Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

114results about How to "Uniform void" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

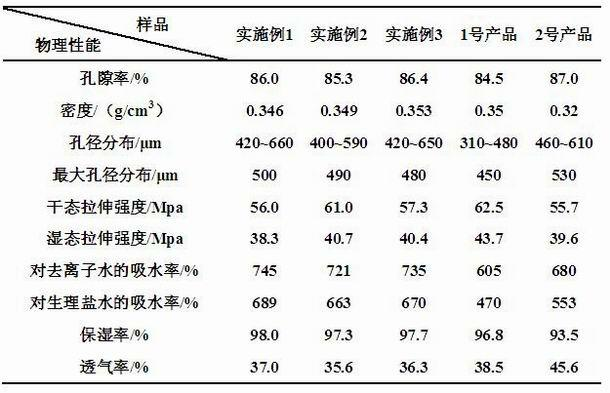

Method for preparing nanosilver/nano silicon dioxide-containing antibacterial biological dressing

InactiveCN101912634AGood biocompatibilityGood hemostasis and antibacterialAbsorbent padsBandagesFiberBiological dressing

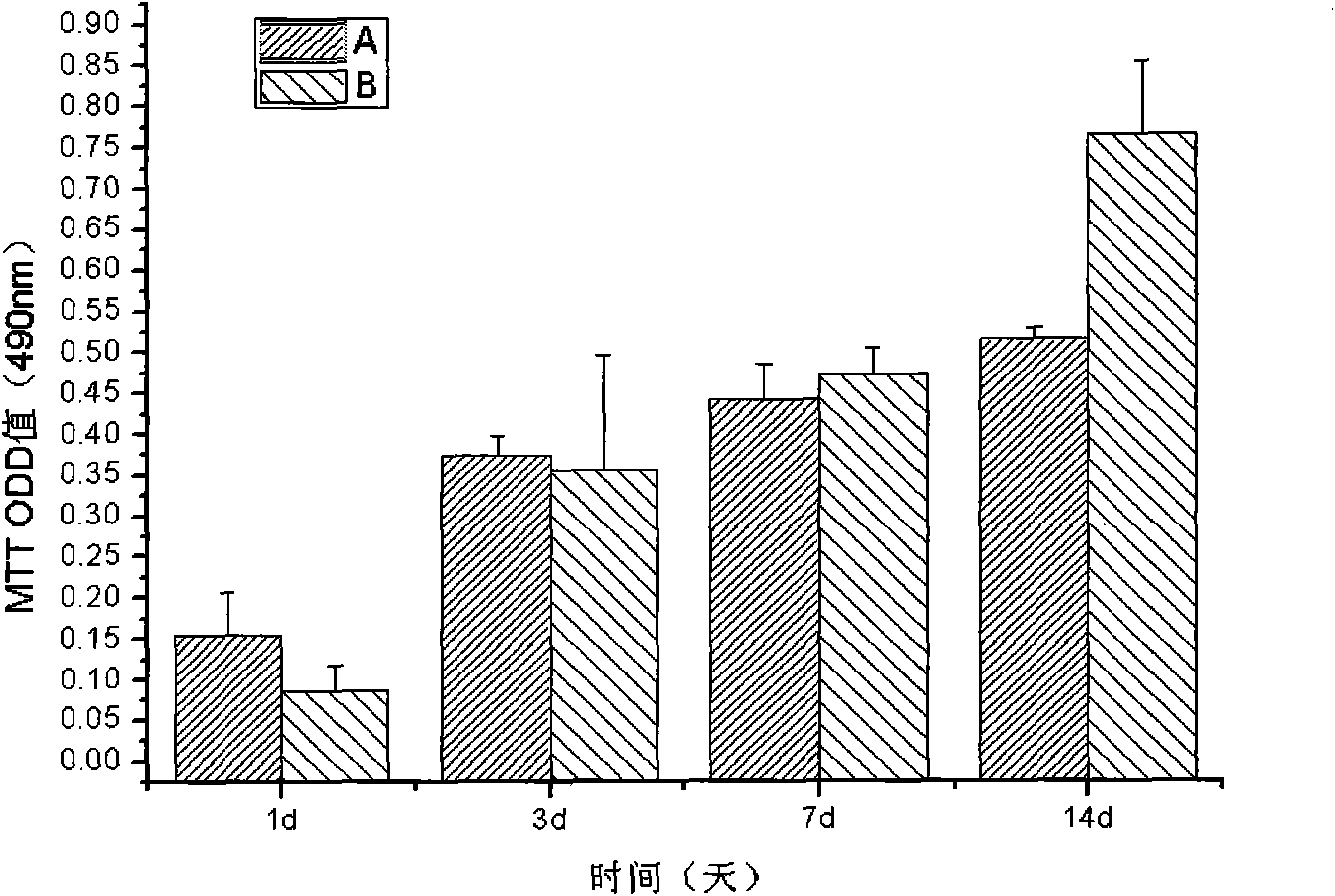

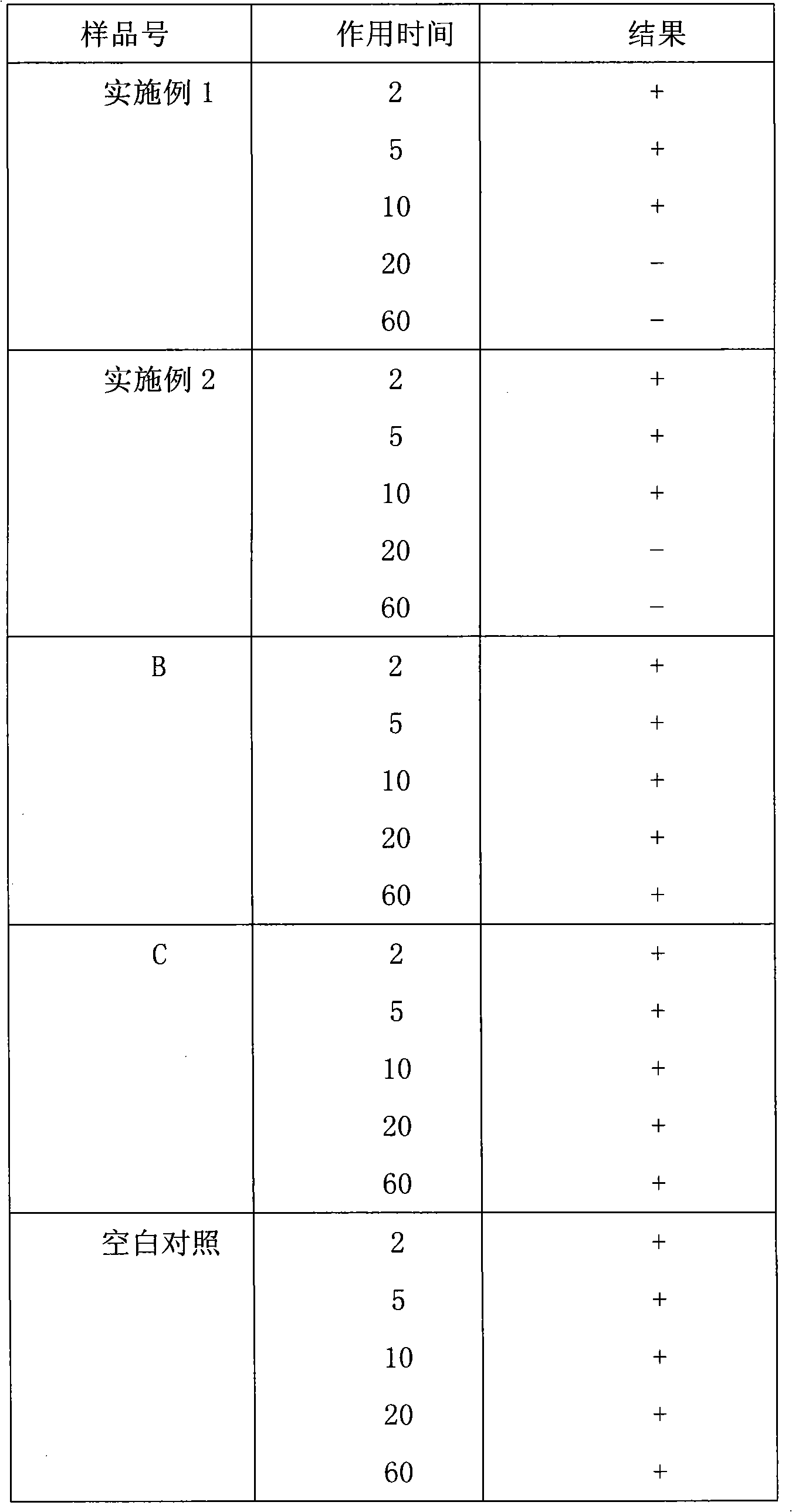

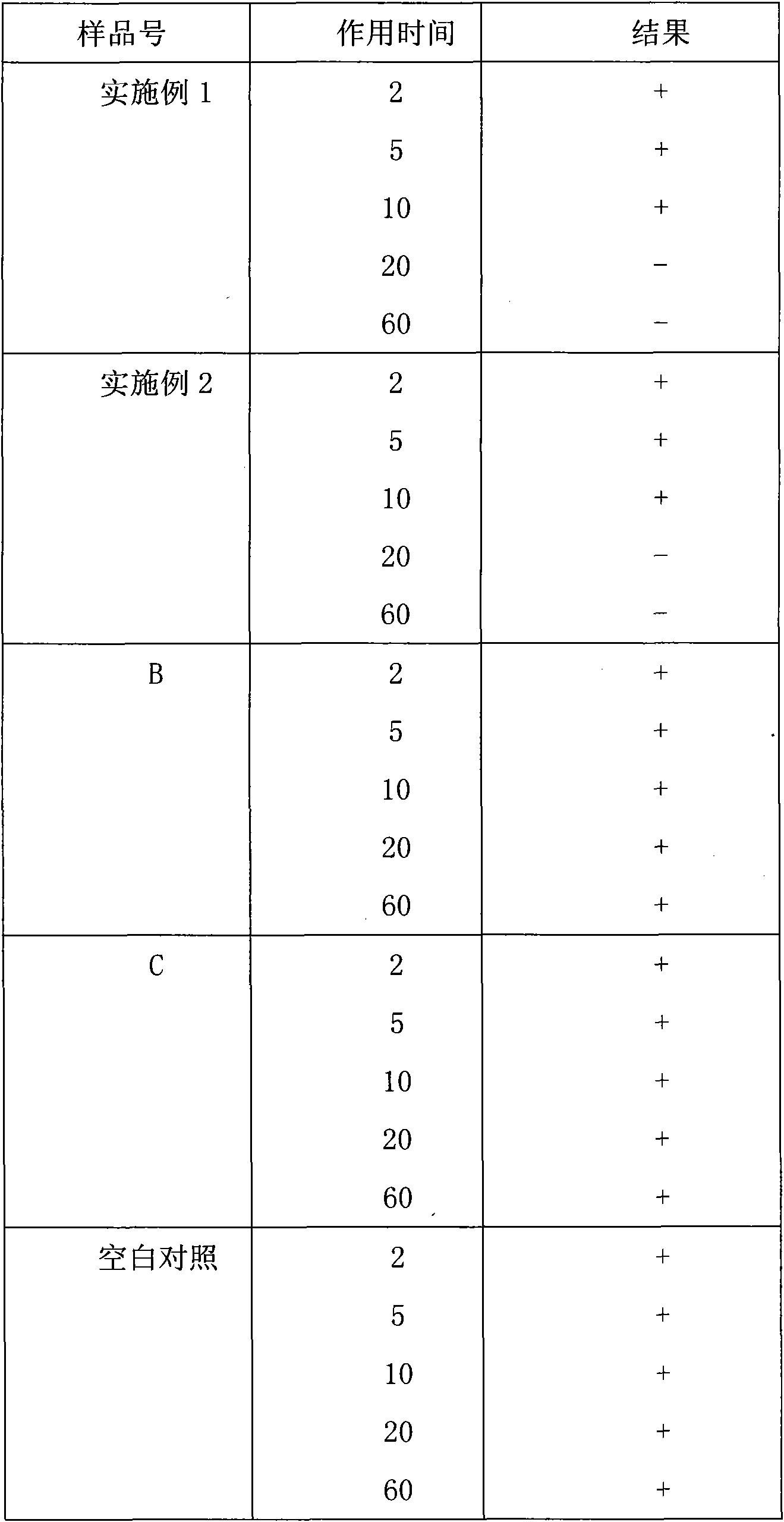

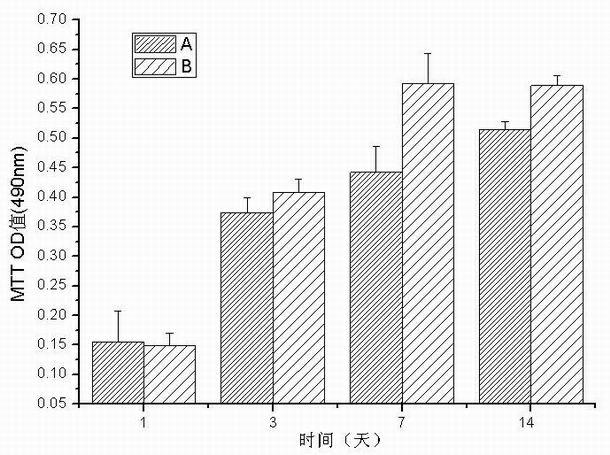

The invention discloses a method for preparing a nanosilver / nano silicon dioxide-containing antibacterial biological dressing, and relates to the field of antibacterial biological dressings. The nanosilver / nano silicon dioxide-containing antibacterial biological dressing is prepared by adding mixed solution of chitosan and polyvinyl alcohol and silver-carried silicon dioxide powder during the acetalation of the polyvinyl alcohol. The nanosilver / nano silicon dioxide-containing antibacterial biological dressing of the invention can accelerate the wound healing, slowly release the silver nanoparticles and continuously act on reproductive bacteria, has the characteristic of durable and high-efficiency sterilization and does not produce medicament resistance; and through the researches on the toxicity of the material to mouse fibroblast cells, the product does not produce obvious toxicity to the cells but promotes the growth of the cells.

