Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Simple annealing process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

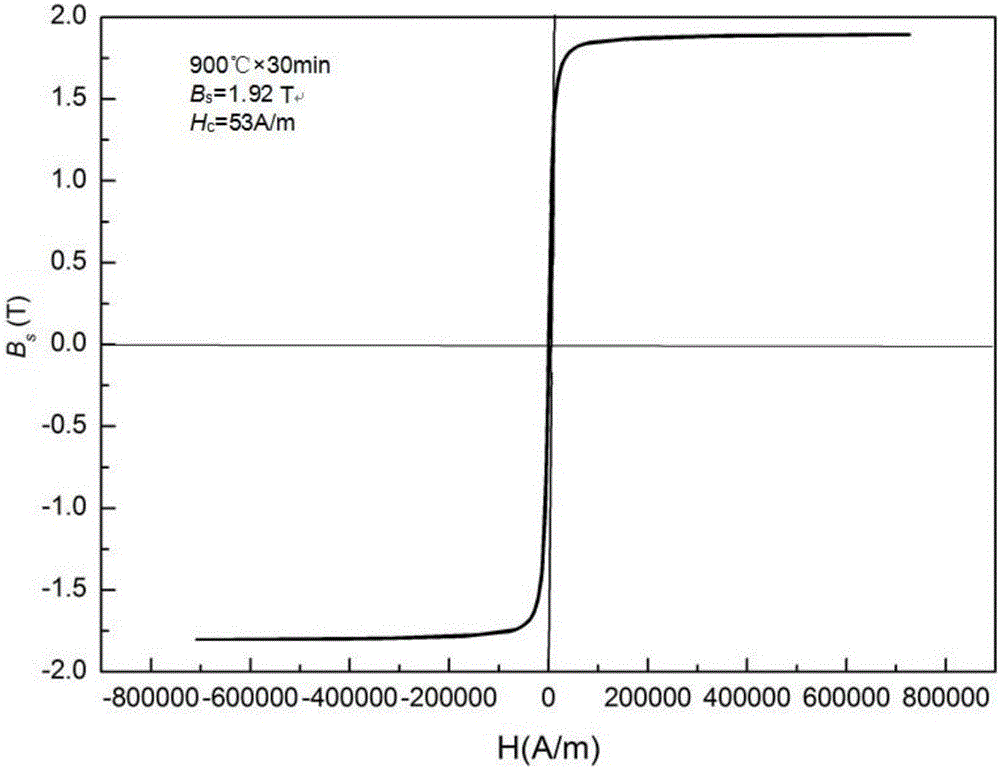

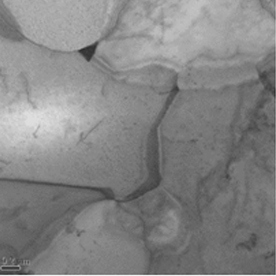

Fe-based nanocrystalline soft magnetic alloy with strong amorphous forming ability and preparing method of Fe-based nanocrystalline soft magnetic alloy

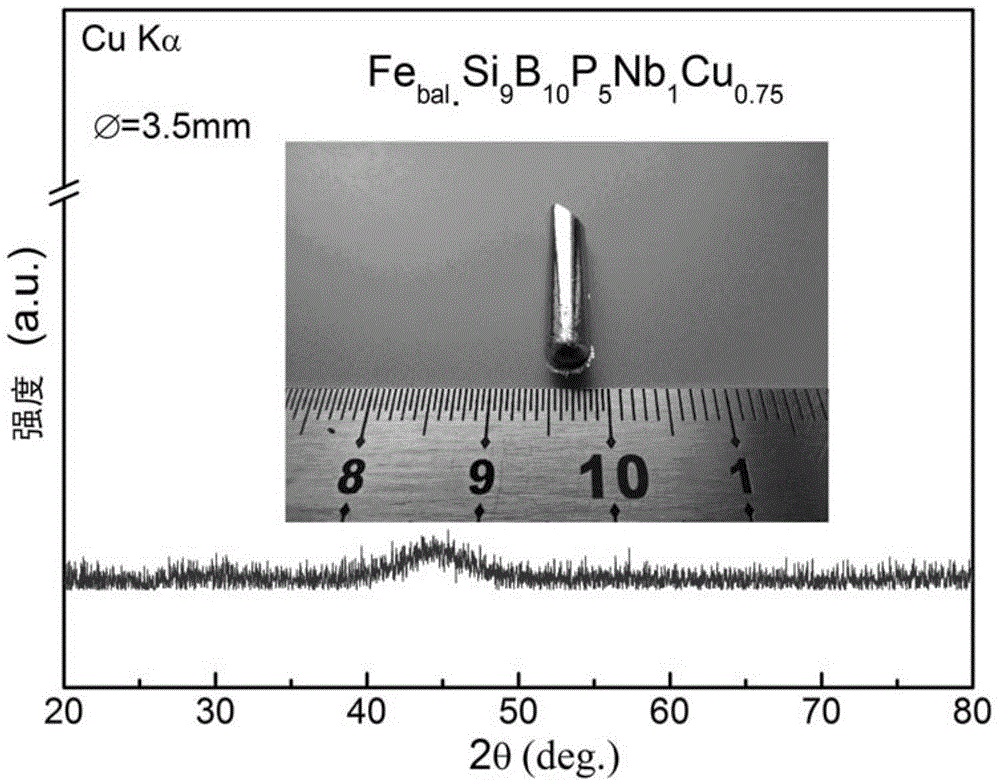

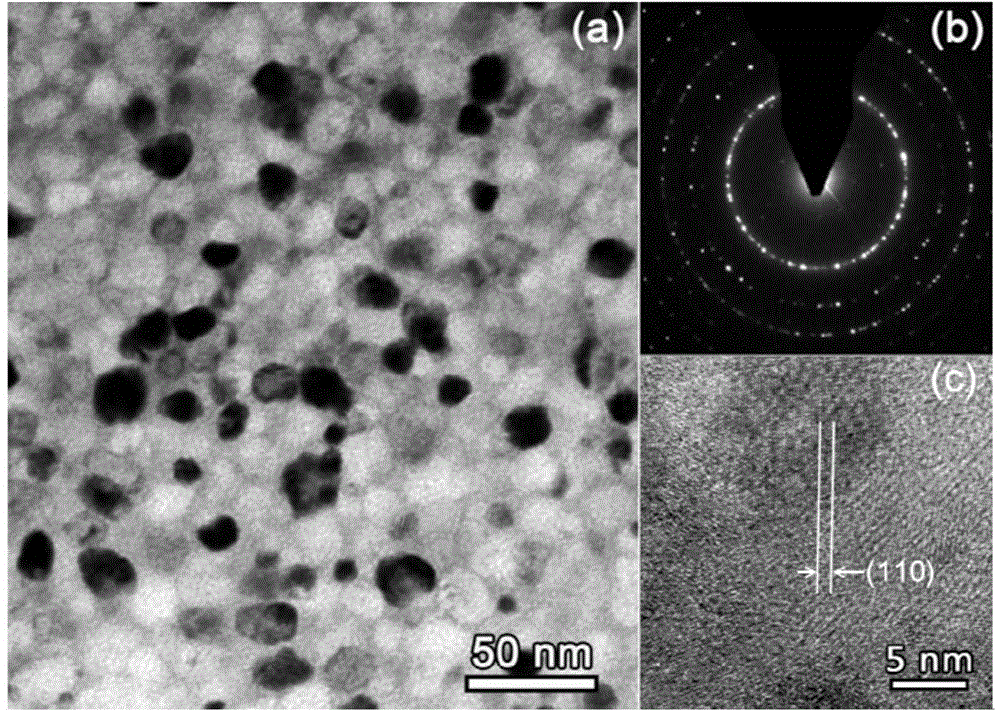

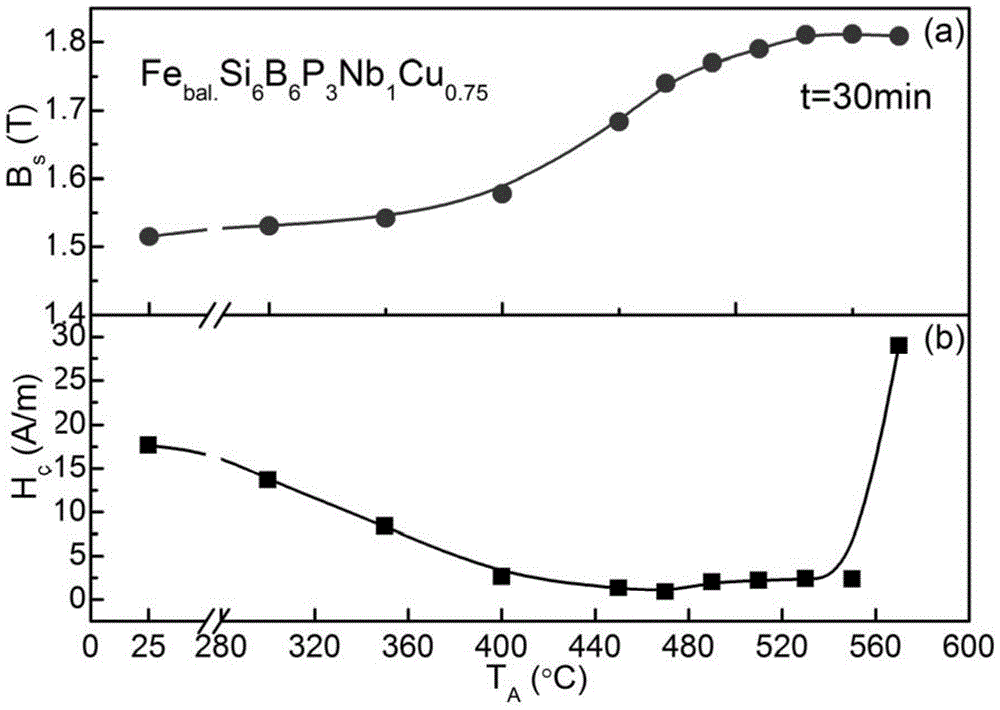

ActiveCN104934179AHigh saturation magnetic inductionLow coercivityMagnetic materialsCopper moldMagnetic alloy

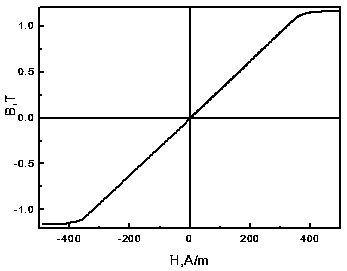

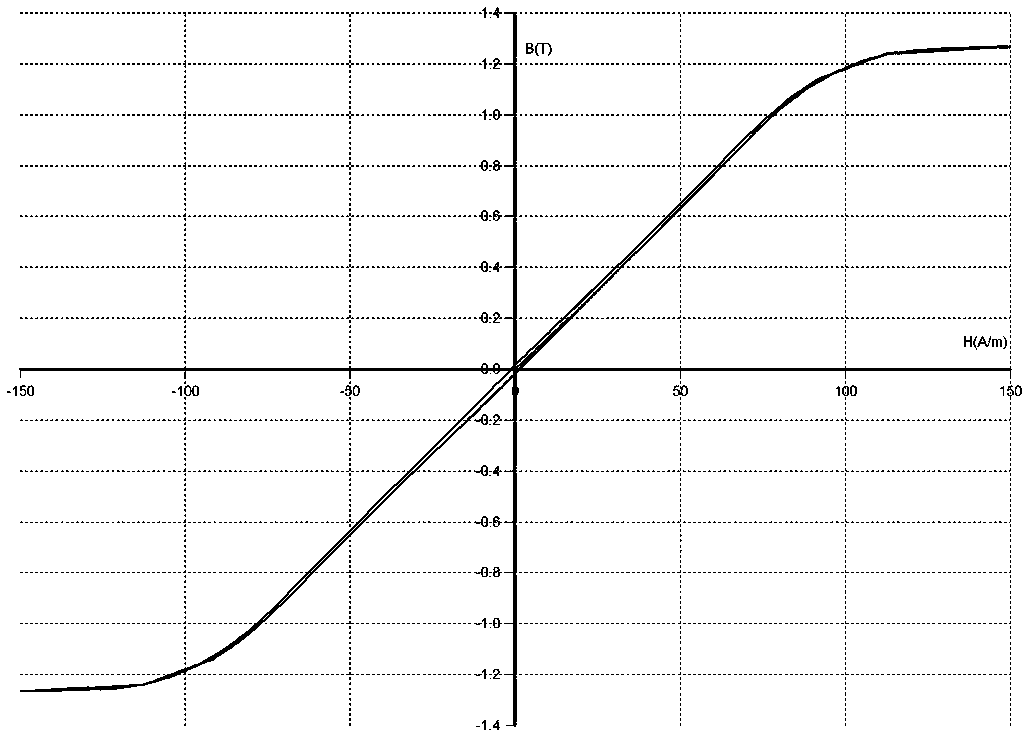

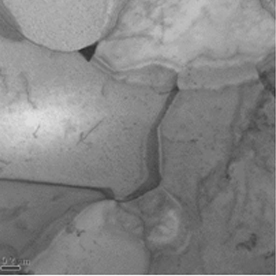

The invention discloses a Fe-based nanocrystalline soft magnetic alloy with strong amorphous forming ability and a preparing method of the Fe-based nanocrystalline soft magnetic alloy. The alloy has an expression of Fe<x>SiBP<c>Nb<d>Cu<e>, wherein in the expression, each of the x, the a, the b, the c, the d and the e shows the atomic percentage content of the corresponding ingredient, and meets the following conditions that the a is greater than or equal to 0.5 but smaller than or equal to 12; the b is greater than or equal to 0.5 but is smaller than or equal to 15; the c is greater than or equal to 0.5 but smaller than or equal to 12; the d is greater than or equal to 0.1 but smaller than or equal to 3; the e is greater than or equal to 0.1 but smaller than or equal to 3; the x is greater than or equal 70 but smaller than or equal to 85; and the sum of the x, the a, the b, the c, the d and the e is 100 percent. The soft magnetic alloy has the advantages that an ordinary copper mold casting method can be used for preparing a Fe-based amorphous alloy with the critical dimension being 3.5mm; after the annealing; the saturation flux density is greater than 1.5T; and the coercive force value is smaller than 1A / m.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

