollution caused by ironmaking, steelmaking, steel rolling, pickling and alkaline cleaning is very serious. In the method, reducing is performed with H2 and / or CO gas,the highest temperature is about 1200 DEG C, three wastes are subjected to ultra-low emission and zero emission, and compared with a traditional ferrous metallurgy and steel powder rolling process, the method is simpler, more environmentally-friendly and more energy-saving.

Owner:武汉桂坤科技有限公司

Manufacturing method for prolonging service life of KR stirrer

The invention discloses a manufacturing method for prolonging the service life of a KR stirrer, specifically comprising the steps of: selecting a steel core, removing impurities on the surface of the steel core, washing and cleaning the steel core, and airing; welding a group of riveting pieces with different heights ranging from 30mm to 80mm on the surface of the steel core; covering a refractory fiber material layer with the thickness of 0-50mm on the surface of the steel core, coating a castable layer with the thickness of 60-120mm on the refractory fiber material layer, and baking the entire device for 36-60h at the temperature of 80-100 DEG C; and continuously heating the baked device to ensure that the temperature reaches 320-350 DEG C, and maintaining the temperature for 8-16h. Themethod is simple and energy-saving, and the used materials are not molten at high temperature and can stop the heat from being transmitted to the steel core, therefore, not only is the expansion degree of the steel core alleviated, but also the extrusion stress generated due to the expansion of the steel core can be effectively buffered so that the quantity of the cracks generated after the KR stirrer is baked can be reduced to the minimum.

Owner:宜兴市瑞华工业炉科技有限公司

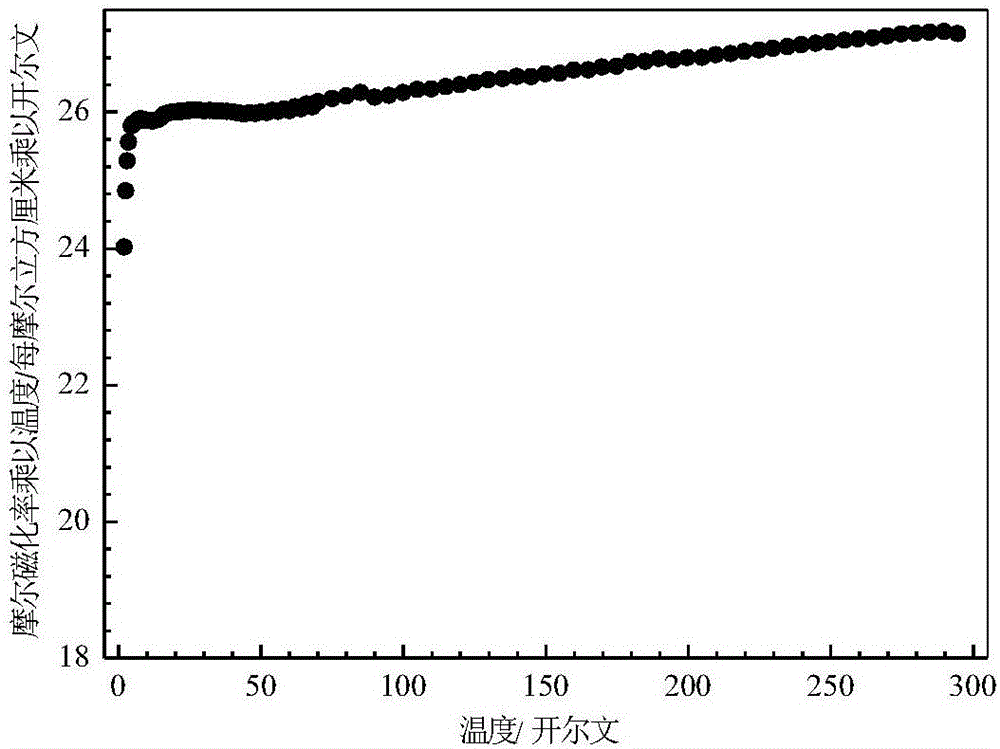

Preparation and application of molecular-based low-temperature magnetic refrigeration material of cobalt-gadolinium cluster base

InactiveCN107527697AHigh magnetic entropy changeWay to save energyGroup 8/9/10/18 element organic compoundsInorganic material magnetismSolventSpace - property

The invention discloses preparation and application of a molecular-based low-temperature magnetic refrigeration material of cobalt-gadolinium cluster base, and belongs to the field of inorganic chemistry. Gadolinium chloride, cobalt chloride, sodium methylate and diethanol amine are adopted as raw materials, methyl alcohol is adopted as a solvent, and a self-assembly reaction is carried out at normal temperature to prepare the molecular-based low-temperature magnetic refrigeration material of the cobalt-gadolinium cluster base. The structure of the prepared low-temperature magnetic refrigeration material is characterized in that the molecular formula is [Co8Gd2(L)4(HL)4(HCOO)4(OH)2(Cl)2(CH3OH)2]2Cl-.4CH3OH.2H2O, the molecular weight is 2199.12, and according to crystallography data, the value of alpha is equal to 71.009(2)o, the value of beta is equal to 67.615(2)o, the value of gamma is equal to 65.536(2)o, the value of z is equal to 1, the material belongs to a triclinic crystal, the space property of the material belongs to P-1 space groups, and specific information is shown in the description. The material has excellent low-temperature magnetic refrigeration performance; when the temperature is 3 K, by magnetizing the material at the constant temperature, the maximum magnetic entropy change can reach 16.3 J / (kg K) when an applied magnetic field is 5T. The raw materials are easy to obtain, and the preparation method can save energy, and is convenient to operate and great in repeatability.

Owner:ANYANG INST OF TECH

Production method capable of prolonging service life of KR (Krypton) stirrer

Owner:宜兴市瑞华工业炉科技有限公司

Method for directly preparing thin strip from ferric oxide

ActiveCN110699588AShort processReduce equipment maintenanceMetal rolling arrangementsPelletizingFerrous metallurgy

The invention relates to a method for directly preparing a thin strip from ferric oxide. The method comprises the following steps of weighing super iron concentrate powder / iron oxide powder with the content larger than 71.5% and an organic binder according to the proportion, mixing in a mixing machine for 30-60 min, pelletizing, sequentially performing preliminary rolling and winding, reducing, rolling and winding for multiple times, and finally sequentially performing secondary sintering, bright heat treatment, finishing and winding, thereby obtaining the thin strip. During the whole production process, ironmaking, steelmaking, hot steel rolling, pickling and alkaline cleaning are not needed, as is known to all, the ironmaking and steelmaking and other processes are performed at the temperature of about 1600 DEG C, and pollution caused by ironmaking, steelmaking, steel rolling, pickling and alkaline cleaning is very serious. In the method, reducing is performed with H2 and / or CO gas,the highest temperature is about 1200 DEG C, three wastes are subjected to ultra-low emission and zero emission, and compared with a traditional ferrous metallurgy and steel powder rolling process, the method is simpler, more environmentally-friendly and more energy-saving.

Owner:武汉桂坤科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com