Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

158results about How to "Solve alignment problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

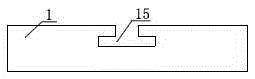

Circuit board having embedded components and manufacturing method thereof

ActiveCN103906372ASolve alignment problemsLow costPrinted circuit assemblingFinal product manufactureConductive pasteElectronic component

Owner:礼鼎半导体科技秦皇岛有限公司 +1

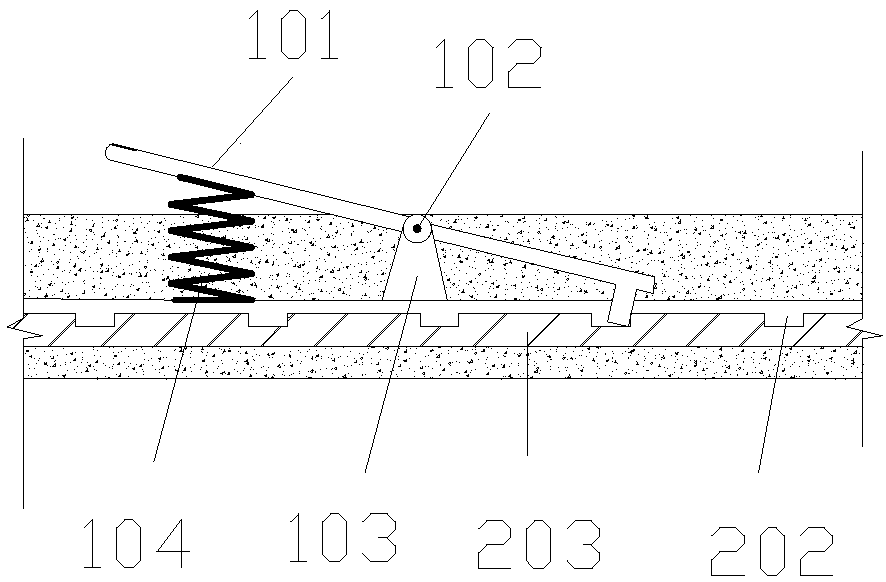

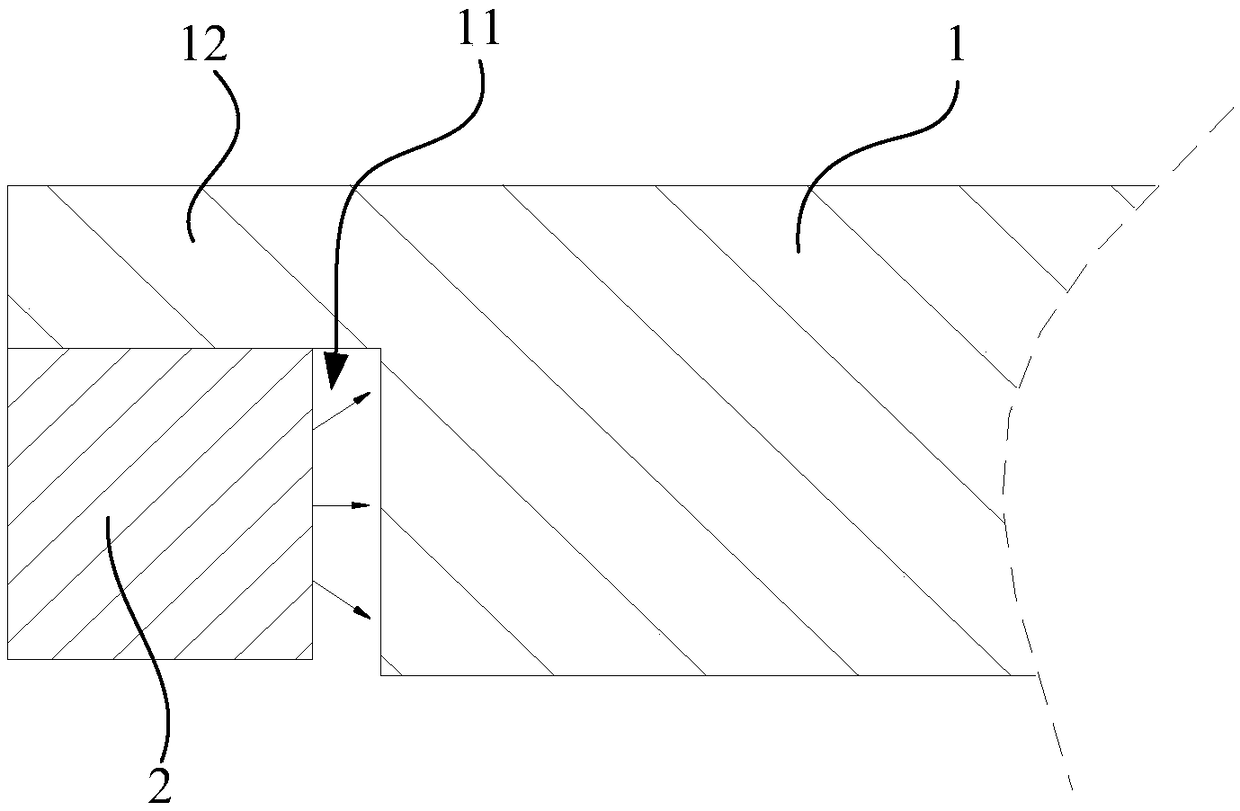

Connecting structure for vertical reinforcement bars of prefabricated wall parts

InactiveCN103132656ACapable of error adjustmentEasy to installBuilding reinforcementsEngineeringRebar

Owner:SOUTHEAST UNIV

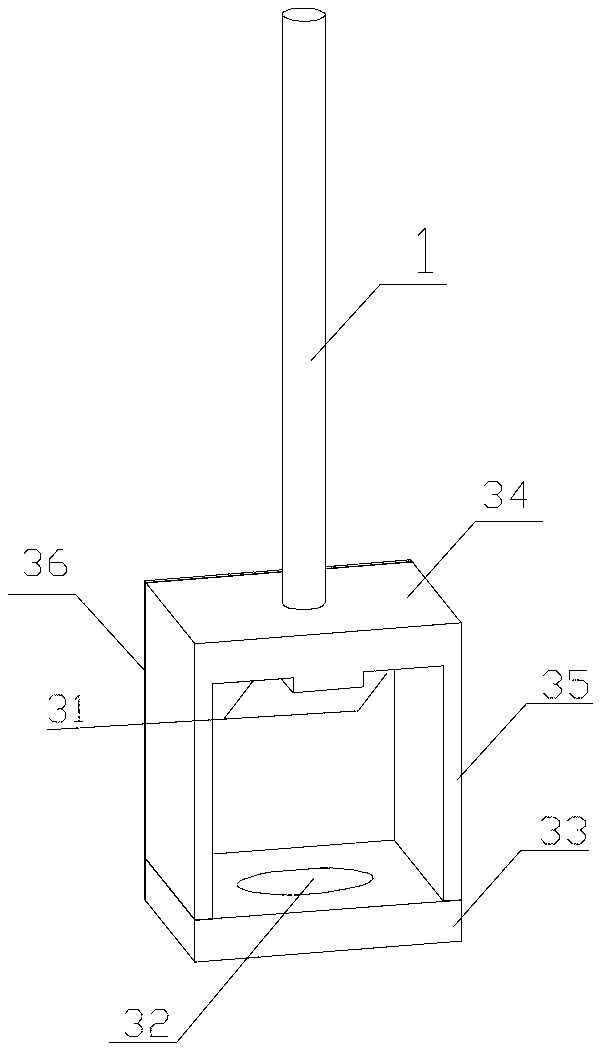

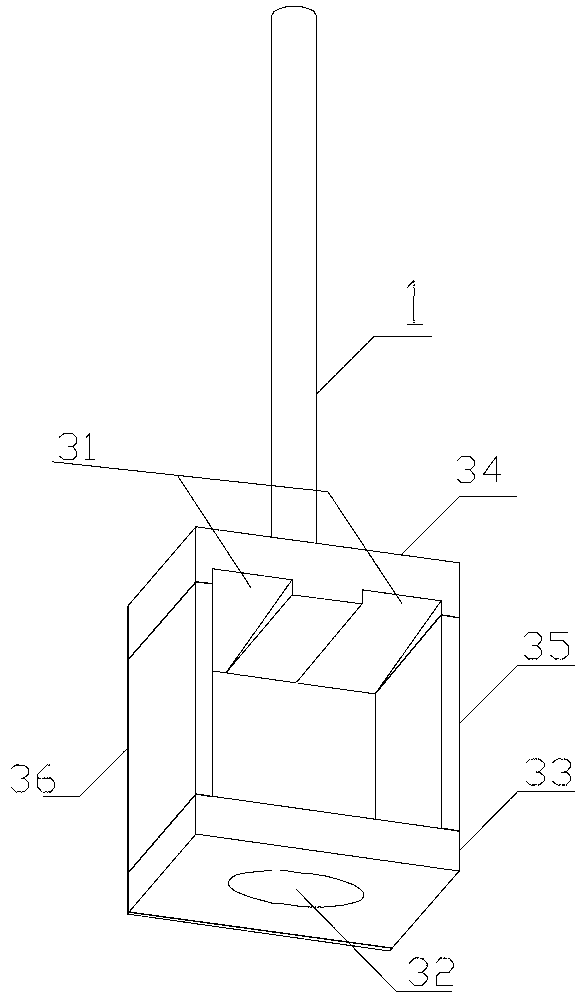

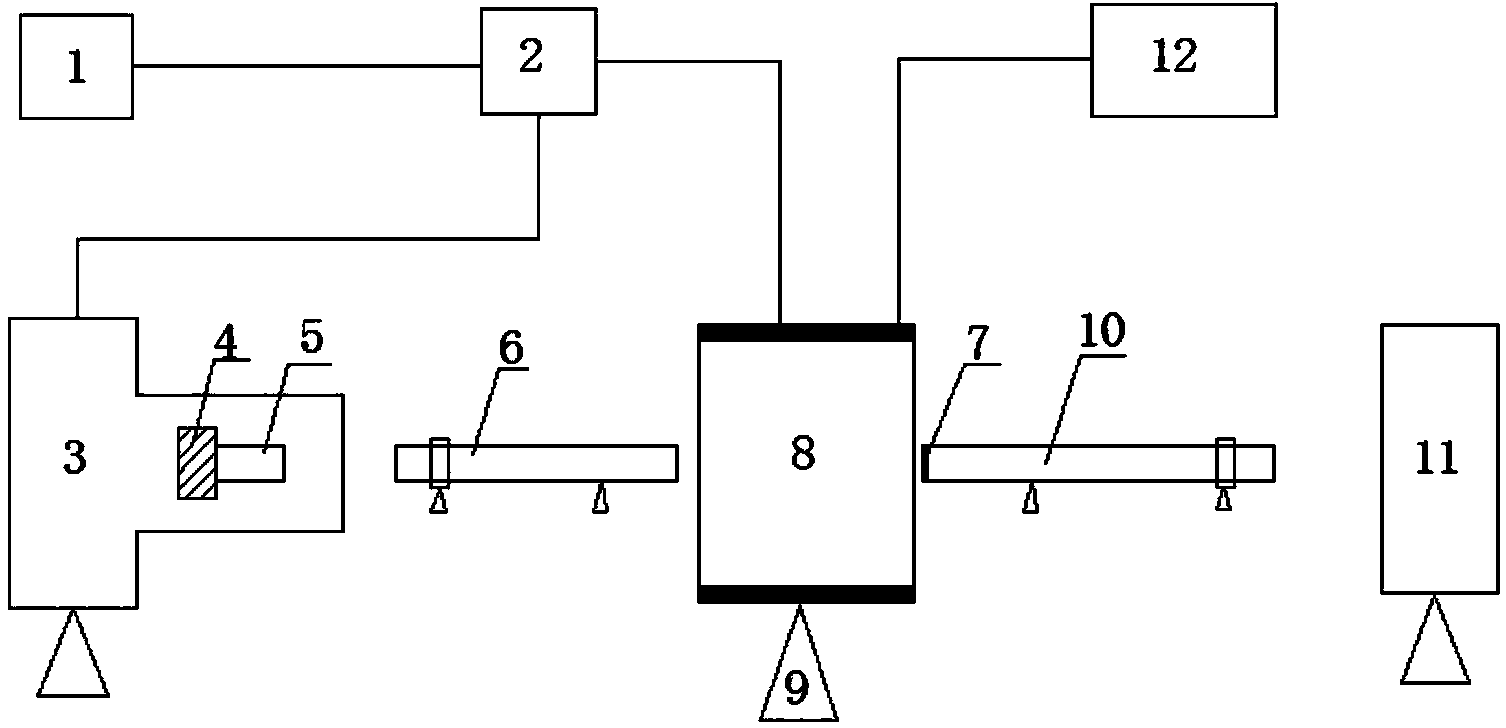

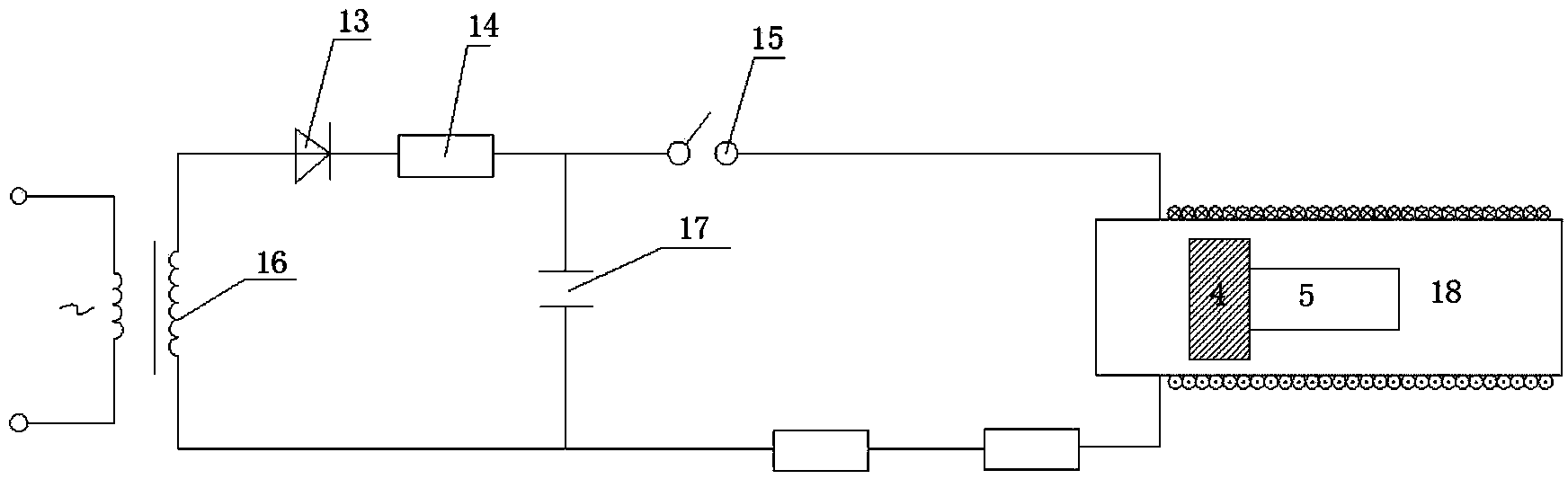

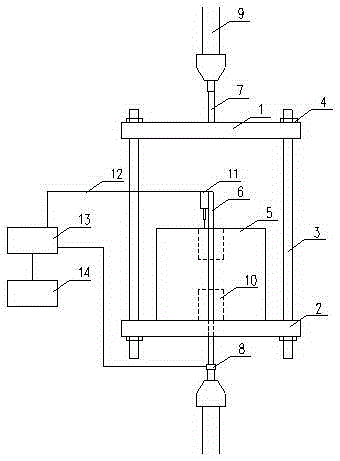

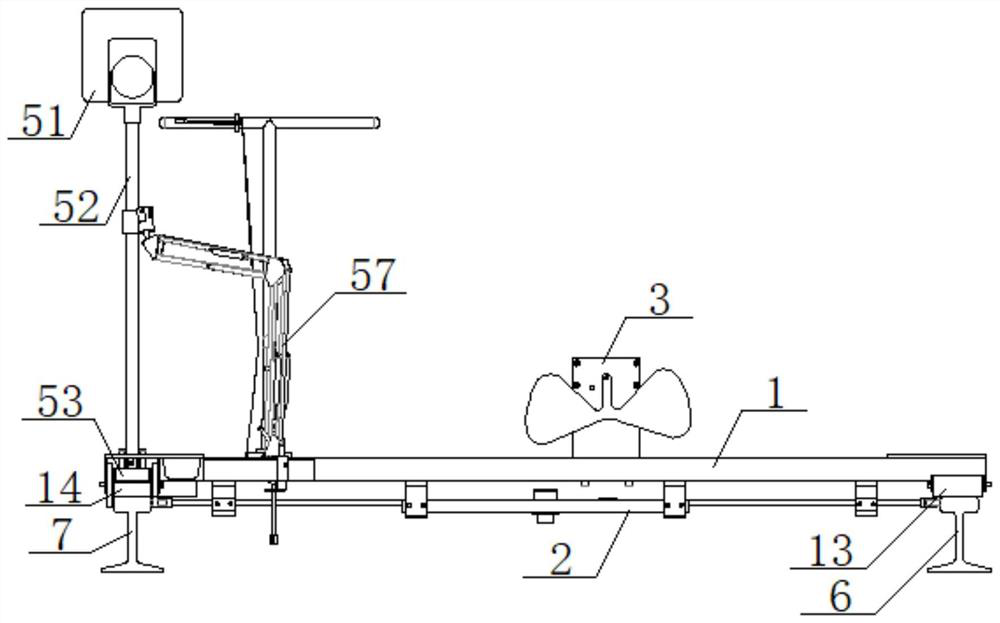

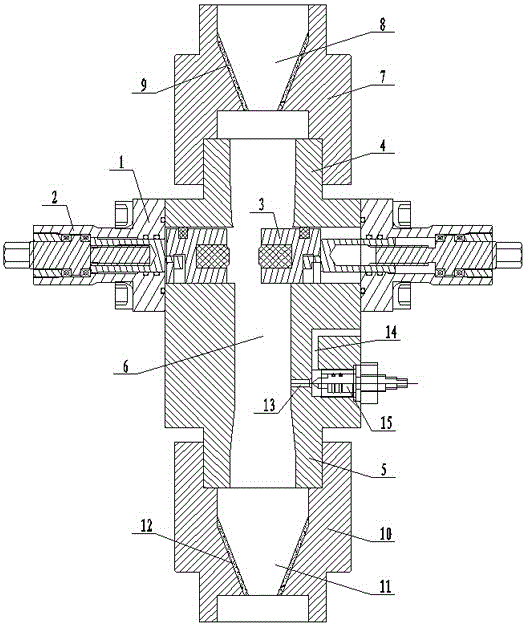

Hopkinson pressure bar experimental apparatus

InactiveCN103868806AAvoid Complexity and UncertaintyHigh repeatabilityStrength propertiesStress waveEngineering

The invention discloses a Hopkinson pressure bar experimental apparatus. The Hopkinson pressure bar experimental apparatus is characterized by comprising an electromagnetic trigger switch (1), a heating furnace door automatic opening switch (2), an electromagnetic driving device (3), a driving panel (4), a bullet (5), an incident pole (6), a force sensor (7), a heating furnace (8), a heating furnace supporting device (9), a transmitting pole (10), a buffer device (11) and an air compressing and filtering device (12); and the heating furnace is designed for preventing a test piece from being oxidized at a high temperature while heating the test piece and keeping the temperature of the test piece; as high temperature can influence the conduction of stress wave, the digital image correlation (DIC) technology is used for obtaining the change images of the test piece and analyzing the strain, the force sensor is used for analyzing stress, so as to obtain a stress strain curve. The Hopkinson pressure bar is combined with the electromagnetic driving technology and the DIC technology, and therefore the application range of the Hopkinson pressure bar experiment is expanded and a new method for acquiring dynamic parameters of high temperature materials is provided.