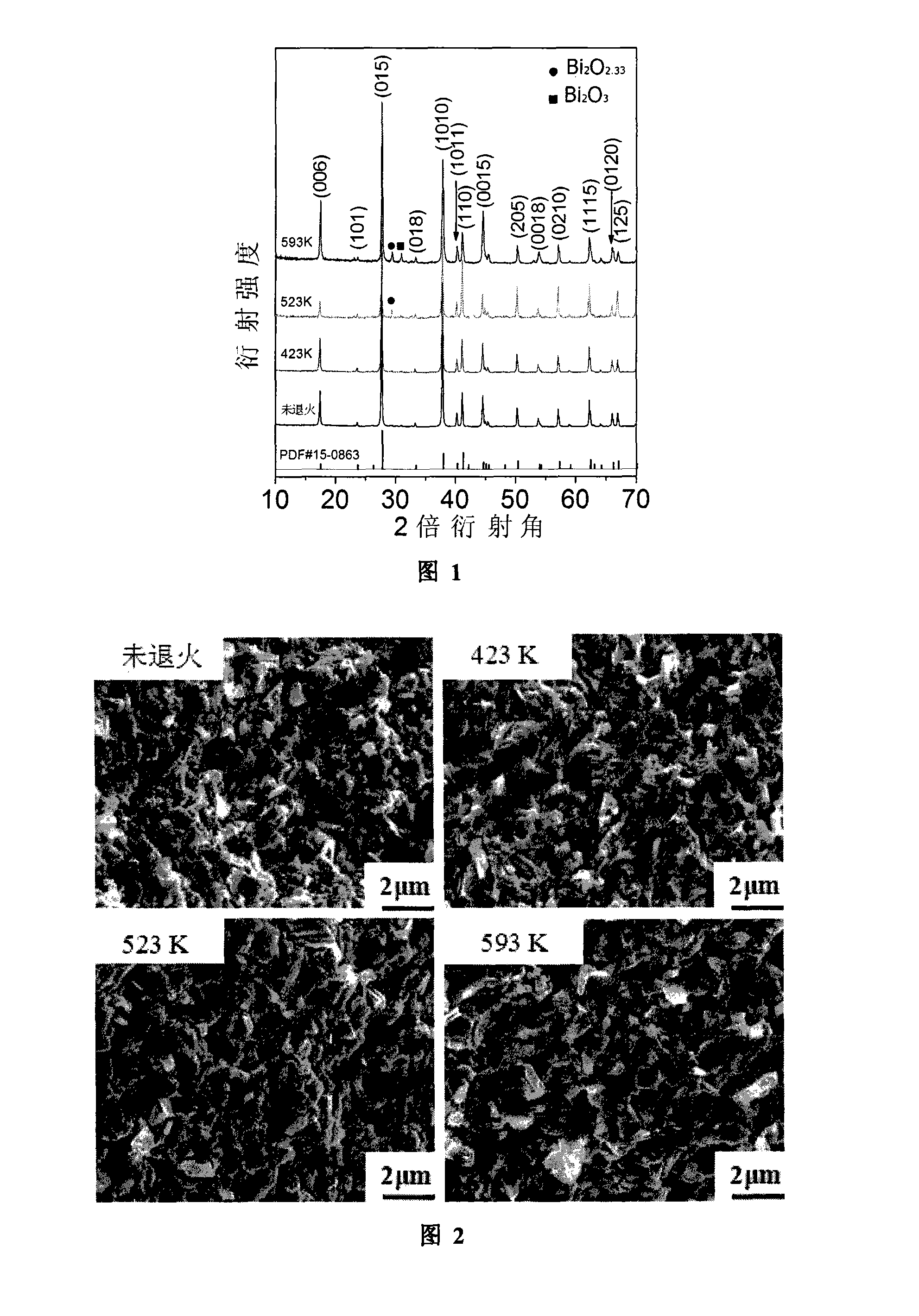

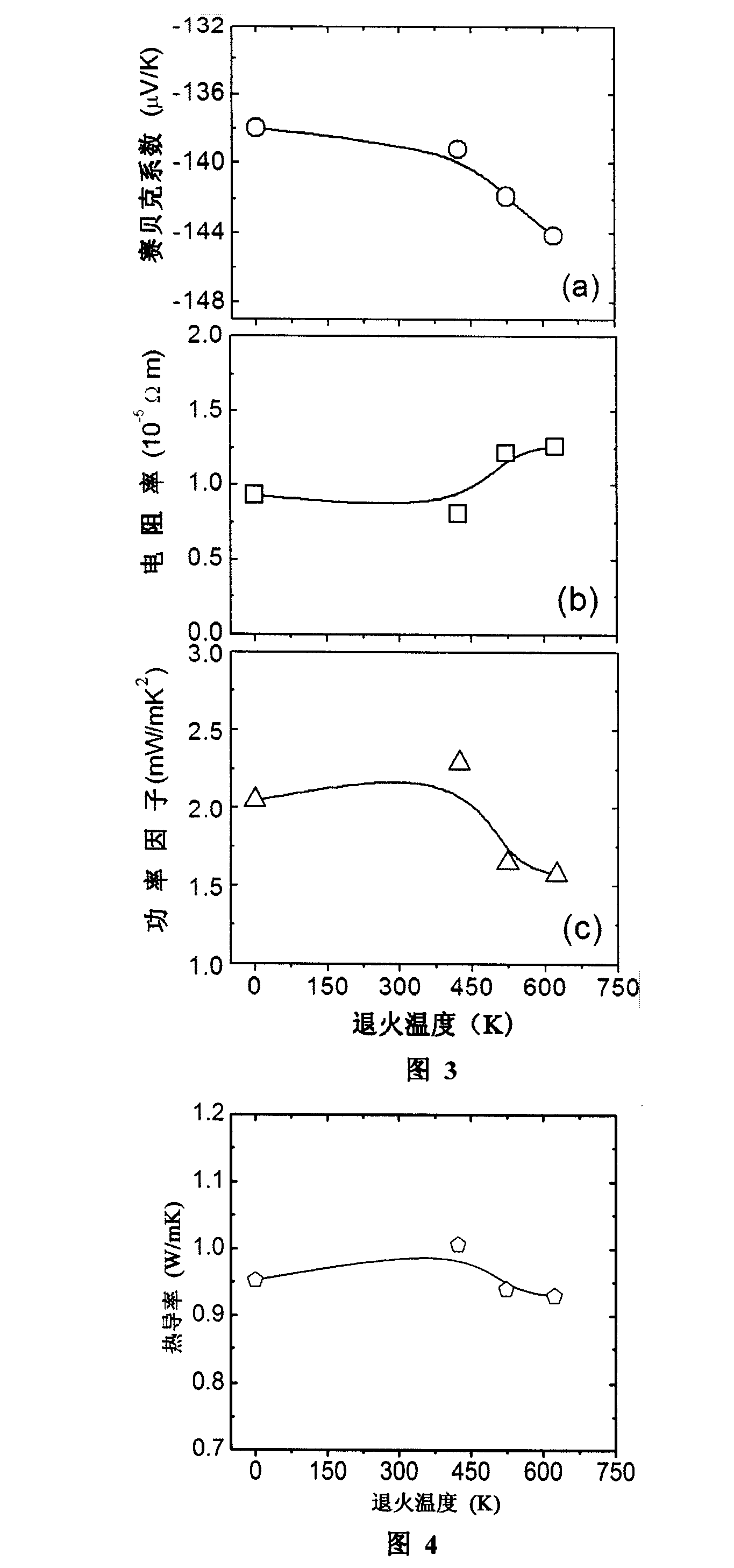

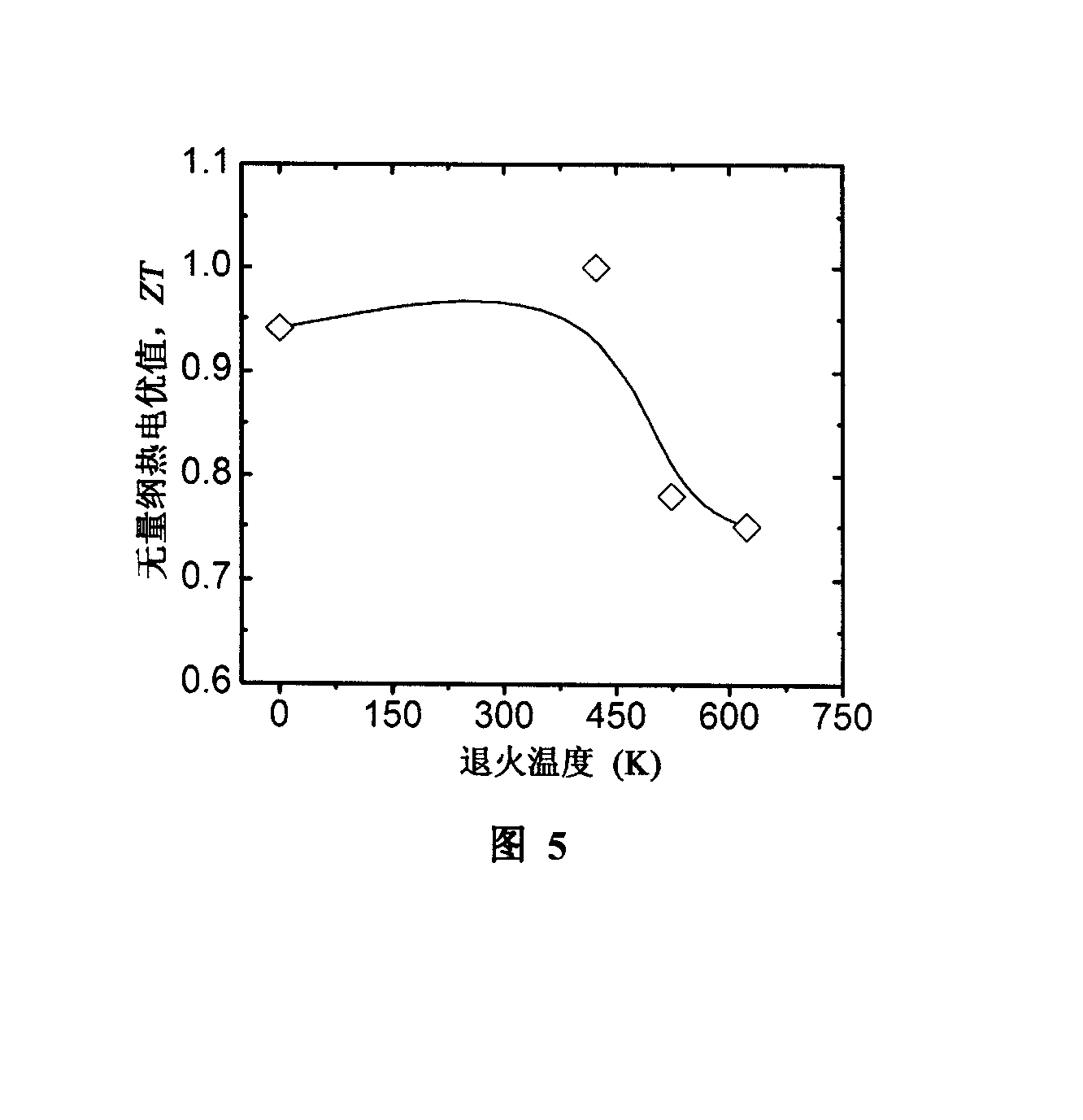

Thermal treatment method for improving type N polycrystal Bi2Te3thermoelectricity capability

InactiveCN101220513AShort synthesis timeShort preparation timePolycrystalline material growthAfter-treatment detailsThermal treatmentVacuum annealing

A heat treatment method that increases the thermoelectric property of N-type polycrystal Bi2Te3 belongs to the technical field of energy materials. The method is divided into two parts: preparing of an N-type polycrystal Bi2Te3 thermoelectric material and annealing. At first, high purity Bi and Te are synthetized into Bi2Te3 compound powder by mechanical alloying, and an N-type polycrystal Bi2Te3 block material is prepared by spark plasma sintering, and then the Bi2Te3 block material is treated with vacuum annealing. Through the annealing treatment, the method increases the thermoelectric property of the N-type polycrystal Bi2Te3 and has the advantages of simple process, low cost and strong practicability, etc.

