Extraction agent and treatment method of high-salt and high-phenol wastewater

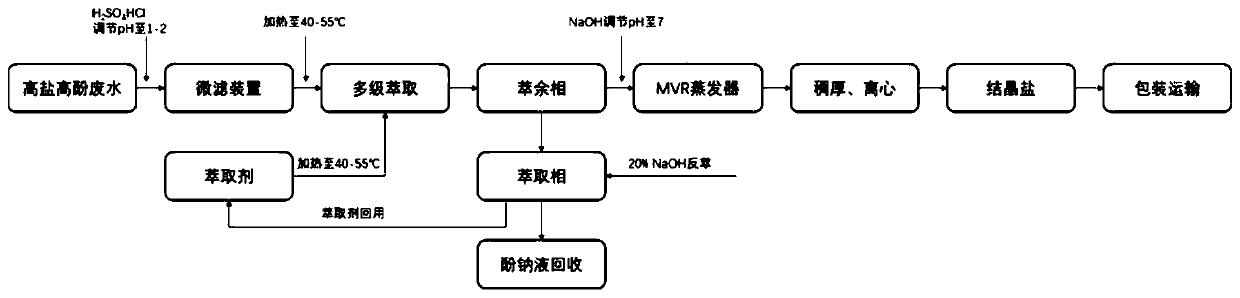

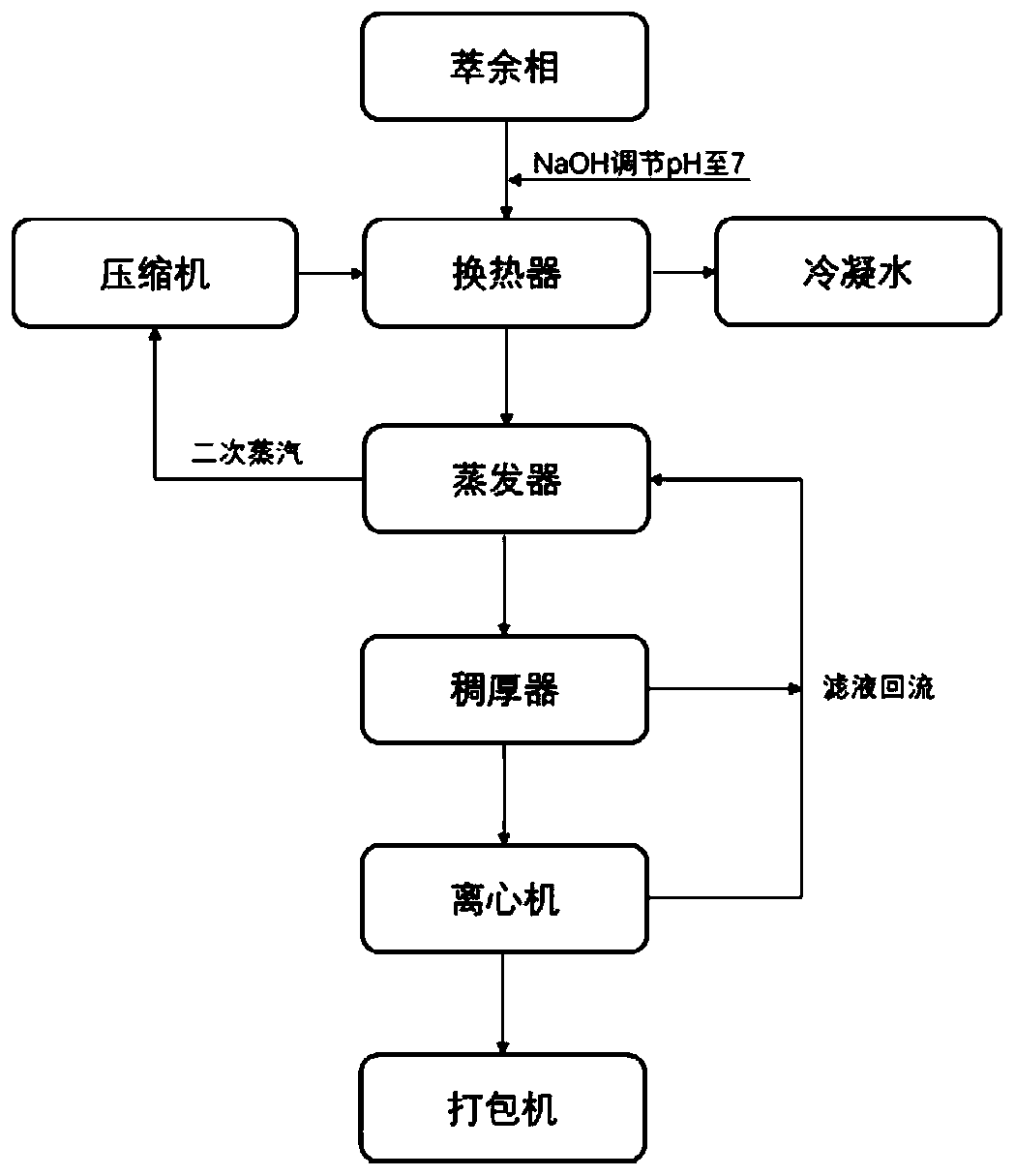

A treatment method and extraction agent technology are applied in the treatment field of extraction agent and high-salt and high-phenol wastewater, which can solve the problems of large investment in equipment, high energy consumption, and difficulty in application, so as to ensure the treatment effect, improve the extraction effect, and reduce the treatment cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] This embodiment provides an extractant, which includes 40 parts of sulfonated kerosene, 5 parts of tributyl phosphate and 10 parts of trioctyl tertiary amine.

[0041] The total amount of high-salt and high-phenol wastewater to be treated is 2m 3 / h, where Na 2 SO 4 The content is 100000mg / L, and the total phenol content is 15000ppm. This embodiment also provides a treatment method for high-salt and high-phenol wastewater, comprising the following steps:

[0042] S1, pretreatment;

[0043]Add 98% concentrated sulfuric acid to the high-salt and high-phenol wastewater to adjust the pH to 2. The acid-adjusted wastewater enters the microfiltration device for filtration to form a filtrate. The pore size of the flat membrane of the microfiltration is 1 micron.

[0044] S2, extraction;