Owner:SOUTH CHINA UNIV OF TECH

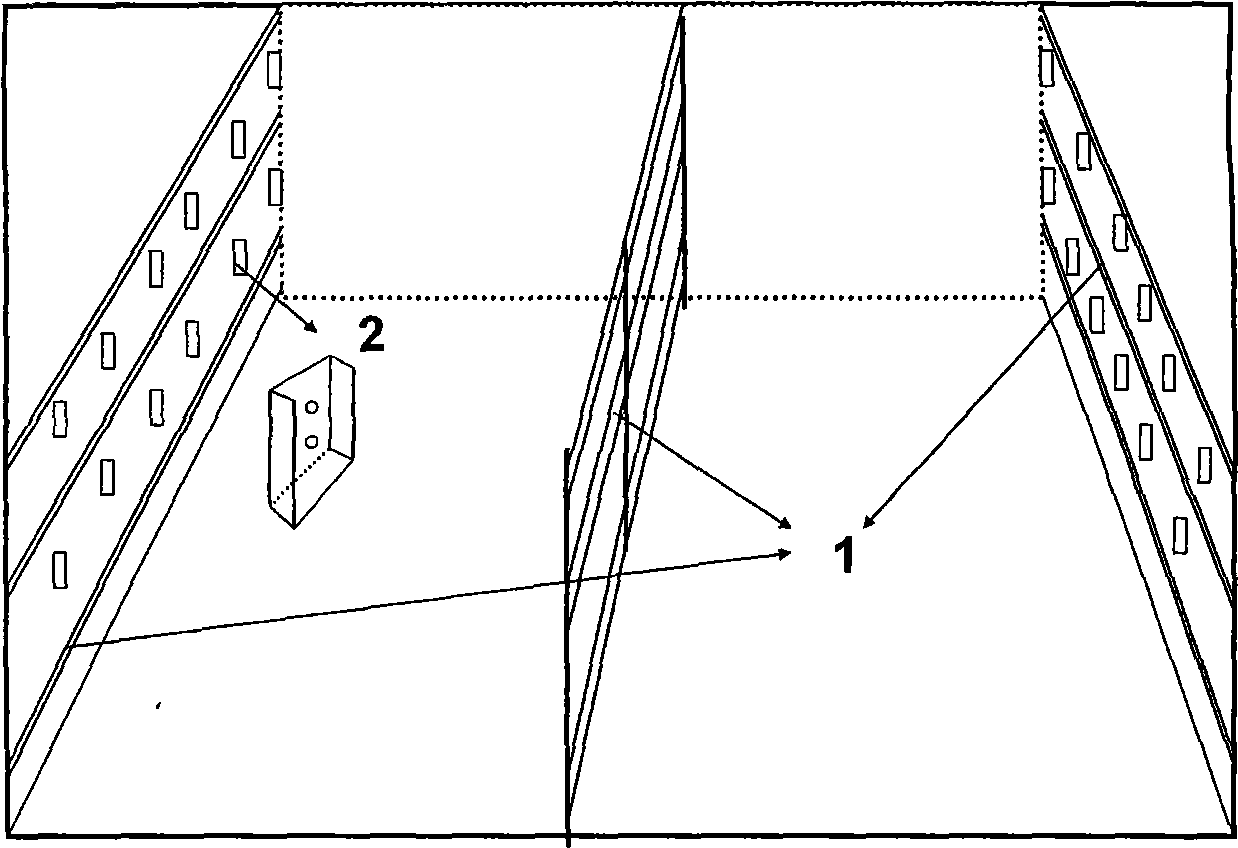

Close hothouse loose-tobacco loading method

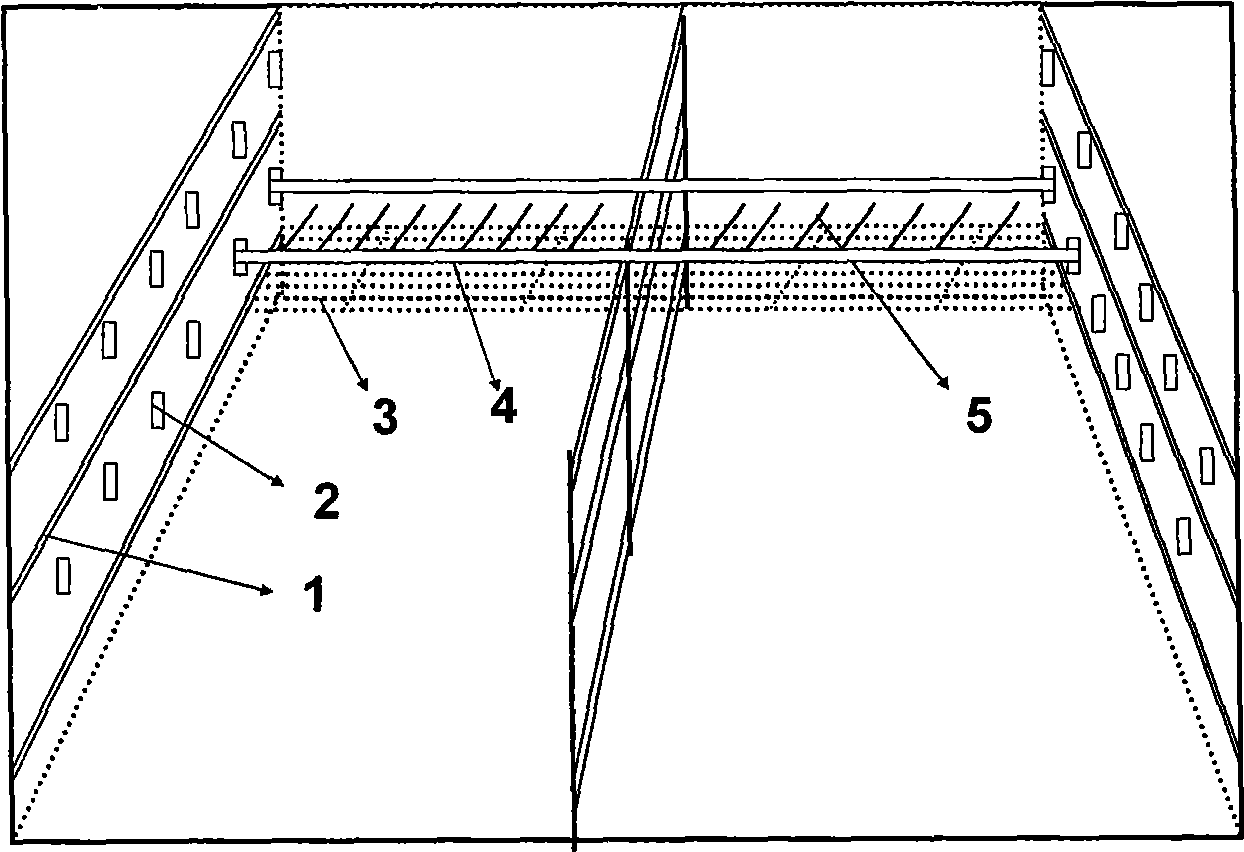

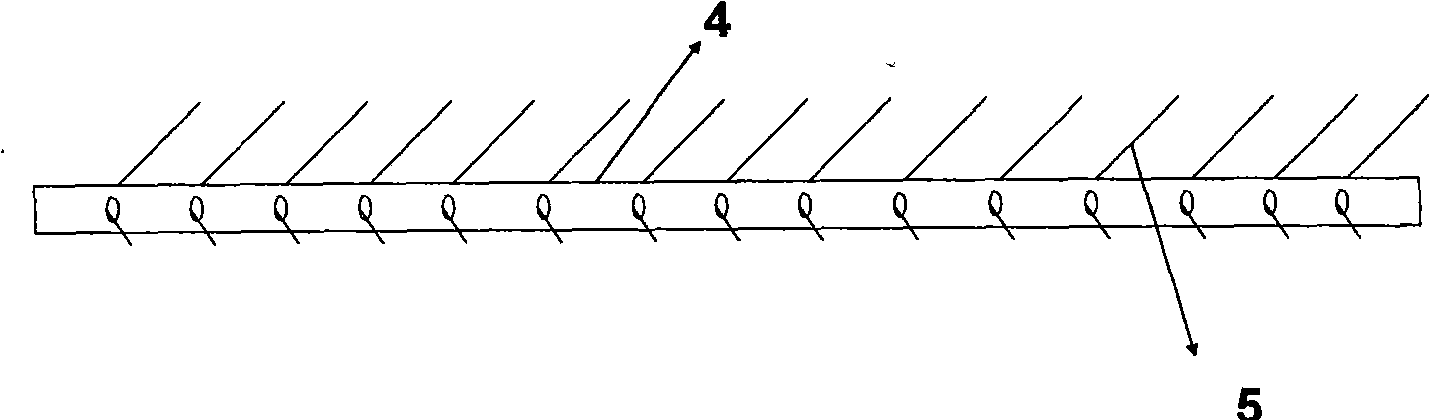

The invention discloses a loose tobacco filling method for a bulk curing barn, which comprises the following steps: firstly, manufacturing fixed square bars, a loose tobacco air-distributing partition board and metal contact pins, arranging a tobacco filling bracket and a fixed groove in the bulk curing barn, horizontally placing the air-distributing partition board on the tobacco filling bracket in the curing barn, and inserting the fixed square bars into the fixed groove; and loosing bundled tobacco leaves before tobacco filling, stacking the loose tobacco leaves with leaf tips upward and leaf bases downward, filling the fresh tobacco leaves into two fixed square bars tidily, then inserting the contact pins into holes of the fixed square bars to fix the tobacco leaves, and curing the tobacco leaves after the curing barn is fully filled with the tobacco leaves. The method has the following advantages: (1) the tobacco filling amount is large and is increased by 30 percent compared with a rod hanging method and increased by 10 percent compared with a loose tobacco stacking method, and the utilization rate of the curing barn is high; (2) the method saves labor and energy, saves about 70 percent of labor, and reduces coal and electricity consumption by 20 percent; (3) the method fills the tobacco tidily and reserves even gaps for the tobacco leaf bases, so the method is favorable for discharging moisture and prevent the tobacco leaves form smoothening and not stretching, and the method is easy to control the curing operation; (4) the structure is simple, and the material cost is reduced by 60 percent; and (5) the bulk curing barn is convenient to load and unload.

Owner:GUIZHOU TOBACCO SCI INST

Preparation method of chitosan/polyvinyl alcohol sponge dressing containing nano-silver

InactiveCN101927029AGood biocompatibilityGood hemostasis and antibacterialAbsorbent padsBandagesPolyvinyl alcohol spongeFiber

The invention discloses a preparation method of a chitosan / polyvinyl alcohol sponge dressing containing nano-silver. The invention relates to an antibacterial dressing for therapy of trauma, and the chitosan / polyvinyl alcohol sponge dressing containing the nano-silver is prepared by adding nano-silver / polyvinyl alcohol solution and polyvinyl alcohol / chitosan blend solution. The obtained dressing has good biocompatibility and hemostatic and antibacterial effects, and can promote the wound healing; the product can accelerate the wound healing, release nano-silver particles in a sustained manner, be acted on regenerated bacteria constantly, have the lasting and high-efficient sterilization characteristics and avoid the drug resistance during the wound treatment process; the research on the toxic effect of the material to mouse fibroblasts shows that the product has no obvious toxicity to the cells and has the effect of promoting the growth of the cells; and preparation method has simple process equipment and low price of experimental raw materials and is conductive to industrialization.