Owner:UNIV OF SCI & TECH BEIJING

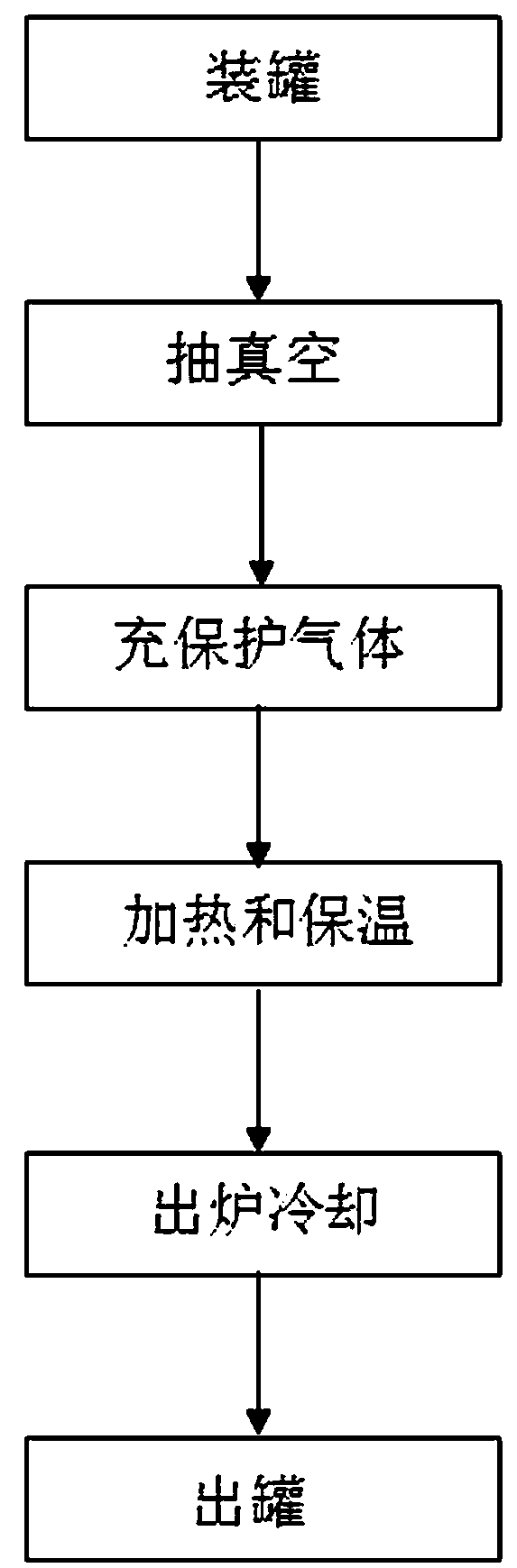

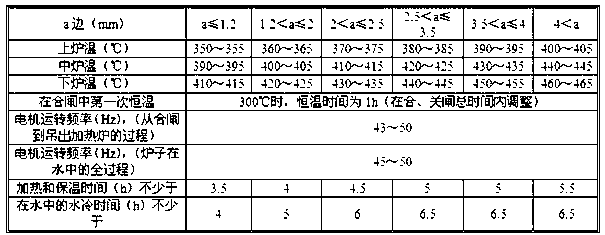

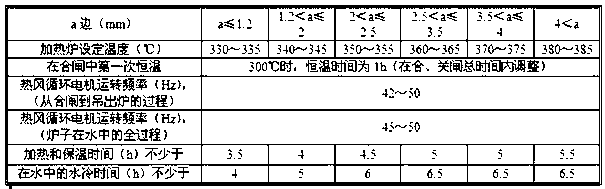

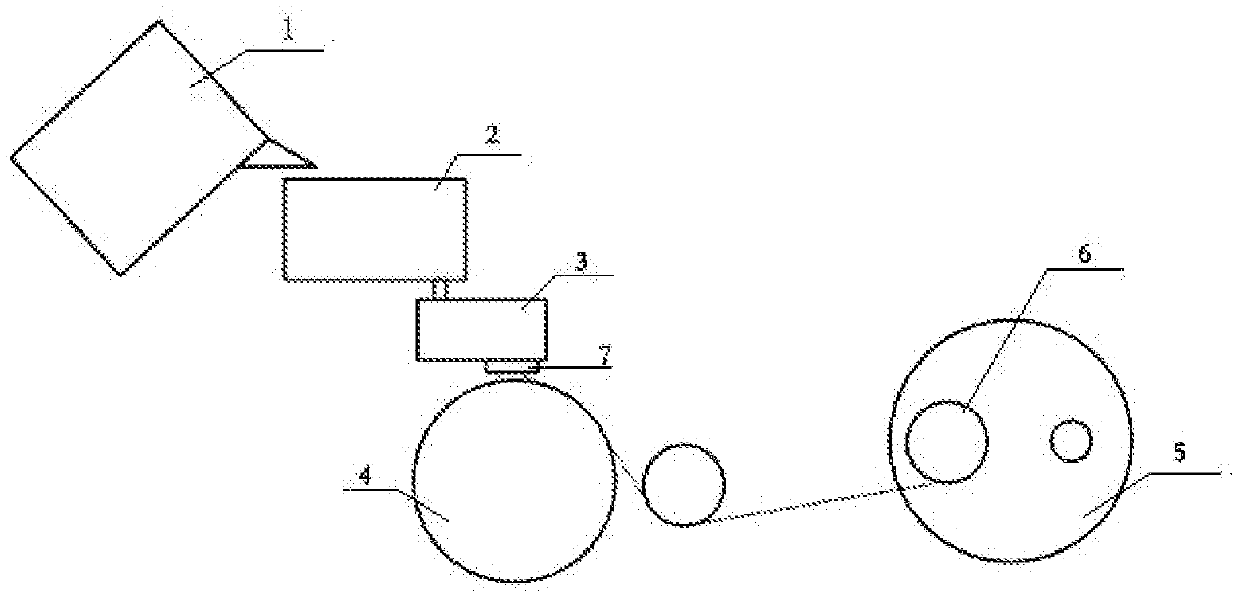

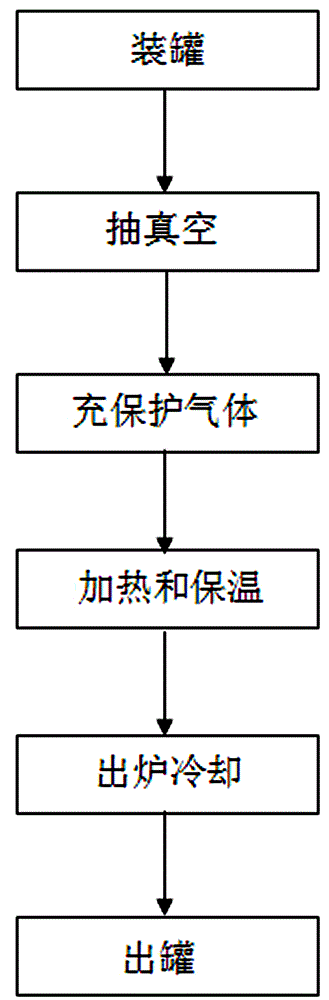

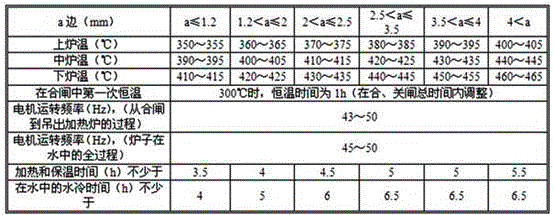

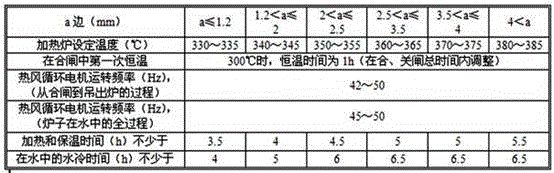

Well type cyclic annealing process for bare copper flat wire

ActiveCN102936642ASimple annealing processWide range of annealing specificationsFurnace typesCable/conductor manufactureProduct gasCopper

The invention provides a well type cyclic annealing process for a bare copper flat wire of a pot type hot-air cyclic annealing furnace with a patent number of ZL201120172272.1. The well type cyclic annealing process comprises the following steps: 1) feeding materials into the furnace; 2) pumping to reach a vacuum state; 3) feeding protective gas; 4) heating and carrying out heat preservation; 5) discharging the materials out of the furnace, and cooling; and 6) discharging the finished product from the furnace. The well type cyclic annealing process for the bare copper flat wire is simple, and the bare copper flat wire annealing specification scope is wide; and the protective gas is supplied and cycled in the annealing furnace, so that the problem that the bare copper flat wire cannot be uniformly annealed due to different temperatures in the upper part, the middle part and the lower part of the annealing furnace can be effectively solved.

Owner:HUNAN XINXIN CABLE

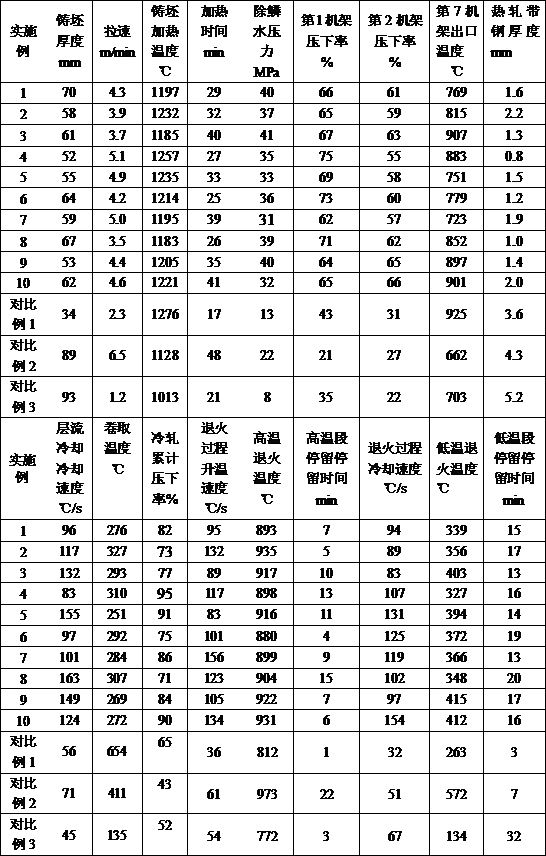

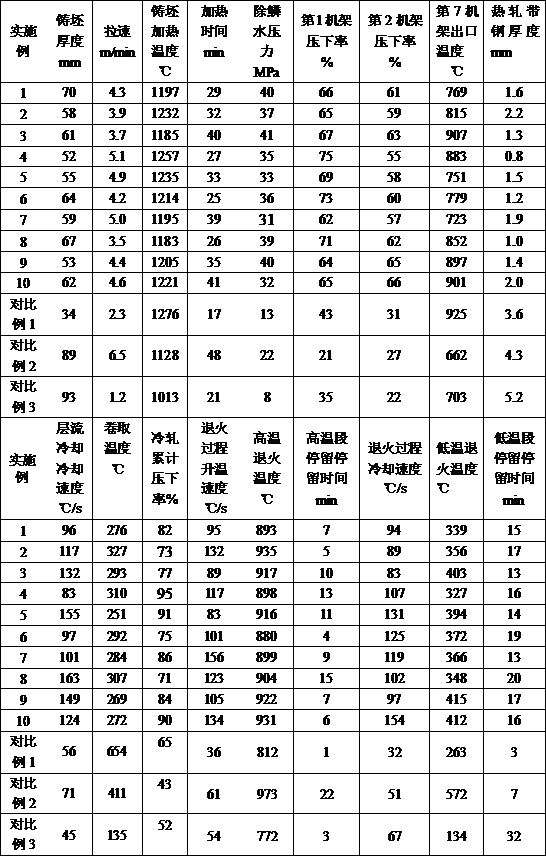

Rolling process beneficial to spheroidizing annealing of Cr and Mo steel

InactiveCN103350116AInhibit growthImprove segregationTemperature control deviceTemperature controlCarbide

