Gas spring

A gas spring and elastic technology, which is applied in the field of suspension system of military motor vehicles, can solve the problems of inability to adjust in real time, complex electronic control system, high production cost and maintenance cost, and achieve the effect of good lubrication and increased stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

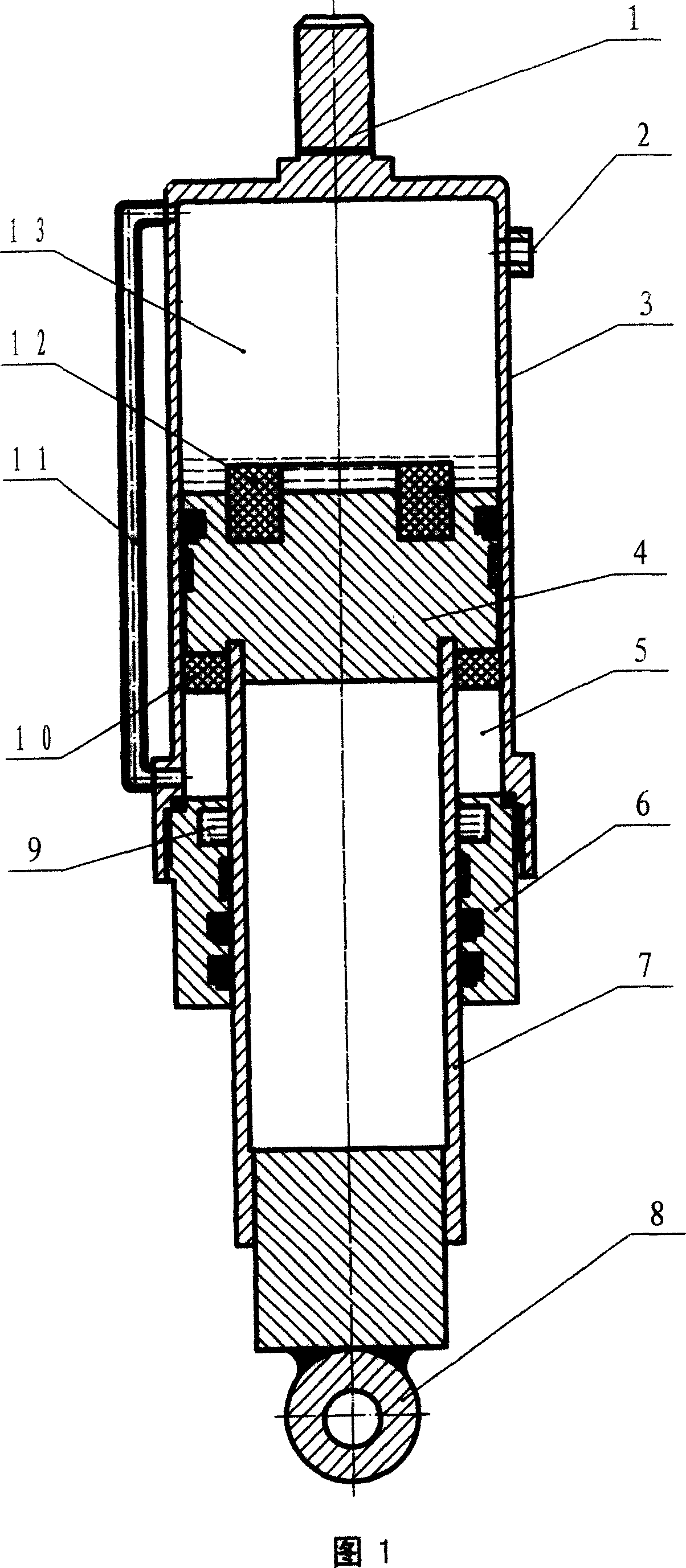

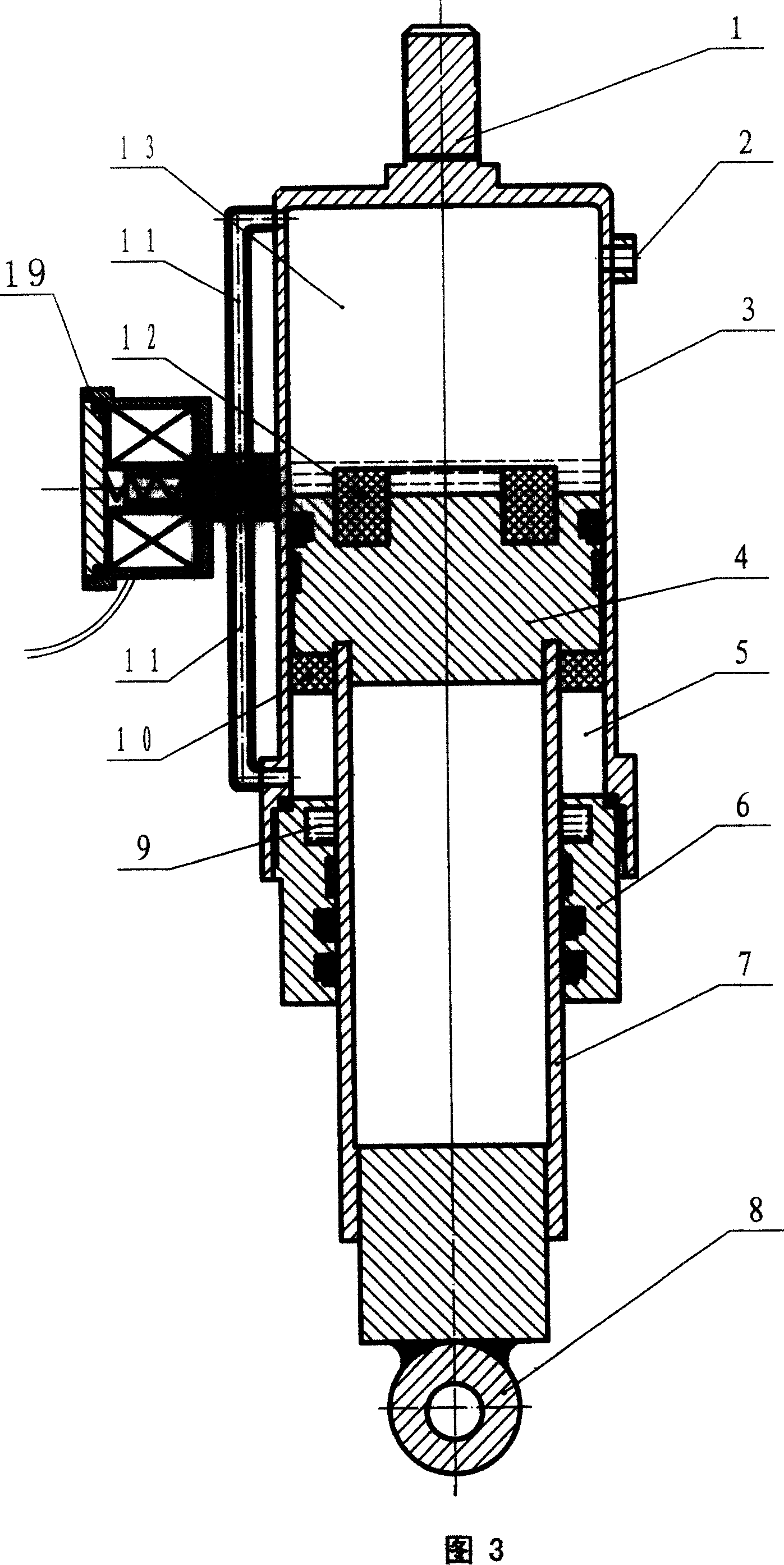

[0033]The gas spring proposed by the present invention is mainly composed of a cylinder body 3 connected with an end cover 6, a piston body 4 fitted in the cylinder body 3 and connected with a piston rod 7, and an upper connecting piece 1 is arranged on the top of the cylinder body 3. , there is a lower connector 8 at the bottom of the piston rod 7, a lubricating oil chamber 9 is arranged on the end cover 6 of the cylinder body 3 and the piston rod 7 of the piston body 4, and an anti-collision chamber is embedded on the piston body 4. The rubber pads 10, 12, the piston body 4 fitted in the cylinder body 3 separate the cylinder body 3 from the main elastic air cavity 13 and the secondary elastic air cavity 5, and damping is arranged between the main elastic air cavity 13 and the secondary elastic air cavity 5 The air duct 11 constitutes a closed air compression system. As a gas spring for suspension, it works like this: the upper connecting piece 1 and the lower connecting piec...

Embodiment 2

[0035] On the basis of the implementation described in Example 1, the damping air passage 11 can be arranged in the cylinder wall of the cylinder block 3, that is to say, when casting and producing the parts of the cylinder block 3, it can be processed and manufactured in a pre-embedded manner. The damping air passage 11 is provided, so that gas spring products can be produced in batches more conveniently.