Owner:SOUTH CHINA UNIV OF TECH

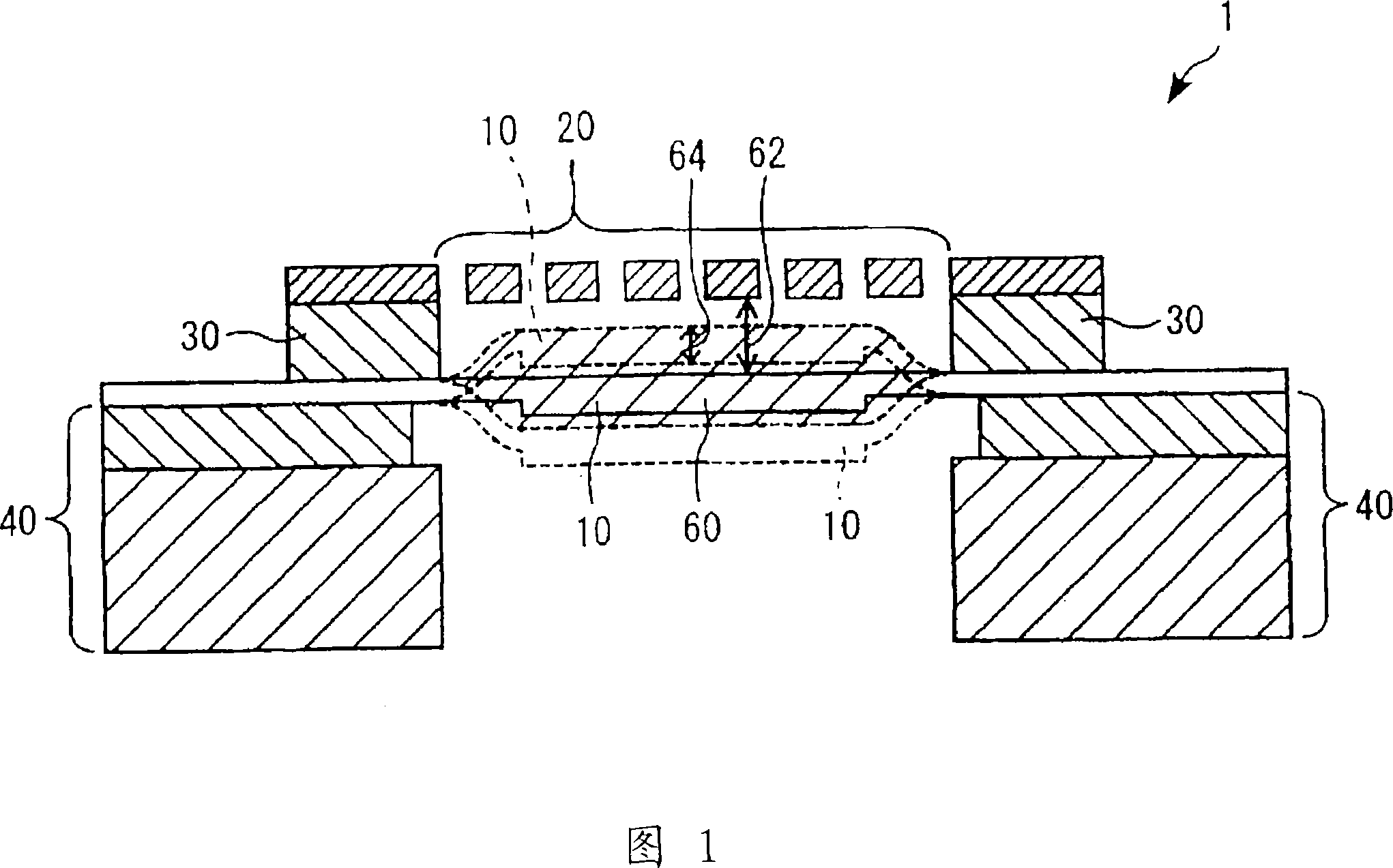

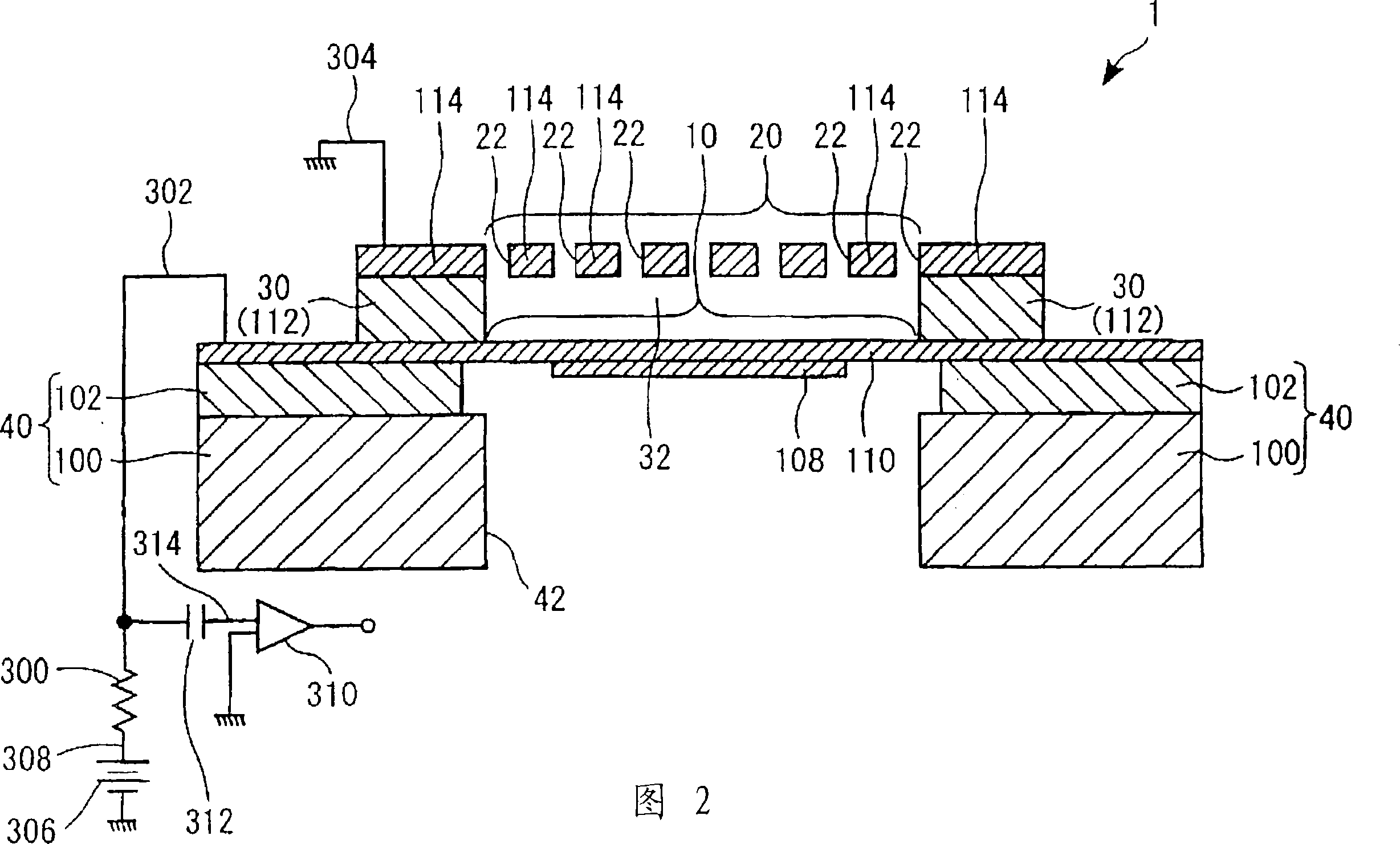

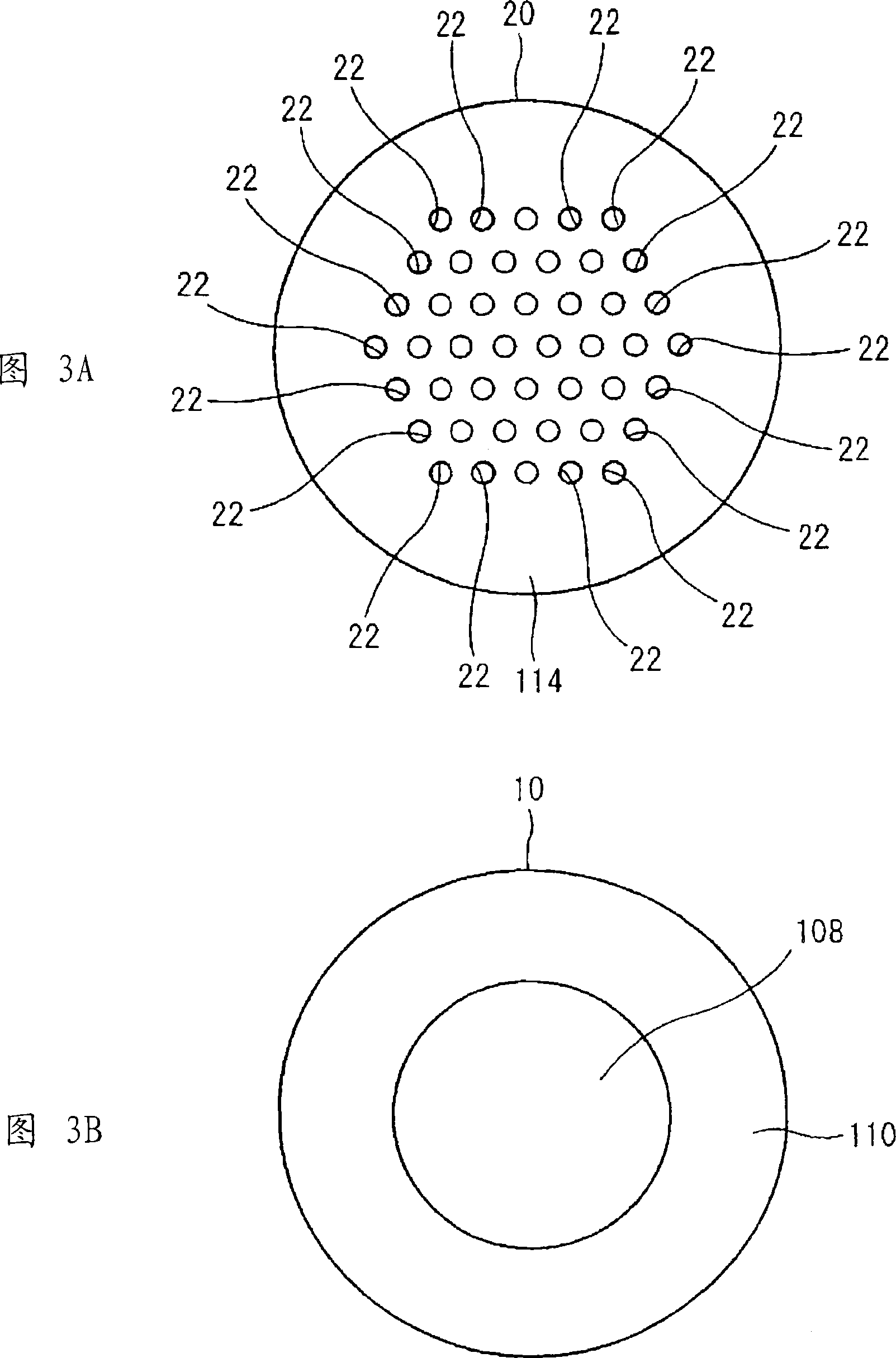

Capacitor microphone

InactiveCN101189910ASmooth vibration without disturbanceSmooth vibrationElectrostatic transducer microphonesEngineeringSound wave

A capacitor microphone is constituted by a plate having a fixed electrode, a diaphragm including a center portion and at least one near-end portion that is fixed to the outer periphery, in which the center portion having a vibrating electrode, which is positioned relative to the fixed electrode and which vibrates in response to sound waves, is increased in rigidity in comparison with the near-end portion; and a spacer that is fixed to the plate and the near-end portion of the diaphragm and that has an air gap formed between the plate and the diaphragm. Alternatively, a diaphragm electrode is horizontally supported by extension arms extended from a circular plate thereof and is vertically held in a hanging state being apart from a fixed electrode with a controlled distance therebetween.

Owner:YAMAHA CORP

Porous ceramic filter and preparation method thereof

The invention relates to a porous ceramic filter and a preparation method thereof. The method comprises the following steps of: mixing 20-40 percent of feldspar powder, 15-25 percent of quartz powder, 30-50 percent of argil, 10-20 percent of calcining argil, 1-10 percent of calcium carbonate powder, 1-10 percent of montmorillonite and 1-5 percent of saw dust according to the weight percentage, meanwhile, adding water which is 20-40 percent of the total weight of the solid powder and uniformly stirring; placing the uniformly stirred raw materials into a die and extruding for moulding; and after the raw materials are dried, placing in a high-temperature furnace, heating to 1,100-1,400 DEG C, maintaining the constant temperature for 1-3 hours and cooling along with the furnace to obtain the porous ceramic filter. The porous ceramic filter has more favorable high-temperature resistance and strength, simple production process, low raw material cost and favorable filtering performance and is particularly suitable for rainwater filtration.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

Heavy metal ions absorbent prepared by straw stalks and preparation method thereof

InactiveCN107159167AHigh porosityUniform voidOther chemical processesWater contaminantsSodium BentoniteSorbent

The invention discloses a heavy metal ions absorbent prepared by straw stalks. The heavy metal ions absorbent prepared by straw stalks is mainly prepared from, by weight, 50-100 parts of straw stalks, 15-30 parts of corncob, 20-30 parts of modified bentonite, 15-25 parts of modified diatomite, 5-10 parts of green alga, 1-2 parts of blue-green algae, 0.5-1 part of bacillus, 5-10 parts of fruit enzymes, 5-10 parts of soybean protein powder, 5-10 parts of tartaric acid, and so on. By taking the straw stalks as the main raw material of absorbent and performing cellulose and alkali water treatment, the prepared straw stalk powder is synergistic with modified bentonite and modified diatomite, thus the absorbent has significant absorption to heavy metal ions; the straw stalk powder is chelated with soybean protein powder, tartaric acid, oligosaccharide and chitosan to form macromolecule, and the macromolecule is tightly absorbed by silica gel and resin; thus the effect of effectively removing heavy metal ion is reached.

Owner:韦卓林

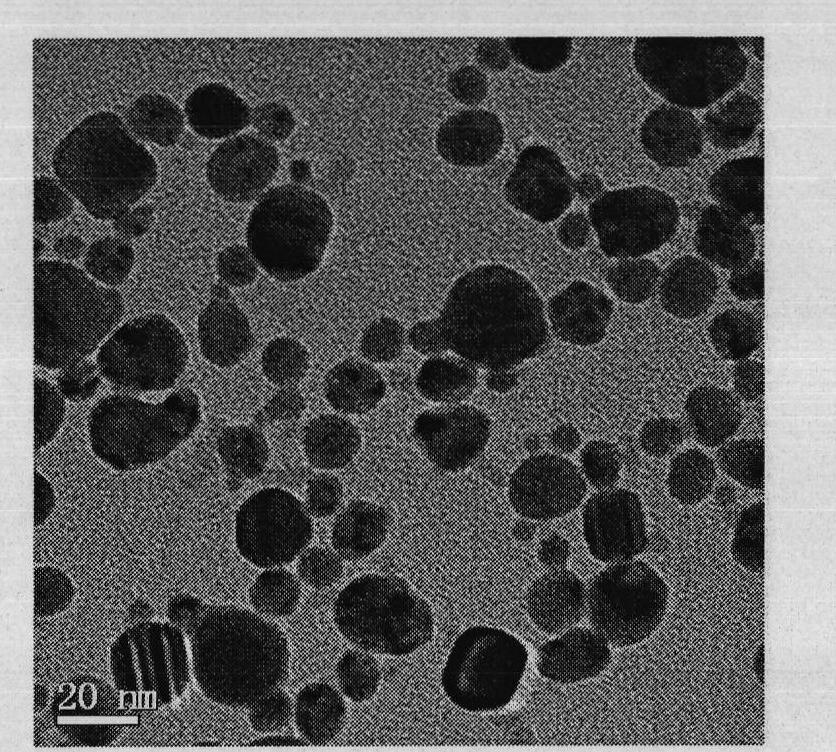

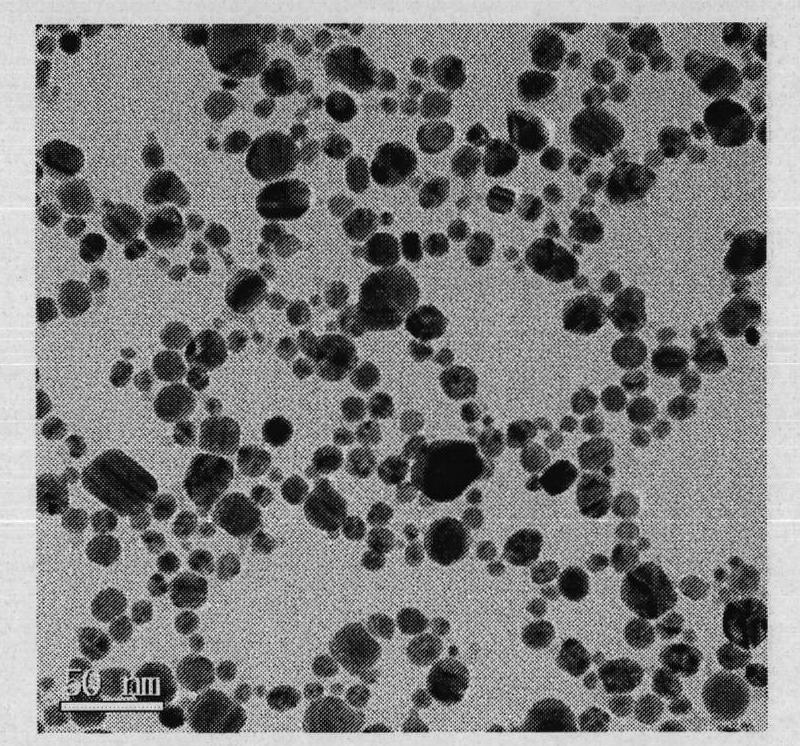

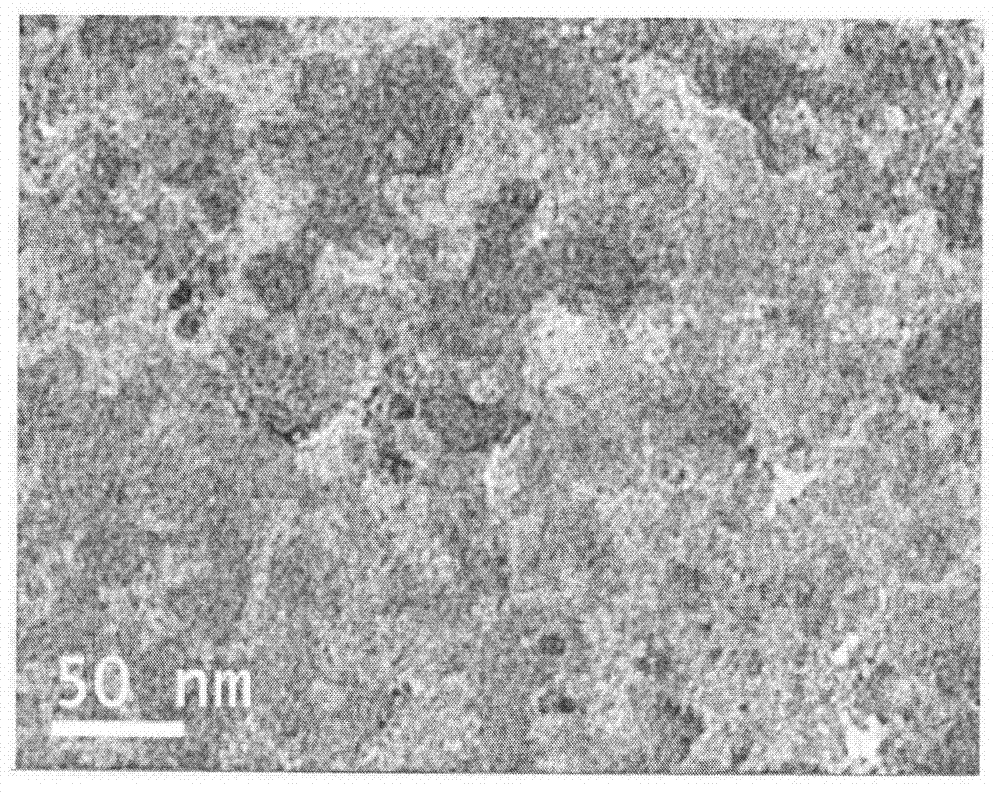

Method for preparing hierarchical porous TiO2/quantum dot composite material

ActiveCN103881709AUniform voidPhysical/chemical process catalystsSolid-state devicesMaterial synthesisQuantum dot

The invention discloses a method for preparing a hierarchical porous TiO2 / quantum dot composite material. The diameter of a hierarchical porous TiO2 particle is 5-500 nm, the material is a hierarchical porous material, the diameter of a quantum dot is 1-20 nm, and quantum dots are uniformly distributed on the surfaces of hierarchical porous TiO2 particles. According to the invention, the hierarchical porous TiO2 / quantum dot composite material is prepared from a vacuum nanometer pouring method step by step, and the method includes the following steps: firstly preparing different quantum dot precursor solutions, weighing a certain amount of hierarchical porous TiO2 powder, adding the hierarchical porous TiO2 powder in the quantum dot precursor solutions in steps, pouring and adsorbing under a vacuum state, then drying and roasting to obtain the hierarchical porous TiO2 / quantum dot composite material. The method reduces the synthesis cost of the material and has a simple process, in the prepared material, the quantum dots are uniformly distributed on the surfaces of TiO2 particles, and the material has a hierarchical porous structure and has great significance in the field of optoelectronic materials and photocatalytic materials etc.