The invention belongs to the technical field of metallurgy and particularly relates to a rolling process beneficial to spheroidizing annealing of a Cr and Mo steel. The rolling process is carried out according to the following steps of: carrying out cogging, rolling and spinning on a continuously cast steel billet; then always carrying out heat preservation to about 300 to 350 DEG C on a roll table cooling line and carrying out coil collection so as to obtain a Cr and Mo steel rolled product. According to the invention, by cogging heating control, steel rolling temperature control and after-rolling cooling control, segregation at the position of one second of R and center segregation are improved, grains are refined and growth of abnormal grains is avoided. Meanwhile, generation of large granular ferrite and pearlite is controlled, martensite is controlled below 35 percent; tissues mainly comprising bainite is formed, and carbide of the tissues is more uniformly distributed on a matrix. Moreover, according to a product produced by using the process, time of spheroidizing annealing is greatly shortened, an annealing process is simplified and spheroidized cementite is more dispersively and finely distributed.

Owner:NORTHEASTERN UNIV +1

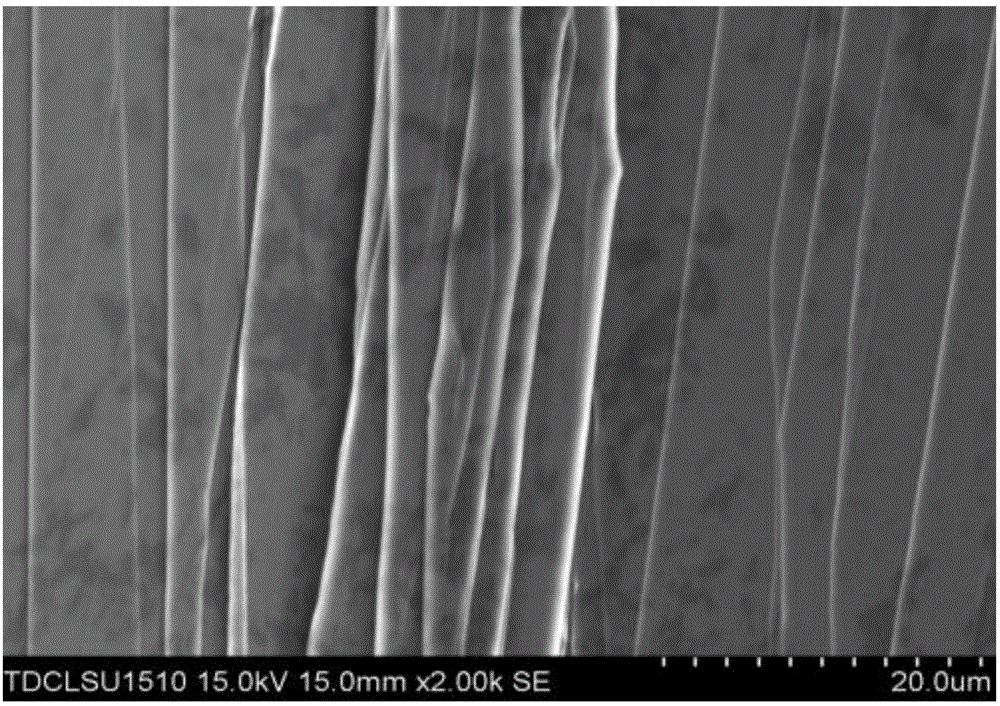

Magnetically soft alloy strip based on high-plasticity high silicon and manufacturing method of magnetically soft alloy strip

The invention relates to a magnetically soft alloy strip based on high-plasticity high silicon. The magnetically soft alloy strip based on the high-plasticity high silicon is characterized in that the component expression of the magnetically soft alloy strip is FexSiaBb, wherein x, a and b are wt%, a is larger than or equal to 4 and smaller than or equal to 8, and b is larger than and equal to 0.001 and smaller than or equal to 2, and x+a+b is equal to 100%. According to the magnetically soft alloy strip based on the high-plasticity high silicon, a multi-slit nozzle and warm roller cooling plane flow casting method is used for manufacturing the strip, the manufactured magnetically soft alloy strip is 5 mm to 200 mm in strip width and 0.02 mm to 0.2 mm in strip thickness, the lamination coefficient is larger than 0.9, and the saturation flux density is larger than 1.8 T. The magnetically soft alloy strip is widely suitable for the fields of electric power, electronics, information, communication and the like.