Embodiment 3

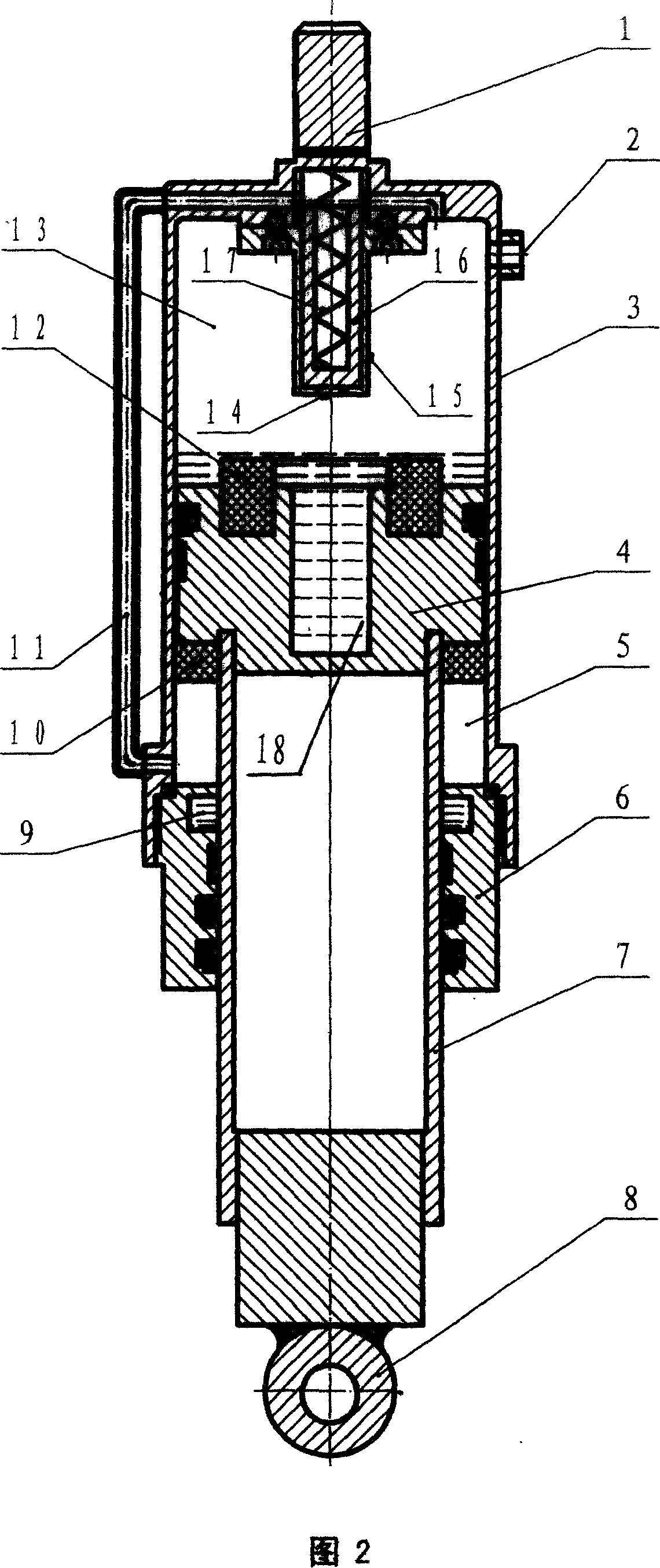

[0037] On the basis of the implementation described in Example 1, a stroke valve 15 that can open or close the damping air passage 11 is equipped in the cylinder body 3, and a valve that is compatible with the stroke valve 15 is provided at the corresponding position of the piston body 4. The oil cylinder 18 is equipped with a spring 17 on the spool 16 of the stroke valve 15. When the piston body 4 moves up and down in the cylinder body 3 and the stroke valve 15 enters or exits the oil cylinder, the oil in the gap between the oil cylinder 18 and the stroke valve 15 Under the damping force of the medium, the oil medium will force the valve core 16 to move up and down through the hole 14 of the travel valve 15, thereby controlling the opening or closing of the damping air passage 11. The function of the spring 17 is to change the gas spring from compression to elongation. The instantaneous acceleration of the spool 16 moves downward to quickly open the damping air passage 11. Whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com