Owner:SHIJIAZHUANG TIEDAO UNIV

Dry method paper cigarette filter candle and preparation method thereof

InactiveCN1669491AThe production process is simpleFeel fullTobacco smoke filtersPaper sheetCigarette filter

The invention discloses a dry method paper cigarette filter candle and preparation method, wherein the filter candle comprises filtering element base material and forming paper, the filtering element base material is prepared paper made through dried bulking process. During the filter candle manufacturing procedure, the dry method paper meeting the index point is arranged onto the feed arrangement of the conventional filter candle forming machine, wherein filter candles are formed on the forming machine through bundled modeling. Since no cellosolve or modeling adhesive are needed, the preparation process can be simplified. The filtering ratio of the obtained cigarette filter tip is over 40%.

Owner:梅建华

Carbon nano tube surface loaded nano cobaltosic oxide composite material and preparation method thereof

ActiveCN104167295ALarge specific surface areaImprove conductivityMaterial nanotechnologyHybrid capacitor electrodesCooking & bakingOxide composite

The embodiment of the invention discloses a carbon nano tube surface loaded nano cobaltosic oxide composite material and a preparation method thereof. The preparation method comprises the following steps: deionized water and DMF are weighed according to a ratio of 1:1 to 1:9 to obtain a mixed solvent; purified carbon nano tube and the mixed solvent are weighed according to the compounding concentration of 0.1-1g / L, and ultrasonic processing is performed for 10-60min; cobalt(II) acetate tetrahydrate of which the concentration is 10-60g / L relative to carbon nano tube dispersion liquid is weighed, and cobalt(II) acetate tetrahydrate is dispersed in the carbon nano tube dispersion liquid and stirred evenly; the obtained mixed solution is put in a hydrothermal tank with a tetrafluoroethylene liner and then cooled along with a furnace; after the solution is cooled to room temperature, black deposits are cleaned by a centrifuge; and baking is performed until a sample is dried. Co3O4 particles of the carbon nano tube surface loaded nano cobaltosic oxide composite material prepared by the method are cubic and uniform in size, have a side length smaller than 7nm, and are uniformly distributed on the surface of the carbon nano tube.

Owner:杭州中盟智控科技集团有限公司

Production process of frozen and dried tofu

The invention discloses a production process of frozen and dried tofu. The production process comprises the steps of selecting materials, soaking, pulping, carrying out centrifugal filtering, continuously heating the pulp, curdling, pressing and forming, steaming and forming, freezing, curing, expanding and softening, and packaging and the like. The frozen and dried tofu prepared by the production process is good in water regaining characteristic, fine in structure and uniform in voids; after water regaining, a product is expanded and softened, is good in toughness and unique in flavor, can be used as an auxiliary material of chaffy dish, also can be used as a main material in fried dish, soup dish and cooked dish, is a convenient non-staple food and is long in quality guarantee period and convenient for transportation and storage.

Owner:安吉祖名豆制食品有限公司

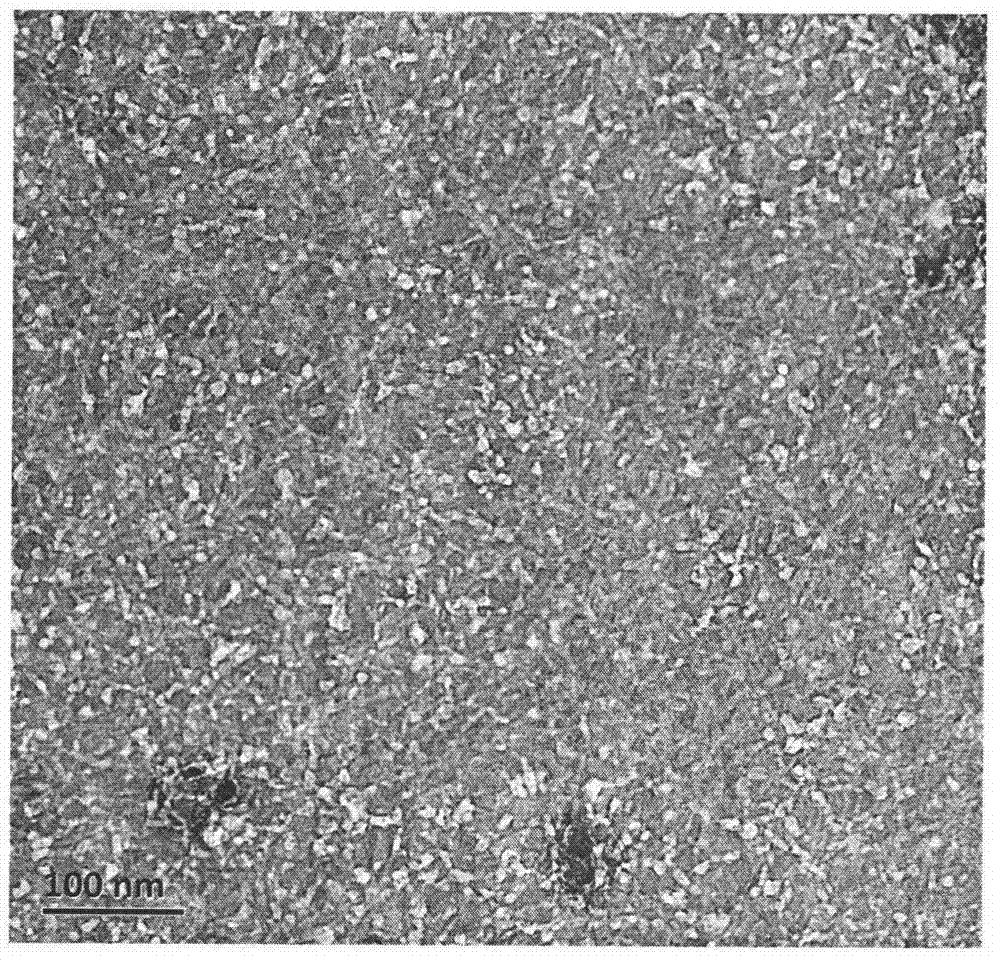

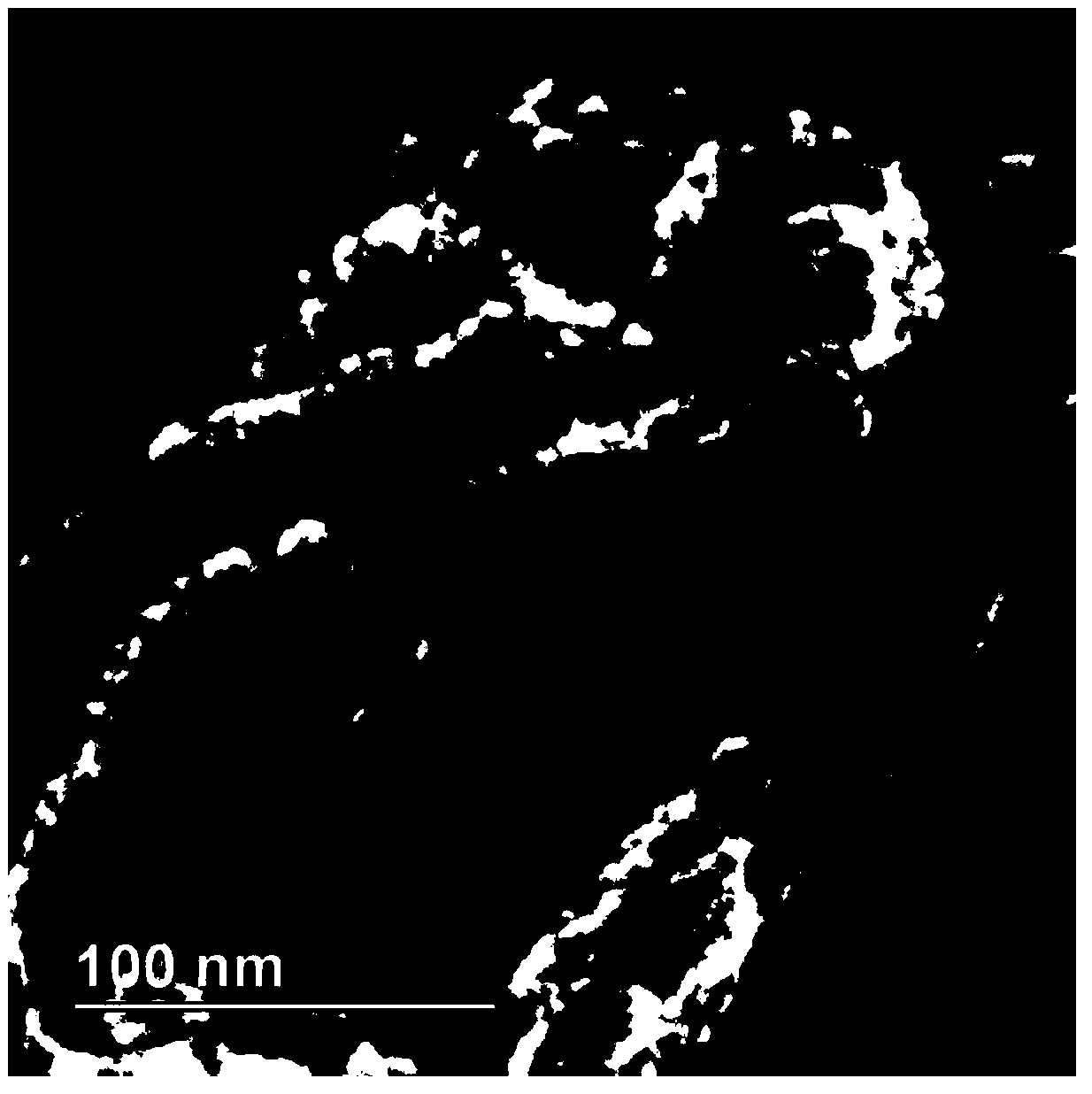

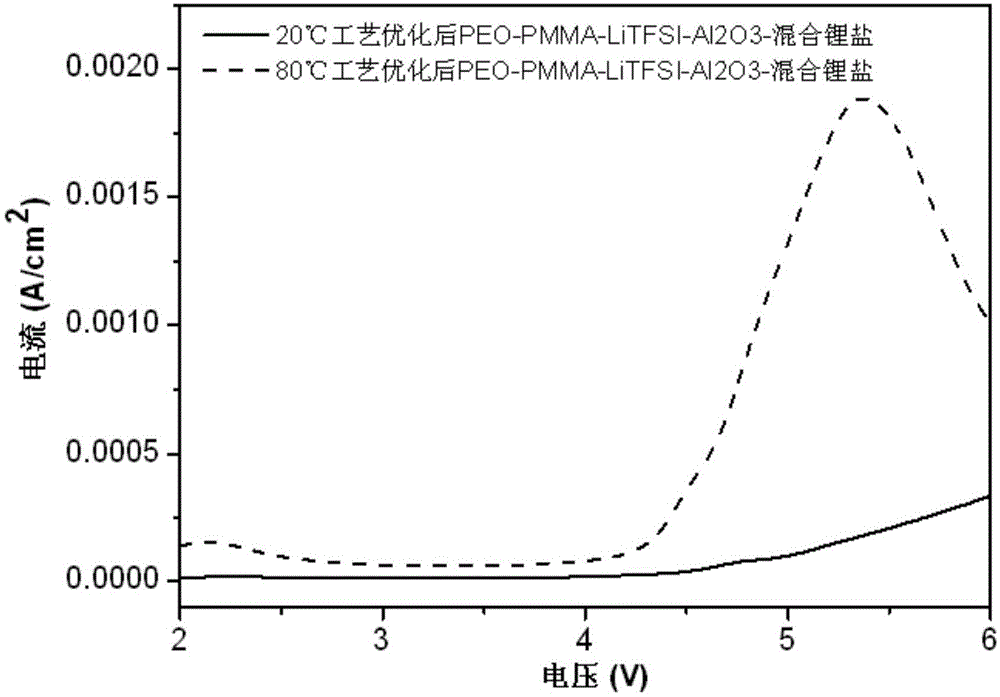

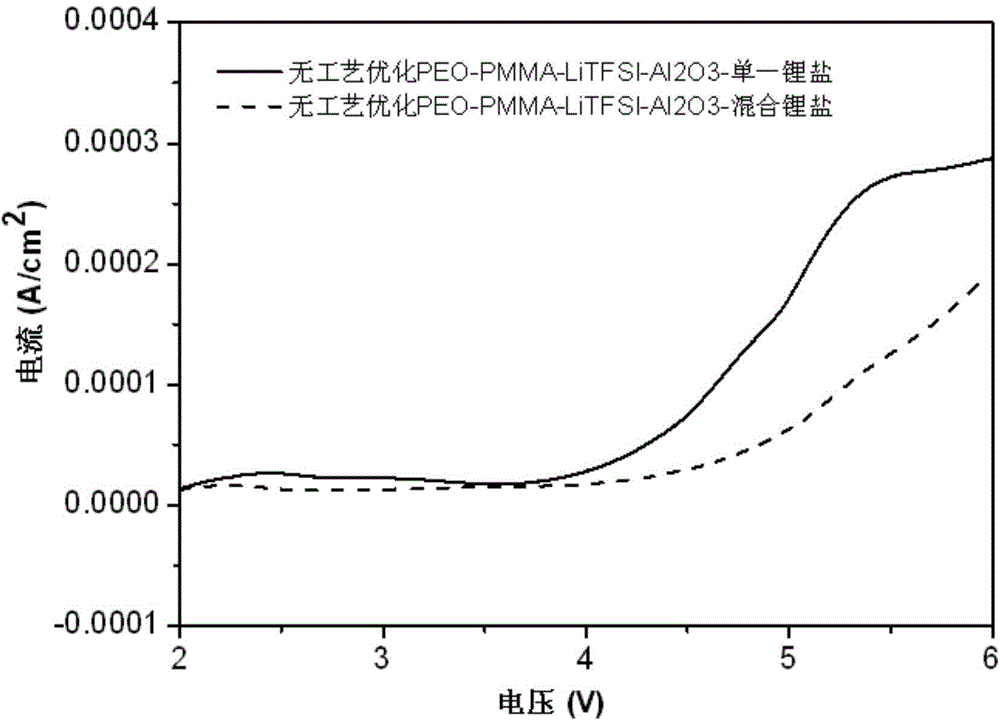

Preparation method of composite polymer electrolyte membrane

InactiveCN104650375AImprove interface performanceImprove electrochemical performanceFinal product manufactureElectrolyte accumulators manufactureLithiumPolymer science

The invention discloses a preparation method of a composite polymer electrolyte membrane. The preparation method comprises the following steps: dissolving a polymer matrix in a solvent, then adding nanometer oxide, carrying out ultrasonic dispersion for 15-60 minutes while stirring at the temperature of 25-45 DEG C, and then stirring for 3-6h at the temperature of 25-45 DEG C to obtain a homogeneous system; then adding first lithium salt into the homogeneous system, further stirring for 16-24h, and drying for 12-24h to obtain a membrane liquid; and finally, carrying out membrane preparation on the membrane liquid to obtain the composite polymer electrolyte membrane. When or before the composite polymer electrolyte membrane is mounted in a battery, an electrolyte solution containing second lithium salt is added to form a mode of mixed lithium salt. According to the preparation method disclosed by the invention, the composite polymer electrolyte membrane is good in interfacial properties and electrochemical properties, is nonflammable, can not leak and is simple in preparation process, wide in raw material source, excellent in interfacial compatibility and good in electrochemical stability window.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Preparation method of nitrogen-doped graphene electrode material

ActiveCN106450397AUniform voidIncrease output powerCell electrodesBiochemical fuel cellsElectrolysisCarbonization

The invention discloses a preparation method of a nitrogen-doped graphene electrode material. The preparation method comprises the following steps: 1) using a carbon-based material as a substrate; 2) putting the carbon-based material into water, and applying current between a positive electrode and a negative electrode for electrolysis; 3) after the electrolysis is finished, immerging the carbon-based material into a nitrogen-containing compound solution for soaking; 4) taking out the carbon-based material, drying, and carbonizing in an anaerobic condition to obtain the nitrogen-doped graphene electrode. According to the method disclosed by the invention, conventional water is taken as an electrolyte solution, and chemical agents with relatively high toxicity such as potassium permanganate, sulfuric acid and hydrogen peroxide are not needed; the carbon-based material with uniform gaps can be obtained by using alternating current to replace original direct current; and nitrogen element is deposited on the surface of the electrode by using carbonization, so that the nitrogen-doped graphene electrode is prepared and obtained. The method disclosed by the invention is simple and quick in preparation process, the obtained electrode is relatively high in output power, the long-time operational stability is relatively high, and the method is a sustainable in-situ preparation nitrogen-doped graphene electrode method.

