Chemical-additive-free and safe preparation method of graphene oxide

A chemical and graphene technology, applied in the field of electrochemical preparation of graphene oxide, can solve problems such as safety risks and complex preparation processes, and achieve the effects of easy regulation, high purity and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

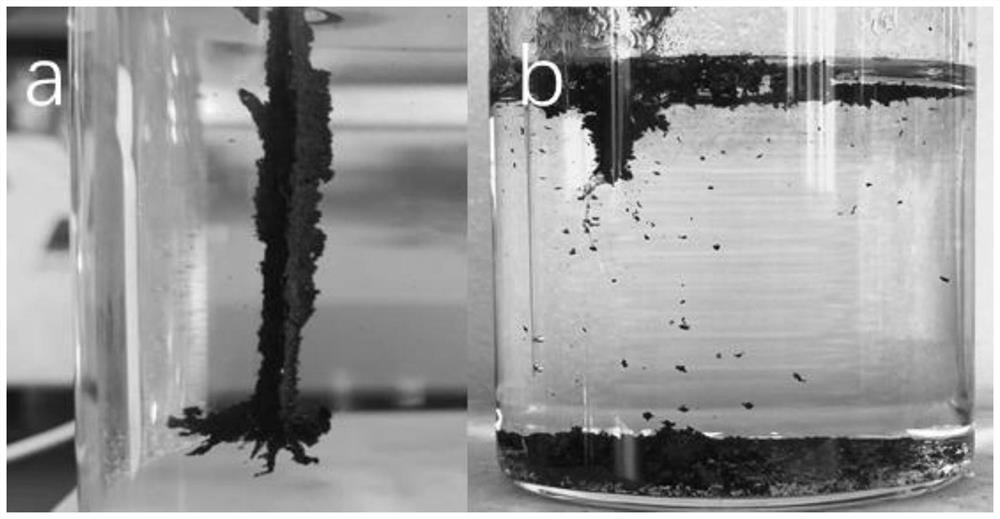

[0028]Under normal temperature and pressure conditions, the solution in the electrolytic cell is pure water with a conductivity of 24.8μs / cm, a flexible graphite paper material with a carbon content of 99.8% by weight is used as the anode, platinum sheets are used as the cathode, and the distance between the two electrodes is 0.170mm. A cellulose porous membrane is blocked by 0.159mm, and the bias voltage is +5V; when the applied voltage is about 60s, it can be observed that graphite oxide particles are attached to the anode. After 20s ultrasonic peeling, a yellow graphene oxide solution (figure 2 a) The carbon to oxygen ratio reaches 2:1. The solution is then freeze-dried to directly obtain graphene oxide powder.

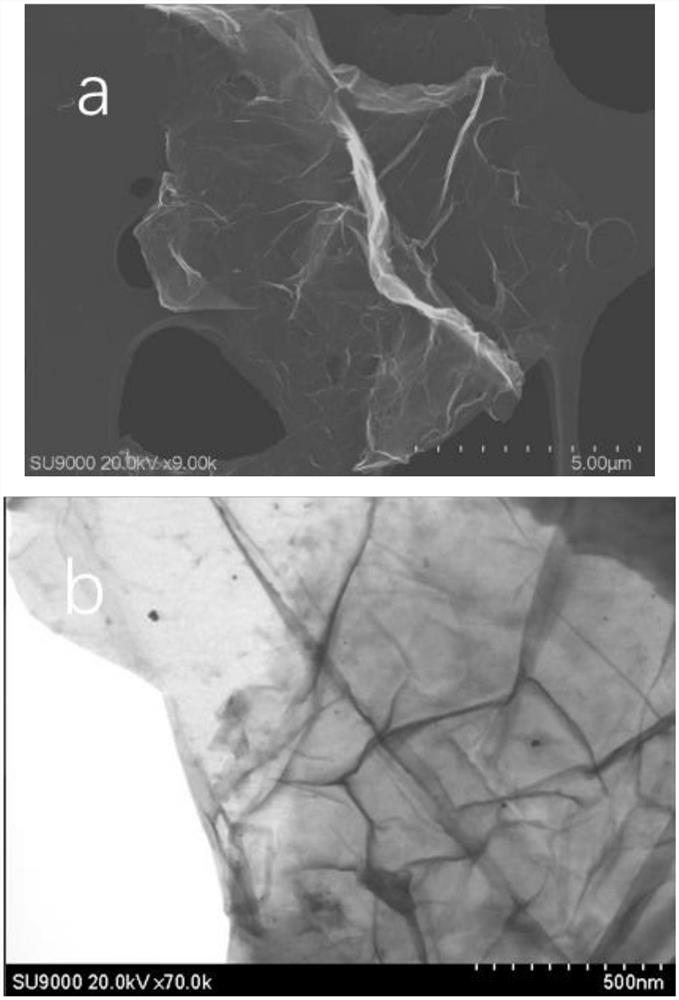

[0029]Under a scanning transmission electron microscope (Hitachi STEM SU9000, acceleration voltage 20KV), the secondary electron morphology of graphene oxide obtained by the above process (image 3a), transmission electron micrograph (image 3b), the atomic force micrograph (...

Embodiment 2

[0031]This embodiment has the same process as the first embodiment. The difference is that the electrode spacing is 10mm, the diaphragm thickness is 0mm, and the bias voltage is +60V. When the voltage is applied for about 120 hours, a large amount of graphite oxide particles can be found in the solution. The solution was peeled off ultrasonically for 20 seconds to obtain a darker color graphene oxide solution (figure 2 b). STEM electron microscopy characterization was performed under the same conditions, and the results were consistent with Example 1.

Embodiment 3

[0033]This embodiment has the same process as the first embodiment. The difference is that the electrode spacing is increased to 10mm, the diaphragm thickness is 0mm, and the voltage application time is increased to 180 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com