Single-sided hollow stainless steel welded filter plate

A stainless steel and filter plate technology, applied in the fields of filtration and separation, fixed filter element filters, chemical instruments and methods, etc., can solve the problems of high temperature resistance, easy clogging, low material strength, etc. , high-strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

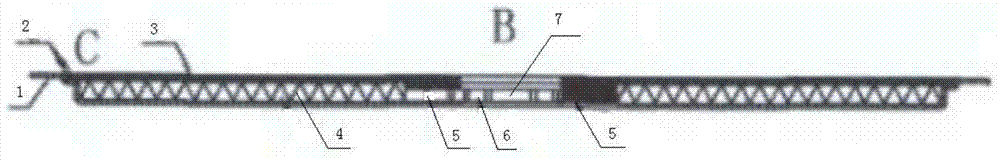

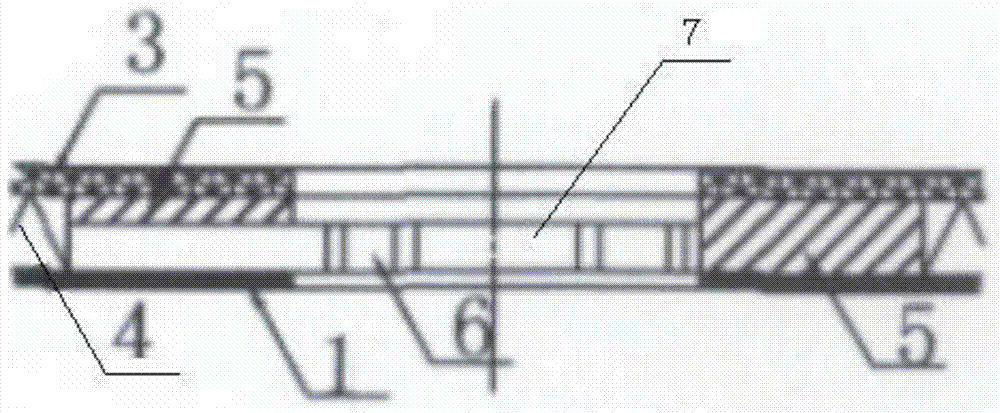

[0020] Example: such as figure 1 As shown, a single-sided hollow stainless steel welded filter plate is made of a stainless steel forming bottom plate 1 with a diameter of 44cm and a stainless steel wire mesh 3 with a diameter of 41cm. The aperture of the stainless steel wire mesh 3 is 0.025cm, and the stainless steel forming bottom plate 1 is arranged on a stainless steel The lower layer of the wire mesh 3, the supporting layer 4 integrally welded with the stainless steel forming base plate 1 is set between the stainless steel forming base plate 1 and the stainless steel wire mesh 3, the supporting layer 4 is mesh (or strip-shaped), the outer diameter is 39cm, and the material is stainless steel The wire mesh has an aperture of 0.5cm; the outer edge of the stainless steel forming bottom plate 1 and the stainless steel wire mesh 3 ranges from 0 to 40mm, and is welded and fixed by adding stainless steel welding wire or self-fluxing welding to form an integral welding seam 2; the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com