Multi-functional sucker rod blowout preventer

A sucker rod and blowout preventer technology, which is used in wellbore/well components, earthwork drilling, sealing/packaging, etc. problems, to eliminate the hidden danger of blowout, improve the service life, and achieve good results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

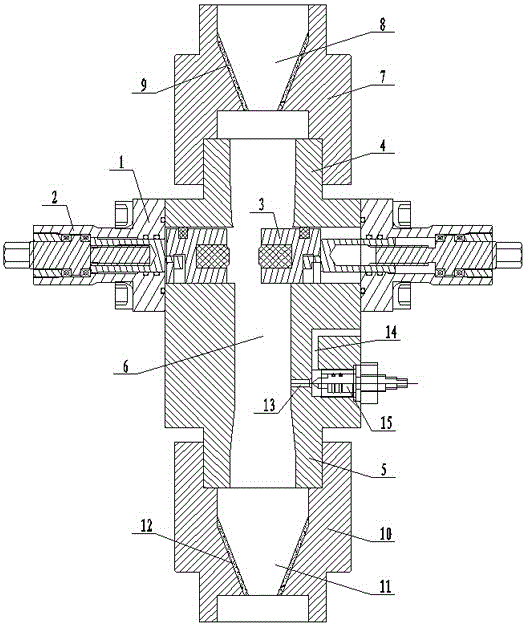

[0011] like figure 1 As shown, the multifunctional sucker rod blowout preventer includes: the sucker rod blowout preventer casing 1, the side door assembly 2 arranged on both sides of the sucker rod blowout preventer casing 1, arranged on the sucker rod blowout preventer The U-shaped ram assembly 3 in the injector housing 1, the upper joint 4 arranged at the upper end of the sucker rod BOP housing 1, and the lower joint 5 arranged at the lower end of the sucker rod BOP housing 1, pass through The sucker rod channel 6 arranged in the sucker rod blowout preventer housing 1, the upper joint 4 and the lower joint 5, the upper joint 4 is sleeved with an upper nut pressing cap 7 cooperating with it, in the An upper conical centering guide channel 8 cooperating with the sucker rod is arranged in the upper nut pressing cap 7,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com