Owner:HUNAN UNIV

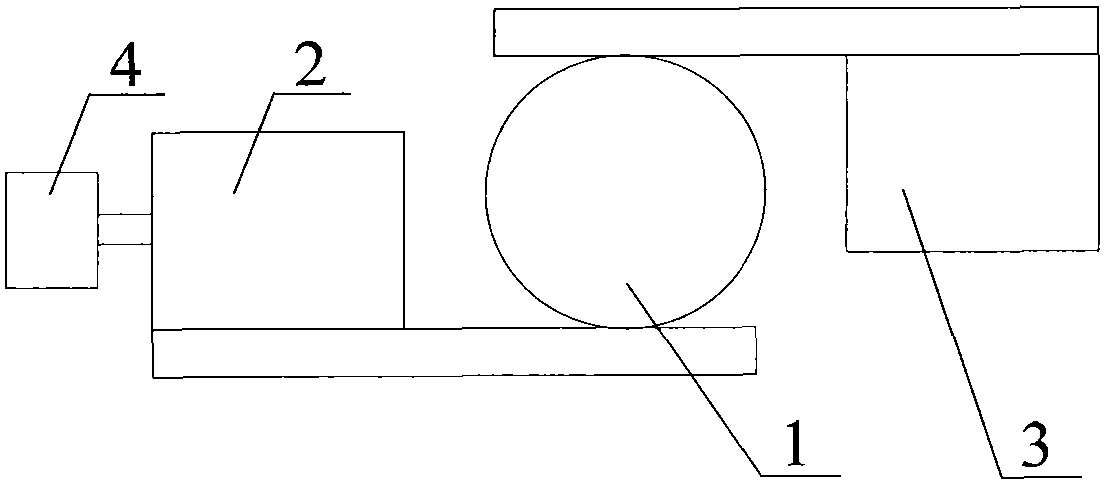

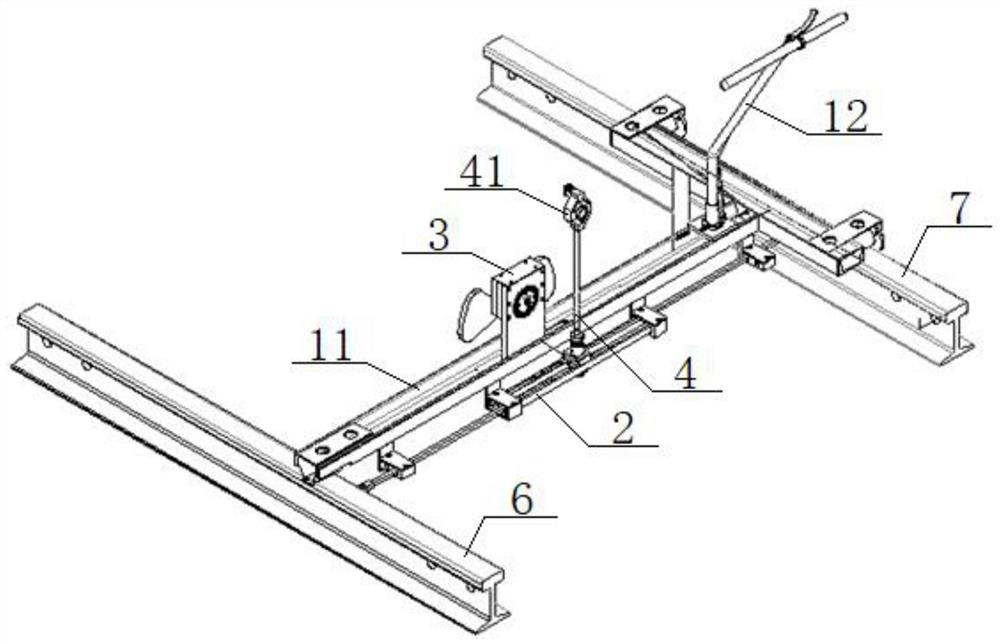

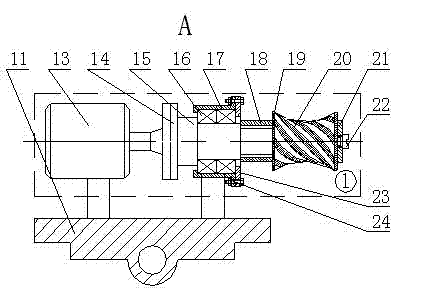

Centering adjustment method for wheel sets of locomotive test stand and traction force meter stand thereof

ActiveCN102564777AMeet the requirements of the test conditionsEasy to control and moveRailway vehicle testingMeasurement of vehicle's tractive/propulsive powerMeasurement deviceReduction drive

The invention relates to a centering adjustment method for wheel sets of a locomotive test stand and a traction force meter stand thereof. In order to enable all locomotive wheels of a locomotive to completely fall into corresponding rail wheels in foundation pits of the test stand, during test, the centers of the locomotive wheels are required to be kept perpendicularly centered with the centers of the rail wheels, and the locomotive is required to run in location mode in the horizontal direction, and thus the tested locomotive can be ensured to run stably and safely on the test stand. The centering adjustment method of the test stand of the locomotive comprises the following steps of 1 selecting the central lines of the foundation pits of the rail wheels to serve as location reference lines; 2 adopting a double-traction force meter stand to serve as the test stand; 3 performing secondary centering adjustment on the locomotive wheel sets and the rail wheel sets; and 4 providing the same pre-tightening force for a car coupler of the tested locomotive, and offsetting or reducing the horizontal displacement of the locomotive caused by deformation of the car coupler buffer. A speed reducer shaft of the traction force meter stand is parallel with a crew, a nut is screwed on the screw, a chain wheel on the speed reducer shaft is connected with a chain wheel on the nut through a chain, and one end of the screw is connected with a traction force measurement device.

Owner:CRRC DALIAN INST CO LTD

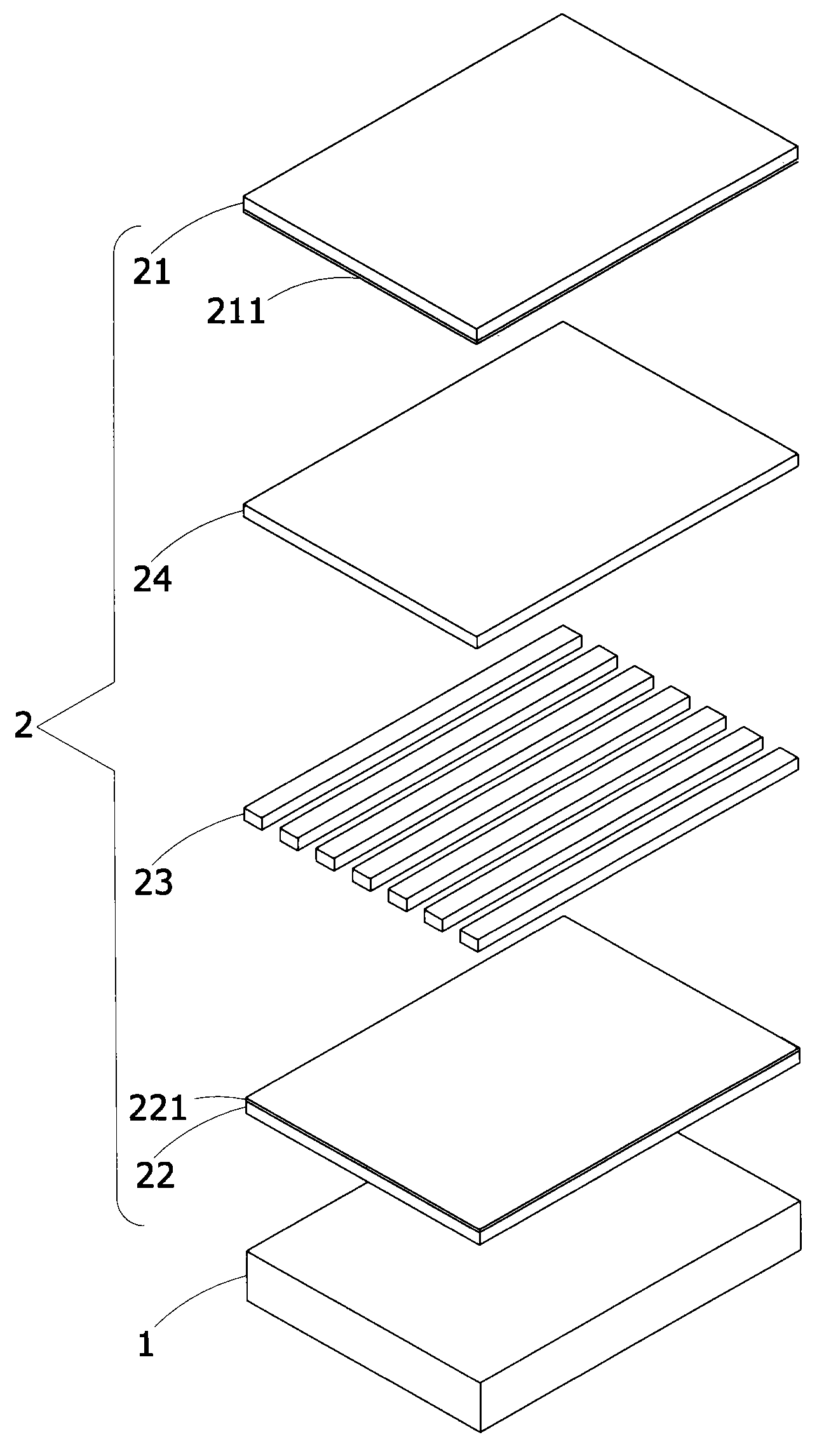

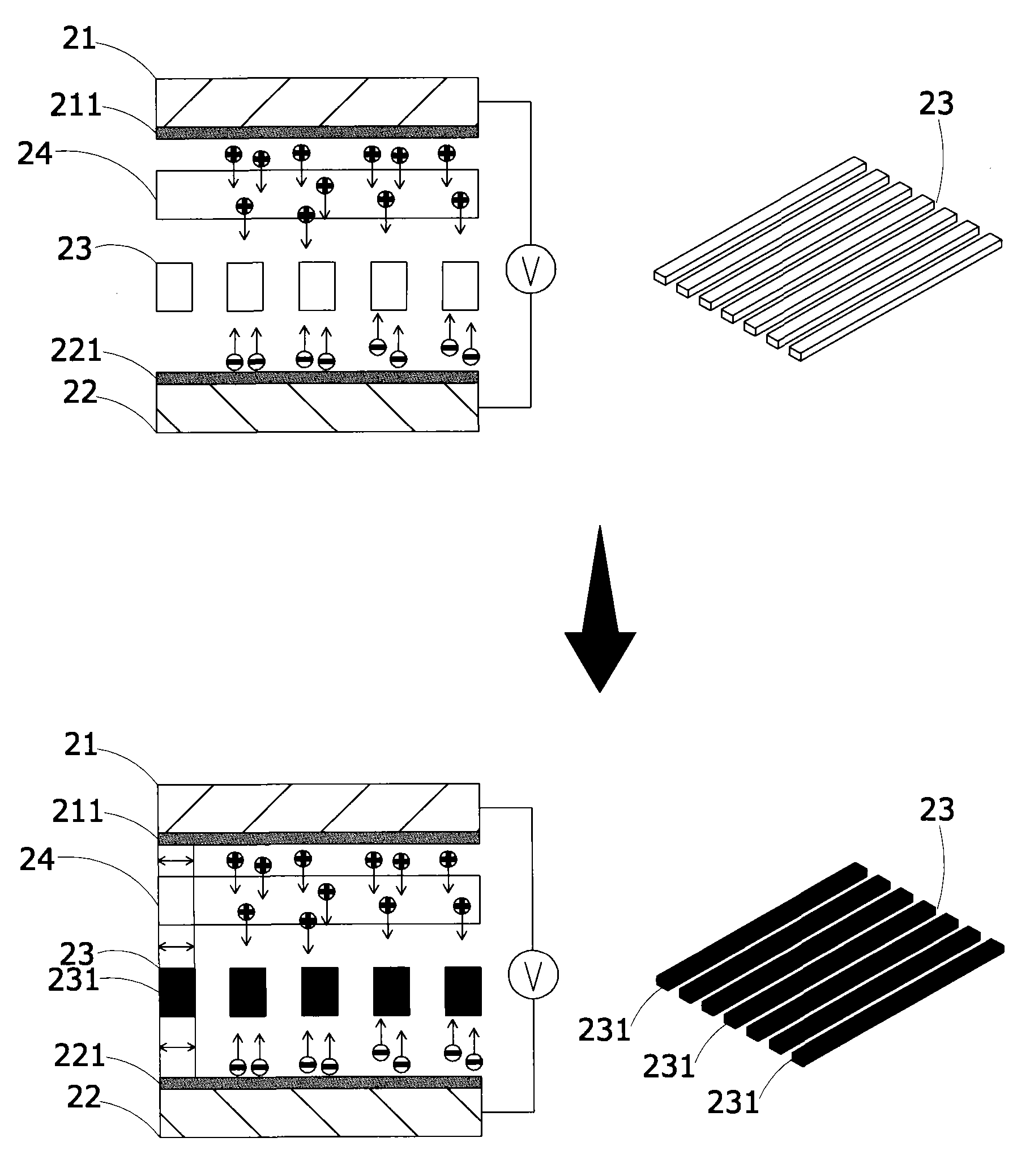

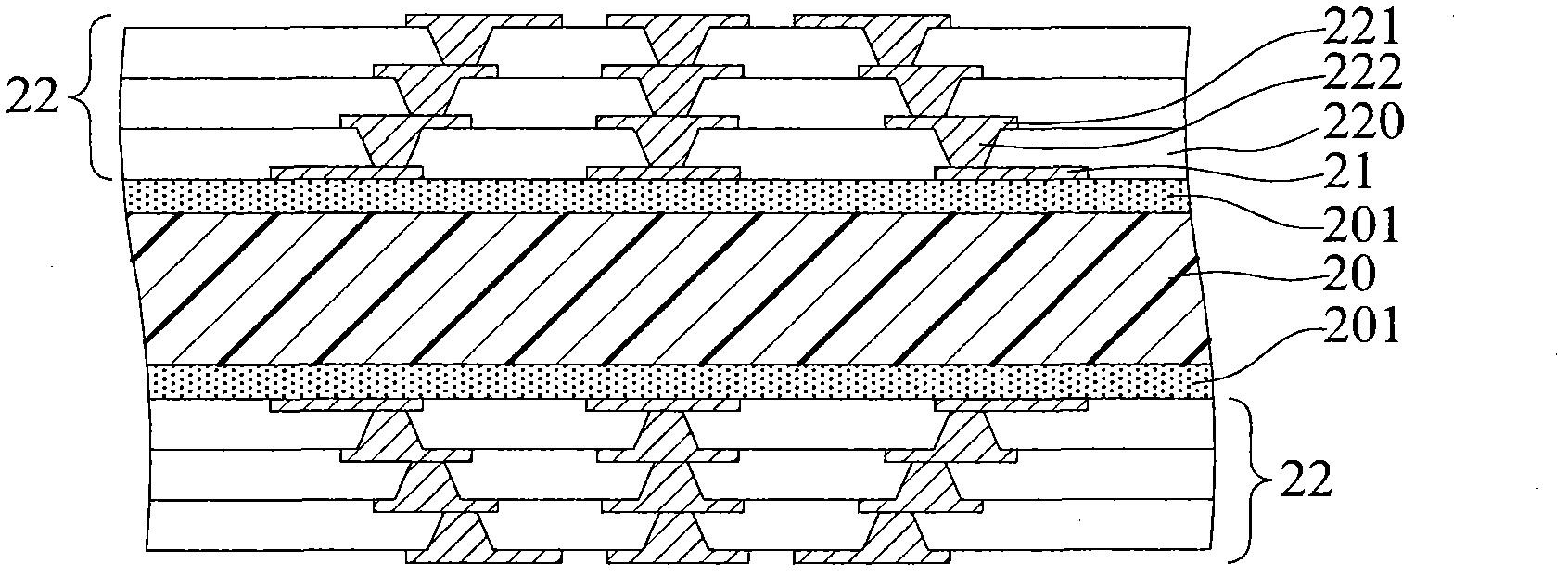

2D/3D(2 dimensional/3 dimensional) image switching display device

InactiveCN102338960ANo moiréDoes not affect discoloration mechanismSteroscopic systemsNon-linear opticsElectricity3d image

The invention relates to a 2D / 3D(2 dimensional / 3 dimensional) image switching display device which comprises an image display unit and an image switching unit combined with the surface of the image display unit, wherein the image switching unit comprises a first transparent substrate and a second transparent substrate; the surfaces of the first transparent substrate and the second transparent substrate are respectively and correspondingly provided with a first transparent conductive element and a second transparent conductive element; an electrochromic layer and an electrolytic layer are arranged on the first transparent substrate and the second transparent substrate; accordingly, when the image display unit is converted from the plane image display into the solid image display, the first and second transparent conductive elements are electrically conducted, thereby converting the electrochromic layer from transparent state to a dark color shading area and generating no folded grain when an solid image divided into a left image and a right image is received by eyes; when the solid image is displayed by the 2D / 3D image switching display device, the solid image can be displayed directly without using an additional parallax barrier shielding device; and the image switching unit can switch different shielding angles according to an image direction of the image display unit, so that a user is capable of viewing the solid image in all directions of a device.