Owner:南京腾元软磁有限公司 +3

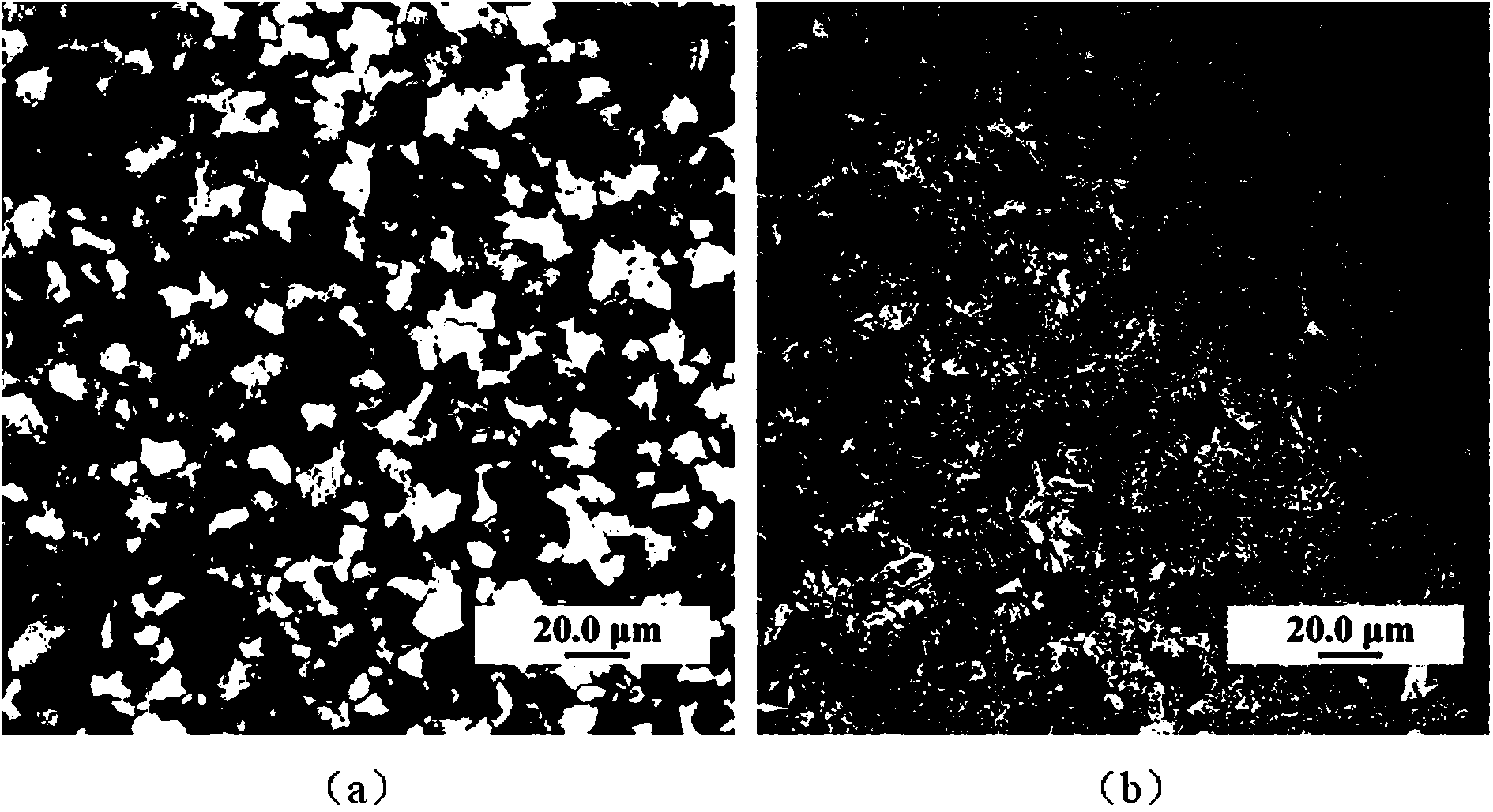

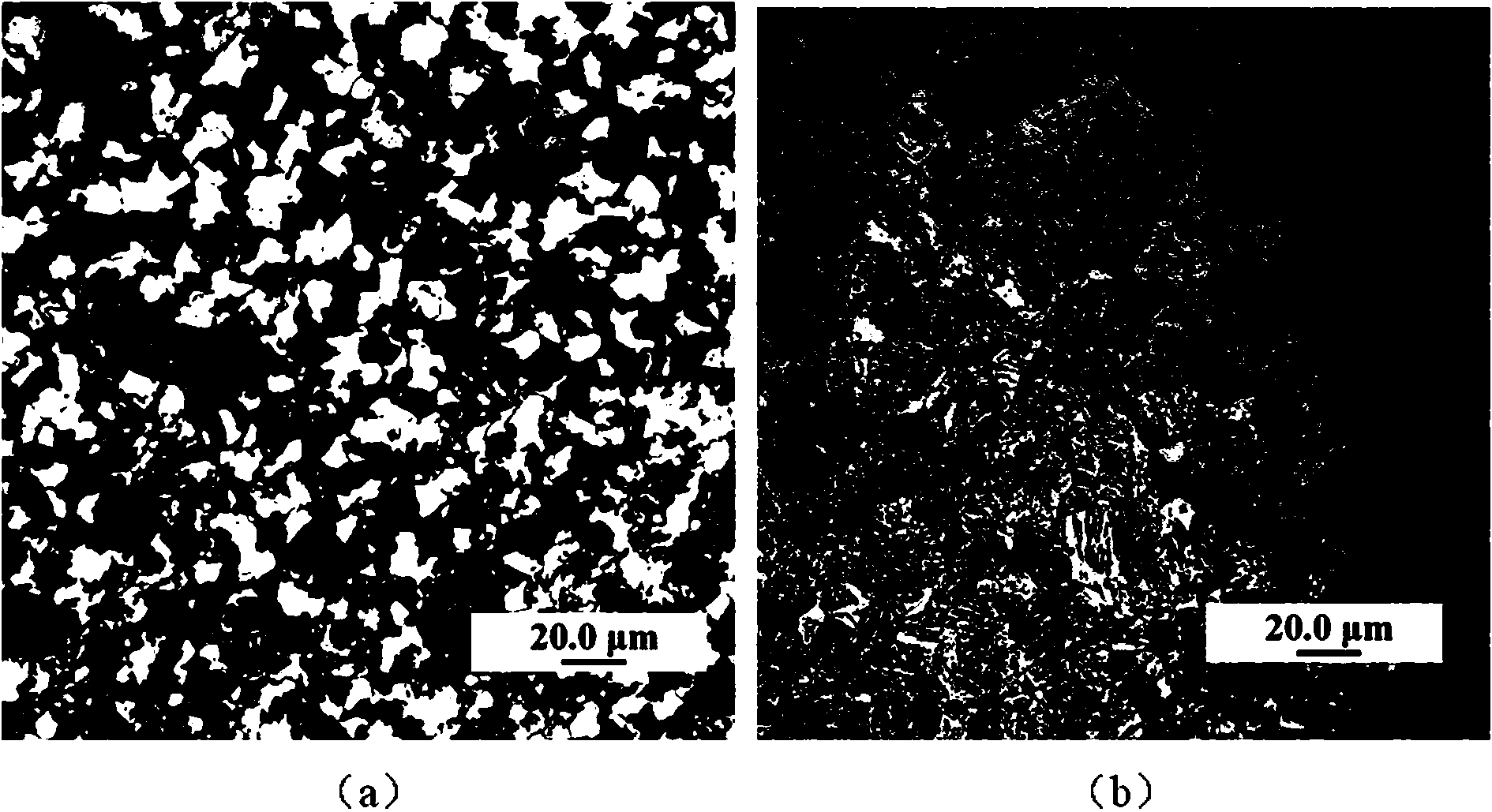

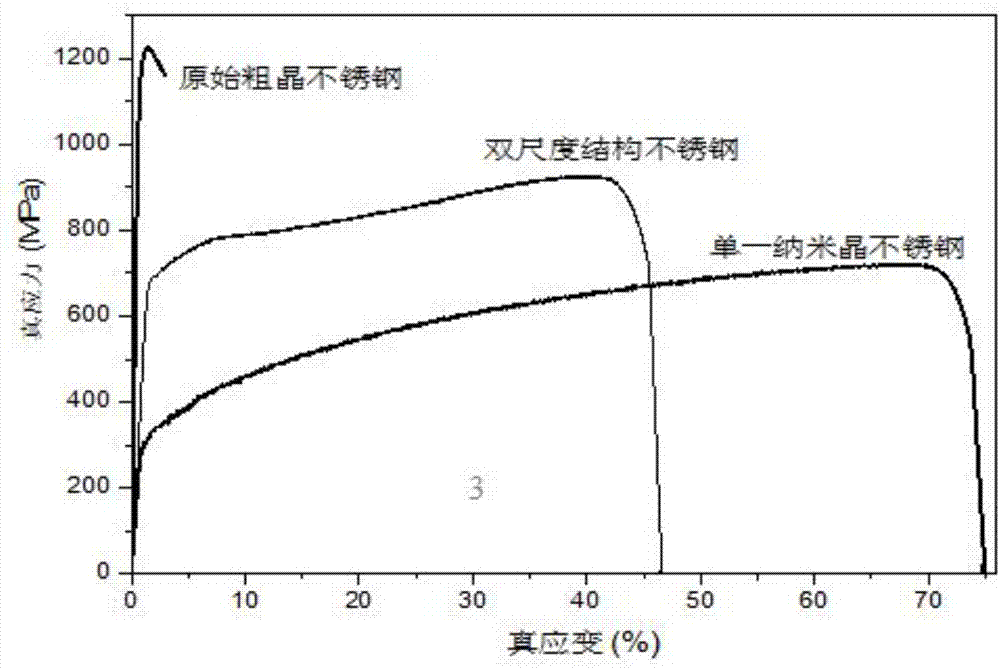

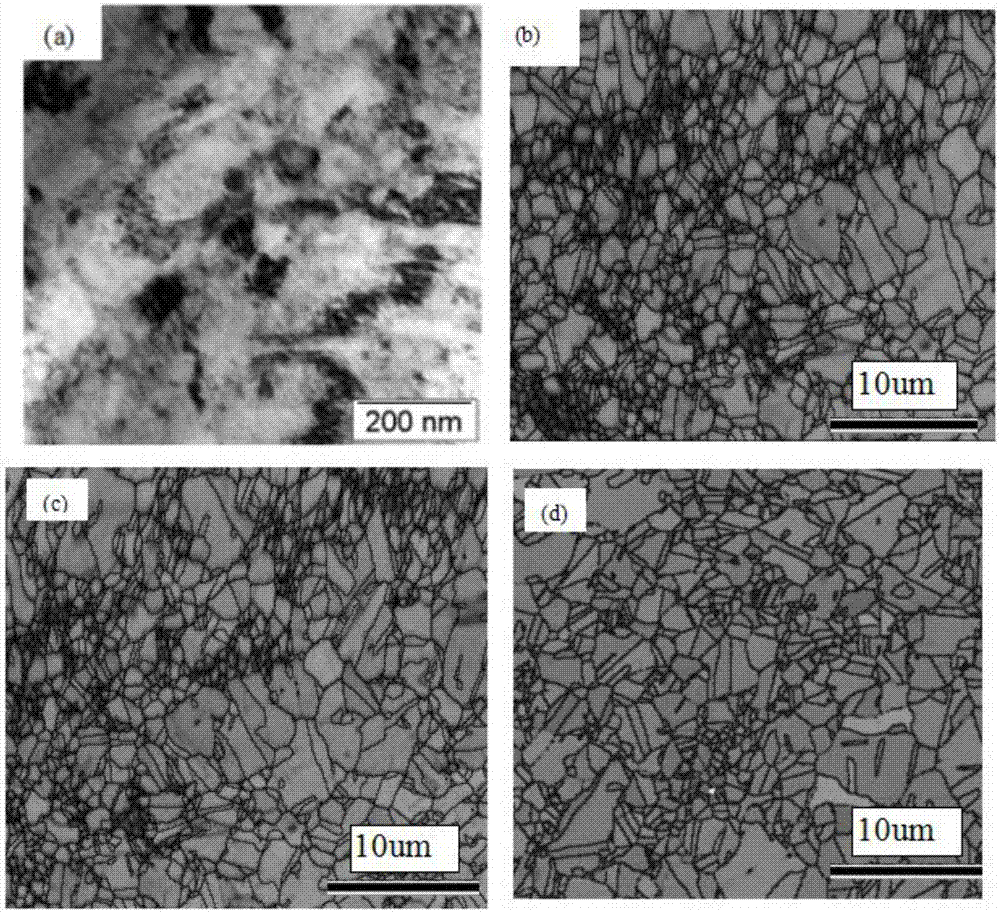

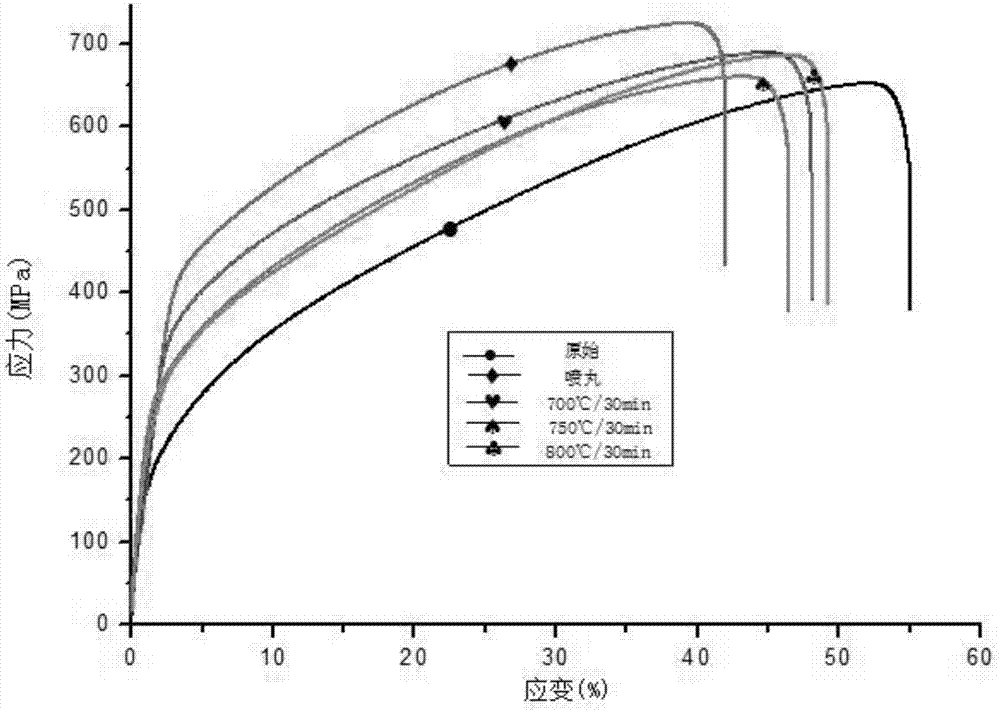

Preparation method of high-strength and high-tenacity stainless steel

The invention discloses a preparation method of high-strength and high-toughness stainless steel. The invention adopts a compound process of shot peening surface nanometerization and annealing treatment. Firstly, a layer of nanocrystalline refinement layer is obtained on the surface of the stainless steel plate through shot peening surface nanotechnology, and then through appropriate annealing treatment, the nanocrystalline structure is transformed into a dual-scale structure, that is, ultrafine grains + micron-sized coarse grains Composed of two parts, using ultra-fine grains to improve the strength of stainless steel (fine-grain strengthening), and through the combined action of the micron-sized coarse-grained part in the surface layer and the original coarse-grained part that has not been refined in the shot peening process, to Continue to maintain the good plasticity of stainless steel. In order to obtain high-strength and high-toughness stainless steel plate.

