Lithium ion battery

A lithium-ion battery and battery protection board technology, which is applied to secondary batteries, battery pack components, circuits, etc., can solve the problems of firmness, troublesome assembly operations, and poor strength of end cap heads, and achieves enhanced firmness, Meet the needs of use and ensure the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

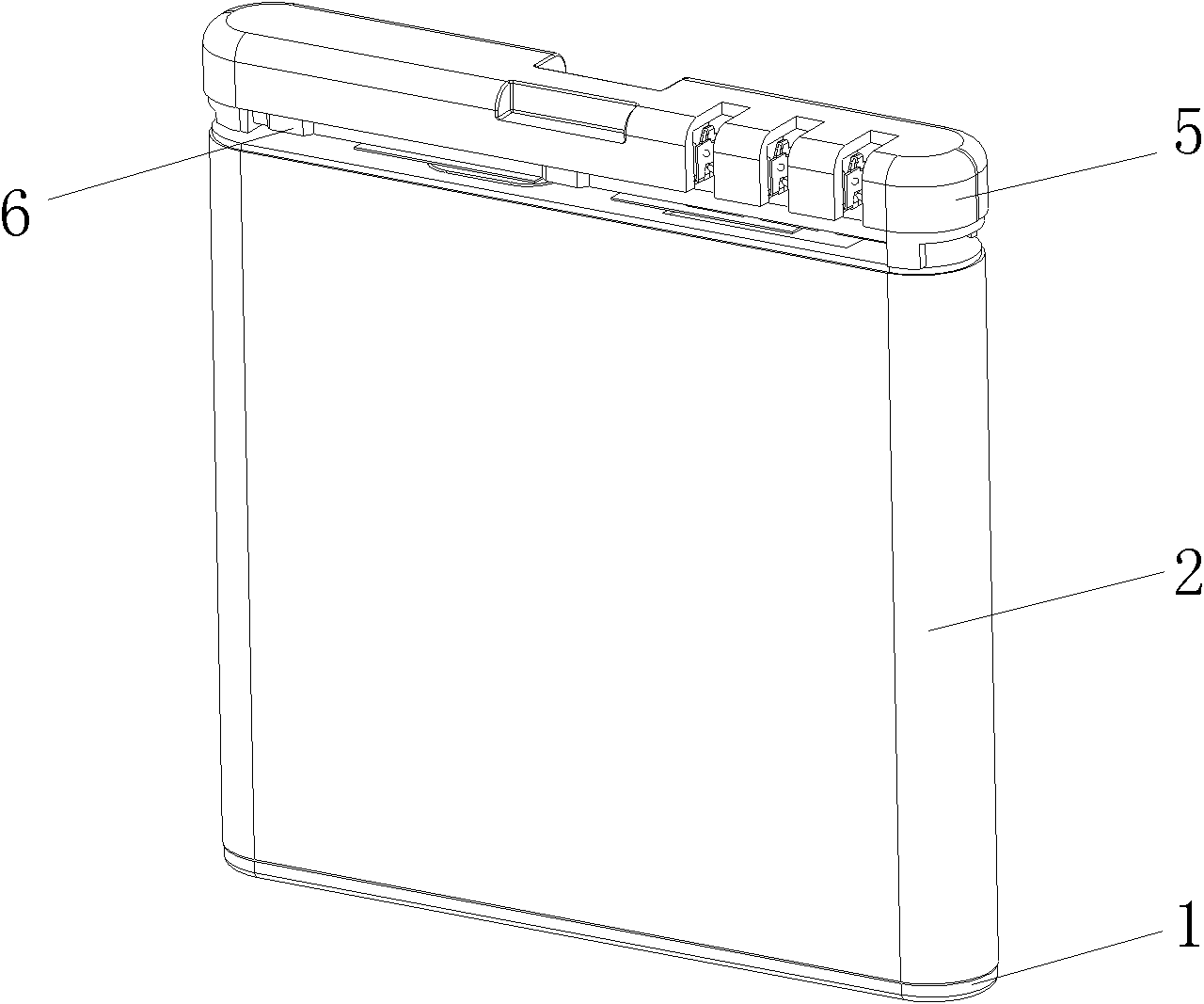

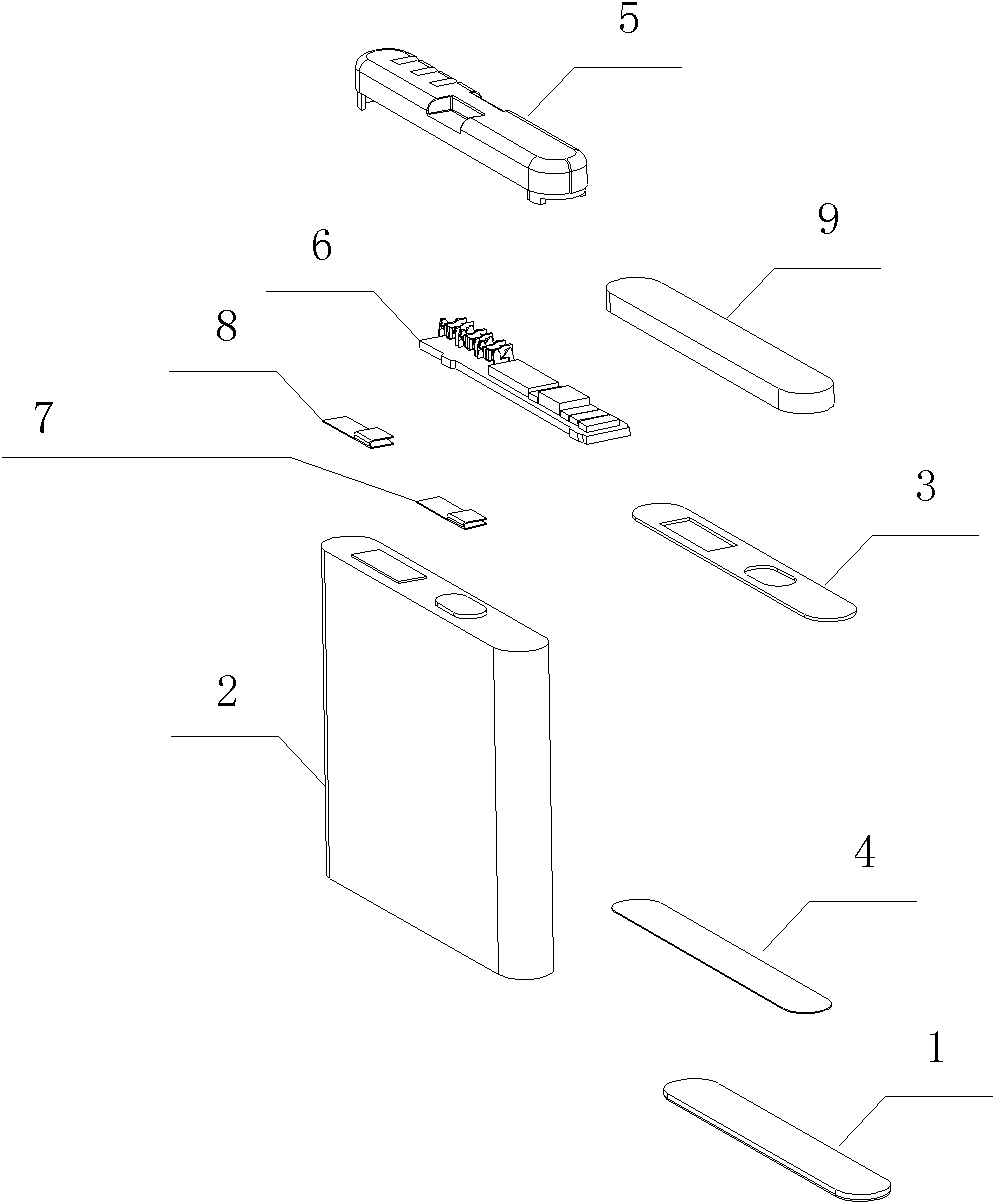

[0019] Such as Figure 1 to Figure 4 A lithium-ion battery shown includes a cell 2 , a battery protection plate 6 , an end cap 5 , a tail cap 1 , a positive tab 8 , and a negative tab 7 . The inside of the battery cell 2 includes a positive electrode sheet, a negative electrode sheet, a current collector, a diaphragm, and an electrolyte. The battery cell 2 adopts a metal shell and is packaged after liquid injection. The positive pole ear 8 and the negative pole ear 7 are connected to the positive and negative pole pieces inside the battery core. The battery protection board 6 has functions such as overcharge, overdischarge, overcurrent, high temperature protection, etc., to ensure the safety of battery use. During assembly, PVC insulation film 3 is used to insulate and isolate the battery protection plate 6 from the upper end surface of the battery cell. The upper surface of the battery protection board 6 is provided with a plurality of electrical terminals (golden fingers) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com