Owner:J TOUCH CORPORATION

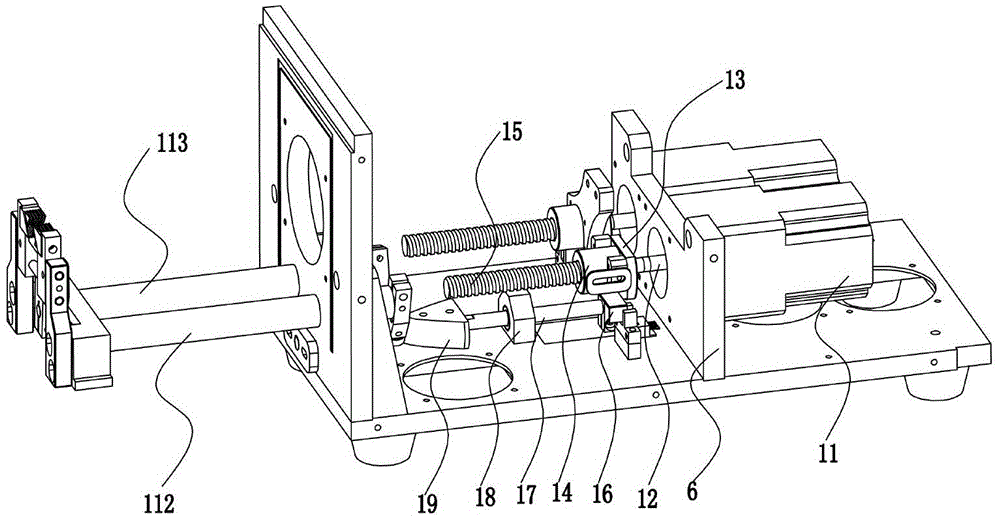

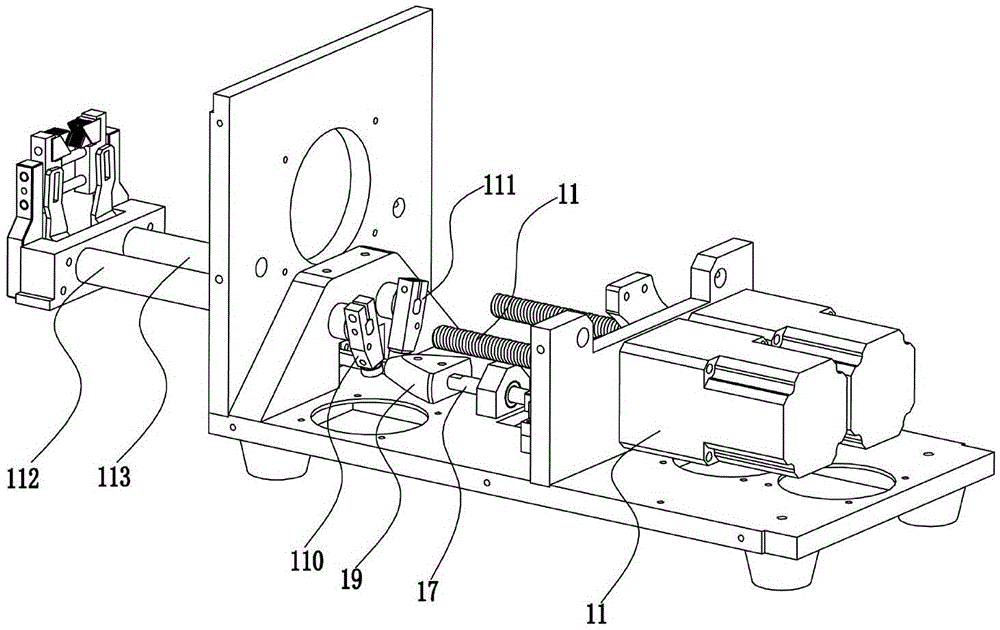

Wire-stripping machine equipped with three-cutter type stripping mechanism

InactiveCN105071194ASolve peeling alignment and balanceGuaranteed peeling qualityLine/current collector detailsApparatus for removing/armouring cablesEngineeringMechanical engineering

The invention discloses a wire-stripping machine equipped with a three-cutter type stripping mechanism. The wire-stripping machine comprises a cutter rest assembly, a stripping assembly, a cutter rest driving mechanism, a stripping rotation driving mechanism, and a stripping axial motion driving mechanism. The stripping assembly extends out of the wire-stripping machine. The inner end of the stripping assembly is connected with the stripping rotation driving mechanism and the stripping axial motion driving mechanism, so that the stripping assembly is driven to rotate radially and move axially. The cutter rest assembly extends out of the stripping assembly, and a cable to be stripped is placed inside the cutter rest assembly so as to be clamped and fixed. The cutter rest driving mechanism is connected with the inner end of the cutter rest assembly, so the cutter rest assembly is driven to move to enable the cable to be fastened and loosened. The wire-stripping machine is simple in structure. Through adoption of a structure with three cutters that are arranged evenly in a circumferential direction, the high centering effect is exhibited, and the stripping quality is high.

Owner:SHENZHEN JALASO AUTOMATION EQUIP CO LTD

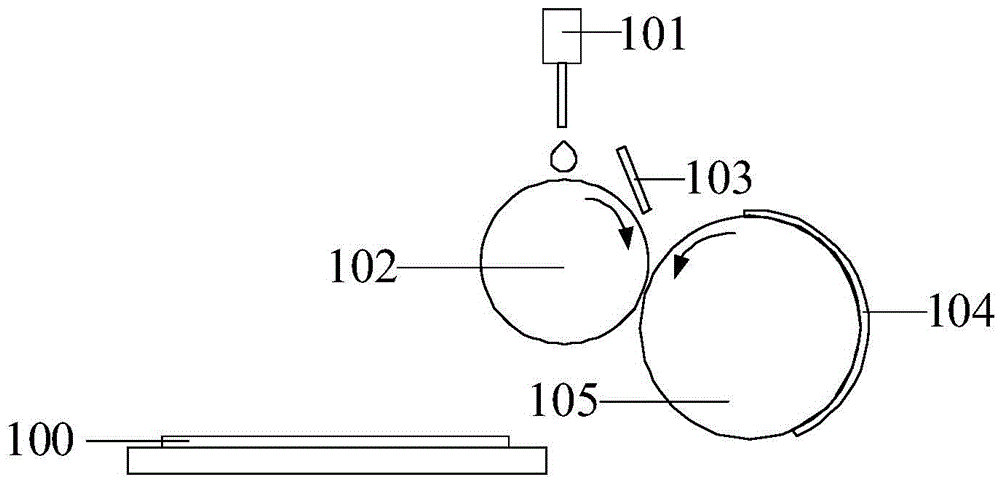

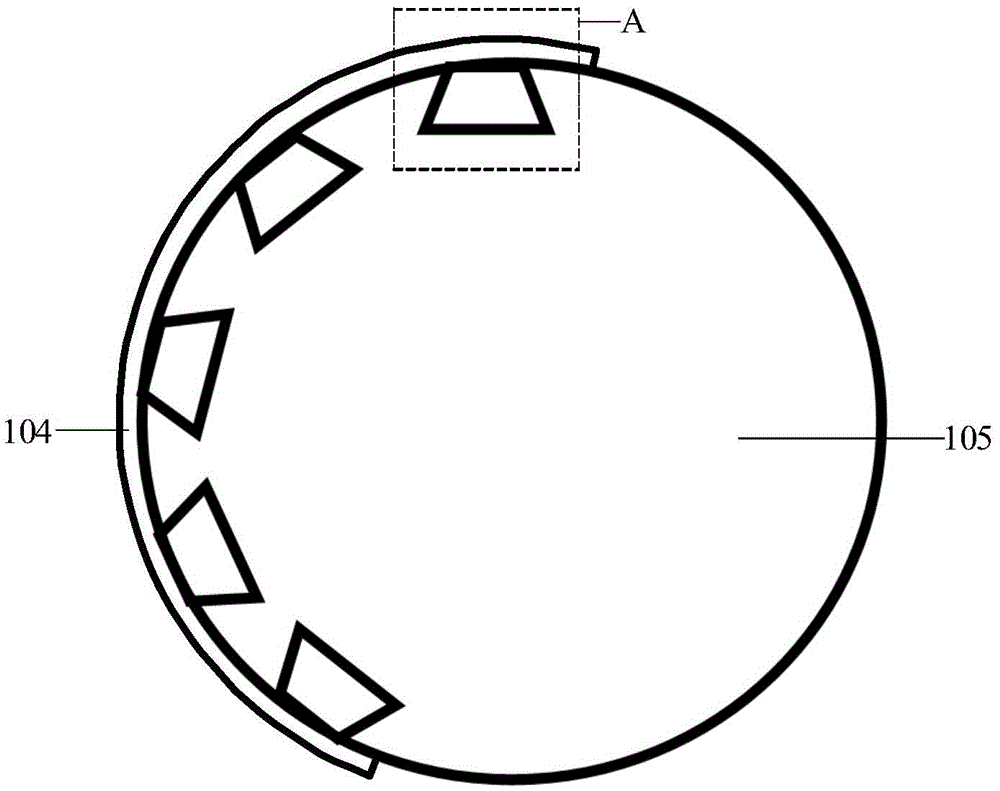

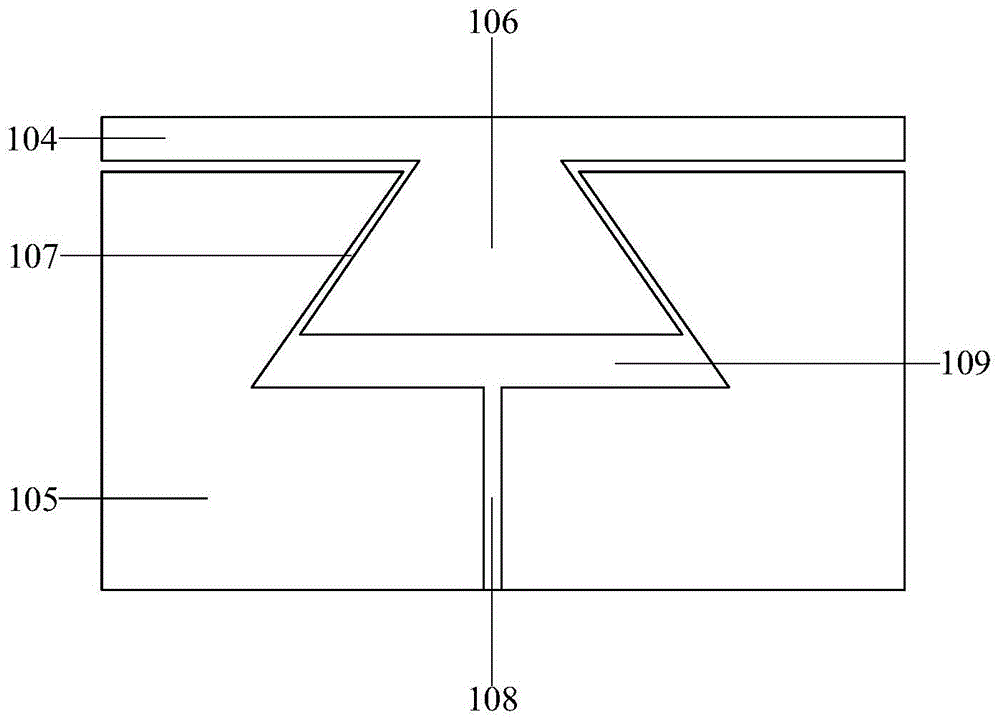

Transfer printing equipment and coater

InactiveCN105644135APrevent slidingSolve alignment problemsTransfer printingVacuum evaporation coatingEngineeringContrast ratio

The invention discloses transfer printing equipment and a coater. The transfer printing equipment comprises an Asai Kasai photosensitive resin plate (APR plate) and a printing roller, wherein a bump of the APR plate is mutually matched with a groove of the printing roller for fixing the APR plate and the printing roller, so that the aligning problem of the APR plate and the printing roller can be solved, the capacity of accommodating polyimide of the APR plate can be regulated, and the orientation and the uniformity of an orientation film are optimized, and therefore, the order of liquid crystal molecular arrangement is strengthened, and the contrast ratio of a display panel is finally improved. Besides, according to the technical scheme provided by the invention, a vacuum adsorption mode is adopted to replace a mechanical fixing mode for firmly adsorbing the APR plate onto the printing roller, so that the APR plate does not generate extension deformation and sliding under the action of printing external force. The technical scheme provided by the invention can prevent the APR plate from generating extension deformation and sliding, and production printing is guaranteed to not deviate, so that the product quality is guaranteed to the greatest extent.

Owner:BOE TECH GRP CO LTD +1

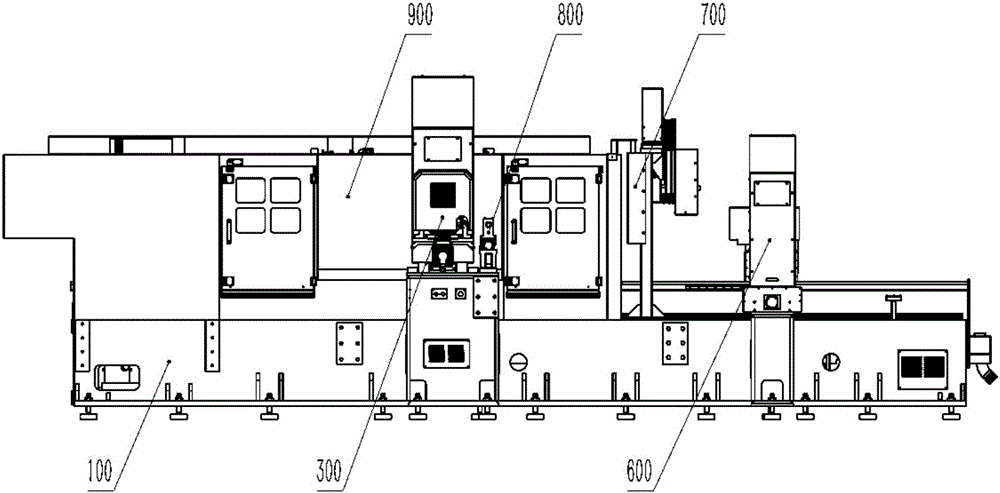

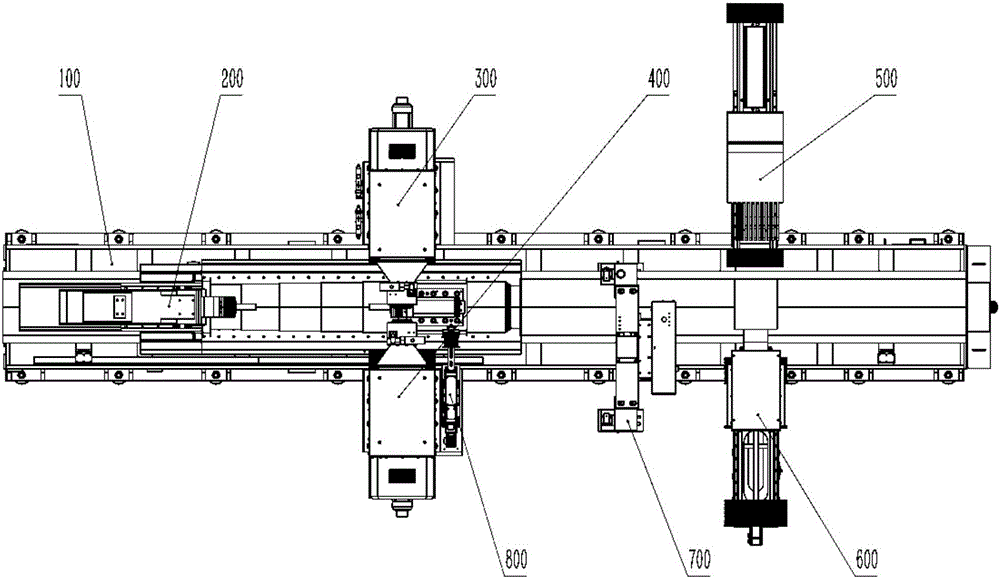

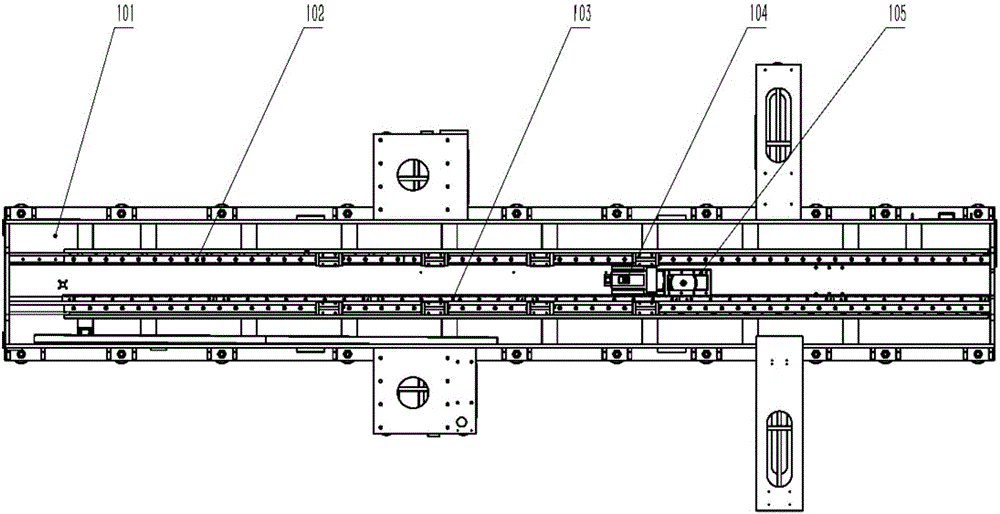

Full-automatic silicon single-crystal rod rolling and grinding integrated equipment

ActiveCN106475878AReduce time between processesImprove processing efficiencyGrinding carriagesGrinding drivesManipulatorEcological environment

The invention relates to silicon single-crystal rod machining equipment and aims to provide full-automatic silicon single-crystal rod rolling and grinding integrated equipment which comprises a long-strip-shaped large bottom frame. Two parallel main guide rails are arranged on the surface of the large bottom frame in the length direction. A grinding work table assembly is movably installed on the two main guide rails, and a main driving motor drives a connecting mechanism so that the grinding work table assembly can move along the main guide rails. Four platforms used for bearing are arranged on the two sides of the large bottom frame and used for bearing a coarse grinding power head assembly, a fine grinding power head assembly, a feeding mechanical hand assembly and a centering mechanical hand assembly correspondingly. A crystal orientation detecting device and a radius detecting unit are further arranged on the large bottom frame. The machining range of the crystal rod rolling and grinding equipment is widened greatly, the machining ability of the crystal rod rolling and grinding equipment is improved greatly, and a silicon bar can be centered automatically; the machining efficiency is improved, and cost of manpower and logistics is saved; long and stable high-precision operation of the equipment can be ensured; and the production noise is remarkably reduced, no organic matter emission is generated, less waste is generated, and the ecological environment is protected.