Owner:SOUTH CHINA UNIV OF TECH

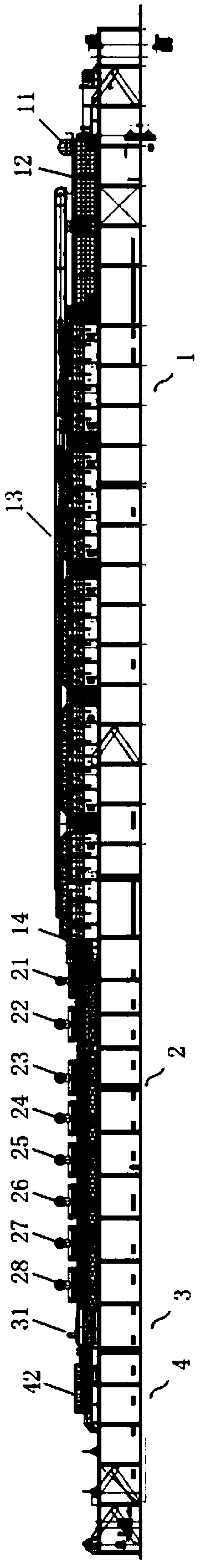

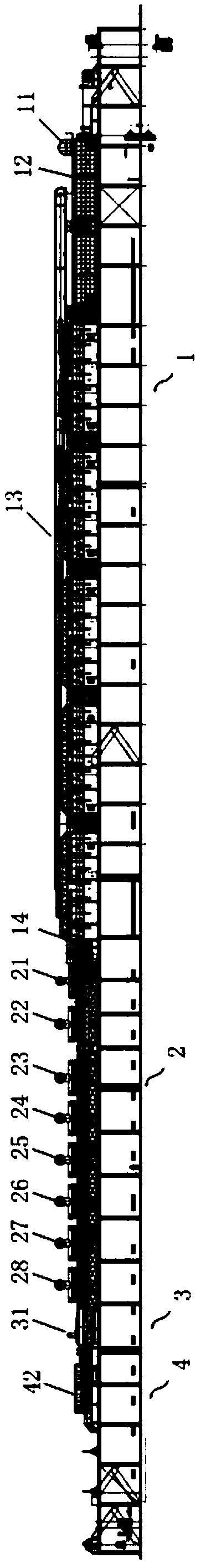

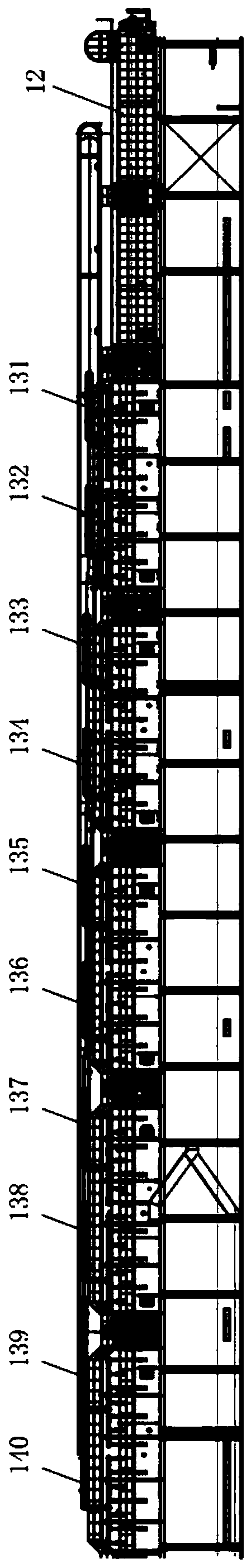

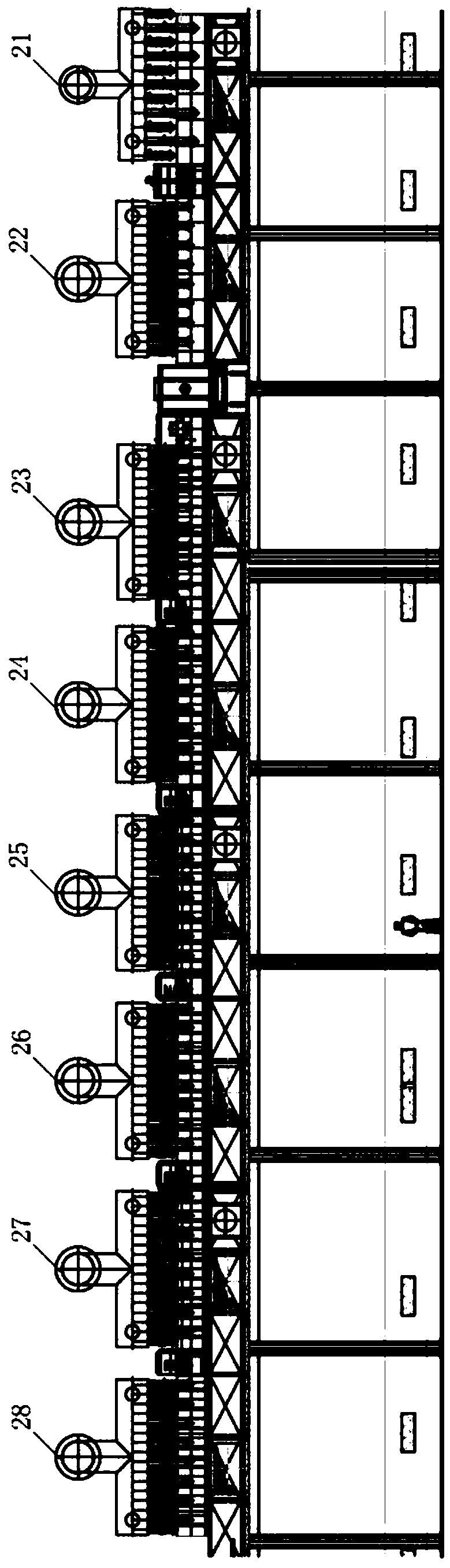

Annealing furnace for stainless steel belt

PendingCN109652639AImprove mechanical propertiesImprove flatnessFurnace typesHeat treatment process controlThermal energyFlue gas

The invention discloses an annealing furnace for a stainless steel belt. The annealing furnace comprises a heating mechanism, an air cooling mechanism, a water cooling mechanism and a drying mechanism, wherein the heating mechanism comprises an inlet sealing section, a preheating zone, a heating zone and an outlet sealing section, the preheating zone and the heating zone are enclosed as a closingmechanism through the inlet sealing section and the outlet sealing section, the heating zone is provided with a heating nozzle, the heating nozzle sprays a flame to heat the stainless steel belt and generate flue gas, the preheating zone preheats the stainless steel belt through flue gas convection and radiation, the drying mechanism includes a hot air blower, and a heat source of the hot air blower is flue gas and waste heat generated by the heating mechanism. By adopting the annealing furnace, the structure is simple, the traditional annealing process is simplified, the prepared stainless steel belt has good mechanical properties, moreover, heat consumption is small, and the energy saving effect is remarkable.

Owner:佛山市诚德新材料有限公司

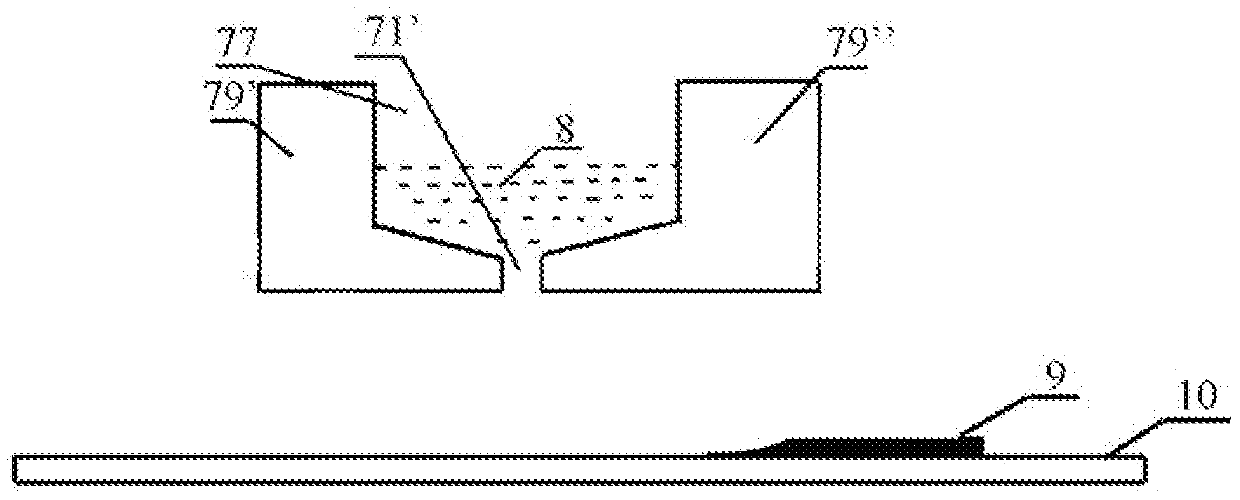

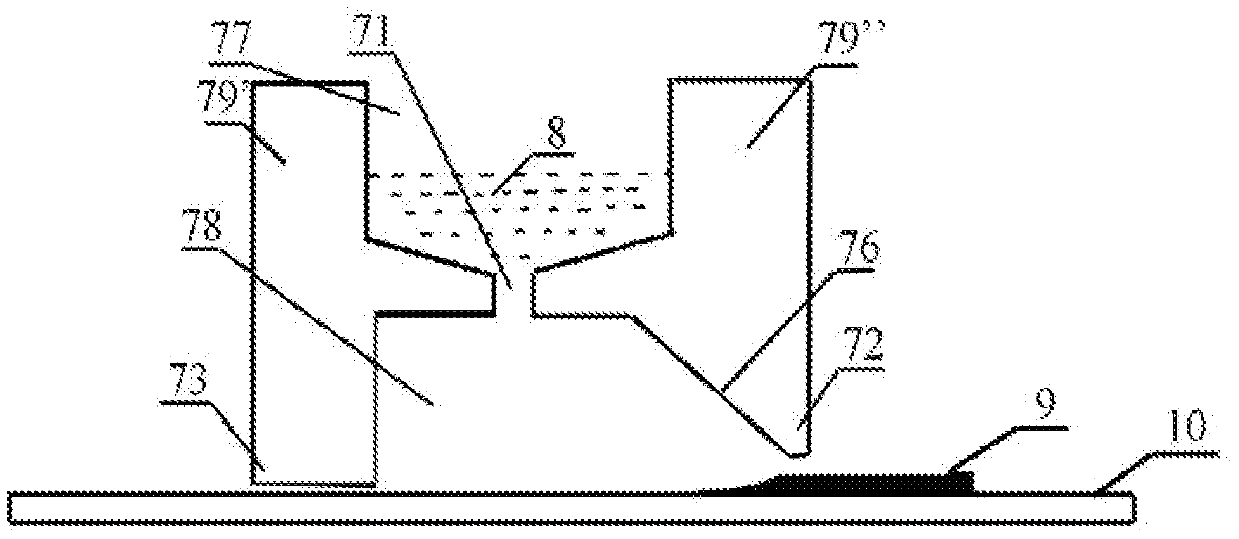

Fire-resistant case for annealing sapphire and production method thereof

ActiveCN103265301ASimple annealing processReduce the difficulty of productionElectric furnacesSapphire

The invention discloses a fire-resistant case for annealing sapphire and a production method thereof. The fire-resistant case for annealing sapphire is formed by adding colloid into main ingredients and then pressing and sintering; the main ingredients include mullite premixture and white emery, wherein the mullite premixture is prepared by high-purity aluminum oxide, silica and high-quality kaolin; the fire-resistant case for annealing sapphire comprises a defensive wall, a bottom board, a cover board and an interior middle lamina board which form a relatively closed space. The production method of the fire-resistant case for annealing sapphire comprises the steps of proportioning the mullite premixture; carrying out ball milling; carrying out spray drying; mixing; carrying out dry mixing; adding colloid; homogenizing; pressing; and sintering to obtain finished product. According to the fire-resistant case for annealing sapphire and the production method thereof, the sapphire annealing technique can be simplified, a special vacuum or inert gas protection electric furnace or an expensive tungsten alloy fire-resistant bracket case is unnecessarily adopted for sapphire annealing, the production difficulty and cost of the sapphire annealing technique can be greatly lowered, the investment of equipment and fire-resistant case in the sapphire annealing procedures can be greatly saved.

Owner:湖南华联特种陶瓷有限公司

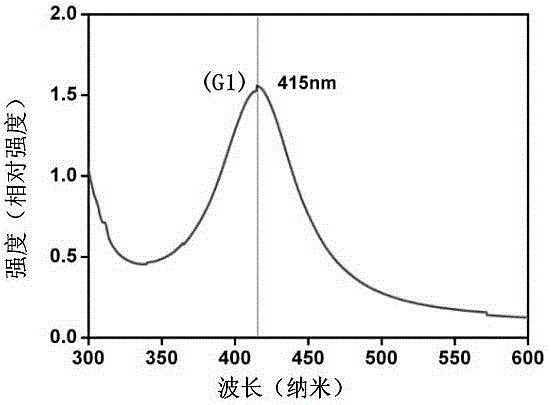

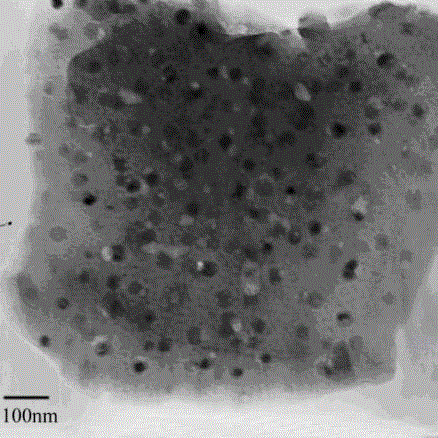

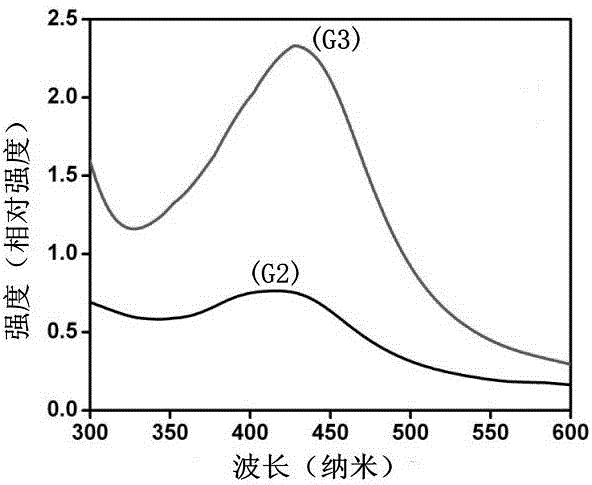

Preparation method and luminescent glass capable of efficiently extracting size-controllable Ag nano particles under low-concentration AgNO3 doping condition

The invention discloses a preparation method and luminescent glass capable of efficiently extracting size-controllable Ag nano particles under a low-concentration AgNO3 doping condition. The luminescent glass is prepared from the following components in mole ratio: 60-70% of SiO2, 4-14% of B2O3, (18-x)% of X2O (X=Li / Na / K), x% of XF (X=Li / Na / K), y% of MF2 (M=Ca / Sr / Ba), (8-y)% of RF3 (R=Y / Gd) and 0.01-0.5% of Ag, wherein x is greater than zero and not greater than 1 and y is not smaller than zero and not greater than 6. The preparation method comprises the steps: firstly, weighing raw materials according to the mole ratio; secondly, smelting a sufficiently ground and uniformly mixed batch in the air; finally, pressing, molding and annealing, thereby obtaining glass containing Ag nano particles. The luminescent glass containing Ag nano particles has the characteristics of low initial AgNO3 doping content, adjustable size distribution of extracted Ag nano particles and no complex thermal treatment process; smelting and annealing are carried out in the air; cost is low and the luminescent glass has no pollution to the environment.