Owner:FUJIAN AGRI & FORESTRY UNIV

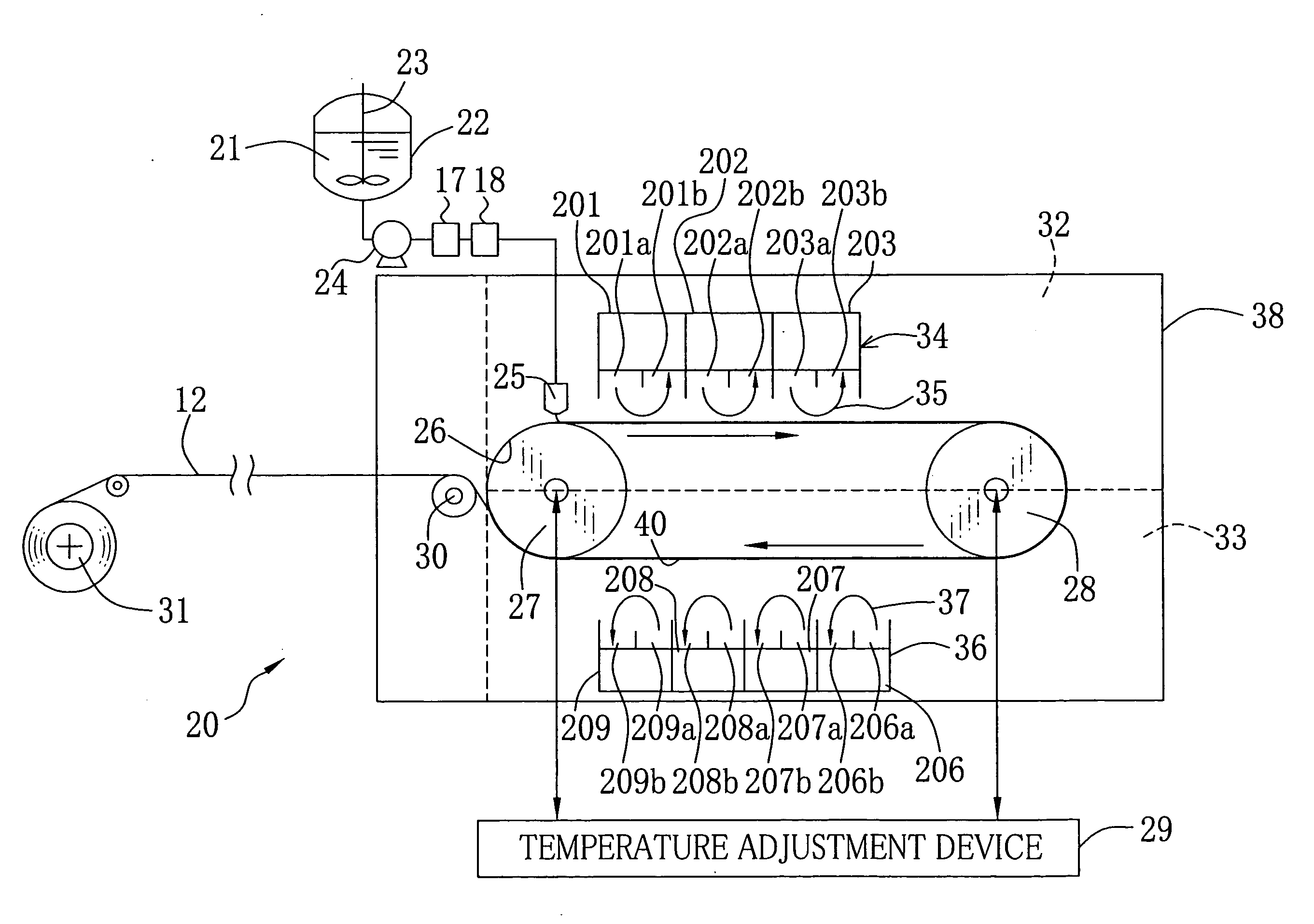

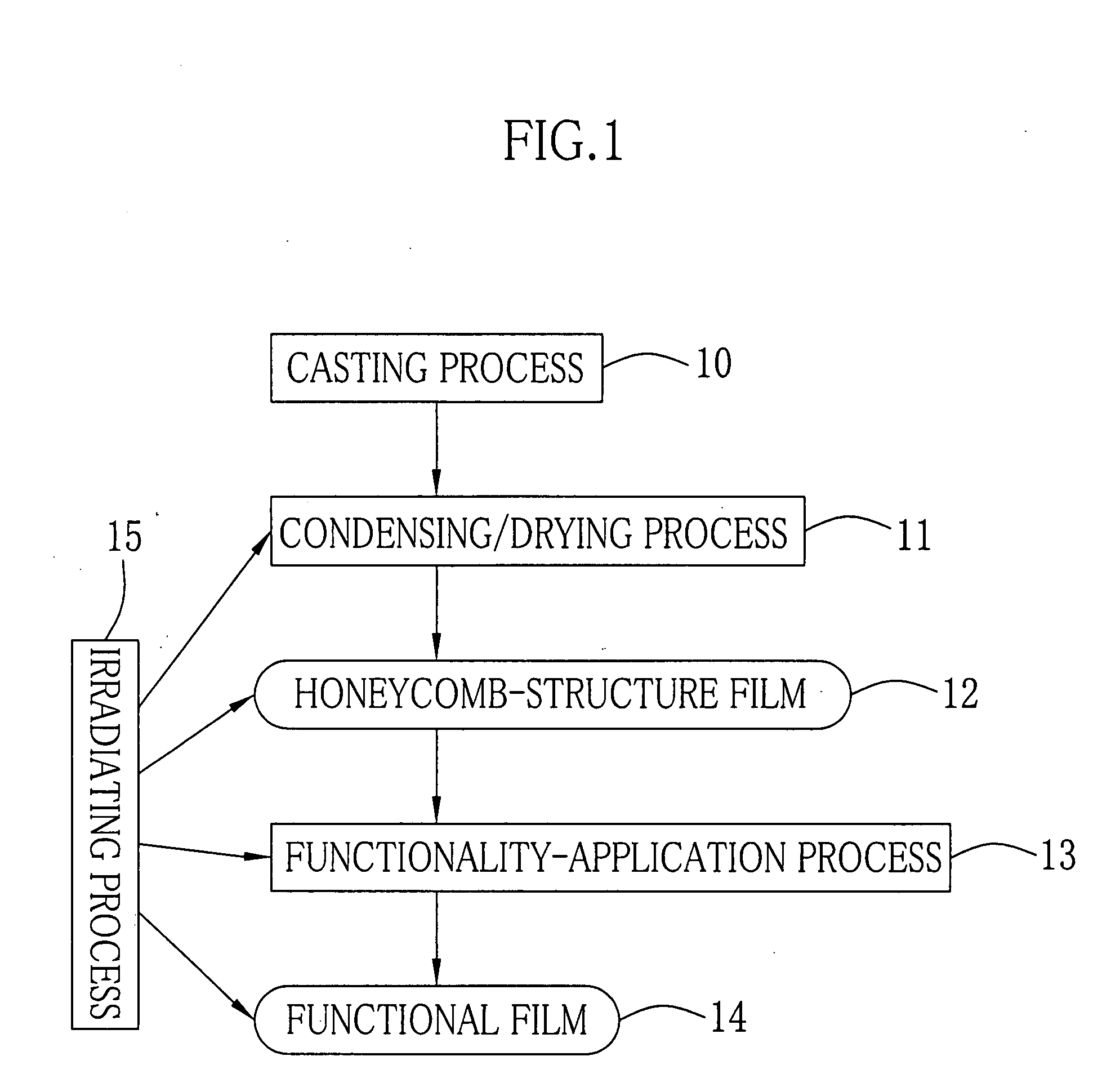

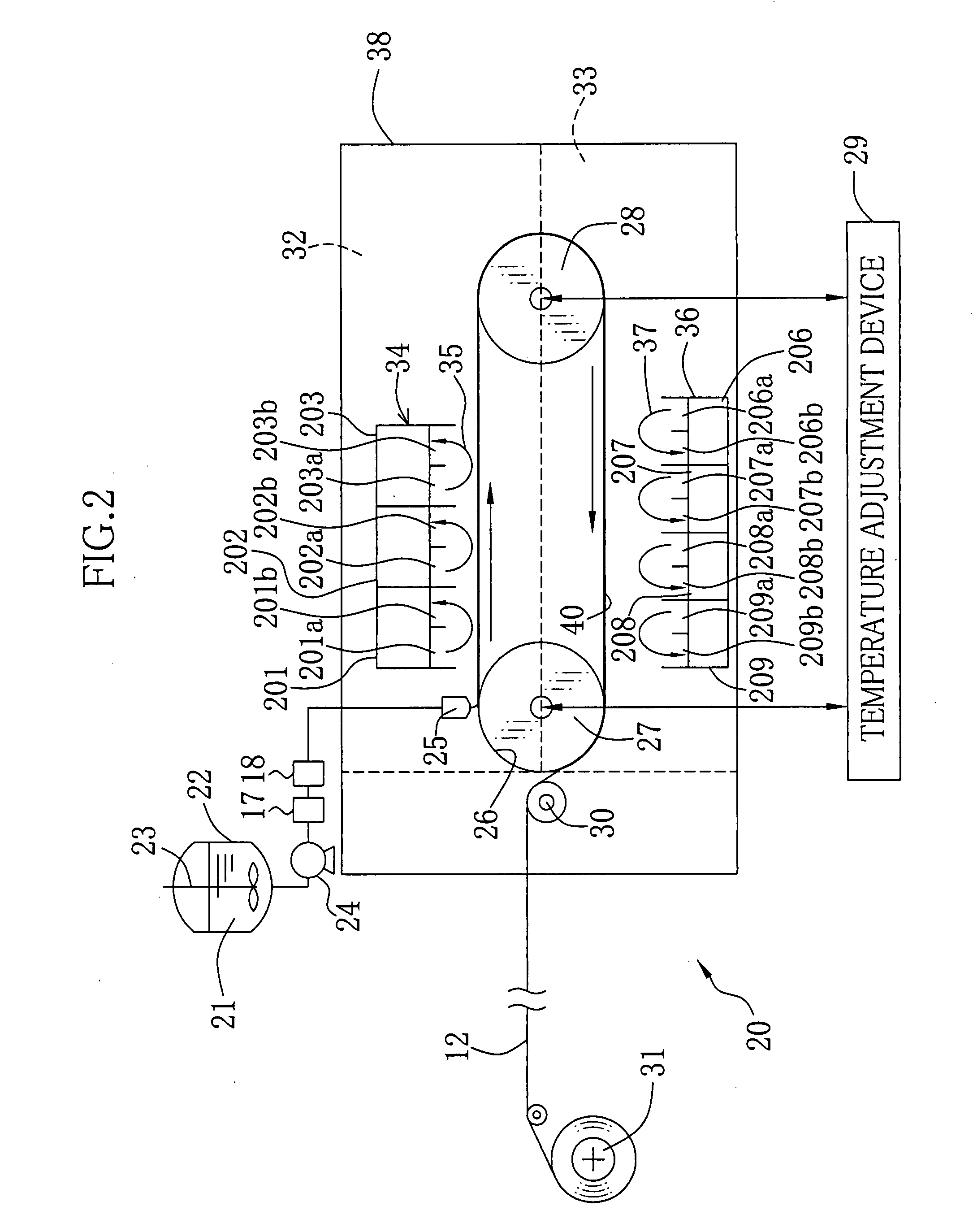

Producing method for film

ActiveUS20090134553A1Continuous productionEasy to produceFlat articlesCoatingsOrganic solventMetallurgy

A polymer solution (21) is prepared by dissolving poly-.ε.-caprolactone and amphipathic polyacrylamide in an organic solvent. The polymer solution (21) is cast from a casting die (25) onto a casting belt (26) to form a casting film (40). Air (35) from a blowing and suctioning device (34) is sent to the casting film (40) to generate droplets (44). The relative speed of drying air (37) to the moving speed of the casting belt (26) is adjusted at 5 m / min in parallel flow. The water in the drying air (37) is condensed in the casting film (40) to form the droplets (44). The droplets (44) are evaporated after evaporating the organic solvent in the casting film (40), so that a honeycomb-structure film (12) can be obtained.

Owner:FUJIFILM CORP

Preparation method for anode foil of medium-high voltage aluminum electrolytic capacitor and capacitor

ActiveCN110718393AUniform voidUniform current distributionElectrolytic capacitorsAl powderOrganic acid

A preparation method for an anode foil of a medium-high voltage aluminum electrolytic capacitor comprises the following steps: 1) performing powder deoxidation: carrying out vacuum annealing on aluminum powder or aluminum alloy powder or annealing for 1-3 hours under the protection of inert gas; 2) performing slurry mixing: uniformly mixing a binder with the aluminum powder or aluminum alloy powder obtained in the step 1); 3) forming a film on an aluminum foil substrate; 4) performing sintering: sintering the aluminum foil prepared in the step 3) at the temperature of 560-660 DEG C; 5) etchingthe sintered aluminum foil in weak acid such as organic acid or low-concentration inorganic acid, wherein the time is 3 min to 2 h; 6) performing formation. According to the method, the anode foil issubjected to weak acid corrosion for a period of time after being sintered, and bulges and spines in the sintered film are corroded to a certain extent, so that gaps in the sintered film are uniformto a certain extent, the current is uniformly distributed during formation, and an oxide film formed on the sintered film is uniform as much as possible; therefore, the formation quality is ensured.