Owner:ZHEJIANG JINGSHENG MECHANICAL & ELECTRICAL

Coreless package substrate and fabrication method thereof

ActiveCN102867798ASolve alignment problemsSimple manufacturing methodSemiconductor/solid-state device detailsSolid-state devicesEngineeringDielectric layer

Owner:UNIMICRON TECH CORP

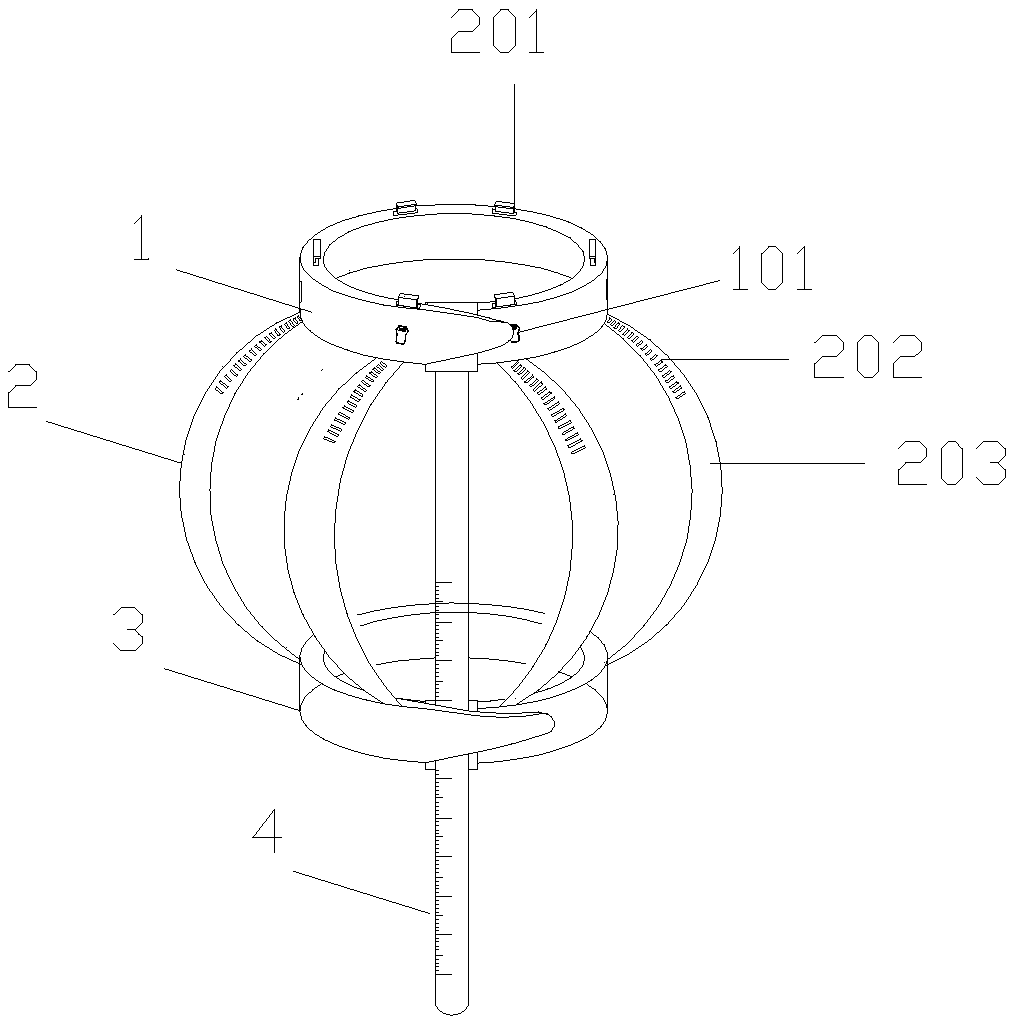

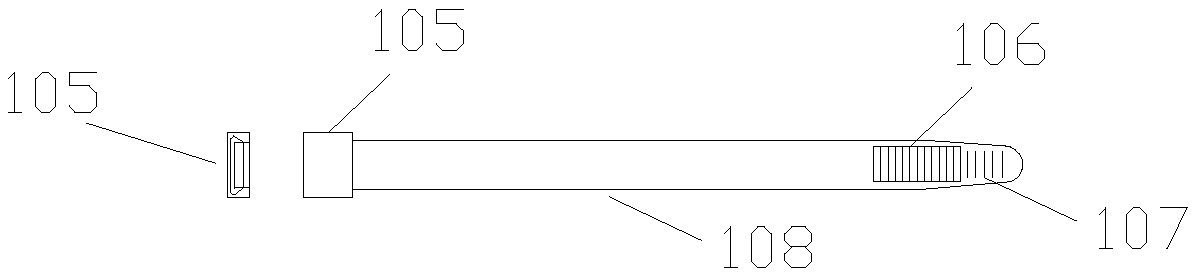

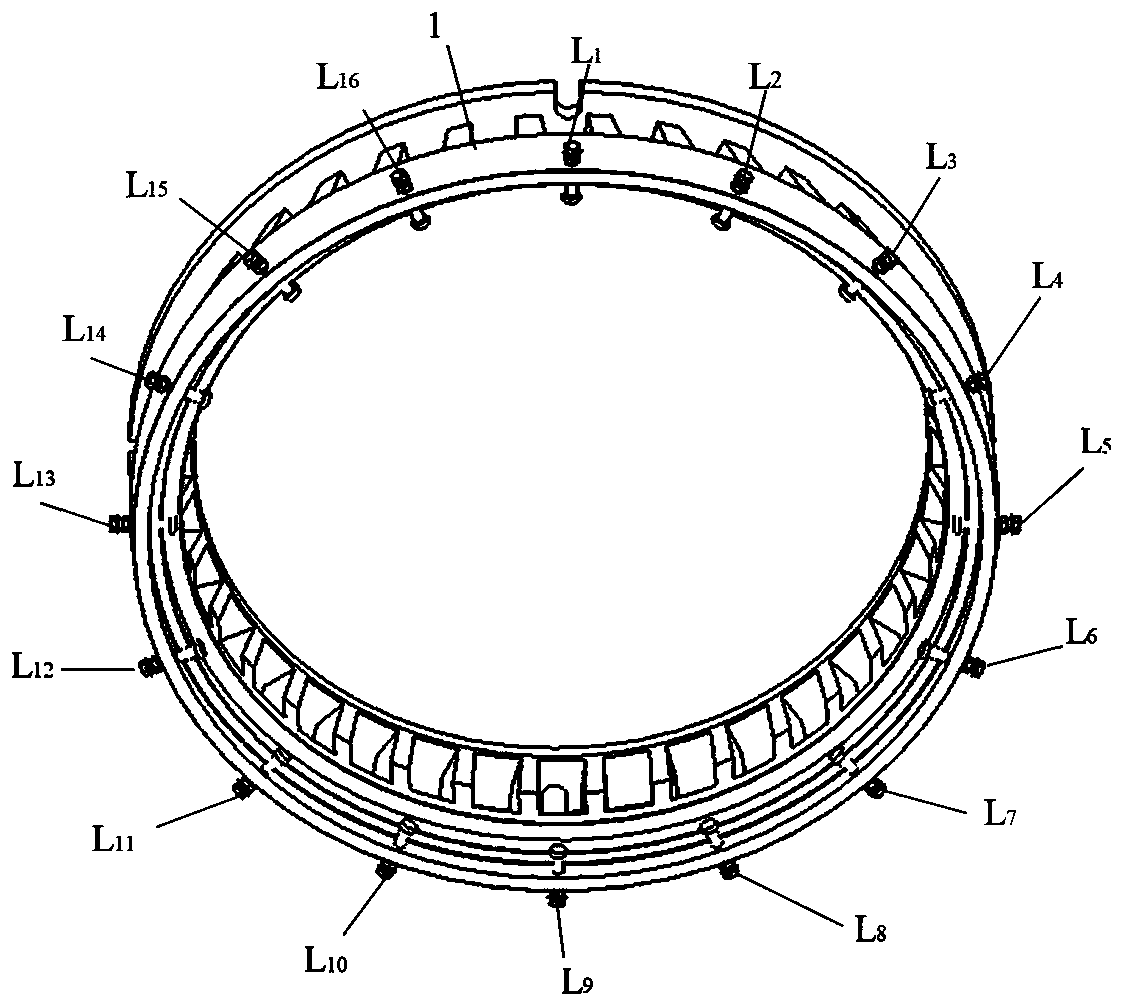

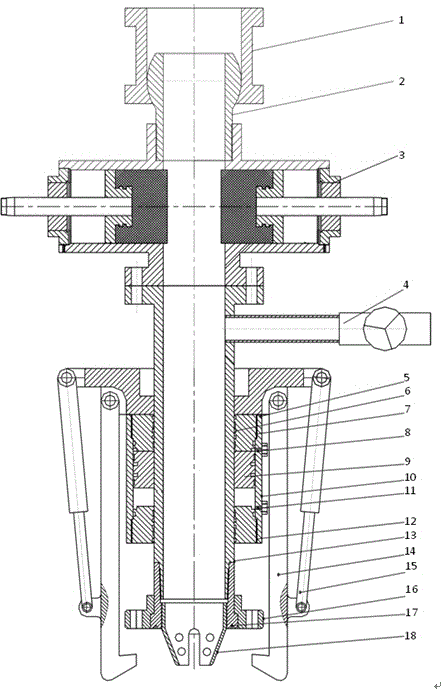

Uncoupled charging positioning device and methods

The invention discloses an uncoupled charging positioning device. The uncoupled charging positioning device mainly comprises an upper ring unit, an elastic support piece unit, a lower ring unit and ascaleplate. The upper end of the elastic support unit is movably connected with the upper ring unit, and the lower end of the elastic support piece unit is fixedly connected to the lower ring unit. The scaleplate is in a straight strip shape, and the scaleplate is provided with scales matched with the expansion radius of the elastic support unit. The upper end of the scaleplate is fixedly connected with the upper ring unit, and the lower end of the scaleplate is movably connected with the lower ring unit. The invention further discloses a concentric uncoupled charging method and an eccentric uncoupled charging method. The positioning device and the methods have the beneficial effects that an upper ring, a lower ring and elastic support pieces are used, the upper ring and the lower ring arefixed by an explosive roll, the explosive roll is separated from a blasthole wall by using the elastic support pieces, the centering problem of the uncoupled charging and the positioning problem in the eccentric uncoupled charging process in the prior art are solved, and meanwhile the breakage of the explosive roll and the hole blockage caused by the rough hole wall during the charging process are avoided as well.

Owner:WUHAN UNIV OF TECH

Device for testing bond performance of reinforcing steel bar and concrete through drawing and testing method

InactiveCN105259107AEasy to assembleEasy to operateUsing mechanical meansMaterial analysisTest sampleMaterials testing

The invention discloses a device for testing bond performance of a reinforcing steel bar and concrete through drawing. The device comprises a loading frame, a concrete test sample, a T-shaped steel bracing wire, the reinforcing steel bar, a force sensor, a universal material testing machine, a displacement meter, a static signal test analysis system and a computer, wherein a PVC (polyvinyl chloride) pipe is arranged in the middle positions of the upper part and the lower part of the concrete test sample, the reinforcing steel bar penetrates through the PVC pipe, accordingly, the bonding-slip section of the poured test sample is only located in the middle of the concrete test sample, a T-shaped slide chute and a notch are reserved in steel plates at the upper part and the lower part of the loading frame, size scales are marked, and the loading device is accurately aligned by adjusting the positions of the reinforcing bar and the T-shaped steel bracing wire. The device is simple in structure and convenient to disassemble, few materials and instruments are required, and the device is applicable to scientific research and test of the bond performance of the reinforcing steel bar and the concrete on a construction site.

Owner:THE CITY VOCATIONAL COLLEGE OF JIANGSU

Advance support fast construction method in shallow tunnelling loose pebble bed

ActiveCN101818647ASolving Mobility IssuesSolve alignment problemsAnchoring boltsUnderground tunnelSlurry

The invention discloses an advance support fast construction method in shallow tunnelling loose pebble bed. A guide rail type independent rotary rock drill and a triangle drilling rig are adopted, and a self-advancing hollow grouting anchor bar is adopted to drive the advance support rod body; multi-hole spacing grouting is adopted, and appropriate double grout matching is selected. The invention has the beneficial effects that: part of pebble can be impacted to be crushed or be extruded into a hole, the problems of shifting and aligning of heavy duty drill in a narrow underground tunnel are effectively solved; not only grouting speed is increased, but also grout diffusion can be better controlled; the method can adapt loose pebble stratum well, not only perfect diffusion effect of grouting can be achieved, but also single-hole long-distance diffusion can be controlled, and reinforcing in unpermitted range can be achieved.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +1

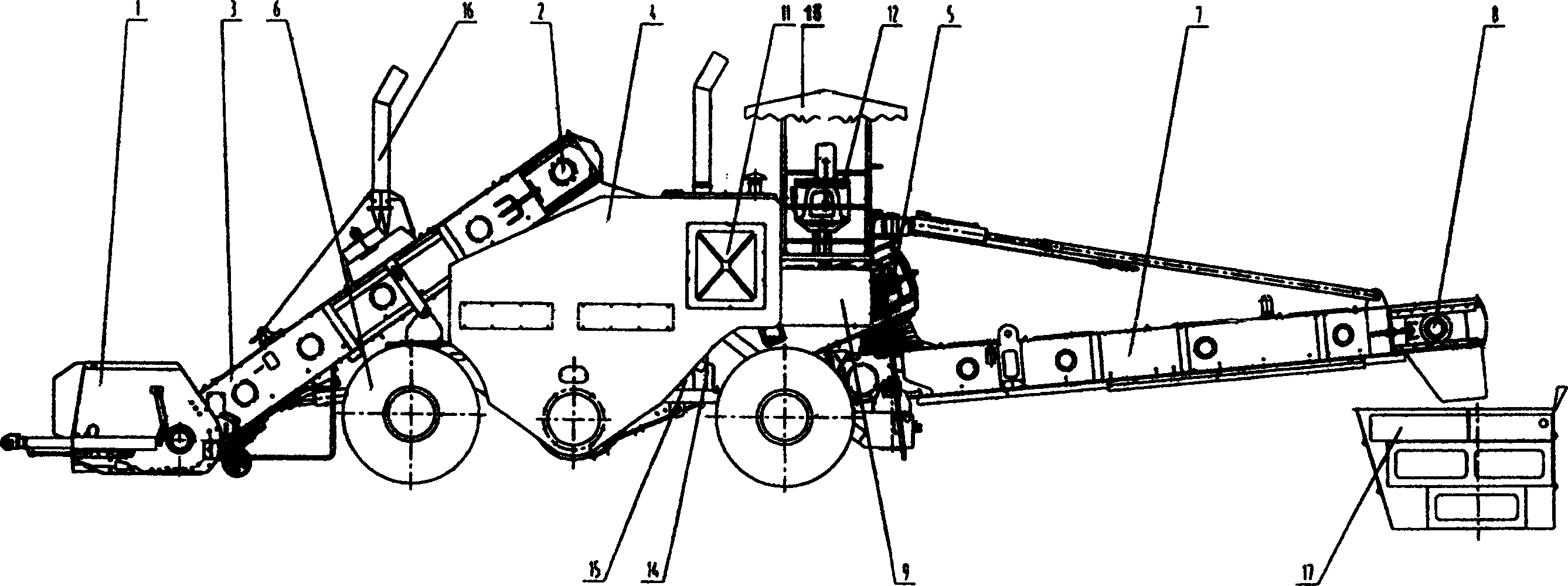

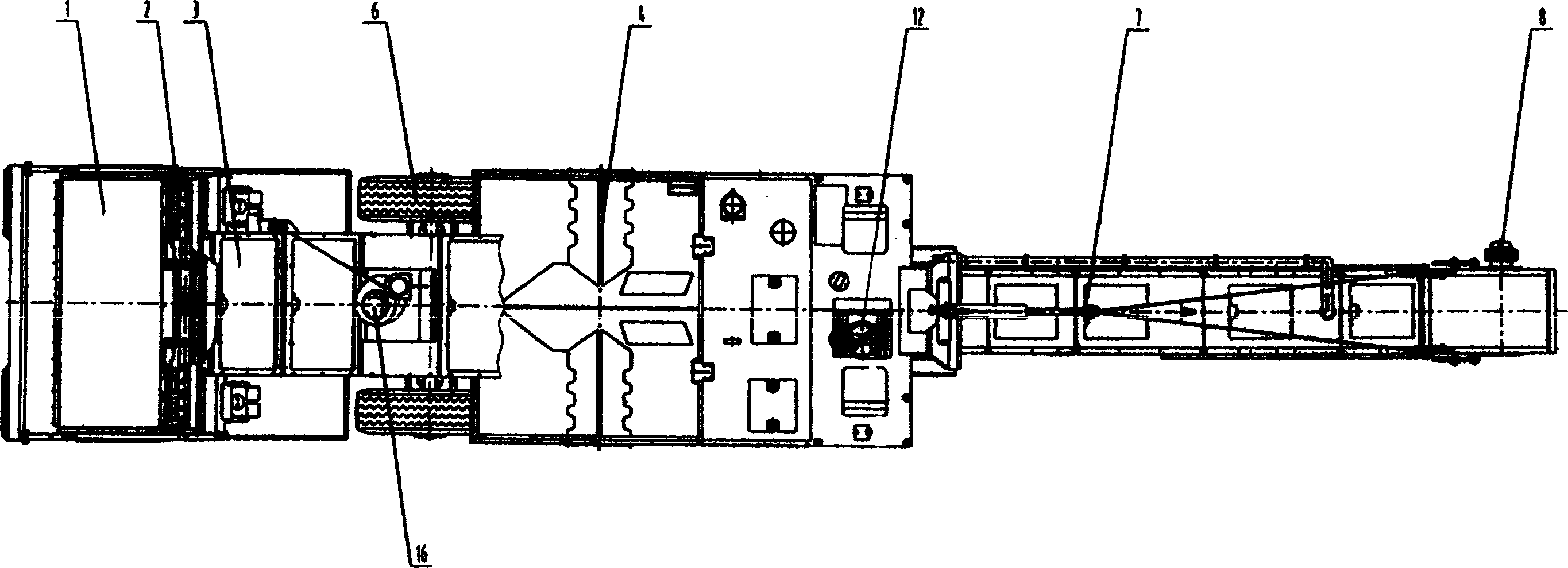

Bituminous mixture transfer car

InactiveCN1594739AFully lubricatedSimple structureRoads maintainenceLoading/unloadingRoad surfaceCopper

Bituminous mixture transfer car comprises hopper, material inlet helix, material tank body, material tank, first discharge device, moving system, second discharge device, second discharge drive system, hydraulic pressure system, electrical system, power system, driving cap, top, cleaning device, centralized lubricating system, exhaust emission system and discharge holding hopper. The invention improves the copper, material tank body, material tank, first discharge device, second discharge device, hydraulic pressure system, top, centralized lubricating system, and discharge holding hopper so as to increase the combination property index of the set. Meanwhile, the using effect and operating style gets a good improvement relative to the current bituminous mixture transfer car so as to improve the pavement spreading quality.