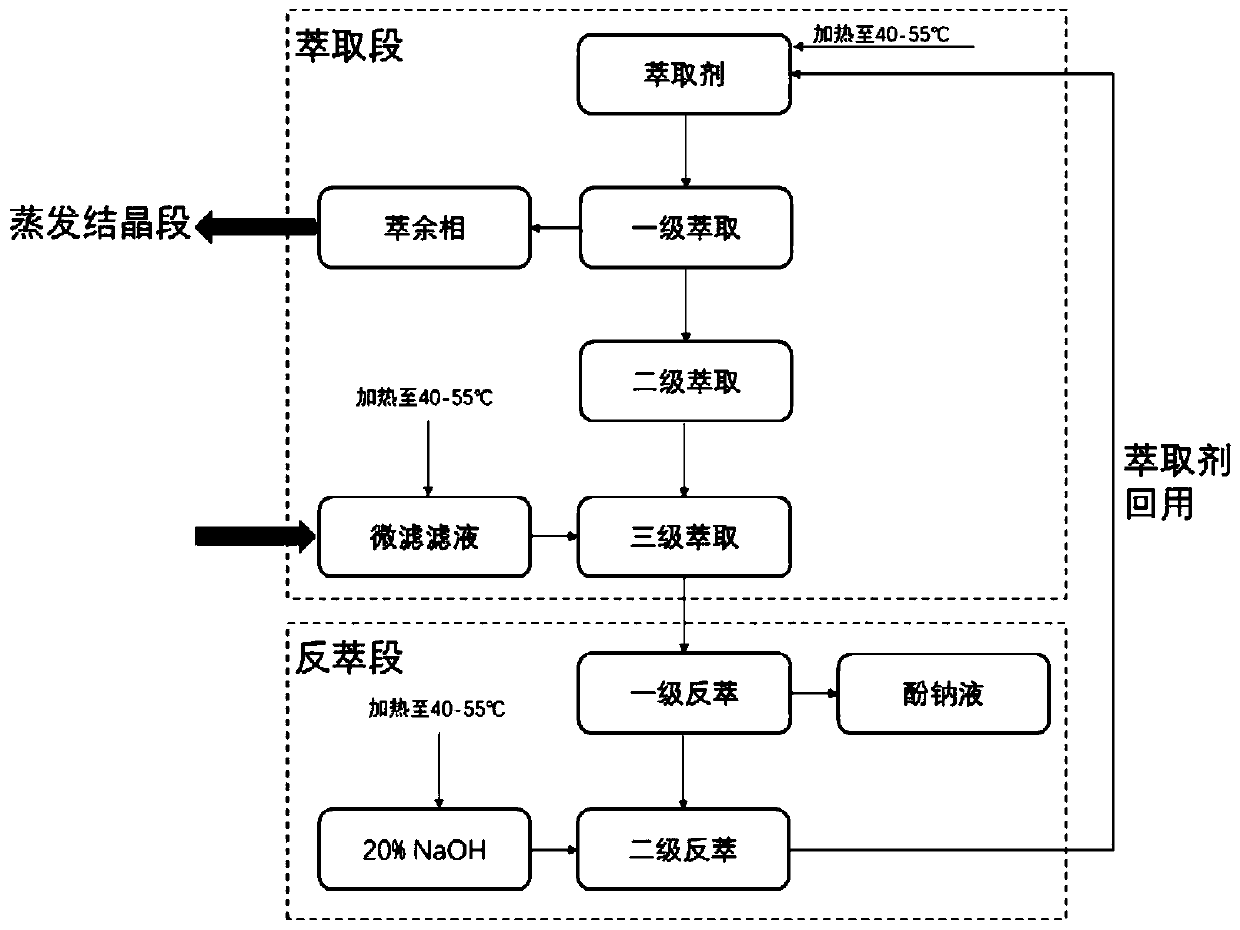

[0045] In this embodiment, the extraction treatment section has 5 stages of extraction, including 3 stages of extraction and 2 stages of stripping.

[0046] The filtrate and extractant w...

Embodiment 2

[0053] This embodiment provides an extractant, which includes 90 parts of sulfonated kerosene, 70 parts of tributyl phosphate and 80 parts of trioctyl tertiary amine.

[0054] The total amount of high-salt and high-phenol wastewater to be treated is 5m 3 / h, wherein the NaCl content is 200000mg / L, and the total phenol content is 20000ppm. This embodiment also provides a treatment method for high-salt and high-phenol wastewater, comprising the following steps:

[0055] S1, pretreatment;

[0056] Add 20% dilute hydrochloric acid to the high-salt and high-phenol wastewater to adjust the pH to 2. The acid-adjusted wastewater enters the microfiltration device for filtration. The pore size of the flat membrane of the microfiltration is 1 micron.

[0057] S2, extraction;

[0058] In this embodiment, the extraction treatment section has 5 stages of extraction, including 3 stages of extraction and 2 stages of stripping.

[0059] The filtrate and extractant were heated to 50°C, resp...

Embodiment 3- Embodiment 5

[0066] The raw materials of the extractant provided in Example 3-Example 5 are all the same, the difference is that the ratio is different, and the operation of the treatment method of the high-salt and high-phenol wastewater provided by Example 3-Example 5 is basically the same, the difference is that the specific operating conditions are different.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com