Owner:HUNAN AIHUA GRP

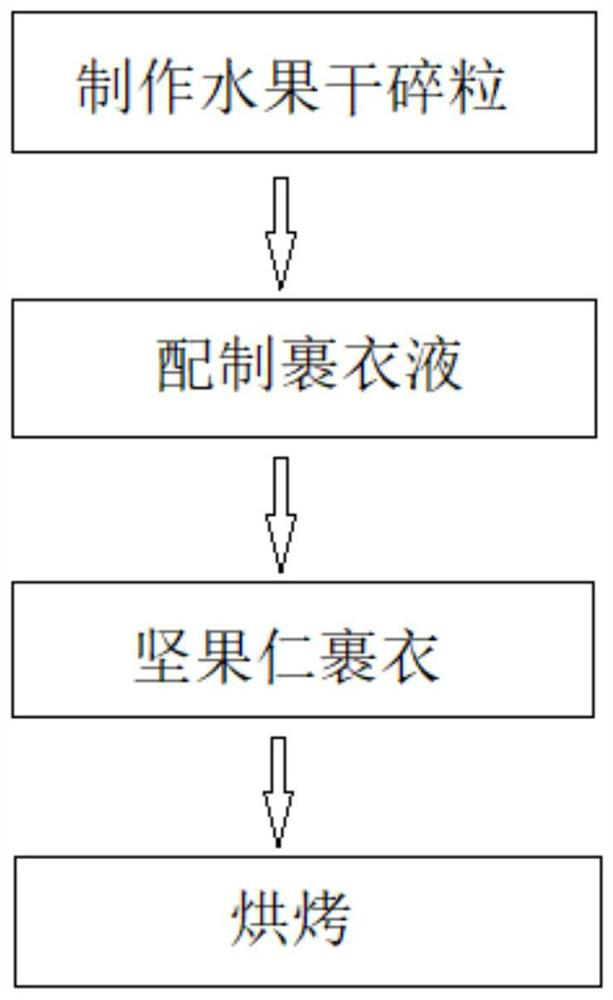

Preparation method of coated nut meat

InactiveCN112568315ANot easy to fall offExcellent adhesionConfectioneryFood preservationBiotechnologySugar

The invention discloses a preparation method of coated nut meat, and belongs to the field of food processing. The preparation method comprises the steps: mixing dried fruits with white granulated sugar, crushing by using a crusher, and sieving for later use; mixing and dissolving white granulated sugar, malt syrup and water, and then boiling the mixture to 115-140 DEG C with soft fire; then uniformly coating the surface of the nut meat with the prepared coating liquid, and then uniformly coating the surface of the nut meat with the dried fruit particles and seasoning powder; and finally, drying the nut meat wrapped with the coating liquid to obtain the coated nut meat. Compared with the prior art, the dried fruit granules are uniformly embellished on the surface of the nut meat, so that the appearance of the nut meat can be improved, the appearance of the nut meat is exquisite, the dried fruit granules are endowed with the flavor of the nut meat, the flavor of the nut meat is richer, and in addition, the problems of granule falling and powder falling of the existing coated nut can be relieved; and secondly, a double-stage temperature baking process is adopted, so that the product is crisp in taste and pleasant in fragrance.

Owner:CHACHA FOOD CO LTD +1

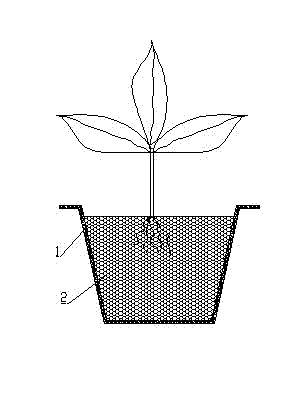

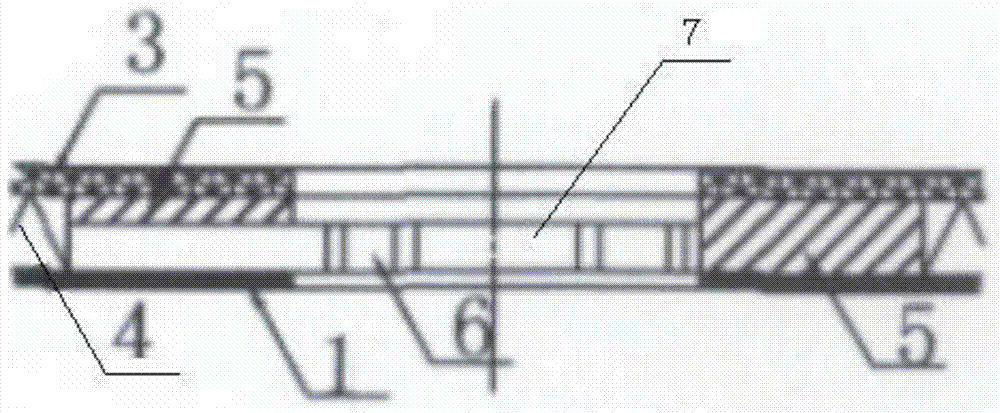

Multi-hole planting sand and sand planting structure

ActiveCN103168638ACircumstances against lossIncrease profitCultivating equipmentsPlant StructuresNatural sand

The invention belongs to the field of sand planting and particularly relates to multi-hole planting sand which can be directly used for retaining water and fertilizer and a sand planting structure with the planting sand. The planting sand is a sand ball with a multi-hole structure which is formed by sticking natural sand grains and binder which at least contains hydrophily binder, and a hole which is suitable for adsorbing is formed between the adjacent natural sand grains. According to the planting sand, existing natural sand grains are utilized to form holes through cementation, holes which are suitable for use and enable external beneficial compositions are enabled to be loaded on the surface of the sand ball to be formed between the adjacent sand grains, multi-hole performance of the sand ball is utilized to effectively maintain nutrition fertilizer, fertilizer such as the nutrition compositions which are fertilized in the outside world in a planting process is loaded in the holes which are formed among the sand grains, and therefore a situation that the fertilizer is lost with the loss of water is prevented, and use ratio of the fertilizer is increased.

Owner:BEIJING RECHSAND SCI & TECH GRP

Composite sand planting structure

ActiveCN103168641ACircumstances against lossIncrease profitGrowth substratesCulture mediaAdhesivePlant Structures

The invention belongs to the field of sand planting, and particularly relates to a composite sand planting structure containing porous planting sand and nutrient planting sand which are used for planting and have functions of water retention and fertilizer retention. The composite sand planting structure comprises a planting container, the porous planting sand and the nutrient planting sand, wherein the porous planting sand and the nutrient planting sand are laid in the planting container. The porous planting sand is a sand ball in a porous structure, wherein the sand ball is formed by natural sand granules and adhesion agents at least containing hydrophilic adhesives in an adhesive mode, and a pore suitable for adsorption is formed between each two adjacent natural sand granules. The nutrient planting sand comprises the porous planting sand and nutrient membranes wrapping the surface of the porous planting sand. According to the composite sand planting structure, water retention performance and fertilizer retention performance of the porous planting sand and the nutrient planting sand are made use of, the venting planting container performs an assistant function, fertilizer loss is beneficially reduced, and growth of plants is benefited.

Owner:BEIJING RECHSAND SCI & TECH GRP

Anti-short-circuit AGM partition plate

The invention discloses an anti-short-circuit AGM partition plate. The anti-short-circuit AGM partition plate is prepared from, by mass, 3%-5% of modified nano-vermiculite powder, 3%-5% of polyoxyethylene, 5%-10% of modified bamboo fibers, 10%-15% of water-soluble polyvinyl alcohol fibers, 5%-10% of polyimide fibers, 30%-35% of high-alkali glass fibers with the diameter ranging from 0.5 micrometer to 0.7 micrometer and the balance high-alkali glass fibers with the diameter ranging from 3 micrometers to 4 micrometers. According to the anti-short-circuit AGM partition plate, a traditional pure glass fiber formula is abandoned, the plate is creatively woven by multiple fibers in a blending mode, the modified bamboo fibers and the polyimide fibers are creatively added especially, the components such as the nano-vermiculite powder and polyoxyethylene are added to serve as auxiliary materials, therefore, the partition plate is high in porosity and uniform in pore, the comprehensive performance is excellent, and the condition that positive electrode lead powder penetrates through the partition plate to a negative electrode to cause a short circuit can be effectively avoided.

Owner:ZHEJIANG CHANGTONG SCI & TECH

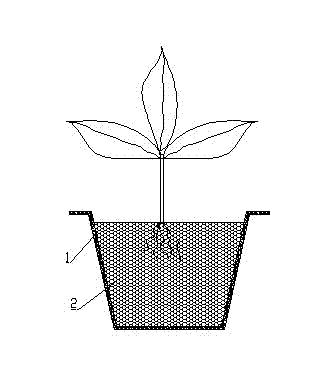

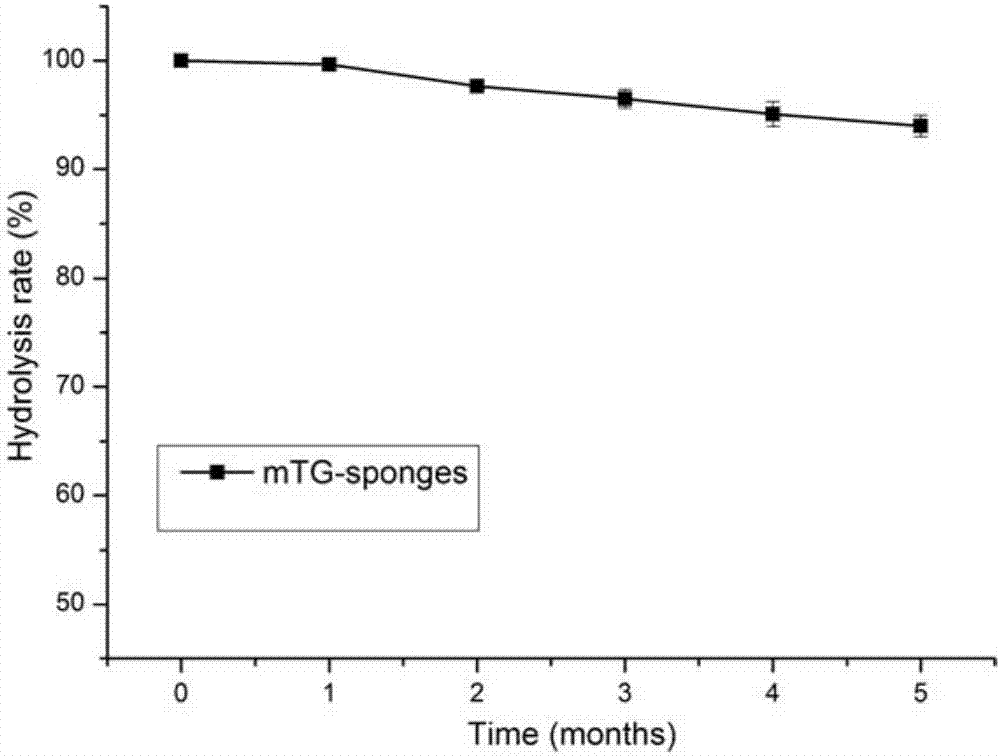

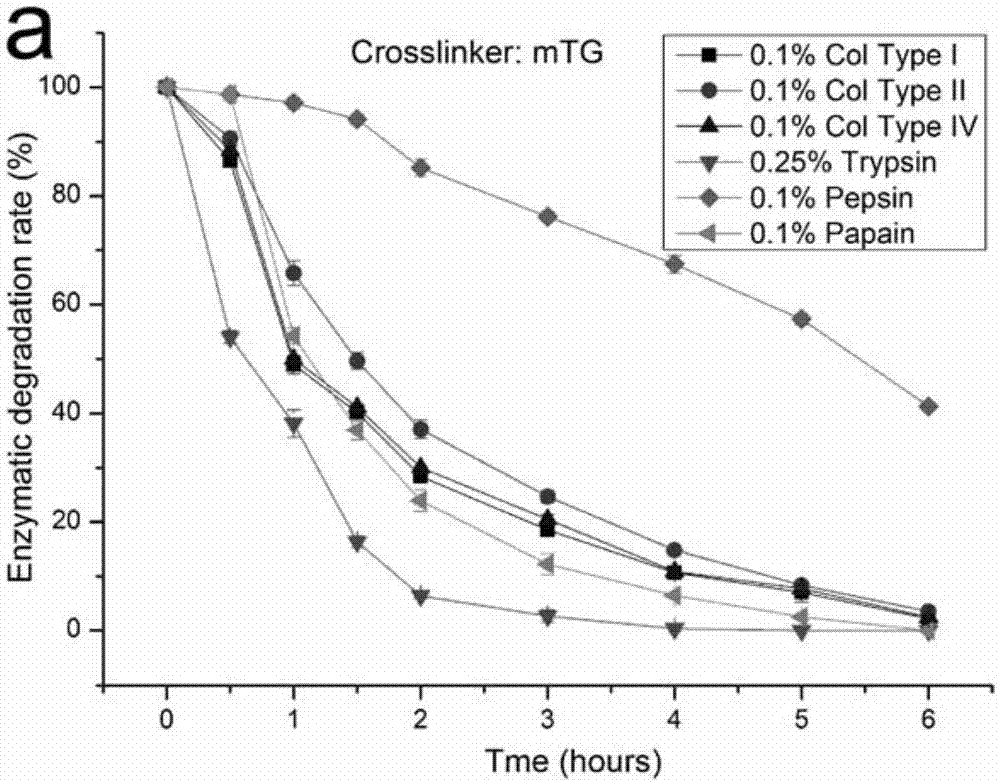

Preparation method of gelatin sponge scaffold

InactiveCN107261216AImprove physical propertiesHigh porositySurgical adhesivesPharmaceutical delivery mechanismPorosityControlled release

The invention discloses a gelatin sponge scaffold. A preparation method of the gelatin sponge scaffold comprises the following steps: (1) preparing gelatin solution; (2) preparing transglutaminase solution; and (3) mixing the gelatin solution prepared in the step (1) and the transglutaminase solution prepared in the step (2), carrying out incubating, thus forming hydrogel, carrying out refrigerating, and carrying out freeze drying, thus preparing the sponge scaffold. The sponge scaffold is free of cytotoxicity, and has excellent physical property, excellent comprehensive performance, good porosity, good compression modulus, and good degradation resistance; in addition, the biocompatibility is good, so that cells can well grow in the scaffold; the scaffold is implanted into the body, a formed material wrapping layer is thin, blood capillaries are formed on the outer wrapping layer, and thus the growth of the regenerated tissue is facilitated; the gelatin sponge scaffold can be taken as the materials such as the tissue engineering scaffold, clinical hemostatic sponge and medicine controlled-release carriers to be used for the cell and tissue engineering applications, and has the broad prospect.