Owner:益阳市科技成果转化服务中心 +1

Wireless charging self-positioning alignment system and method for electric vehicle

PendingCN108454420ASolve alignment problemsLow costCharging stationsElectric vehicle charging technologyParking spaceEngineering

The embodiment of the invention discloses a wireless charging self-positioning alignment system and method for an electric vehicle. The system includes a vehicle-mounted positioning micro label arranged on the electric vehicle, a plurality of parking space positioning base stations arranged at the preset position of the parking space and used for carrying out ranging communication with the vehicle-mounted positioning micro label; a positioning processor used for determining the actual coordinates of the vehicle-mounted positioning micro label in a preset coordinate system according to the ranging information of each parking space positioning base station and the vehicle-mounted positioning micro label and calculating the difference between the actual coordinates of the vehicle-mounted positioning micro label and the target coordinate of the vehicle-mounted positioning micro label when the receiving coil of the electric vehicle and the transmitting coil of the parking space are aligned.The alignment condition of the vehicle can be obtained through the difference between the target coordinate and the actual coordinate of the vehicle-mounted positioning micro label. The system effectively solves the problem of the alignment of the coil when the wireless charging vehicle is parked. The system not only can reduce the cost, but also can meet the application logic of positioning whenthe vehicle is parked.

Owner:ZONECHARGE (SHENZHEN) WIRELESS POWER TECH CO LTD

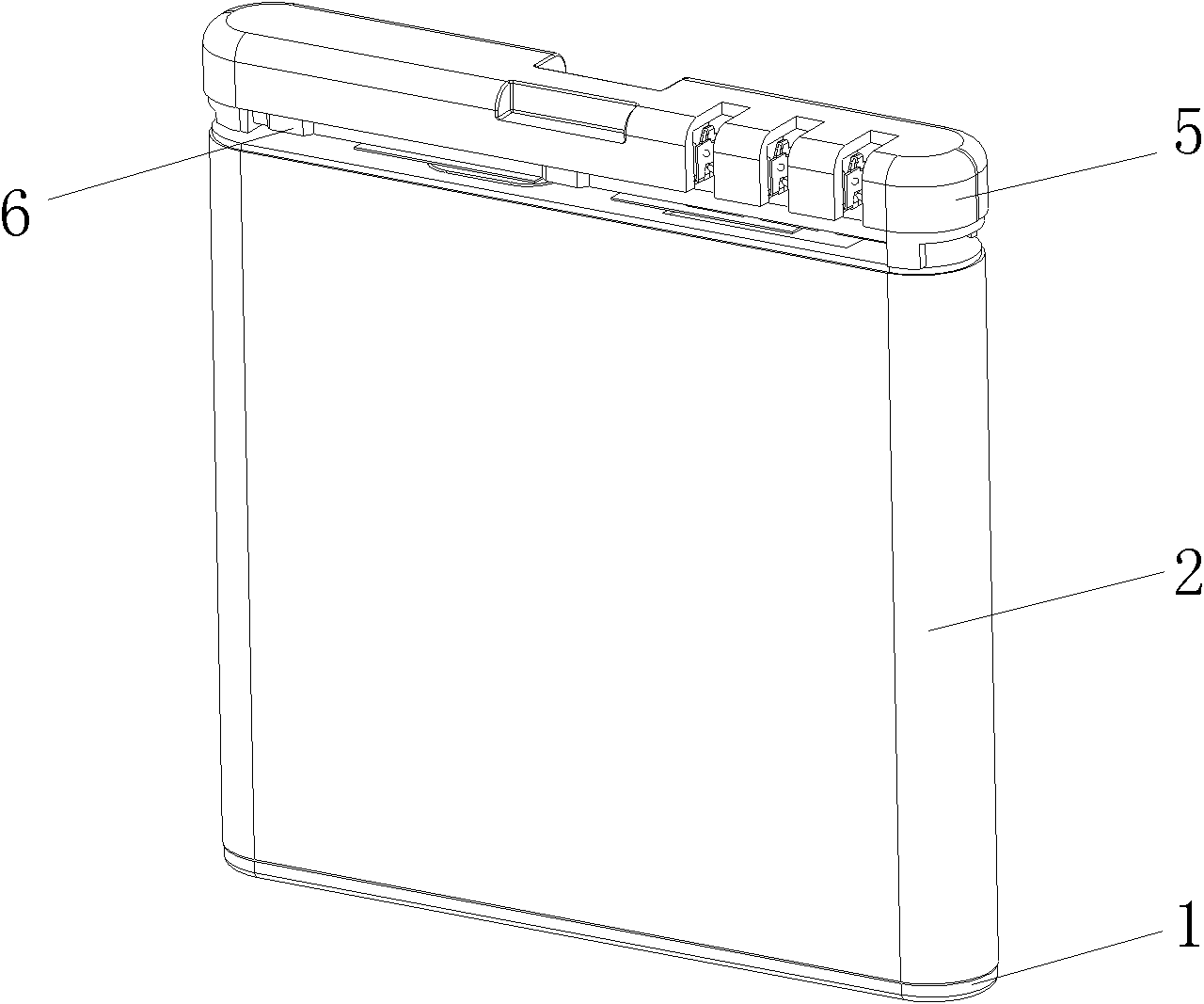

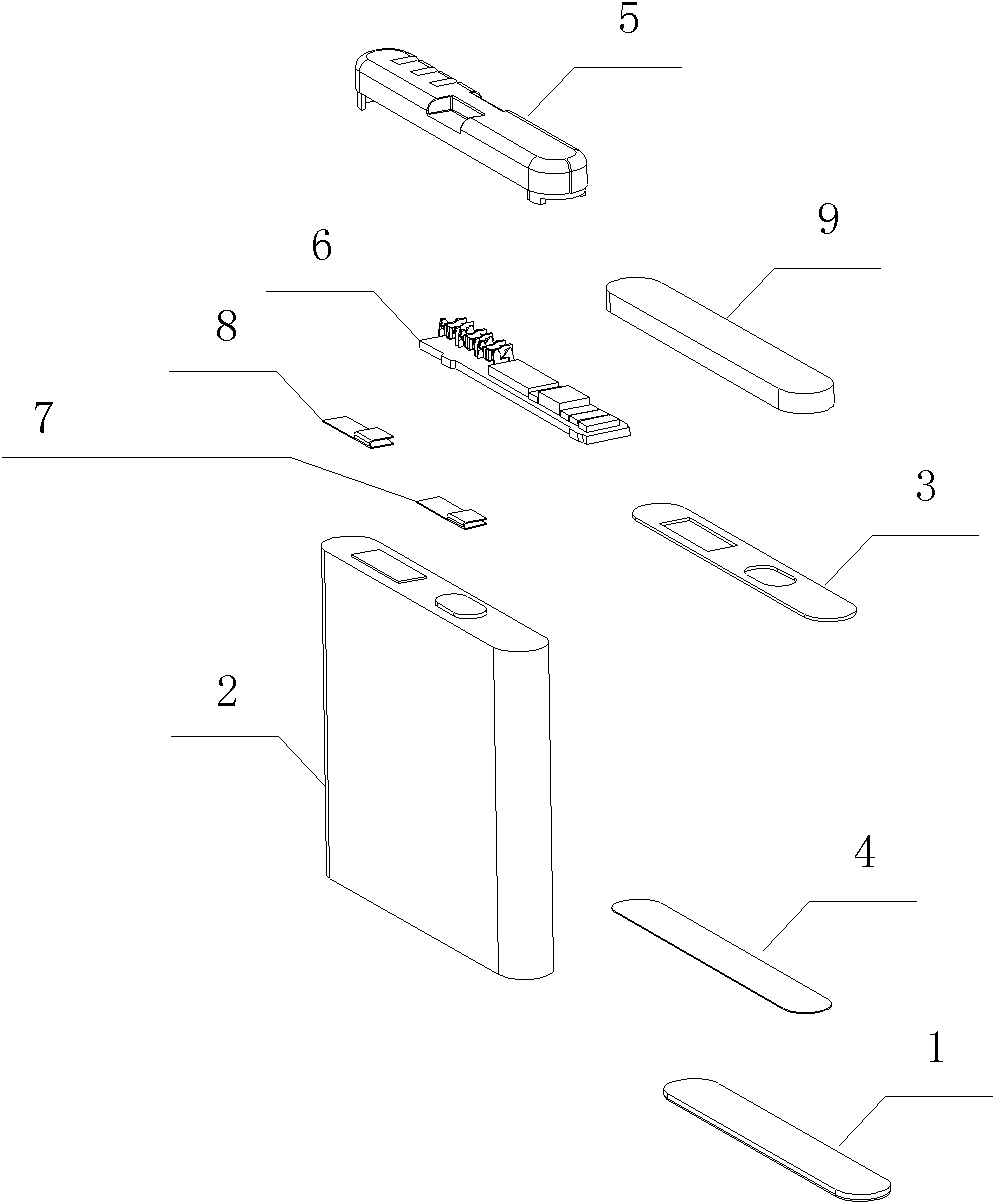

Lithium ion battery

ActiveCN102340026ASolve alignment problemsMeet the needs of useSecondary cellsCell component detailsEngineeringLithium-ion battery

The invention discloses a lithium ion battery, comprising a battery core, a battery protective plate and an end cover, wherein, the battery protective plate is fixed between the battery core and the end cover and connected with the anode ear and cathode ear of the battery core electrically, the end cover is provided with a fixed column or fixed groove, the portion of the battery protective plate corresponding to the fixed column or fixed groove of the end cover is provided with a fixed groove or fixed column, the fixed column is inserted into the fixed groove with close fitting, and a hot melt adhesive is injected among the battery core, the battery protective plate and the end cover for fixing. The invention guarantees the stability of the connection between the end cover and the battery protective plate when being assembled, and achieves the advantages of no need of twisting screws, no damage to the battery core, and simple technology.

Owner:SHENZHEN BAK POWER BATTERY CO LTD

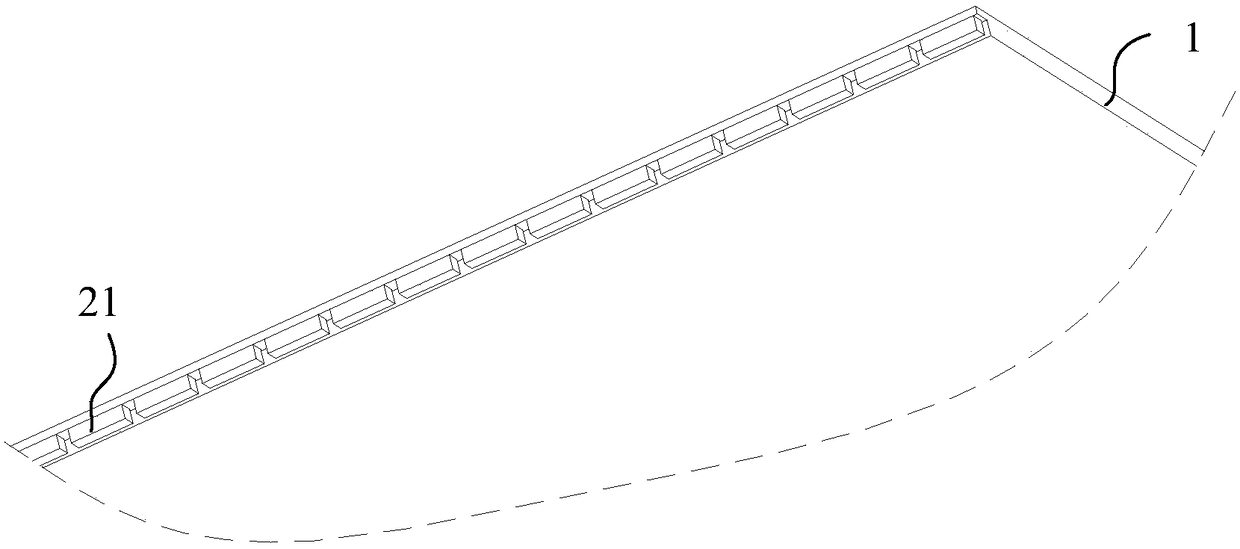

Lateral entering type backlight module and display device

InactiveCN108345146AHigh cooling requirementsSolve alignment problemsOptical light guidesNon-linear opticsElectricityLight guide

The invention discloses a lateral entering type backlight module and a display device. The lateral entering type backlight module comprises a light guide plate and a light source assembly; an opened accommodating groove is formed in the edge of the light guide plate and is internally provided with a conducting line; the light source assembly is arranged in the accommodating groove and is electrically connected with the conducting line; a light incident face of the light guide plate is the groove wall face, close to the center of the light guide plate, of the accommodating groove; the conducting line is arranged on the groove wall face, away from the center of the light guide plate, of the accommodating groove; the light source assembly comprises multiple LED light-emitting units distributed in the length direction of the light incident face of the light guide plate at intervals, the LED light-emitting units comprise light emergent faces, connecting faces and at least two cooling faces,the light emergent faces are spaced with the light incident face of the light guide plate, the connecting faces are connected with the light guide plate, and the cooling faces are provided with cooling structures. By means of the lateral entering type backlight module and the display device, the display device can be super-narrow and super-thin.

