Bituminous mixture transfer car

A technology of asphalt mixture and transfer vehicle, which is applied in the direction of transportation and packaging, road, loading/unloading, etc. It can solve the problems of operator inconvenience, low ceiling, etc., and achieve good lubrication effect, flexible lifting, and convenient detection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

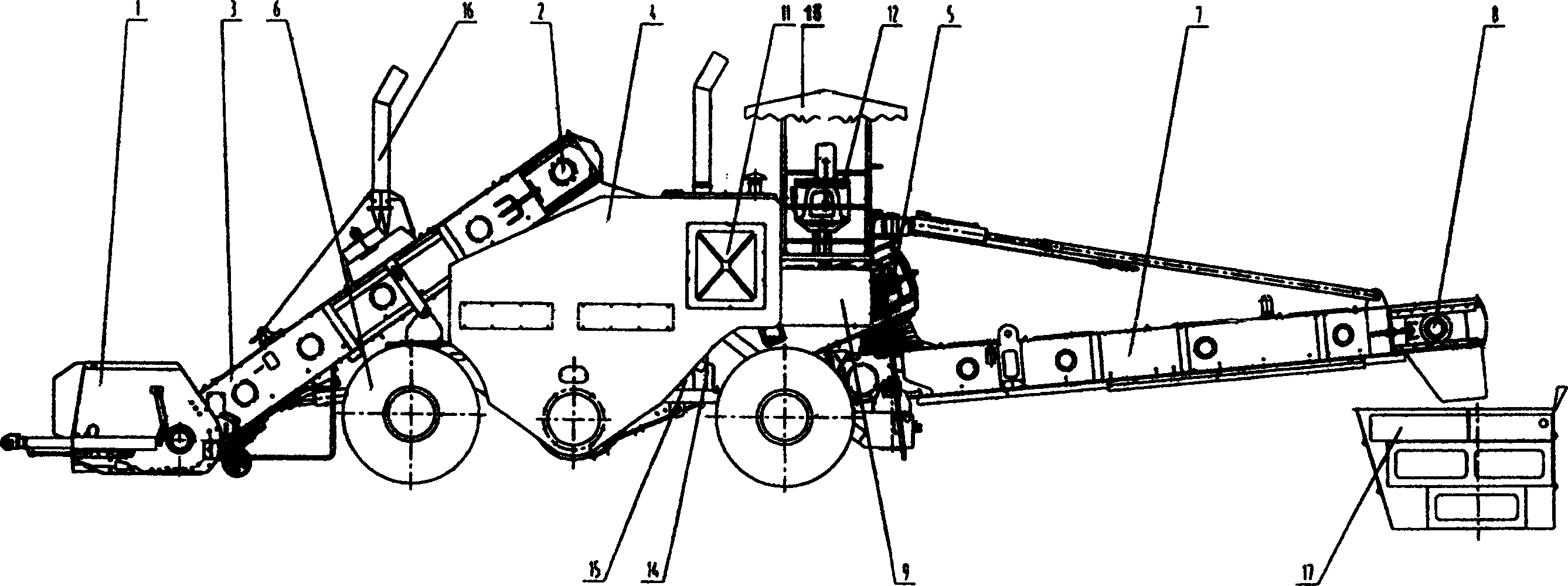

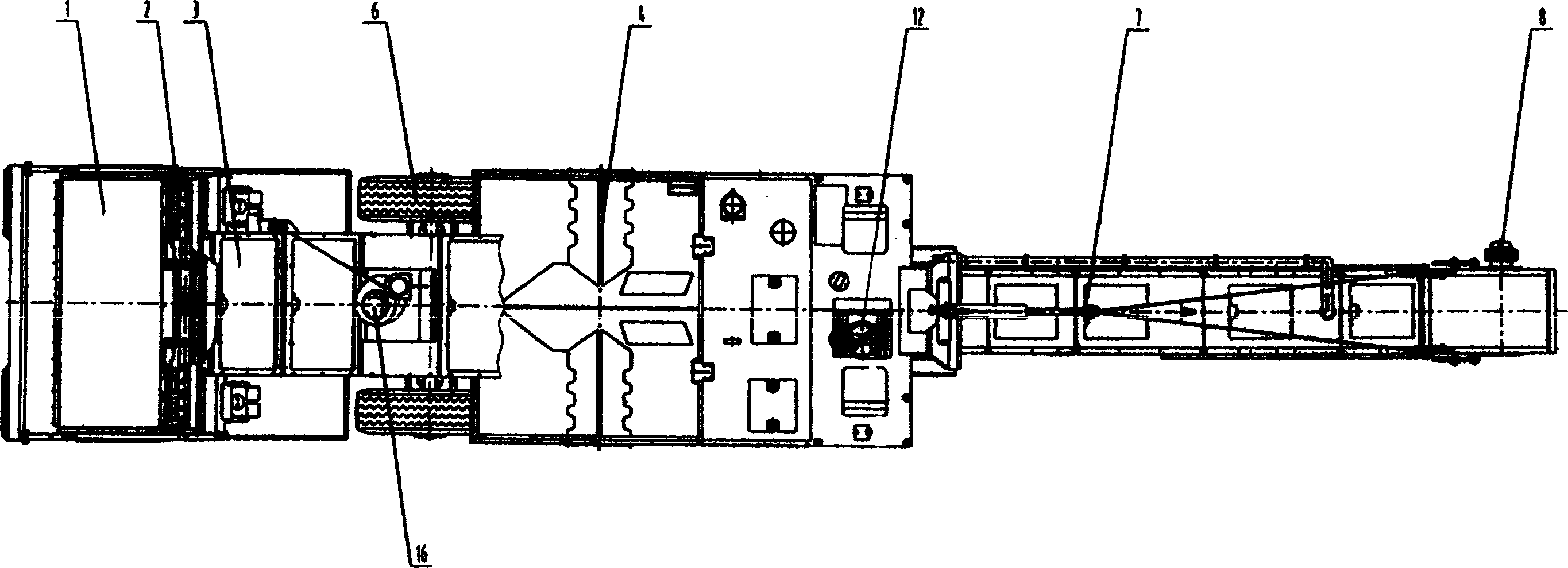

[0044] The invention is an improvement made on the basis of the existing asphalt mixture transfer vehicle. Such as figure 1 , figure 2 As shown, it includes a hopper 1, a feeding screw 2, a feeding box 3, a silo 4, a primary discharge device 5, a walking system 6, a secondary discharge device 7, a secondary discharge transmission system 8, a hydraulic pressure System 9, electrical system 10, power system 11, driver's cab 12, roof 13, cleaning device 14, centralized lubrication system 15, exhaust gas discharge system 16 and discharge receiving hopper 17, through the hopper 1, feeding material in the above-mentioned various mechanisms Casing 3, silo 4, primary discharge device 5, secondary discharge device 7, hydraulic system 9, ceiling 13 and centralized lubricating system 15 are improved to overcome some defects in the prior art, further Improve the overall performance of the asphalt transfer vehicle.

[0045] The specific improvements are described below.

[0046] Such a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com