Owner:SICHUAN UNIV

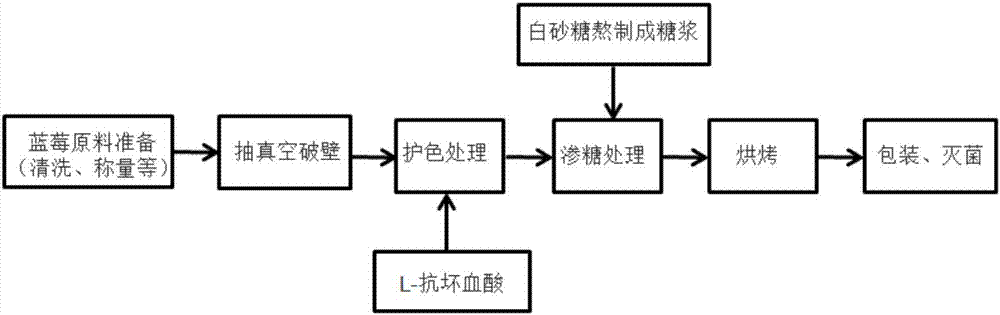

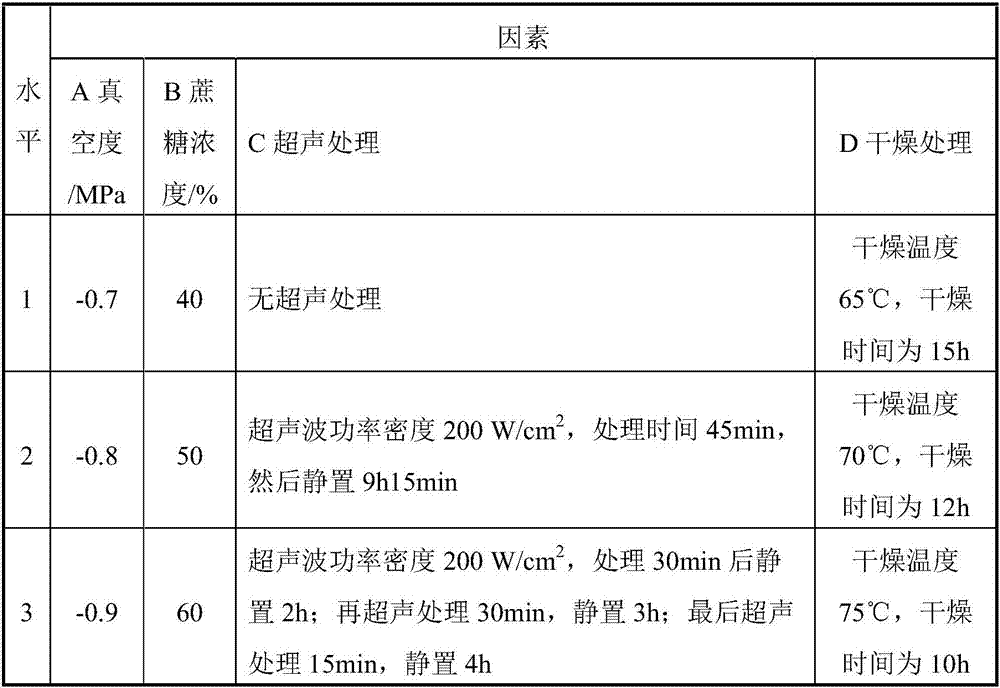

Process for making dried blueberries

ActiveCN107874174AFreeze fastUniform penetrationFood ingredient as colourFood dryingSaline waterSucrose

The invention discloses a process for making dried blueberries. The process comprises the following steps: (1) selecting raw material fruits; (2) performing pretreatment, namely washing blueberry fruits with clean water or salty water; (3) performing wall breaking treatment, namely spreading the blueberry fruits of which moisture is drained off on a screening tray, putting into a working cavity ofa vacuum machine, vacuuming till the vacuum degree is minus 0.07MPa to minus 0.1MPa, and maintaining the vacuum degree for 30-60 minutes; (4) performing color fixation treatment, namely mixing and stirring the blueberry fruits with a 0.7% citric acid color fixation liquid in a mass ratio of (1:1)-(1:3) for 10-30 minutes; (5) performing sugar infusion treatment, namely preparing a cane sugar solution, adjusting the pH value of the cane sugar solution by using citric acid, and leaving to stand for 12-20 hours at 25-35 DEG C to degrade cane sugar molecules, thus being convenient for sugar infusion; (6) drying; (7) resoftening, and packaging; and (8) performing sterilization treatment. The dried blueberries made by using the process are fine in taste and good in dried fruit quality, and the process has the characteristics of being high in production efficiency, low in energy consumption, and the like.

Owner:TAIZHOU UNIV

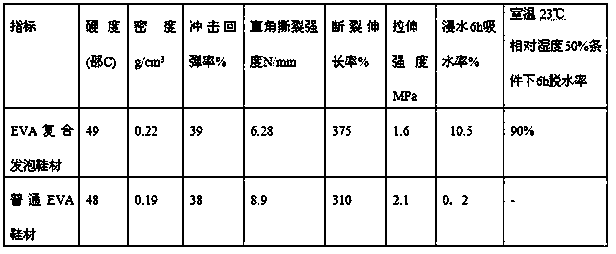

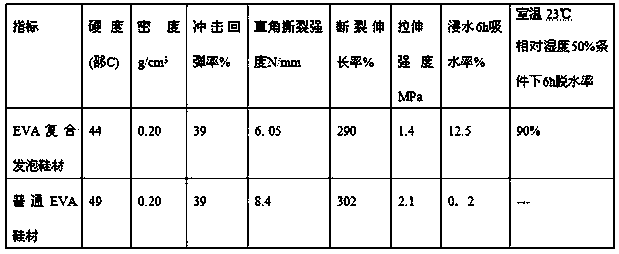

Preparation method of leather scrap composite modified EVA foamed shoe material

The invention relates to a preparation method of a leather scrap composite modified EVA foamed shoe material, which is characterized in that leather scraps obtained by crushing waste leather and wastefur generated in the leather and fur processing process and EVA are subjected to composite modification to produce the shoe material. In the production process, a plasticizer, a demolding auxiliary agent, a foaming agent and a foaming auxiliary agent are added; and the filler and the cross-linking agent are added. The materials are added in batches in an internal mixer, and vulcanization and foaming are completed on a press vulcanizer after uniform mixing. The method is simple; wherein leather wastes (leather scraps) are partially used for producing shoe materials; physical indexes of the EVAshoe material can be completely comparable with those of common EVA shoe materials; the material is low in cost and price, the water absorption performance of the material can be controlled accordingto needs, the material can replace a traditional shoe material EVA to be applied to a shoe insole, sanitation in a shoe cavity can be improved, the shoe material can be naturally degraded, in a soilburying method test, a sample is buried in soil with humus, and the degradation weight loss rate in 60 days can reach about 7.5% at most.

Owner:CHINA LEATHER & FOOTWEAR IND RES INST +1

Flexibly-adjusted steam curing device for concrete members

ActiveCN112589984AFlexible volume adjustmentEasy accessCeramic shaping apparatusStructural engineeringProcess engineering

The invention relates to a flexibly-adjusted steam curing device for concrete members. The flexibly-adjusted steam curing device comprises a curing body with an inverted-U-shaped cross section, a cuboid-shaped base matched with the curing body, a plurality of supporting assemblies used for supporting the concrete members, steam equipment, steam pipes, curing material discharging mechanisms filledwith coal ash, temperature and humidity monitoring assemblies and interaction panels, wherein the nutrient discharging mechanisms filled with the coal ash, the temperature and humidity monitoring assemblies and the interaction panels, are the same as the supporting assemblies in number, correspond to the supporting assemblies in a one-to-one mode. The flexibly-adjusted steam curing device is convenient to assemble and disassemble; the volume of each curing space can be flexibly adjusted by adjusting partition plates; convenience and flexibility are achieved; differentiated curing can be achieved for each curing space; the supporting assemblies are slidably arranged on the base and can be conveniently moved out of the curing body, so that the concrete members can be conveniently taken and placed; the coal ash in the discharging mechanisms is evenly dispersed under the action of steam sprayed by the steam pipes to cure the surfaces of the concrete members; the temperature and humidity monitoring assemblies are used for monitoring the temperature and humidity of curing in real time; and the whole device is simple in structure and convenient to operate and can be flexibly adjusted conveniently according to a production field.

Owner:襄阳路桥建设集团有限公司

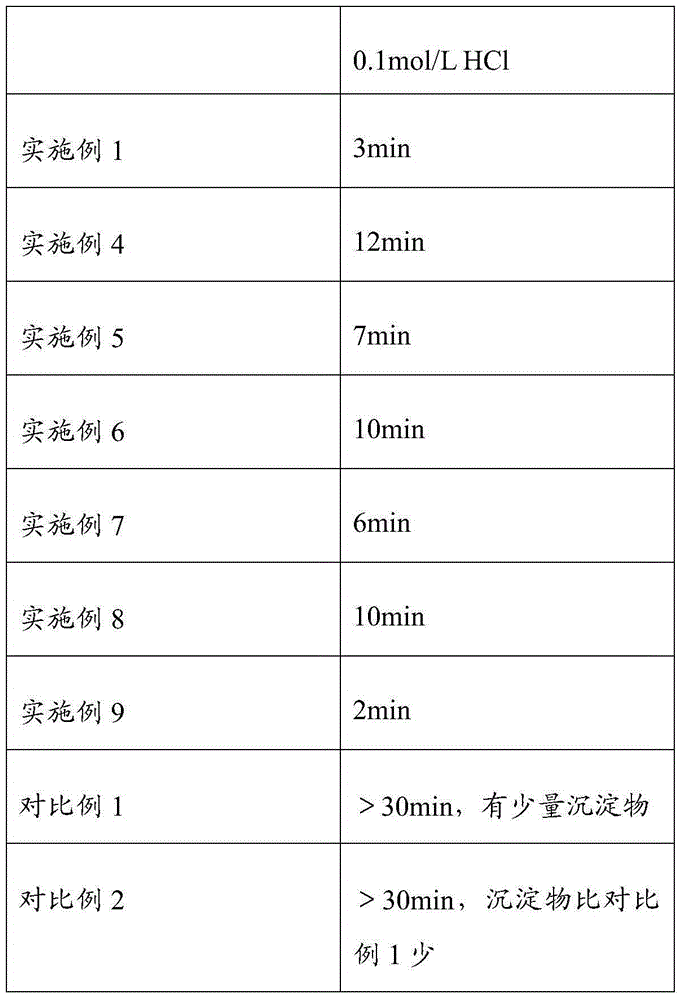

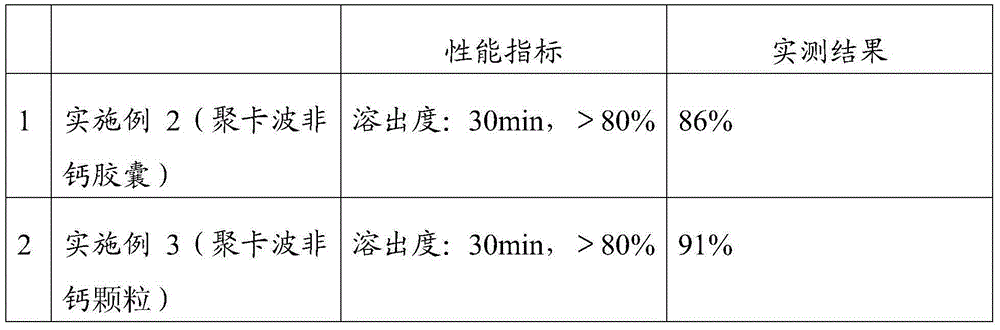

Intestinal disease treatment pharmaceutical composition and preparation method thereof

ActiveCN105012256AImprove organizational structureImprove the disintegration effectDigestive systemPill deliveryDiseaseCalcium Polycarbophil

The invention discloses an intestinal disease treatment pharmaceutical composition and a preparation method thereof. The intestinal disease treatment pharmaceutical composition comprises, by weight, 100 parts of calcium polycarbophil, 7.5-30 parts of disintegrant, 19-48 parts of stuffing, 0.5-4 parts of lubricant and 2.5-8 parts of propylene glycol. The propylene glycol added into the intestinal disease treatment pharmaceutical composition has function of improving tissue structure of the composition and making gaps among particles more uniform so as to quicken disintegration of the particles in an acid environment. As the intestinal disease treatment pharmaceutical composition is prepared by a way of adding the disintegrant in granulation and mixing the disintegrant after granulation, the intestinal disease treatment pharmaceutical composition tablet has good disintegration effect.

Owner:SUZHOU CHUNGHWA CHEM & PHARMA IND

Single-sided hollow stainless steel welded filter plate

ActiveCN104941322BWon't tearQuality assuranceStationary filtering element filtersWire gauzeMetallurgy

A single-sided hollow stainless steel welded filter plate, the support layer is fixed between the stainless steel forming base plate and the stainless steel wire mesh; the outer edges of the stainless steel forming base plate and the stainless steel wire mesh are welded and fixed; the support ring is provided with diversion grooves at intervals, and is installed on the stainless steel forming base plate and the stainless steel wire mesh The stainless steel wire mesh is located in the inner ring of the support layer, and a through liquid outlet hole is provided in the middle of the stainless steel forming bottom plate, the stainless steel wire mesh and the support ring. The advantages of the present invention are: the stainless steel forming bottom plate is integrally welded with the outer edge of the stainless steel wire mesh to form a single-sided filter unit, and the edge is welded firmly during reverse flushing, and the outer edge of the filter plate will not be torn, ensuring the quality of the filtered liquid. The stainless steel wire mesh is not easy to stick to impurities, not easy to clog, and easy to wash. The gap of the stainless steel wire mesh on the upper surface is uniform, and the stainless steel formed bottom plate ensures that the liquid does not leak. It has the characteristics of high strength and high strength.

Owner:天津市宝钜净化设备工程有限公司

Composite nutrient planting sand and manufacture method thereof

ActiveCN103168639ACircumstances to Avoid LossIncrease profitCultivating equipmentsNutrientFertilizer

The invention belongs to the field of sand planting, and particularly relates to composite nutrient planting sand which can be directly used for planting and has functions of water retention and fertilizer retention and a sand planting structure containing the composite nutrient planting sand. The planting sand comprises a porous sand ball, a microbe bacterium membrane and a nutrient membrane, wherein the microbe bacterium membrane and the nutrient membrane are sequentially wrapped outside the surface of the porous sand ball from inside to outside. The porous sand ball is in a porous structure formed by natural sand granules and adhesion agents at least containing hydrophilic adhesives in an adhesive mode, and a pore suitable for adsorption is formed between each two adjacent natural sand granules. According to the planting sand, the existing natural sand granules are adhered and form pores, nutrient fertilizer is effectively maintained by means of porous performance of the sand ball, accordingly the fertilizer and other nutrient substances which are suitable for plant growth can be loaded in pores and on surfaces through hanging membranes, the planting sand capable of supplying the fertilizer is formed, necessary fertilizer nutrients are provided for the plant growth and meanwhile fertilizer the occasion that the fertilizer runs off along with water loss is effectively avoided, and the utilization rate of the fertilizer is beneficially improved.

Owner:BEIJING RECHSAND SCI & TECH GRP

A kind of preparation method of chitosan composite acetalized polyvinyl alcohol medical dressing

ActiveCN102284080ABiocompatiblePromote wound healingAbsorbent padsBandagesSodium bicarbonatePolyvinyl alcohol

The invention discloses a method for preparing a chitosan compound acetalized polyvinyl alcohol medical dressing. The method comprises the following steps of: dissolving chitosan in an acetic acid aqueous solution to obtain a chitosan solution; mixing polyvinyl alcohol-AH26 and polyvinyl alcohol-1799, dissolving the mixture in boiled water, and uniformly mixing the mixture with the chitosan solution to obtain chitosan / polyvinyl alcohol blended solution; mixing the polyvinyl alcohol-AH26 and polyvinyl alcohol-1799, and dissolving the mixture in boiled water, adding sodium dodecyl sulfate, formaldehyde solution, sodium bicarbonate and hydrochloric acid, and stirring until foaming to obtain acetalized polyvinyl alcohol; and adding the polyvinyl alcohol / chitosan blended solution into the acetalized polyvinyl alcohol, injecting into a mold for solidifying to prepare the chitosan compound acetalized polyvinyl alcohol medical dressing. The medical dressing prepared by the method has biocompatibility, can promote wound healing, has high tensile strength, excellent air permeability, water absorption and foamability, does not have remarkable cytotoxicity, and can be used for treating wounds.