Owner:SHENZHEN SKYWORTH RGB ELECTRONICS CO LTD

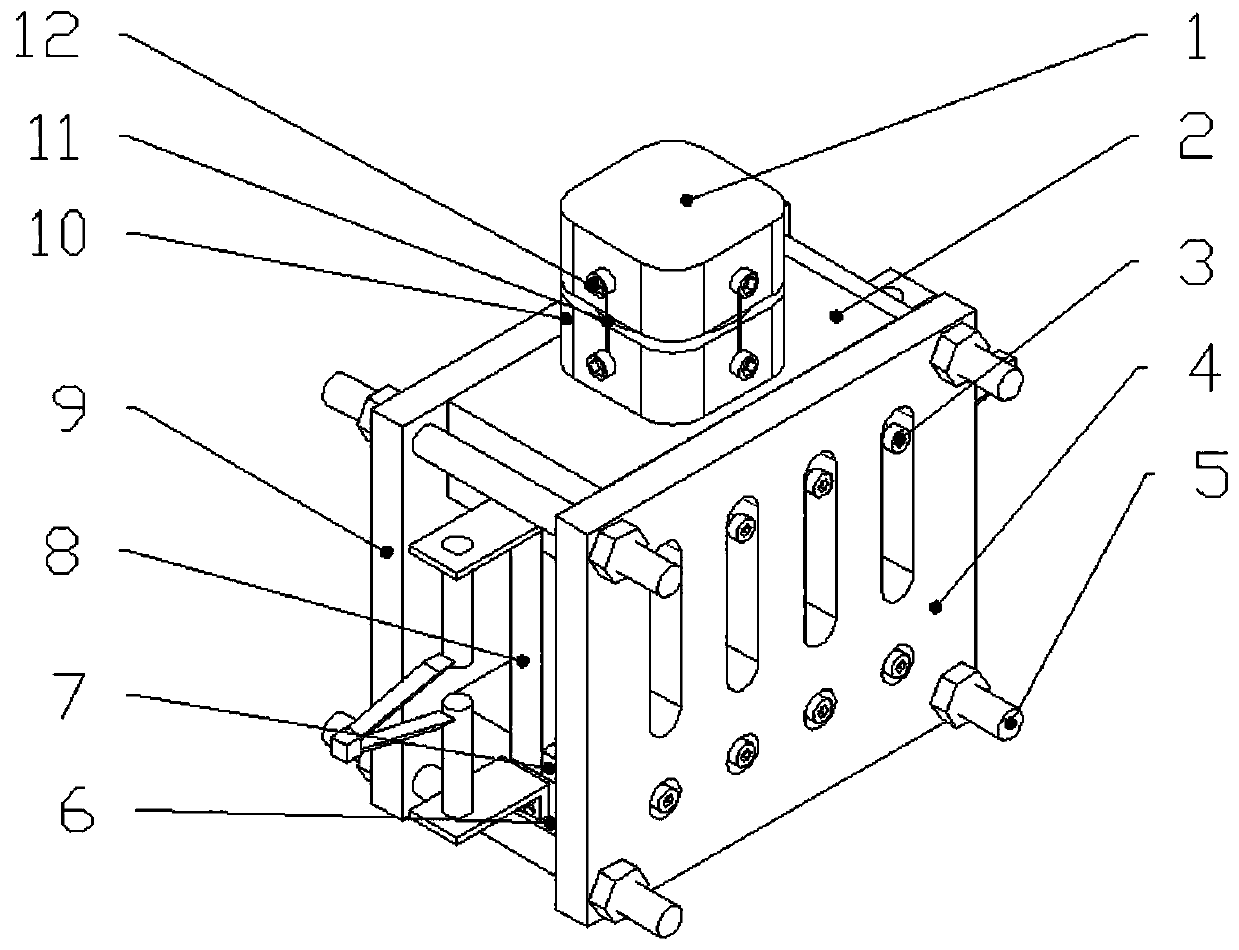

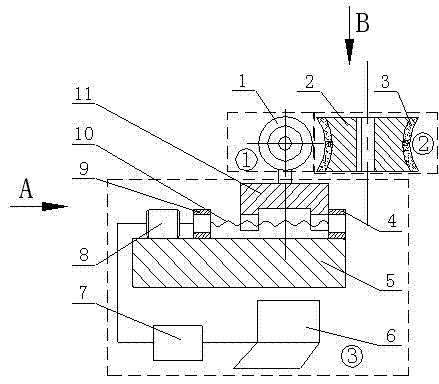

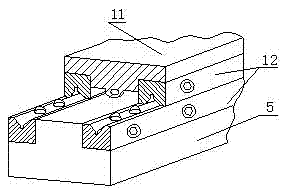

Lattice sandwiching structure edgewise compressive testing device

InactiveCN110031294AHigh measurement accuracyReduce cost of measurementMaterial strength using tensile/compressive forcesElasticity measurementOperabilityCompressive strength

The invention discloses a lattice sandwiching structure edgewise compressive testing device. The testing device mainly comprises a clamping part, a centering loading part and a measuring part, the measuring accuracy can be effectively increased, the measuring cost is lowered, and high-accuracy measuring of lattice sandwiching structure edgewise compressive testing deforming is realized. To improvethe current situation of the low accuracy and poor operability in a measurement standard of edgewise compressive strength of an existing lattice sandwiching structure laminate, the lattice sandwiching structure edgewise compressive testing device solves the problem of centering during mounting and loading of test specimens, the effect of the mounting error and loading error on a testing result isgreatly reduced, and thus the calculation accuracy of the edgewise compressive strength of the laminate is improved. In addition, the device designs an extensometer mounting structure, the problem ofeasily toppling of the testing specimen is improved through a supporting structure, and operability of testing is effectively improved.

Owner:BEIJING UNIV OF TECH

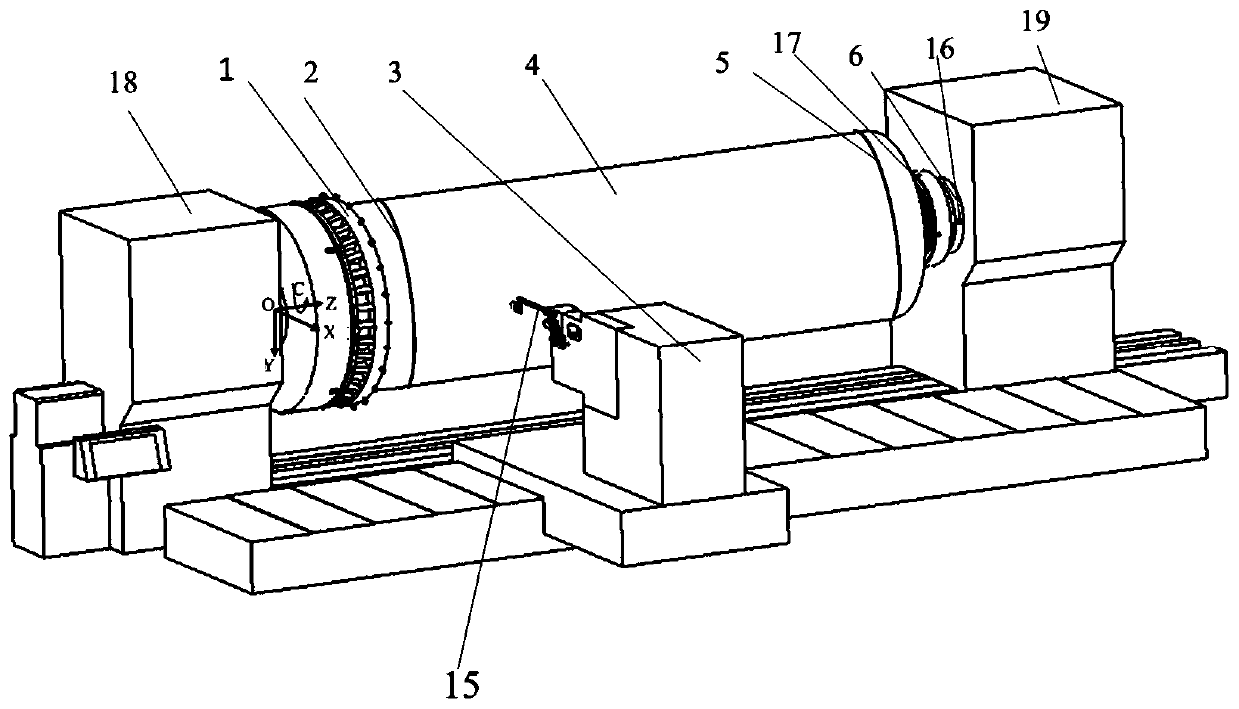

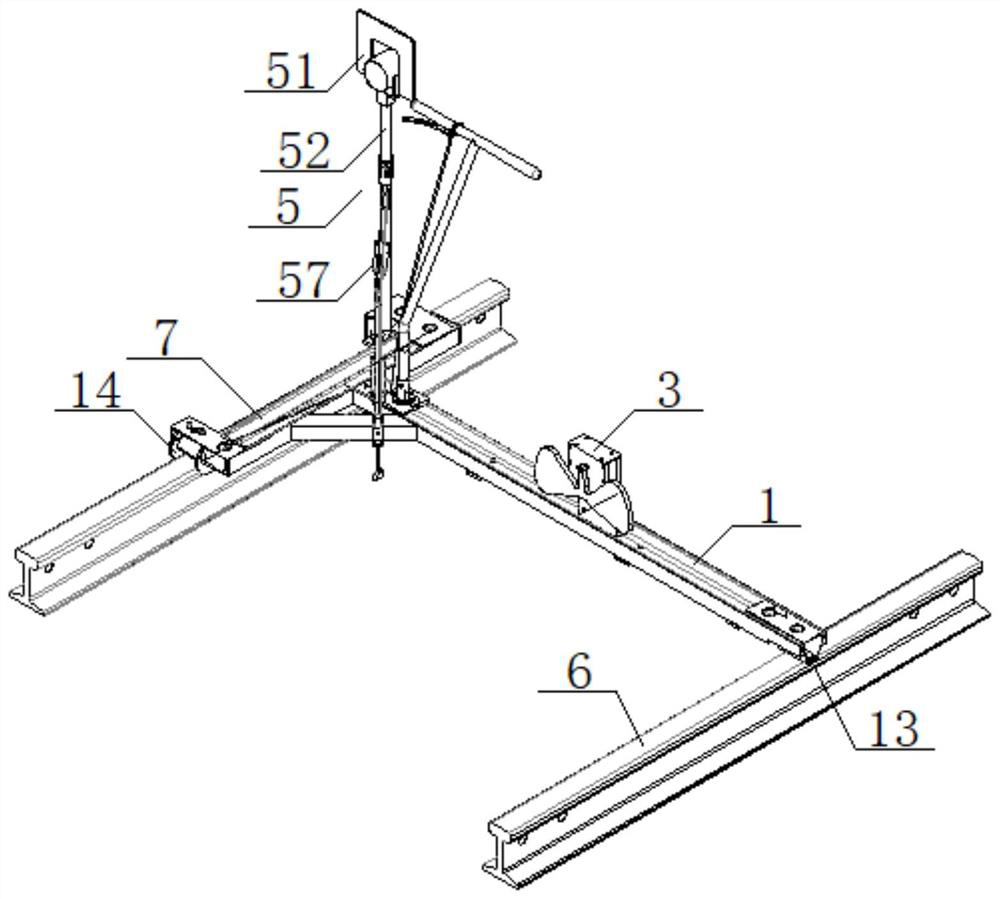

Method for measuring and aligning during large shell horizontal assembly

ActiveCN109759897AReduce labor intensityAccurate calculationMeasurement/indication equipmentsEngineeringLaser sensor

The invention discloses a method for measuring and aligning during large shell horizontal assembly. A circumferential scanning method that a laser sensor is fixed, and a spindle drives a shell to rotate is adopted for measuring, the laser sensor is moved to benchmark positions on the two ends of the shell fixed to a machine tool for measuring position calibration, the radial distance of the shellbenchmark positions is subjected to scanning measuring, the shell coaxiality state information can be automatically resolved, and a bolt pretightening adjusting amount is given out for allowing the shell to be aligned and adjusted. Sensing measuring, data processing, shell position state determining and graphical human-computer interaction functions are integrated, and are integrated on a controlsystem framework of a numerical control machine tool numerical control system, operation is convenient, and embedding is high. The measuring process is precise and controllable, the measuring result calculation is precise, the method is used for measuring and aligning during horizontal assembling of the shell with the diameter larger than two meters and the length being six to seven meters, the needed hour is shortened to be within one hour now from original three hours, and the coaxiality error is reduced to 0.05 mm now from original 0.5 mm.

Owner:XIAN AEROSPACEMOTOR MACHINE FACTORY

VCP copper plating process for flexible printed circuit board

InactiveCN110318079AImprove deep plating abilityImprove qualityPrinted circuit manufactureChemistryCopper plating

The invention provides a VCP copper plating process for a flexible printed circuit board. The VCP copper plating process comprises the following steps of firstly, cleaning a vertical continuous copperplating tank; continuously washing with deionized water, adding the deionized water, copper sulfate pentahydrate, sulfuric acid, hydrochloric acid and a copper-plated additive (polyethylene glycol, sodium polythiodipropionate and Janus Green) into the copper plating tank, starting a circulation filter pump, inputting the to-be-electroplated flexible circuit board into the tank, and starting the current; after electroplating, taking out the circuit board, and cleaning the circuit board with water; and after blow-drying by hot air, transferring the circuit board into a pattern transferring procedure. According to the vertical continuous (VCP) copper plating process for the flexible printed circuit board, after the flexible circuit board is plated copper, the flexibility is stronger and theexpansion shrinkage of the flexible circuit board is smaller, and the deep plating capability of a through hole is higher, so that the bending resistance of the flexible circuit board is greatly improved, the film alignment in subsequent pattern transfer is facilitated, etching of the flexible circuit board with high-density line width / line distance (0.05 mm / 0.05 mm) is more facilitated, the product quality and the product reliability are improved, the production process is pollution-free, and the process is suitable for industrial production.

Owner:东莞市斯坦得电子材料有限公司

Titanium rod peeling and polishing device

The invention discloses a titanium rod peeling device, which comprises a peeling assembly and a centering assembly, wherein the peeling assembly is used for peeling a titanium rod, and is provided with two peeling rolls which are arranged oppositely; the central lines of the two peeling rolls are parallel to each other; the centering assembly is used for driving the peeling rolls to move, and comprises a central gear, a first rack unit and a second rack unit; the first rack unit and the second rack unit are arranged symmetrically by taking the central gear as the symmetric center, and are meshed with a centering gear; the first rack unit and the second rack unit are correspondingly connected with the two peeling rolls respectively. After the adoption of the structural setting of the gears and the racks, the first rack unit and the second rack unit can move relatively at the same time under the rotating action of the centering gear, and the moving distances of the first rack unit and the second rack unit are the same, so that the first rack unit and the second rack unit are symmetrical to each other no matter how the central gear is rotated, and the problem of centering adjustment of the peeling rolls is solved.

Owner:浙江五环钛业股份有限公司

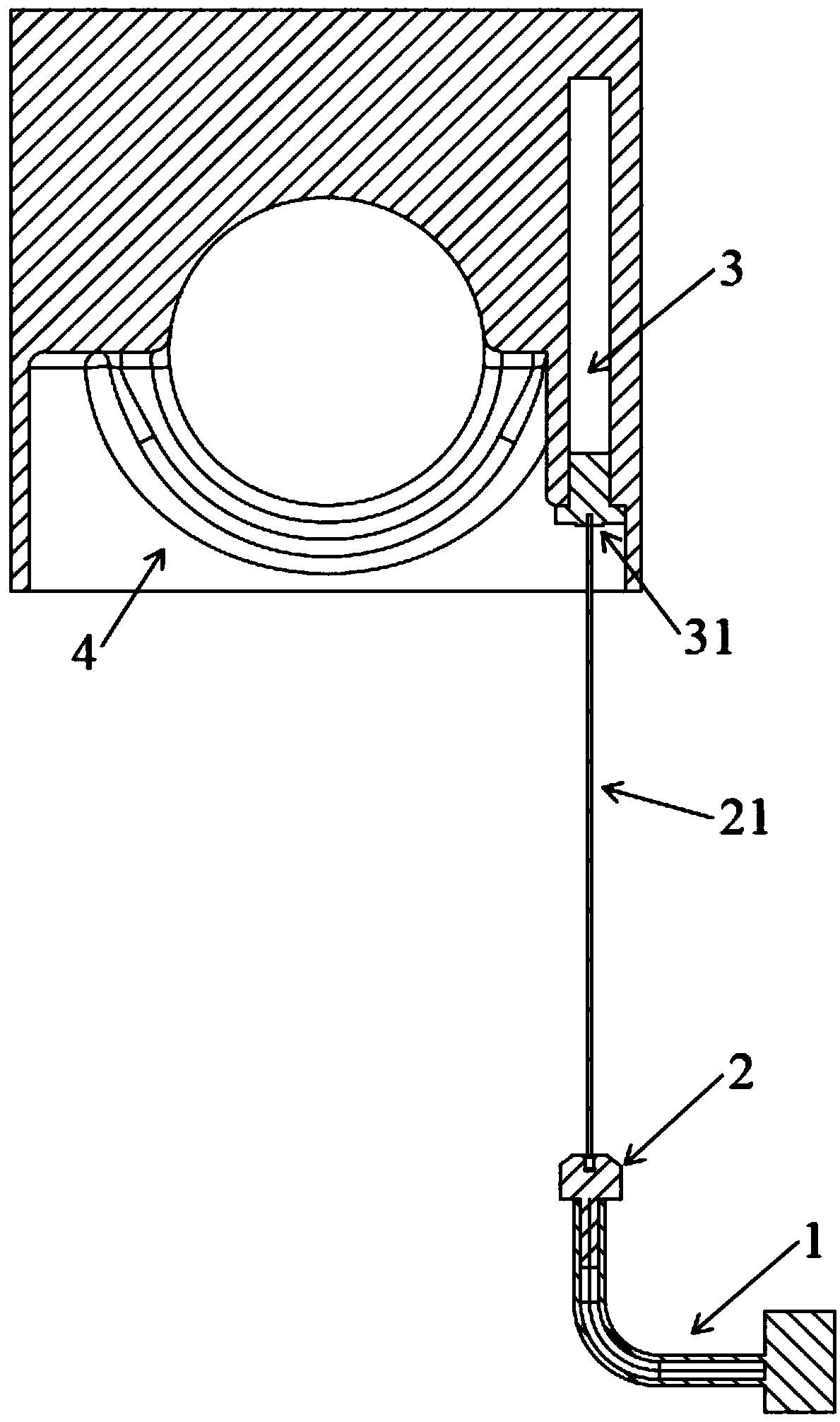

Targeting method of cooling nozzle

ActiveCN108104935AGuaranteed shooting efficiencyHigh target shooting efficiencyLiquid coolingMachines/enginesSpray nozzleLight emitting device

The invention belongs to the technical field of engines and discloses a targeting method of a cooling nozzle, comprising: loosely mounting the cooling nozzle to a valve block, and adjusting the position of the cooling nozzle; allowing a beam from a light emitter at an outlet of the cooling nozzle to irradiate a target plug in an oil incoming hole of an inner cool oil passage; observing whether a light point on the target plug is within a target area; if yes, fastening the cooling nozzle. The beam from the light emitter at the outlet of the cooling nozzle is allowed to irradiate the target plugin the oil incoming hole of the inner cool oil passage; whether the light point on the target plug is in the target area is judged by observing so as to judge whether an oil slow from the cooling nozzle can fully cover the oil incoming hole of the inner cooling passage; therefore, the cooling nozzle can monitor whether the cooling nozzle is aligned with the oil incoming hole of the inner cool oilpassage in real time during assembly phase, dynamic centering is achieved, target efficiency of the cooling nozzle is guaranteed, and the problem that an existing cooling nozzle has low targeting efficiency is solved.

Owner:WEICHAI POWER CO LTD

Railway steel rail center detection vehicle

A railway steel rail center detection vehicle comprises a walking trolley and a prism measuring device. The walking trolley comprises a frame and a hand push rod, a nylon wheel is arranged at the bottom of one end of the frame and arranged on the left steel rail, and a steel groove wheel is arranged at the bottom of the other end of the frame and clamped on the right steel rail; the prism measuring device comprises a prism, a prism bar and a knuckle bearing seat, a mounting hole is formed in the middle of the knuckle bearing seat, a knuckle bearing is arranged in the mounting hole, limiting holes are formed in the two side faces of the knuckle bearing seat, bolts are arranged in the limiting holes and abut against the knuckle bearing, and the knuckle bearing seat is connected with the frame. One end of the prism bar is connected with the prism, the center of the prism coincides with the center of the right steel rail, the other end of the prism bar is in threaded connection with one end of a prism bar connector, the other end of the prism bar connector is inserted into the knuckle bearing, and a universal support is connected between the prism bar and the frame. The railway steel rail center detection vehicle has the advantages of high measurement precision, high working efficiency and low cost.

