Electromagnetic hydraulic valve

A hydraulic valve and electromagnetic technology, applied in the field of electromagnetic hydraulic valve, can solve the problems of increased pressure loss, tight construction cost, high pressure loss of hydraulic medium, etc., and achieve the effects of simple annular sleeve, low production cost, and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

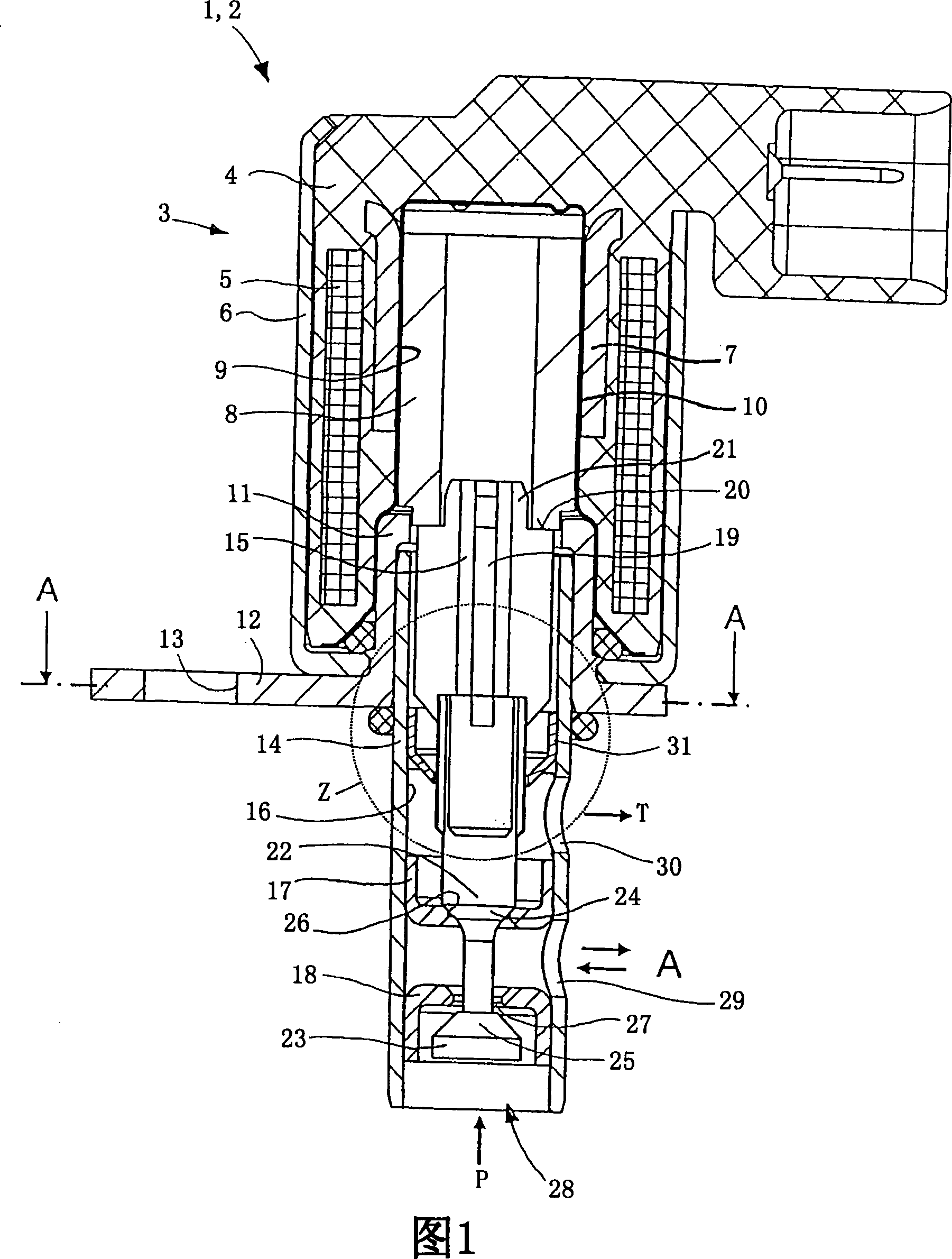

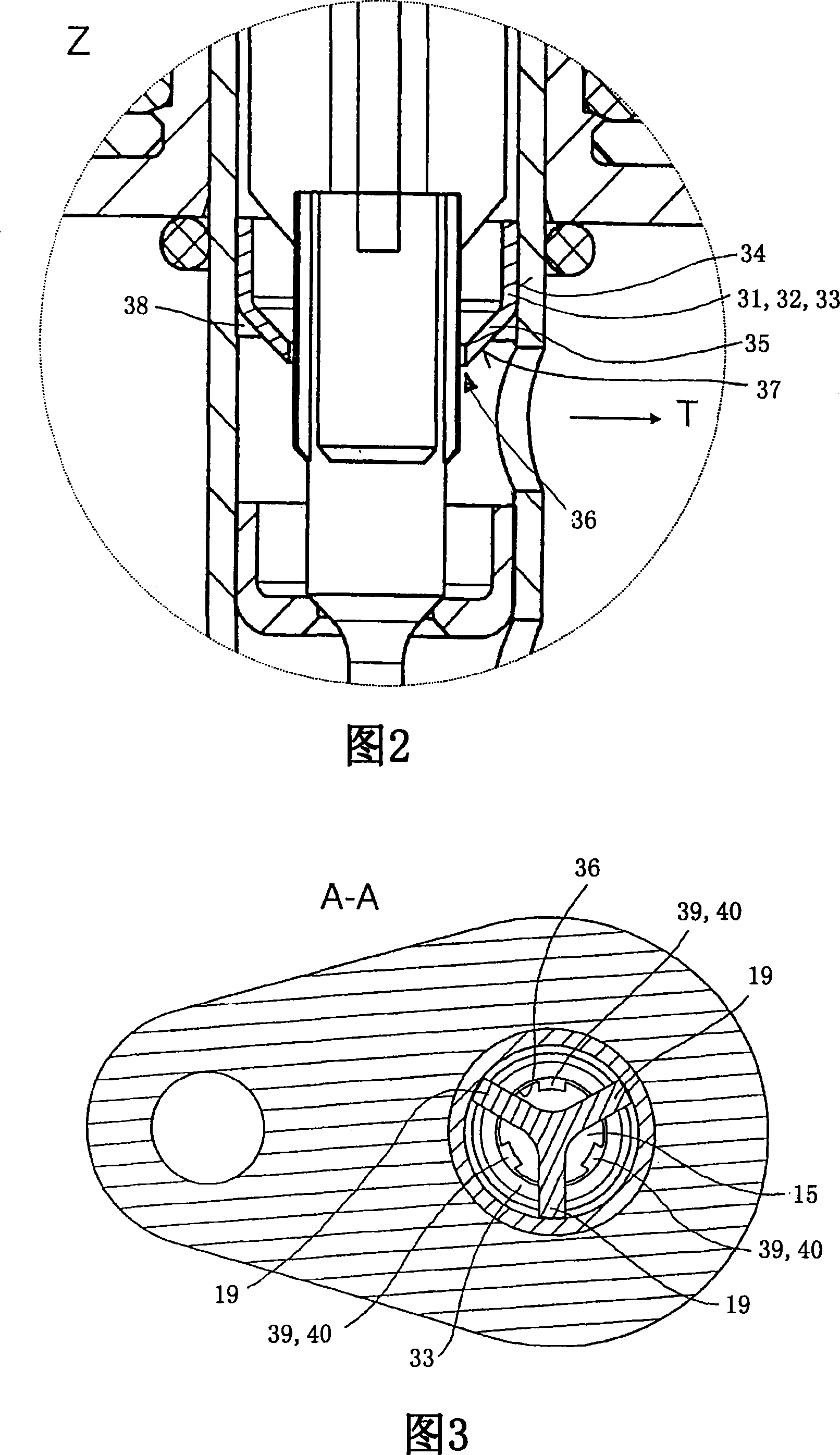

[0020] FIG. 1 shows an electromagnetic hydraulic valve source 1 which is designed as a 3 / 2-way valve 2 and which can be used to control a variable valve drive of an internal combustion engine (not shown). The hydraulic valve 1 consists of an electromagnet 3 with a coil winding 5 cast from plastic in a coil body 4 in a magnet housing 6 . A sleeve 7 , which is likewise injected into the coil body 4 , serves as the upper magnetic pole of the armature 8 , said sleeve surrounding a non-magnetic metal sleeve 10 serving as the armature guide 9 , in which the armature 8 is guided in a longitudinally displaceable manner. The lower magnetic pole is formed by an annular band 11 , which is turned toward the internal combustion engine in a suitable position in a flange region 12 with screw holes 13 for fastening the hydraulic valve 1 .

[0021] In the annulus 11 of the lower pole there is also accommodated the upper part of the valve box 14 facing the electromagnet 3 . The valve housing 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com