Method for preparing high-quality gasoline from cracking biological oil

A bio-oil and high-quality technology, applied in the preparation of liquid hydrocarbon mixtures, biological raw materials, petroleum industry, etc., can solve the problems of high reaction temperature, rapid coking and deactivation, complex reactions, etc., and achieve low cost, simple process, and raw materials Effects from a wide range of sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Example 1: Hydrodeoxygenation of initial bio-oil as raw material to prepare gasoline hydrocarbon fuel

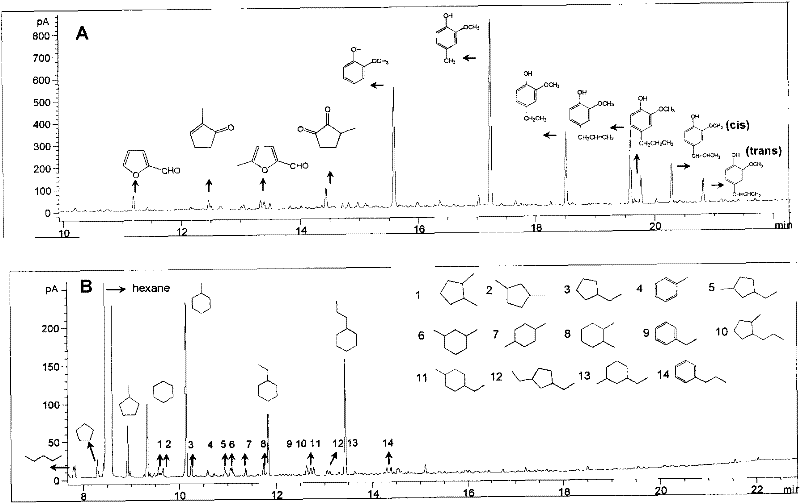

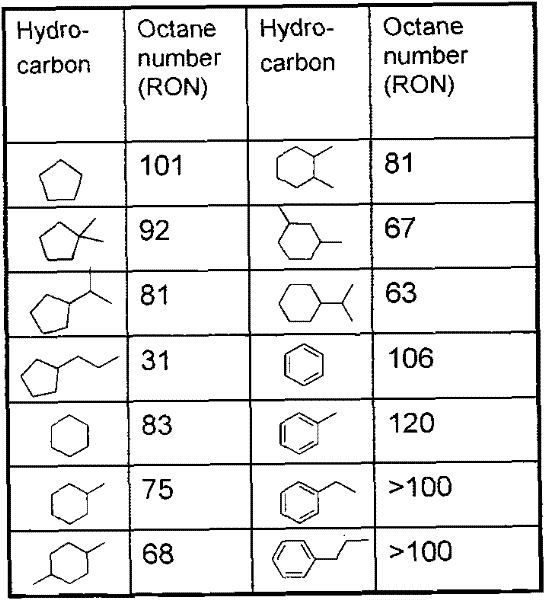

[0021] This embodiment directly uses the initial bio-oil rich in cellulose, hemicellulose and lignin cracked organic small molecule liquid mixture as raw material (component analysis see figure 1 A, mainly including furans C 5 -C 6 derivatives and phenolic C 6 -C 9 Derivatives), through one-step catalytic hydrodeoxygenation of the organic small molecule mixture to prepare gasoline hydrocarbon fuels. The specific method is: take 100ml of crude bio-oil (red and black viscous liquid cracked from pine trees, purchased from BTG-BTL company in the Netherlands) and extract it three times with 50ml of cyclohexane, and combine the extracts after the extraction. The extract was concentrated by distillation under reduced pressure, together with 2.0g Ni / HMFI catalyst (20.wt%, self-made), and 80ml water were added to the high-pressure Parr kettle (the pH value of the reaction ...

Embodiment 2

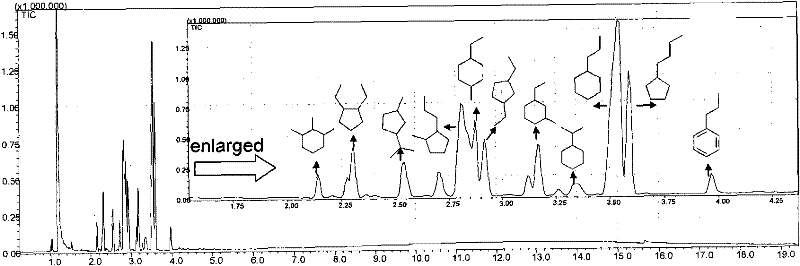

[0025] Example 2: Preparation of gasoline hydrocarbon fuels using lignin-derived phenolic compounds as raw materials

[0026] In this example, lignin-derived C6 -C 9 The functionalized 4-propylphenol, 2-methoxy-4-propylphenol and 2,6-dimethoxy-4-propylphenol are used as raw materials, and the hydrocarbons are prepared by direct one-step hydrodeoxygenation. The specific method is as follows: 0.01 mol of phenolic compound, 2.0 g of 20 wt.% Ni / HMFI and 80 ml of water are mixed and then added to the high-pressure Parr kettle. After the reactor was replaced with hydrogen three times, 50 bar of hydrogen was charged under normal pressure, and the temperature was raised to 250° C. to react for 2 hours. After the reaction, it was naturally cooled to room temperature, and the organic phase was extracted with ethyl acetate for qualitative and quantitative detection by GC and GC-MS, and the gas products were detected by IR. The product conversion results after the hydrodeoxygenation rea...

Embodiment 3

[0032] Example 3: Preparation of gasoline hydrocarbon fuels using cellulose and hemicellulose derived furan compounds as raw materials

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com