Owner:NO 4 ENG CO LTD OF CHINA RAILWAY 11 BUREAU GRP +1

Speed-adjustable permanent magnet inductive worm and wormwheel transmission device

ActiveCN103036392AImprove exercise efficiencyReduce feverDynamo-electric gearsDrive motorMagnetic flux

The invention relates to the technical field of mechanical transmission, in particular to a speed-adjustable permanent magnet inductive worm and wormwheel transmission device which comprises a drive assembly, a driven assembly and a speed adjusting device assembly. The drive assembly is fixed arranged on the speed adjusting device assembly, a worm of the drive assembly and a wormwheel of the driven assembly form an included angle of 90 degrees, and uniform air gaps are formed between the worm and the wormwheel. When the worm is driven by a drive motor to rotate, the whole drive assembly can be driven by the speed adjusting device assembly to conduct side-to-side motion, so that the worm can be driven to move away from the wormwheel or move close to the wormwheel, and at the same time, sizes of the air gaps of conductive bodies or conductive body layers on the worm and of the permanent magnet on the wormwheel are changed and magnetic flux of an air-gap magnetic field can be quickly adjusted. Output rotating speed and torque can be better and more quickly controlled and the aim of achieving infinitely variable speed and transmitting motion and power between two mutually perpendicular shafts is achieved.

Owner:JIANGSU UNIV

Presetting gold-tin cover plate and manufacturing method thereof

InactiveCN104952808AImprove bindingSolve alignment problemsSemiconductor/solid-state device detailsSolid-state devicesSolderingAir tightness

The invention discloses a presetting gold-tin cover plate which comprises a kovar alloy cover plate and a welding frame, wherein the kovar alloy cover plate sequentially comprises a kovar alloy sheet plate, a nickel plating layer and a gold plating layer from inside to outside; the welding frame is a frame made of Au80Sn20 eutectic alloy solder and the size of the frame is matched with the kovar alloy cover plate; the metallurgical bonding of the kovar alloy cover plate and the welding frame is realized through melting corresponding points which are located at four corners of the welding frame and are in contact with the kovar alloy cover plate. The invention also discloses a manufacturing method of the presetting gold-tin cover plate. According to the presetting gold-tin cover plate and the manufacturing method thereof, the firm combination of the gold-nickel-plating kovar alloy cover plate and an Au80Sn20 pre-molding alloy soldering lug is realized, on one hand, the counterpoint problem of the two is solved, and on the other hand, the firm combination of the two is realized, so that a traditional production process is improved, the production efficiency is improved, the gas tightness is guaranteed and the product percent of pass is improved.

Owner:GUANGZHOU XIANYI ELECTRONICS TECH

Multi-functional sucker rod blowout preventer

InactiveCN106121578ASolve alignment problemsExtended service lifeWell/borehole valve arrangementsSealing/packingEngineeringBlowout preventer

The invention discloses a multi-functional sucker rod blowout preventer which comprises a sucker rod blowout preventer shell, side door assemblies arranged on two sides of the sucker rod blowout preventer shell, a U-shaped gate assembly arranged in the sucker rod blowout preventer shell, an upper connector arranged at the upper end of the sucker rod blowout preventer shell, a lower connector arranged at the lower end of the sucker rod blowout preventer shell, and a sucker rod channel arranged among the sucker rod blowout preventer shell, the upper connector and the lower connector in a penetrating manner, wherein the upper connector is sleeved with an upper nut pressing cap matched with the upper connector; an upper conical centered guiding channel matched with the a sucker rod is arranged in the upper nut pressing cap; an upper abrasion-resistant layer is arranged on the upper nut pressing cap in the upper conical centered guiding channel; the lower connector is sleeved with a lower nut pressing cap matched with the lower connector; and a lower conical centered guiding channel matched with the a sucker rod is arranged in the lower nut pressing cap.

Owner:JIANGSU PROVINCE JINFENG PETROLEUM MACHINERY MFG CO LTD

Hydraulic self-locking quick-mounting blowout prevention device and method

ActiveCN105089542ASolve the non-parallelSolve alignment problemsSealing/packingLocking mechanismSelf locking

The invention discloses a hydraulic self-locking quick-mounting blowout prevention device and method, wherein the blowout prevention device comprises a blowout preventer assembly, a central tube and a blowout prevention tube; the central tube is connected with the lower end of the blowout preventer assembly, the blowout prevention tube is branched from the central tube, and an upper flange plate is connected with the lower end of the central tube and correspondingly cooperates a wellhead lower flange plate. The blowout prevention device further comprises a space rotation fine-adjustment control mechanism and a hydraulic self-locking mechanism, wherein the space rotation fine-adjustment control mechanism is connected with the upper end of the blowout preventer assembly; the hydraulic self-locking mechanism sleeves the outer side of the central tube and hooks upwards and locks the wellhead lower flange plate, so that bolt-free quick clamping connection between the upper flange plate and the wellhead lower flange plate is achieved. According to the hydraulic self-locking quick-mounting blowout prevention device and method, no person is required to stand on a wellhead to mount a blowout preventer, and a blowout prevention device for the wellhead is quickly mounted by utilizing a mechanical manner, so as to win time for preventing blowout of an oil / gas production well.

Owner:CHINA PETROLEUM & CHEM CORP +1

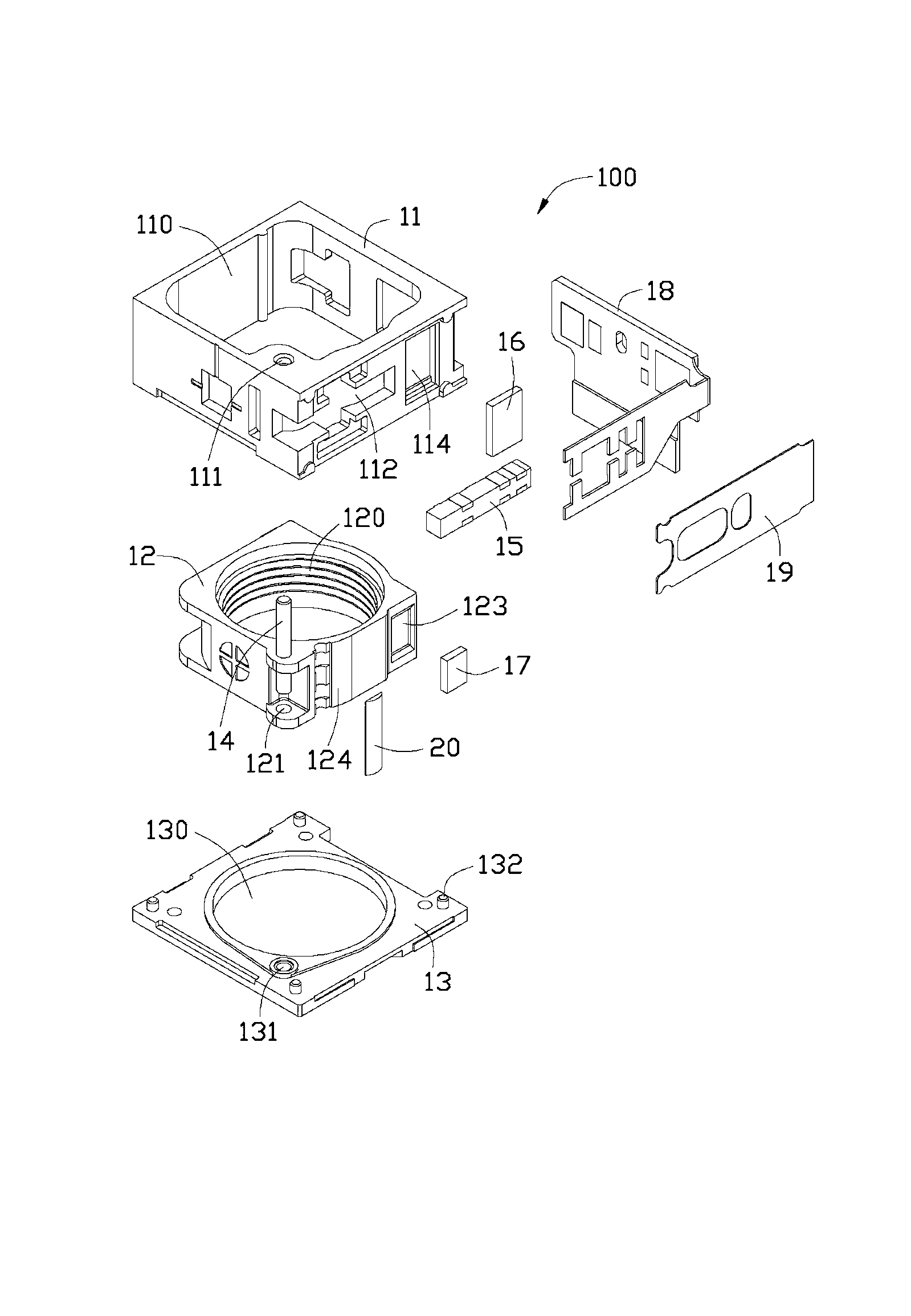

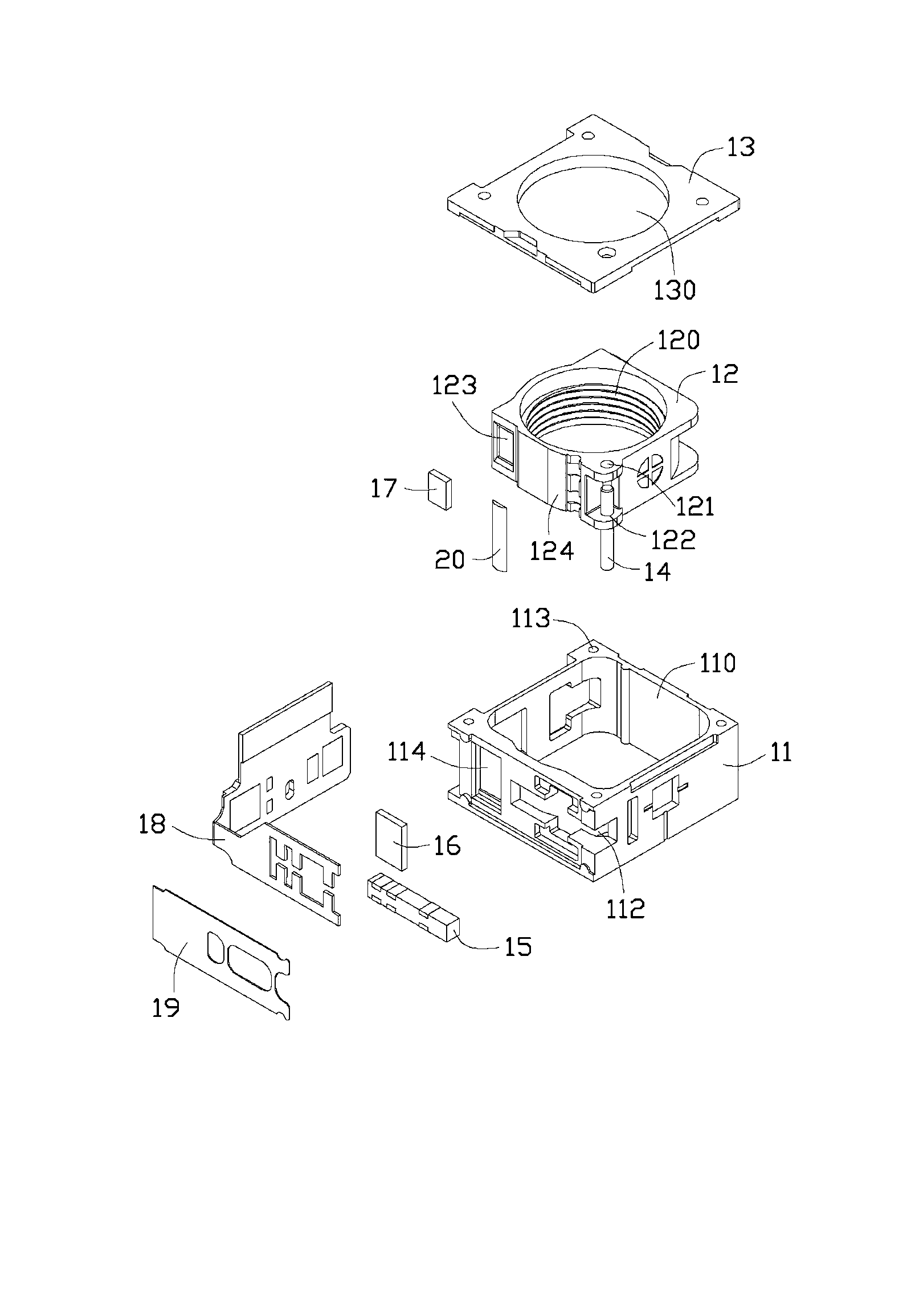

Driving device

InactiveCN103176260ASimplify the assembly processAvoid Alignment ProblemsDynamo-electric machinesMountingsMagnetEngineering

A driving device is used for driving a lens module to move. The driving device comprises a fixing support, a movable piece, a magnet, a magnetic plate, a supporting body, a guiding rod, a contact rod and a piezoelectric unit. The fixing support is provided with an accommodating space and an opening. The movable piece is arranged in the accommodating space and provided with a through hole. The magnet is fixed on the fixing support. The magnetic plate is fixed on the movable piece, and acting force between the magnet and the magnetic plate can fix the movable piece on a preset position in the fixing support. The supporting body is matched with the fixing support and used for accommodating the movable piece. The guiding rod penetrates through the through hole of the movable piece, and two ends of the guiding rod are fixed on the fixing support and the supporting body respectively. The contact rod is fixed on the movable piece. The piezoelectric unit is fixed in the opening, butts against the contact rod and is used for deforming to generate friction between the piezoelectric unit and the contact rod to drive the movable piece to move in the accommodating space along the guiding rod.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