Owner:TONGJI UNIV

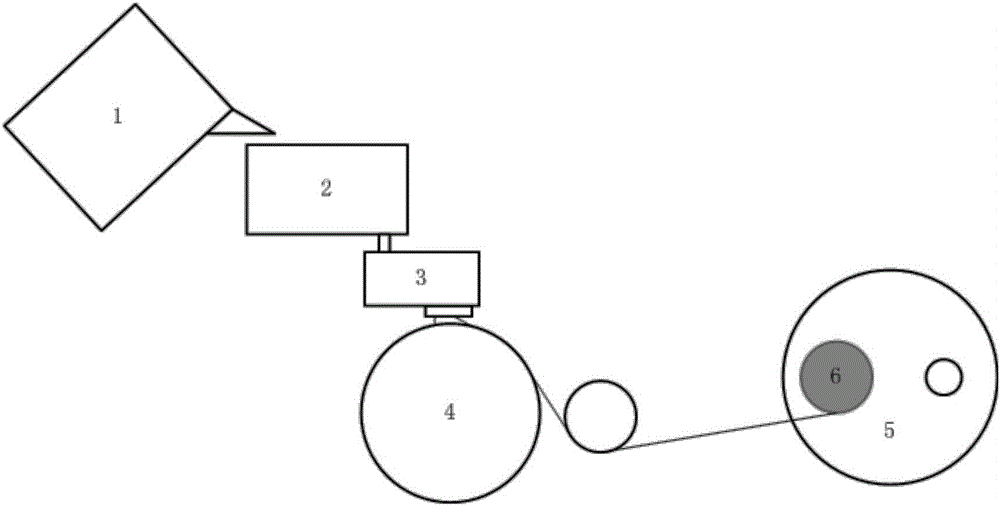

Iron-based nanocrystalline alloy ultra-thin broadband and its manufacturing method

ActiveCN107710352BHigh saturation magnetizationReduce manufacturing costMagnetic materialsMagnetic fluxBroadbanding

An iron-based nanocrystalline alloy ultra-thin broadband and manufacturing method thereof. The ultra-thin broadband has a formula of: FexSiaBbPcNbdCueMf, wherein M is at least one of Sn or Al; and x, a, b, c, d, e, and f are atomic percentages of the corresponding elements, in which 0.5 ≤ a ≤ 10, 0.5 ≤ b ≤ 12, 0.5 ≤ c ≤ 8, 0.1 ≤ d ≤ 3, 0.1 ≤ e ≤ 1, and 0.001 ≤ f ≤ 0.05 such that x + a + b + c + d + e + f = 100. The manufacturing method adopts an improved horizontal flow casting technique. The ultra-thin broadband manufactured thereby has a width of 50-200 mm, a thickness of 0.001-0.02 mm, a horizontal band thickness offset of less than ±0.0015 mm, a stacking factor of greater than 0.80, and a saturation magnetic flux density of greater than 1.7 T. The broadband also has an iron loss of less than 0.30 W / kg under a frequency of 50 Hz and maximum magnetic flux density 1.5 T.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

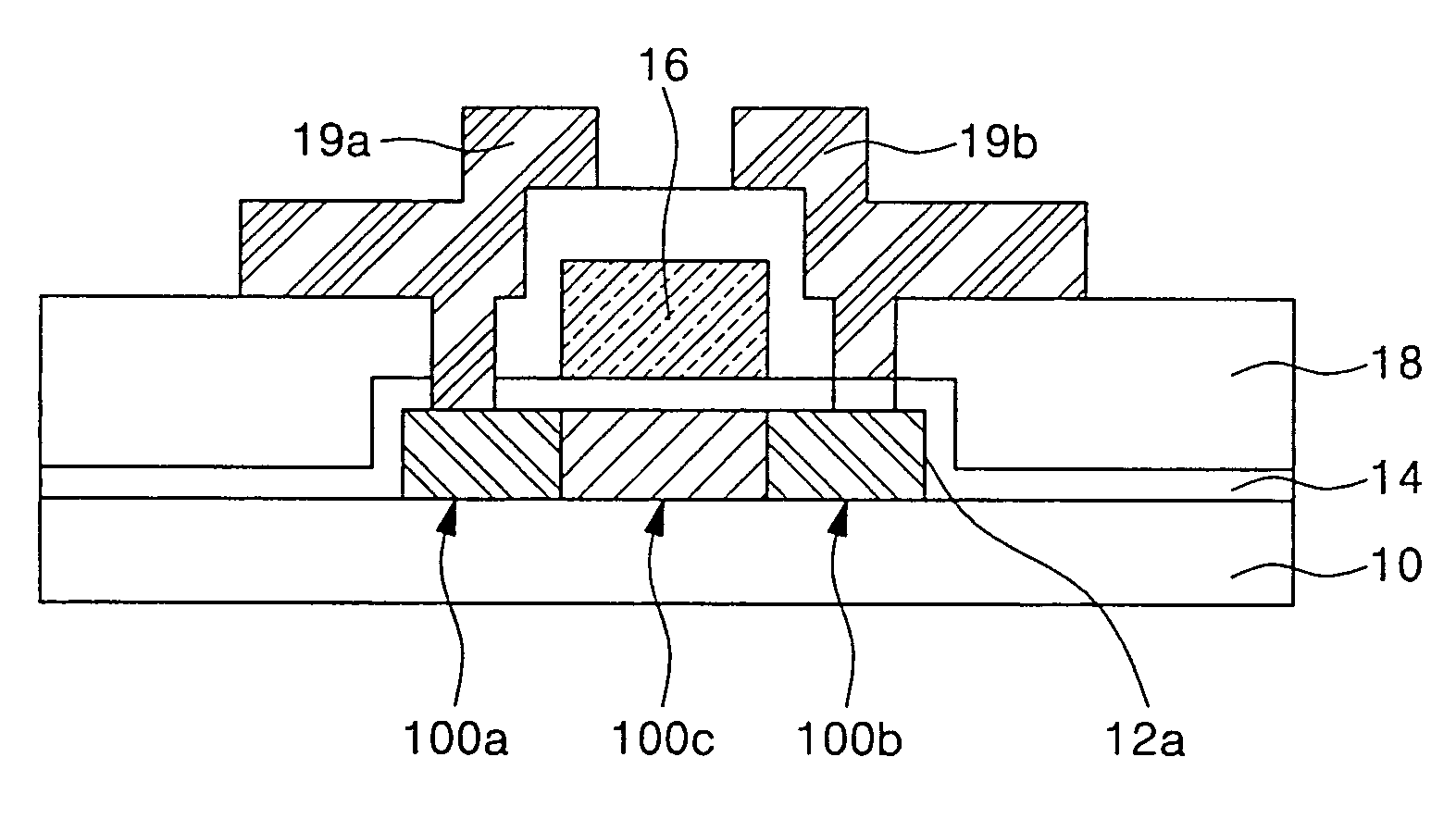

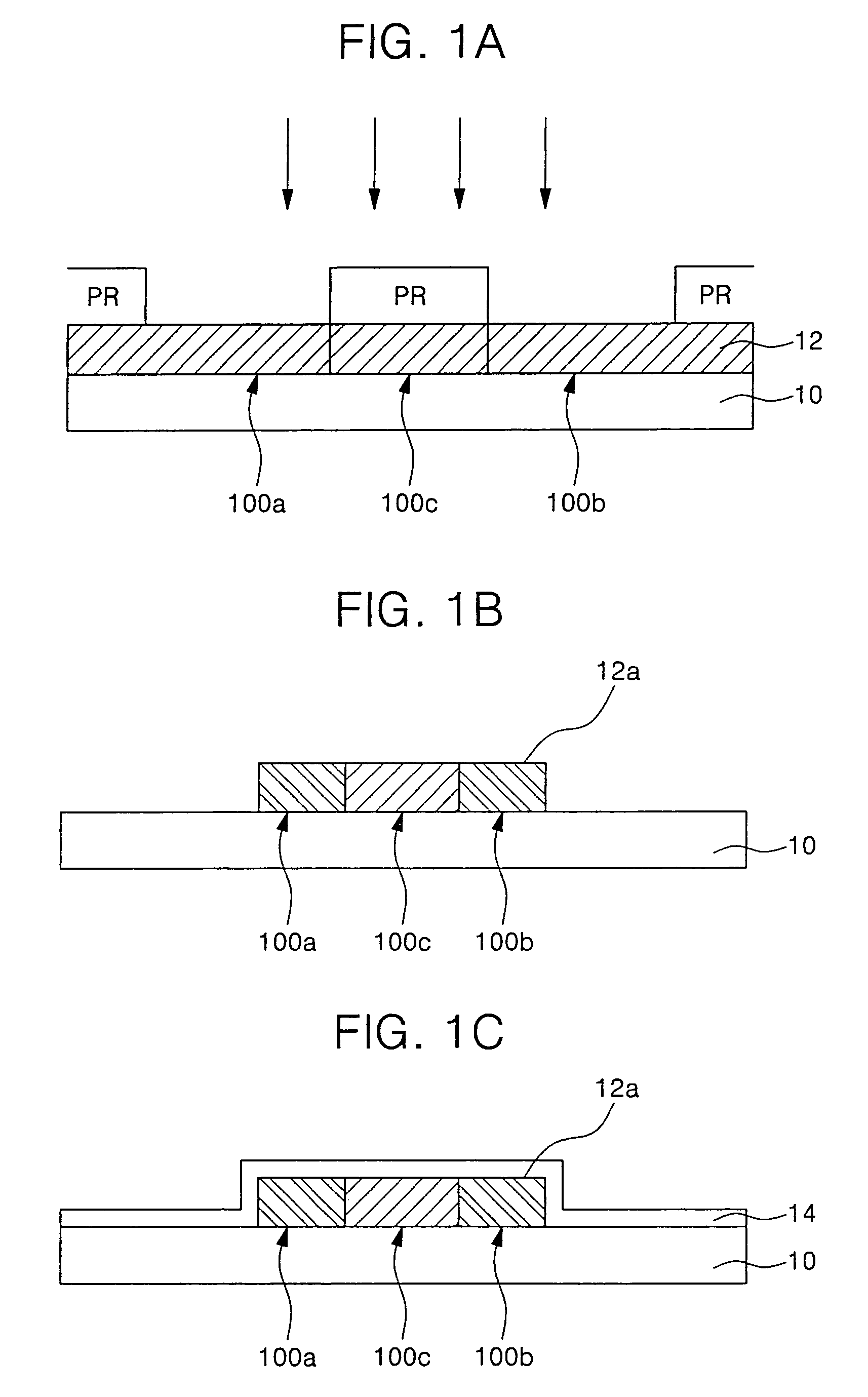

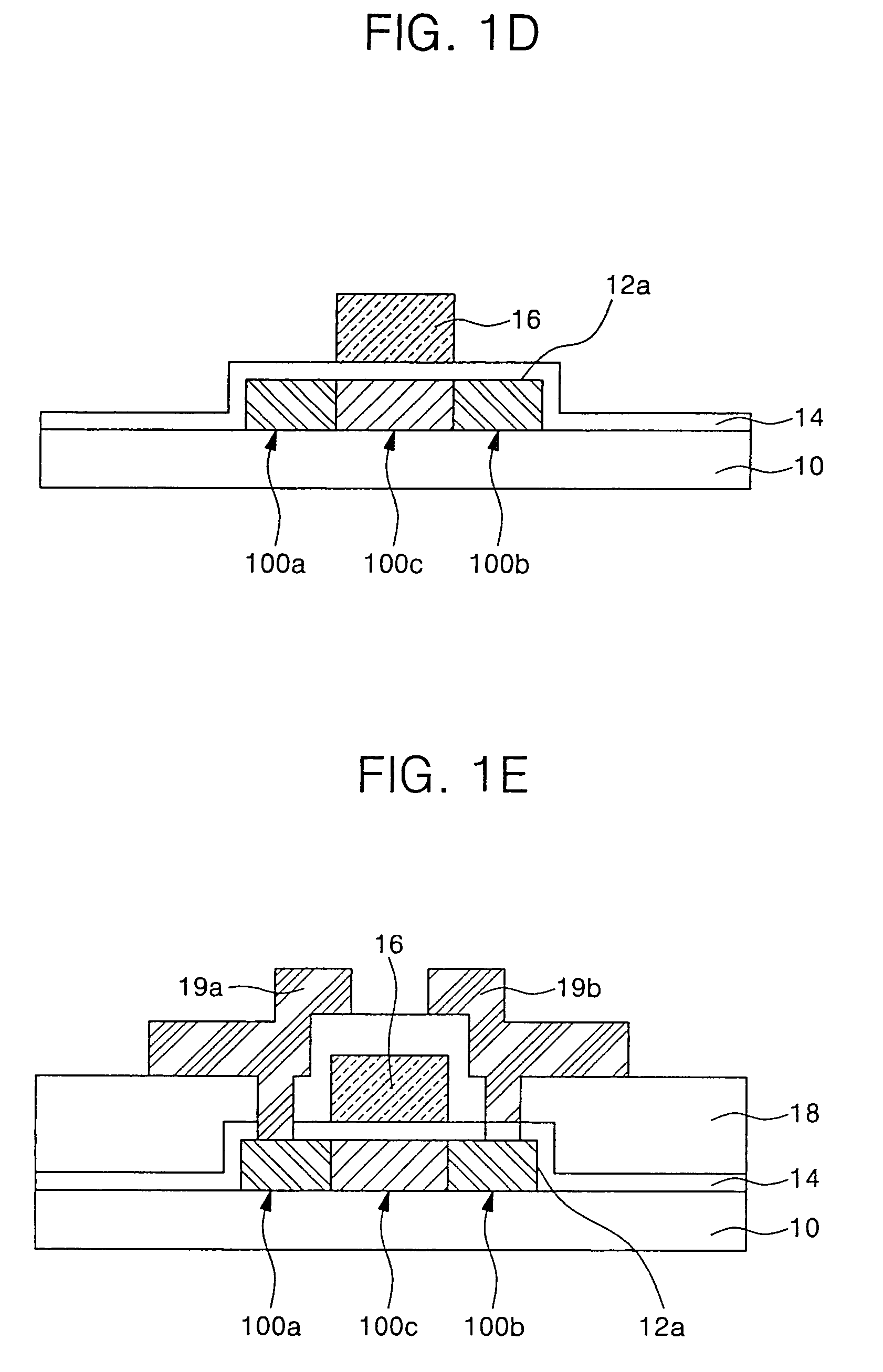

Method of fabricating semiconductor device and semiconductor fabricated by the same method

