Wire-stripping machine equipped with three-cutter type stripping mechanism

A technology of wire stripping machine and stripping knife, which is applied in the direction of line/collector parts, equipment for dismantling/armored cables, electrical components, etc. It can solve the problems of affecting the quality of stripping, inconsistent depth, and increasing production costs. The quality of peeling, the effect of solving the centering and balance of peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

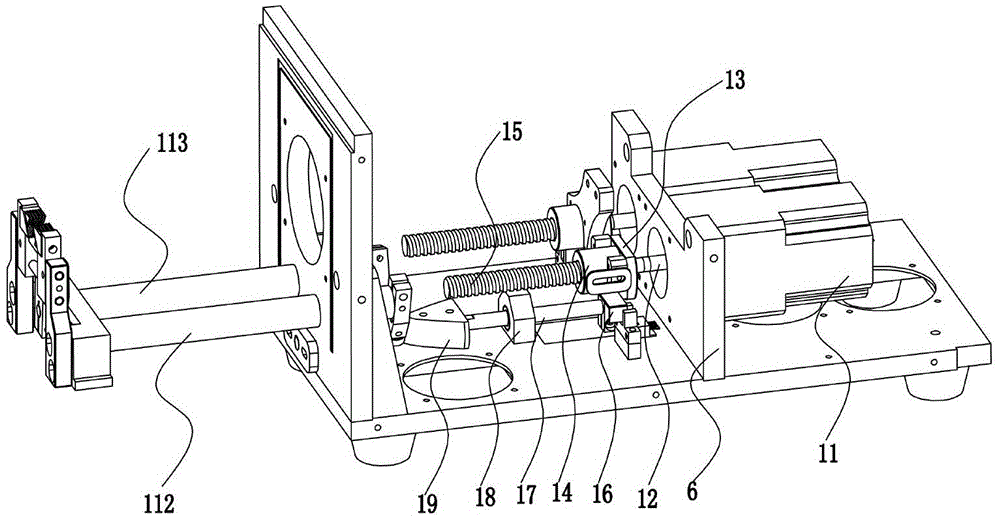

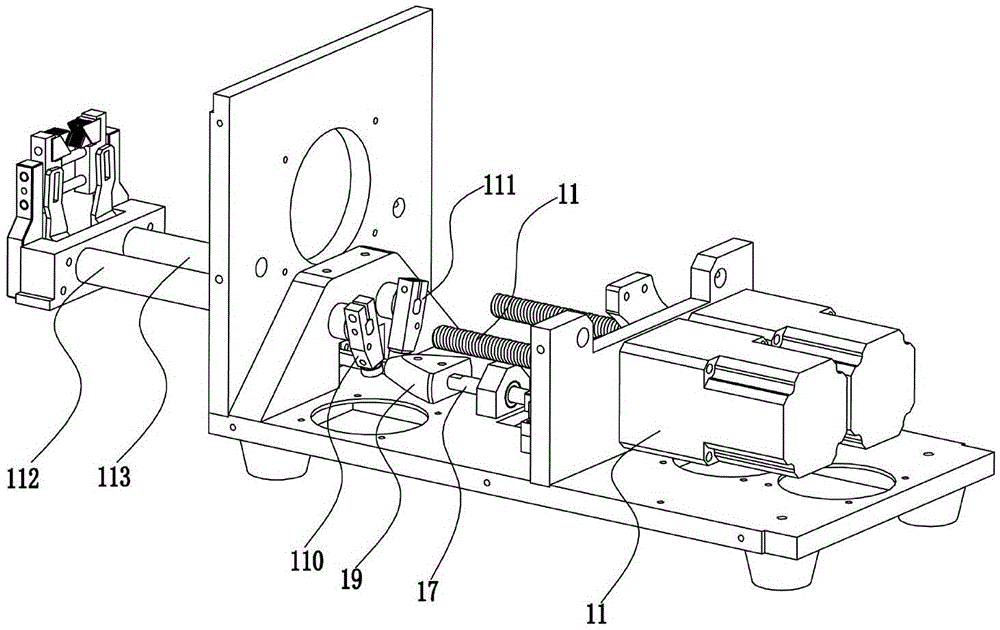

[0027] The present invention will be further described below in conjunction with accompanying drawing:

[0028] Such as Figure 1 to Figure 11 As shown, the technical scheme adopted by the present invention is as follows: a wire stripping machine adopting a three-knife stripping knife mechanism, including a knife rest assembly 4, a stripping knife assembly 3, a knife rest driving mechanism 1, a stripping knife rotation driving mechanism 2 and a stripping knife Knife axial movement driving mechanism 5, wherein, the above-mentioned stripping knife assembly 3 extends out of the wire stripping machine, and the inner end of the stripping knife assembly 3 is connected to the stripping knife rotation driving mechanism 2 and the stripping knife axial movement drive 5, so as to drive the stripping knife assembly 3 Radial rotational movement and axial movement; the above-mentioned knife rest assembly 4 protrudes to the outside of the stripping knife assembly 3, and the cable to be strip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com