Owner:广州智焜生物科技有限公司

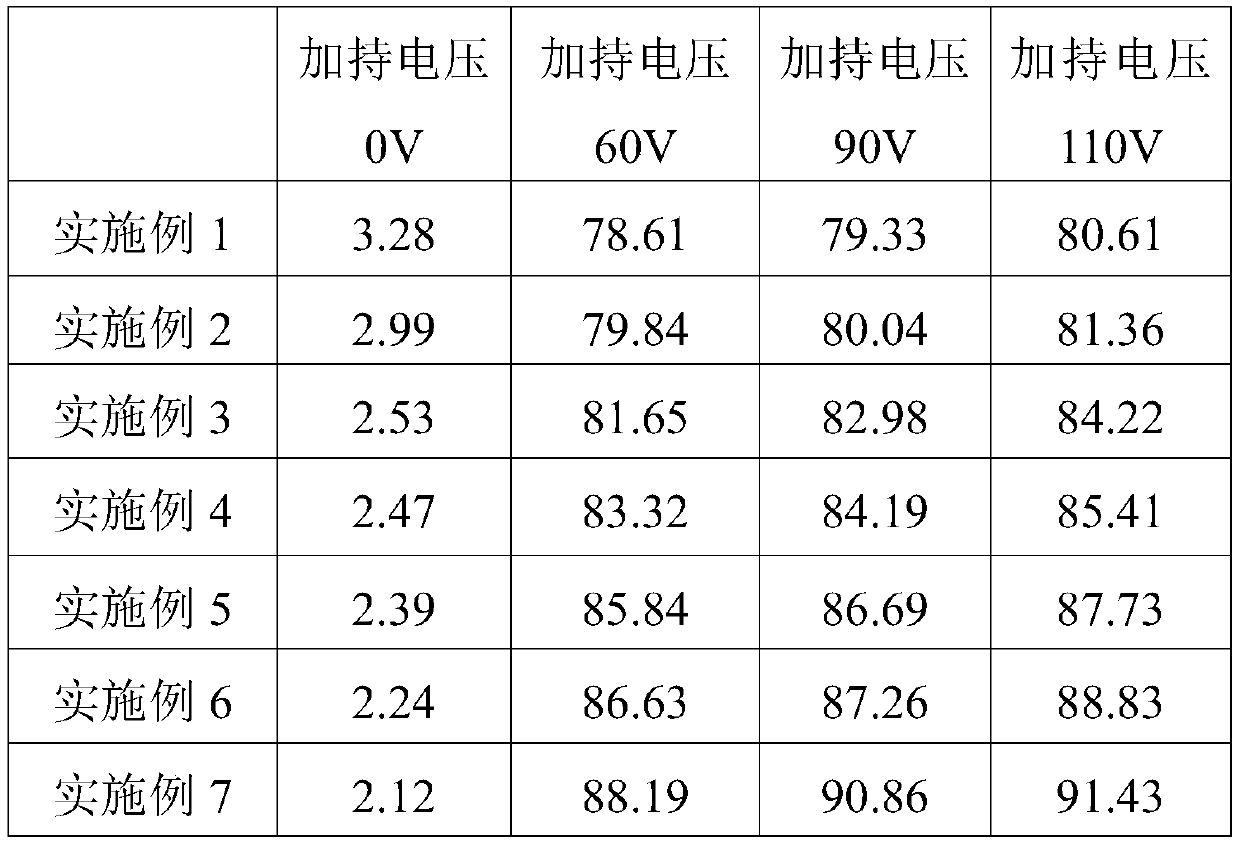

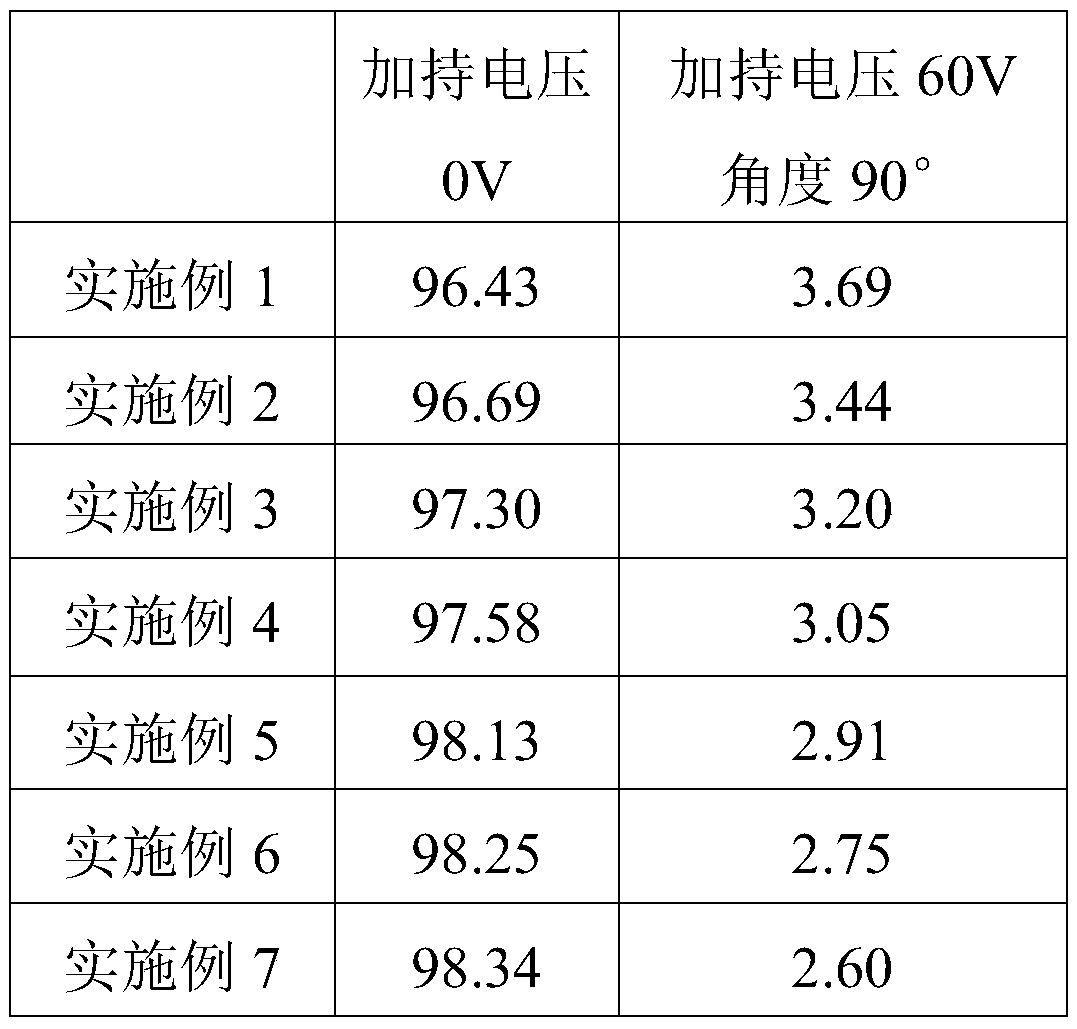

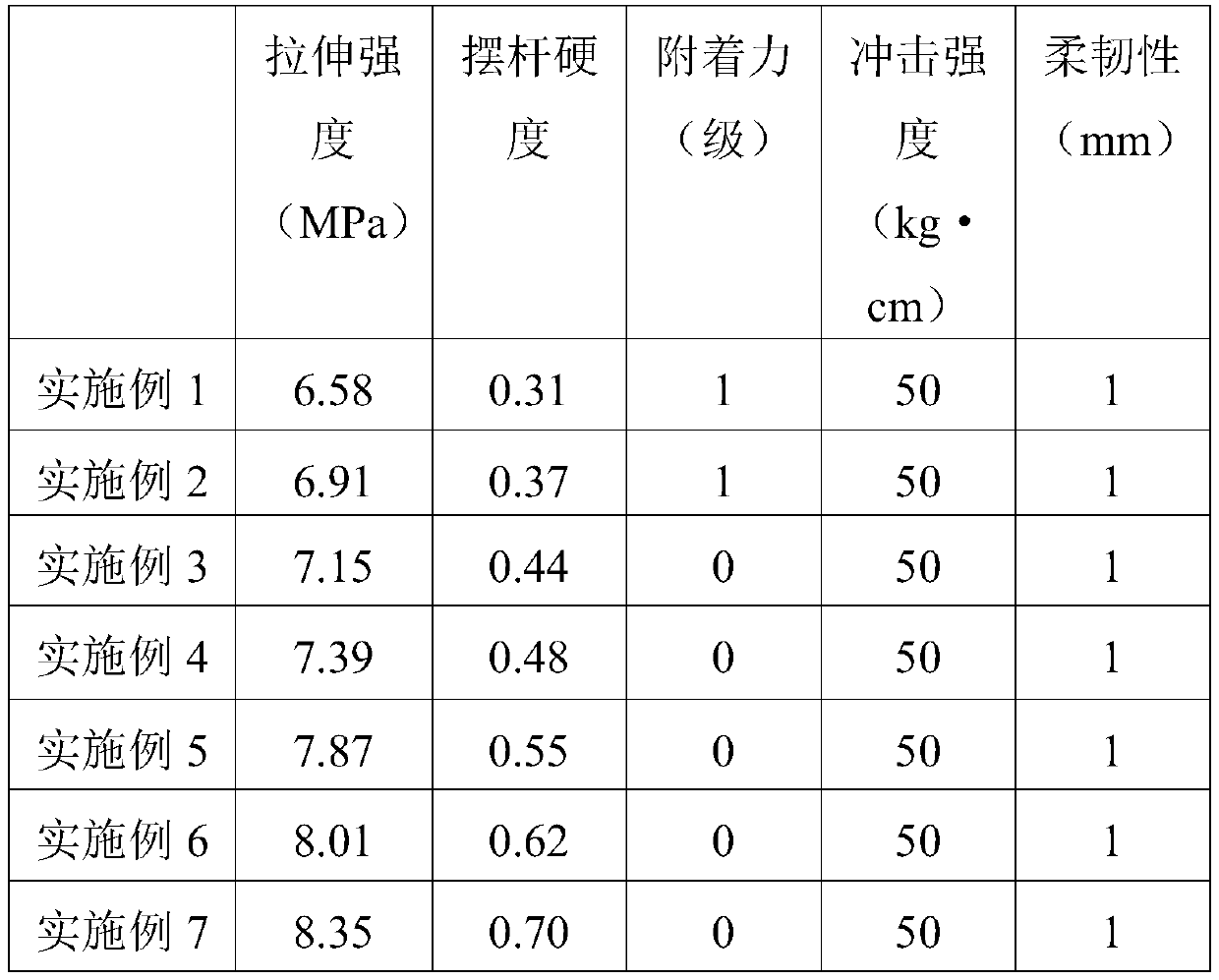

High-transmittance intelligent liquid crystal dimming film and preparation method thereof

The invention discloses a high-transmittance intelligent liquid crystal dimming film and a preparation method thereof. The preparation method of the high-transmittance intelligent liquid crystal dimming film comprises the following steps: step S1, fully and uniformly stirring urethane acrylate, biphenyl liquid crystal, spacer particles, a photoinitiator, a surfactant and pentaerythritol ester to obtain a mixed solution; step S2, placing the mixed solution between two conductive films, and rolling to form a thin film; step S3, carrying out first-step ultraviolet irradiation polymerization on the film; and step S4, under the condition that an electric field is applied to the thin film, performing second-step ultraviolet irradiation polymerization on the thin film to obtain the high-transmittance intelligent liquid crystal dimming film. The high-transmittance intelligent liquid crystal dimming film has good shielding performance when in an off state, has a good visual effect when in an onstate, and is suitable for being used in occasions needing privacy protection, space permeability, safety defense and light ray adjustability.

Owner:佛山市水大光电科技有限公司

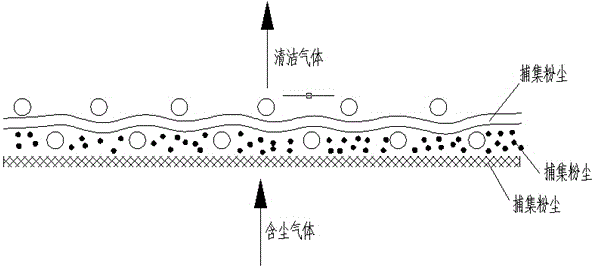

Inertia and filtering compound dust collector

The invention discloses an inertia and filtering compound dust collector which is characterized by comprising an ash bucket (3), an air inlet (1) and an air outlet (5), wherein the ash bucket (3) is arranged at the bottom of a shell (6); the air outlet (5) is formed at the top of the shell (6); the air inlet (1) is formed on one side of the shell (6); one baffle (2) which inclines for 120 degrees from the air inlet (1) is arranged in the shell (6); the other baffle (2) is arranged on the opposite side in the shell (6). The two baffles are parallel to each other.

Owner:GUIZHOU UNIV

Dry process paper filter tip and its prepn process

ActiveCN1810167AElasticity does not affectFeel full and firmTobacco smoke filtersFiberElectrical resistance and conductance

The present invention reveals one kind of dry process paper filter tip and its preparation process. The filter tip material including wood pulp fiber and coat core fiber is first antistatic treated with non-toxic ester or ether to specific resistance smaller than 900 megohm.cm; and the opened material is then metered, conveyed, airflow netted, heated to form under negative pressure, sprayed with glue, stoved, matured, puffed and settled in cold wind to form dry process paper of plane weight 35-75 g / sq m and thickness of 0.8-3.5 mm. The dry process paper is finally formed into the filter tip, and the filter tip has filter rate over 43 %, hardness over 89 % and ideal rebounding effect after kneads.

Owner:SHANGHAI HUABAO BIOLOGICAL TECH

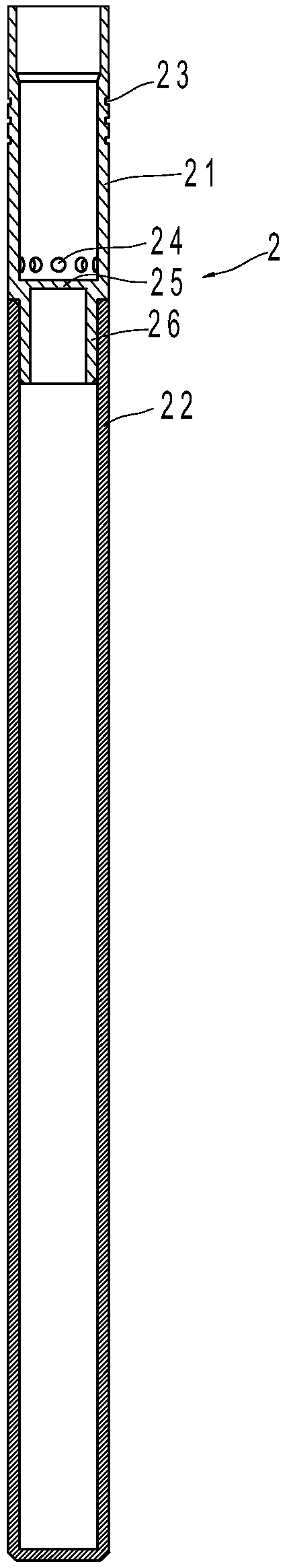

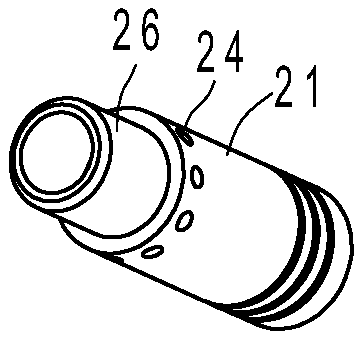

Hollow fiber membrane filter core and packaging method thereof

ActiveCN111359444AReduce sticking phenomenonReduce concentration polarizationSemi-permeable membranesEngineeringHollow fiber membrane

The invention discloses a hollow fiber membrane filter core, which comprises a filter shell, a central pipe, hollow fiber membranes, a glue sealing shell and glue sealing layers, wherein an opening isformed in the upper end of the filter shell, a dirty water outlet hole is formed in a bottom plate, the central pipe is arranged in the middle of the filter shell, one end is opened to form a water inlet port, water distribution holes are formed in the side wall, the hollow fiber membrane is positioned in the filter shell, the periphery of the water inlet port of the central pipe is uniformly coated with the first end of the hollow fiber membrane, the glue sealing shell is arranged on the periphery of the opening of the filter shell, and the sealing glue layers are positioned between the inner wall of the sealing glue shell and the hollow fiber membrane, between the hollow fiber membranes and between the hollow fiber membrane and the outer wall of the central pipe. The invention further discloses a glue sealing method of the hollow fiber membrane filter core. The hollow fiber membrane filter core has the advantages of uniform influent distribution and reduction of membrane filament concentration polarization.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com