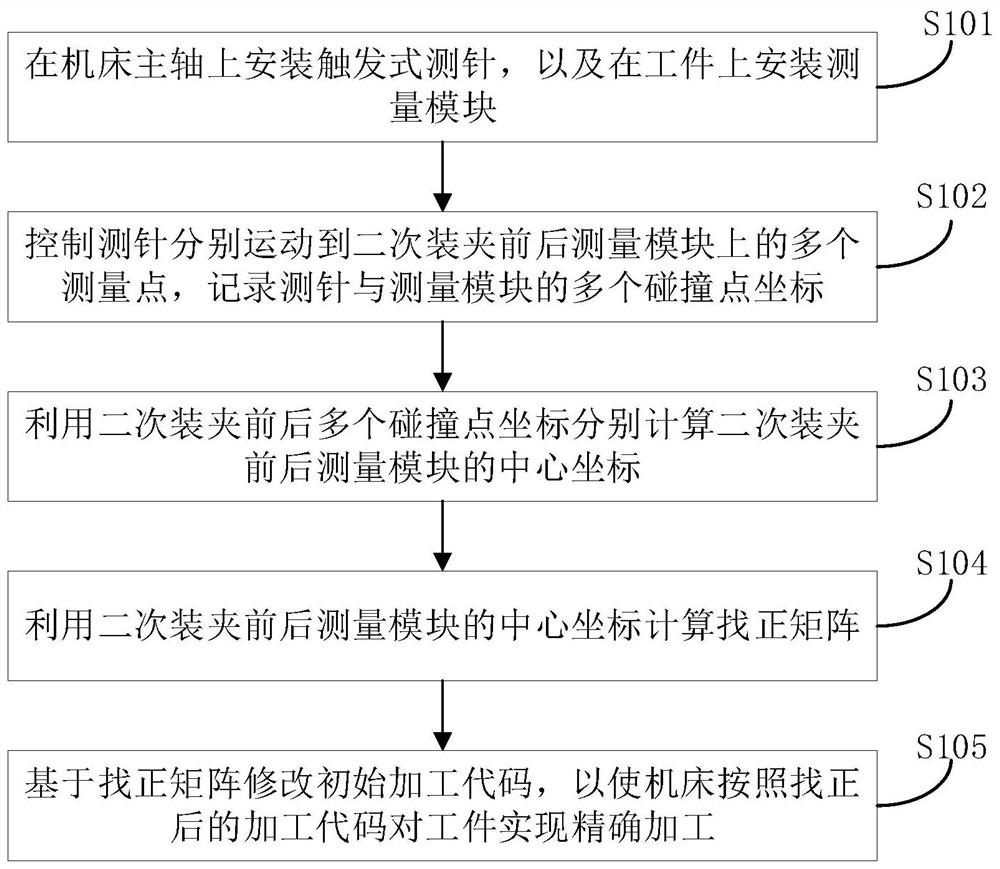

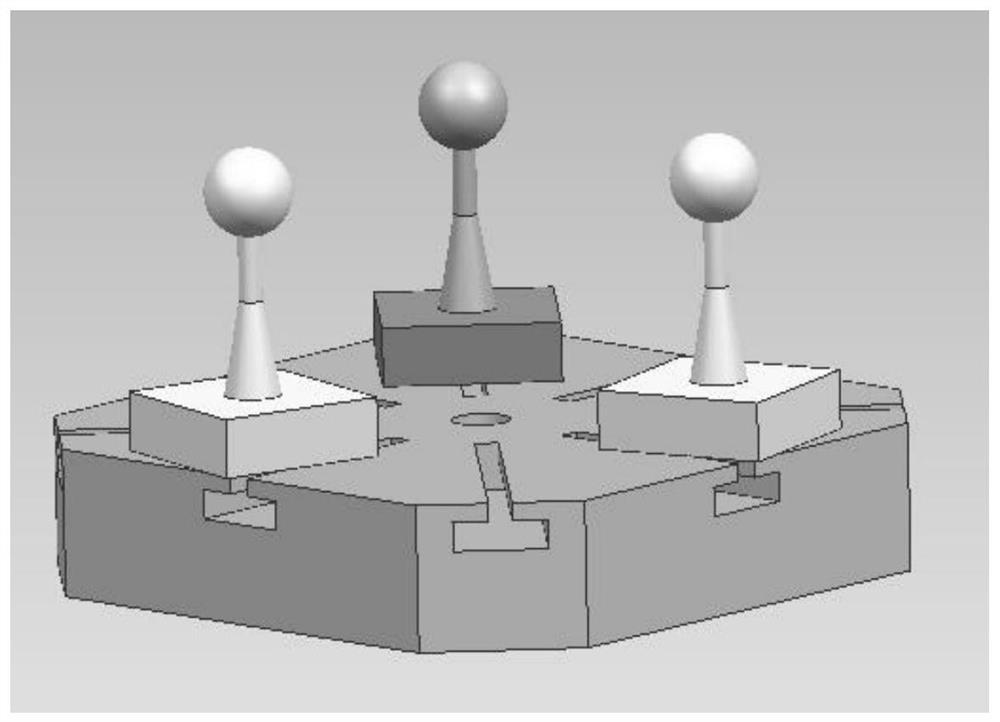

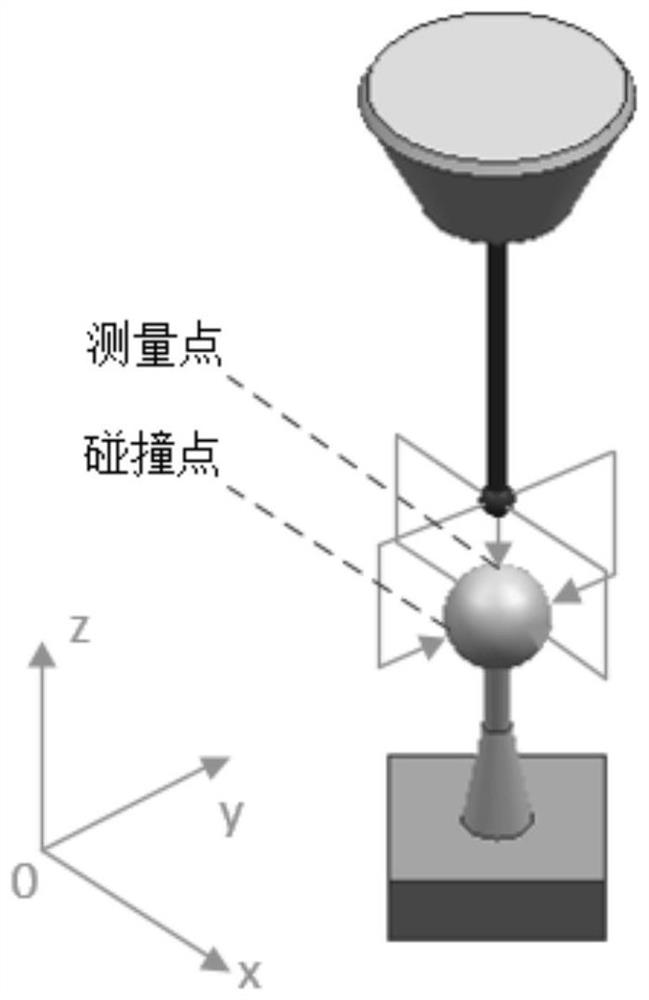

Workpiece alignment method and device for secondary clamping of machine tool and computer storage medium

PendingCN113334112ASolve alignment problemsReduce labor intensityAutomatic control devicesMeasurement/indication equipmentsEngineeringMachine tool

The invention provides a workpiece alignment method and device for secondary clamping of a machine tool and a computer storage medium. The project development method comprises the following steps that a trigger type probe is arranged on a machine tool spindle, and a measurement module is arranged on a workpiece; the probe is controlled to move to a plurality of measurement points on the measurement module before and after secondary clamping, and coordinates of a plurality of collision points of the probe and the measurement module are recorded; center coordinates of the measurement module before and after secondary clamping are calculated by utilizing the coordinates of the multiple collision points before and after secondary clamping; an alignment matrix is calculated by utilizing the center coordinates of the measurement module before and after secondary clamping; and the initial machining code is modified based on the alignment matrix, so that the machine tool can accurately machine the workpiece according to the aligned machining code. According to the workpiece alignment method and device and the computer storage medium, by means of the mode, the project development method can effectively solve the problem of alignment of the position and the posture of the workpiece, the alignment speed of secondary clamping of the workpiece is increased, the measurement time is shortened, and therefore the labor intensity of an operator is greatly reduced.

Owner:ADTECH SHENZHEN TECH

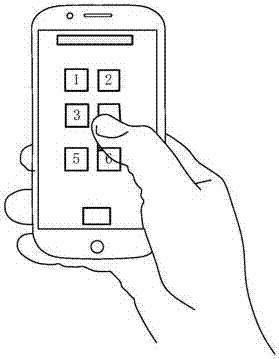

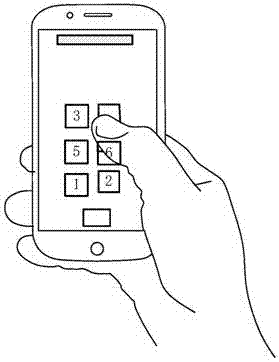

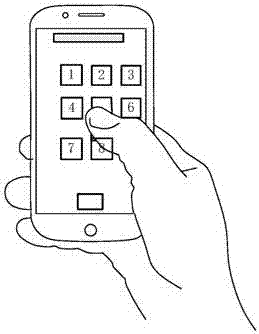

Application icon alignment device and method and terminal

ActiveCN106896988ASolve the tedious problem of alignmentImprove experienceInput/output for user-computer interactionGraph readingComputer engineering

Owner:NUBIA TECHNOLOGY CO LTD

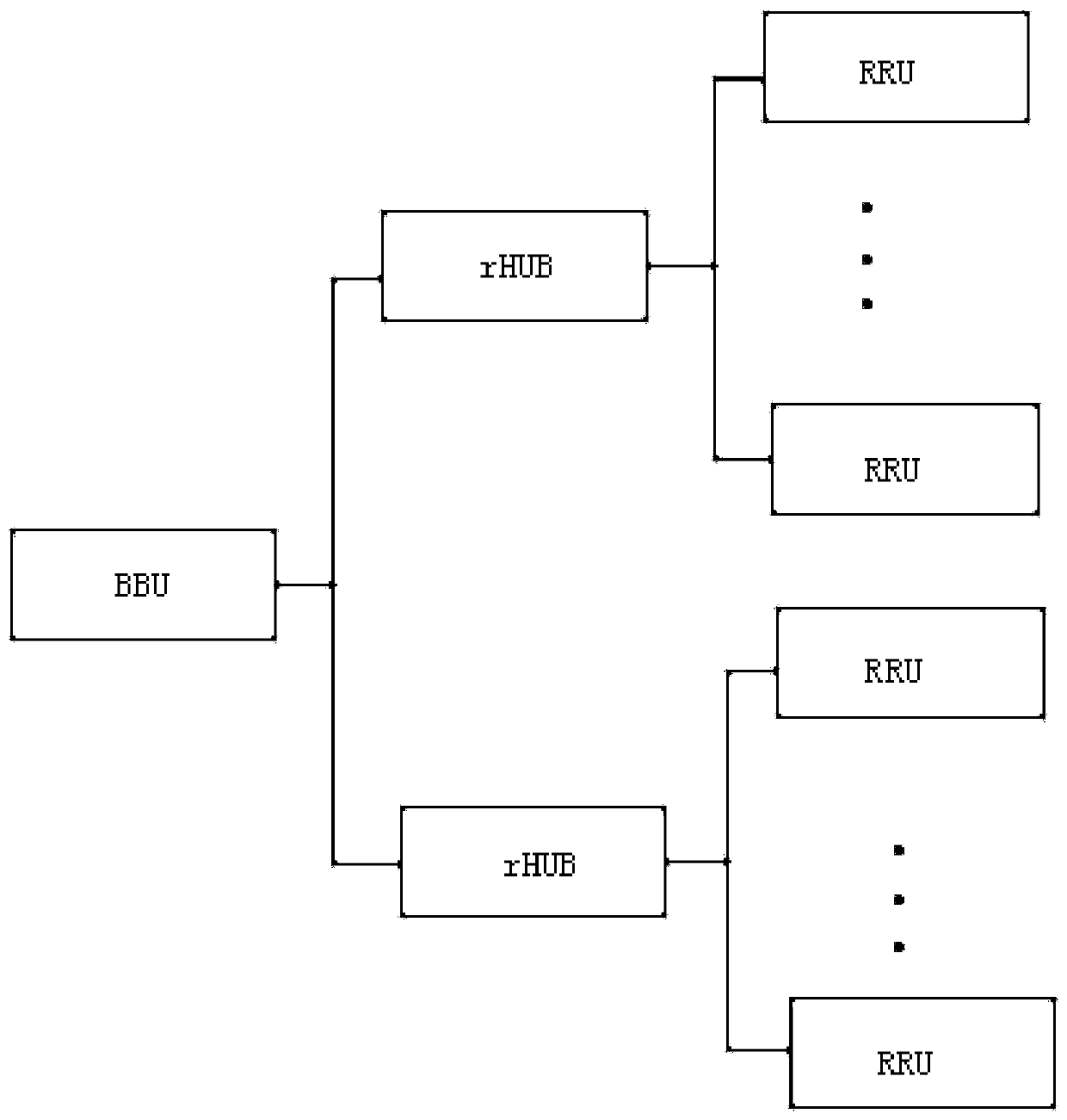

Synchronization method and system for radio remote unit of centralized unit of base station

ActiveCN110913471ASolve alignment problemsReduce work intensitySynchronisation arrangementRadio-over-fibreTelecommunicationsAir interface

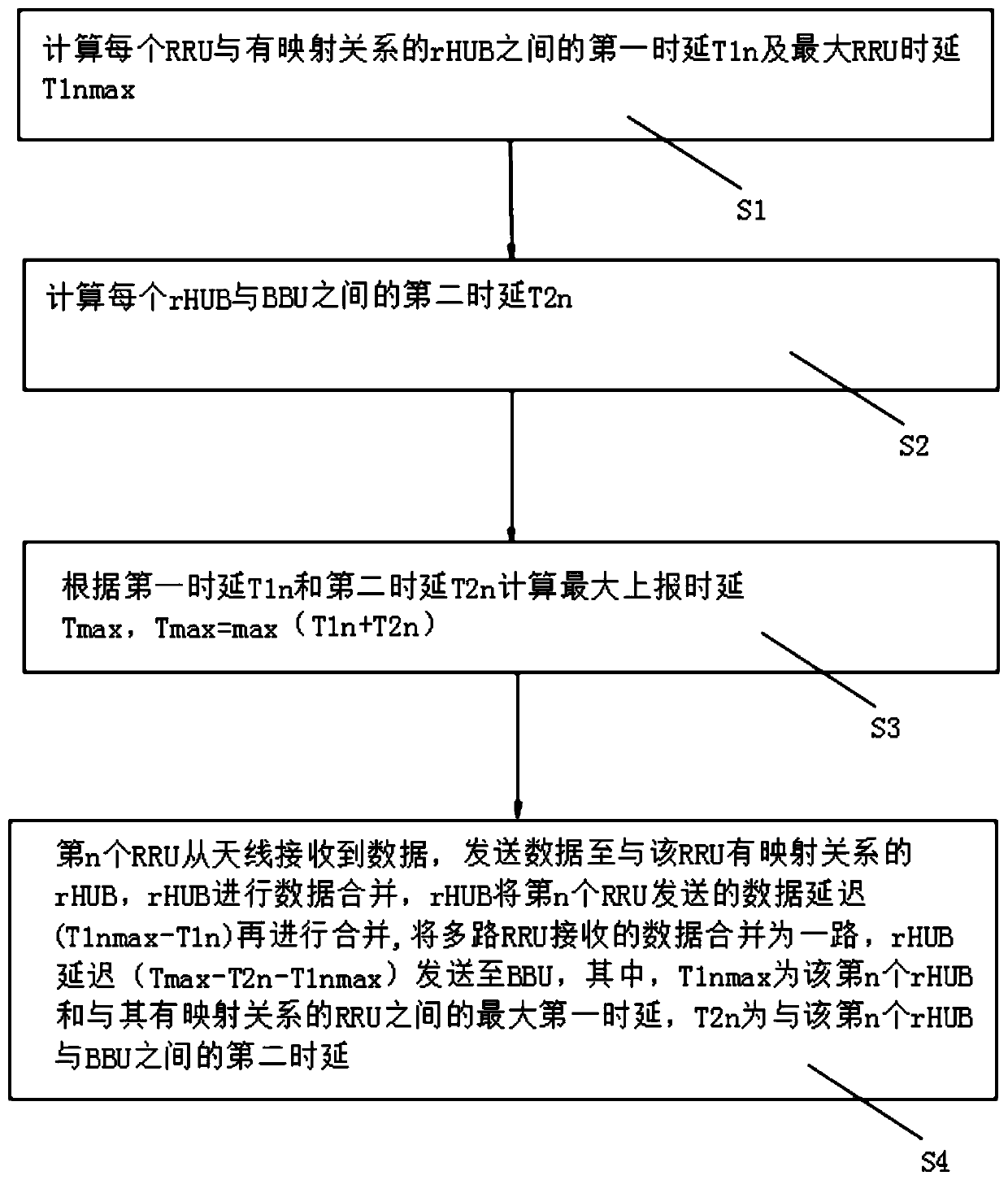

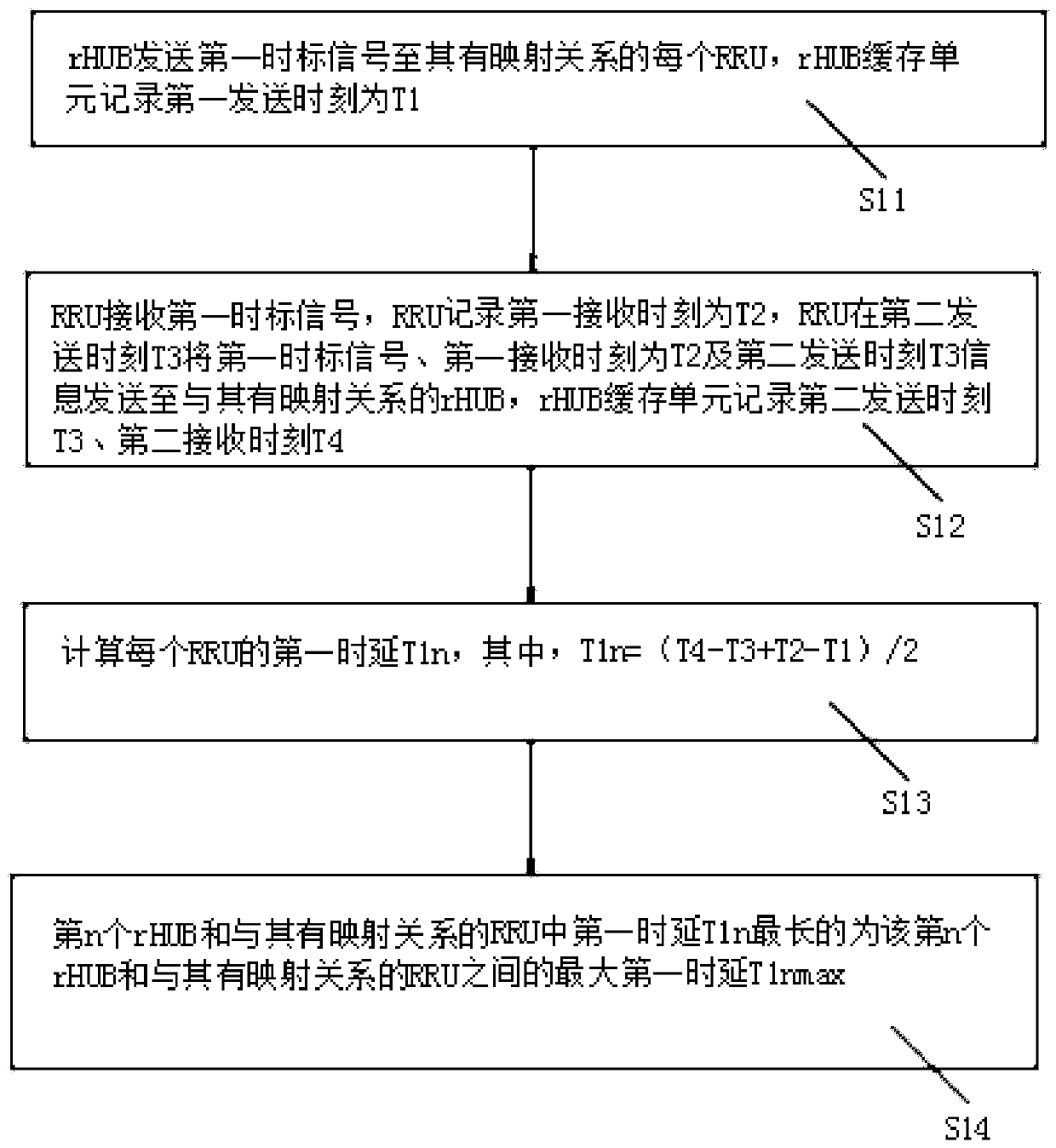

The invention relates to the technical field of communication and aims to provide a synchronization method and system for radio remote units of a centralized unit of a base station. The synchronization method for the radio remote unit of the centralized unit of the base station comprises the following steps: S1, calculating a first time delay T1n and a maximum RRU time delay T1nmax between each RRU and an rHUB with a mapping relationship, and executing S2; S2, calculating a second time delay T2n between each rHUB and the BBU, and executing S3; S3, calculating the maximum reporting time delay Tmax according to the first time delay T1n and the second time delay T2n, wherein Tmax = max (T1n + T2n) and executing the S4 and S4, enabling the nth RRU to receive the data from the antenna and sendthe data to the rHUB having the mapping relationship with the RRU, the rHUB performs data combination, the data received by the multiple paths of RRUs are combined into one path, and the rHUB delays sending to the BBU. The invention has the advantage of solving the problem of wireless signal air interface alignment under the condition of 5G complex networking.

Owner:SICHUAN TIANYI COMHEART TELECOM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com