InactiveUS7544550B2High crystallinitySimple annealing processSemiconductor/solid-state device manufacturingSemiconductor devicesAmorphous siliconImpurity ions

A semiconductor device and method of fabricating the same are provided. The method includes: depositing a silicon layer containing amorphous silicon on a substrate; defining source and drain regions by doping the silicon layer with impurity ions; crystallizing the amorphous silicon by an annealing process under an atmosphere of H2O at a predetermined temperature, and at the same time activating the impurity ions to form a semiconductor layer; forming a gate insulating layer over the entire surface of the substrate having the semiconductor layer; and forming a gate electrode on the gate insulating layer in correspondence with a channel region of the semiconductor layer, in which the annealing process is simplified by crystallizing the polycrystalline silicon and at the same time activating the impurity ions, thereby preventing the substrate from being deformed due to high temperature during the annealing process.

Owner:SAMSUNG DISPLAY CO LTD

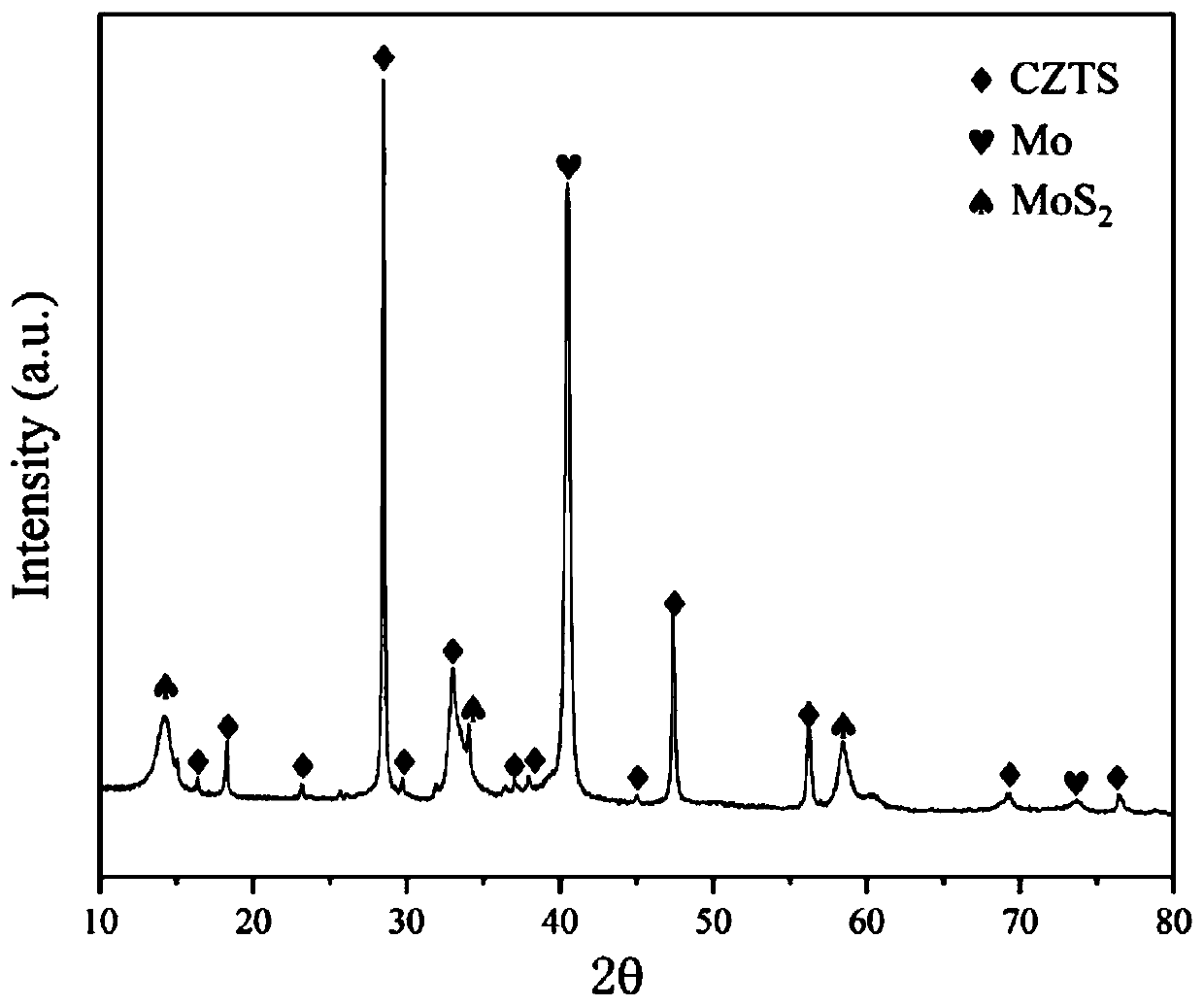

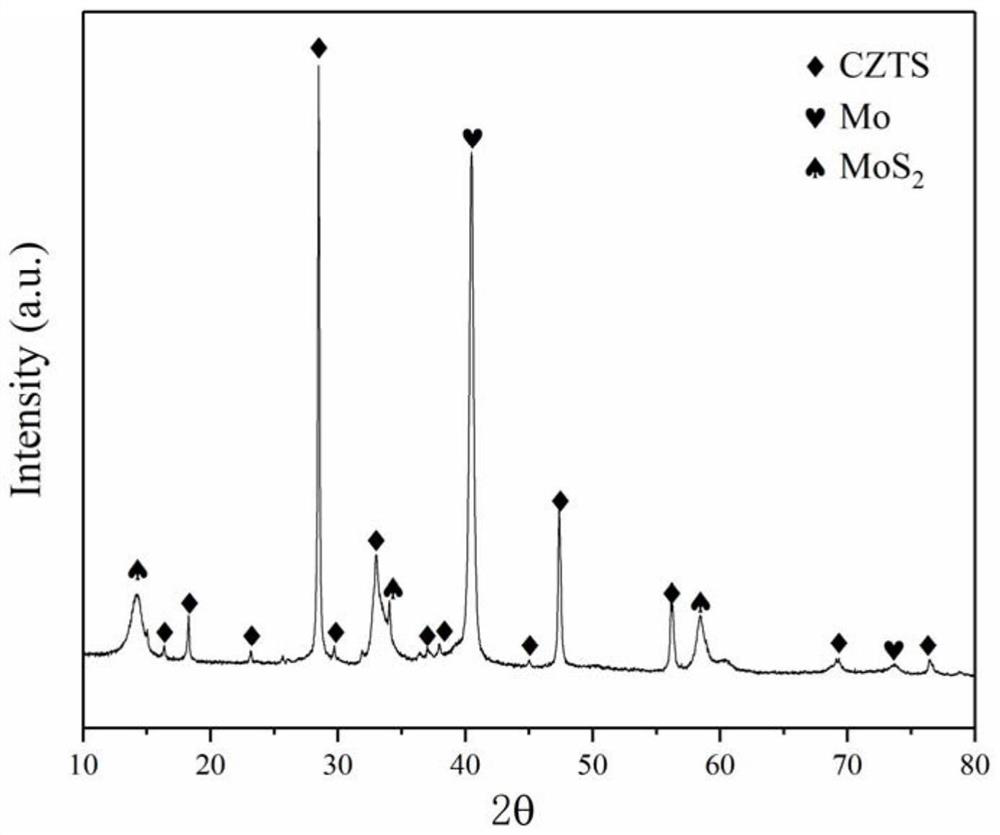

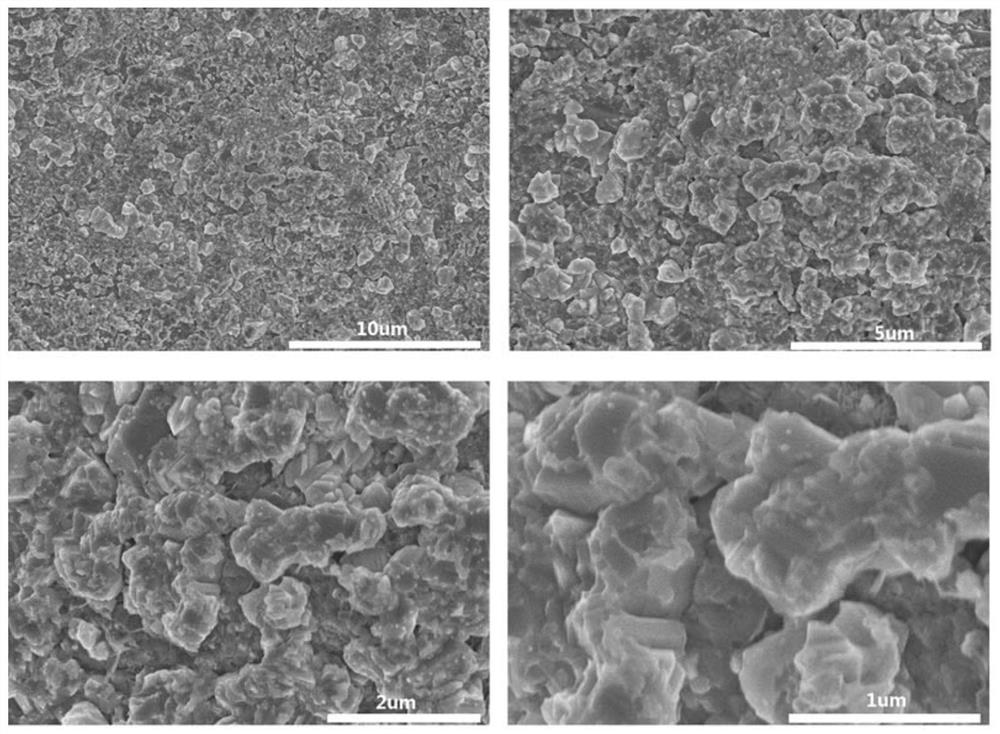

Method for preparing copper zinc tin sulfur film by vulcanization annealing in air

ActiveCN109802011ASimple annealing processThe equipment is not complicatedFinal product manufactureSemiconductor devicesMuffle furnaceTube furnace

The invention discloses a method for preparing a copper zinc tin sulfur film by vulcanization annealing in the air. The method comprises coating a cleaned glass substrate with a mixed paste of CuO, ZnO and SnO2 to form an oxide precursor film; then sealing the oxide precursor film and the sulfur powder in a container resistant to a vulcanization reaction in an air environment; and finally, puttingthe sealed container in a tube furnace or a muffle furnace, and heating the sealed container for a annealing process to obtain the copper zinc tin sulfur film. The method of the invention is simple in high-temperature vulcanization annealing process, cheap in preparation equipment, high in sulfur powder utilization rate, friendly to environment, and suitable for large-scale industrial production.

Owner:FUJIAN NORMAL UNIV

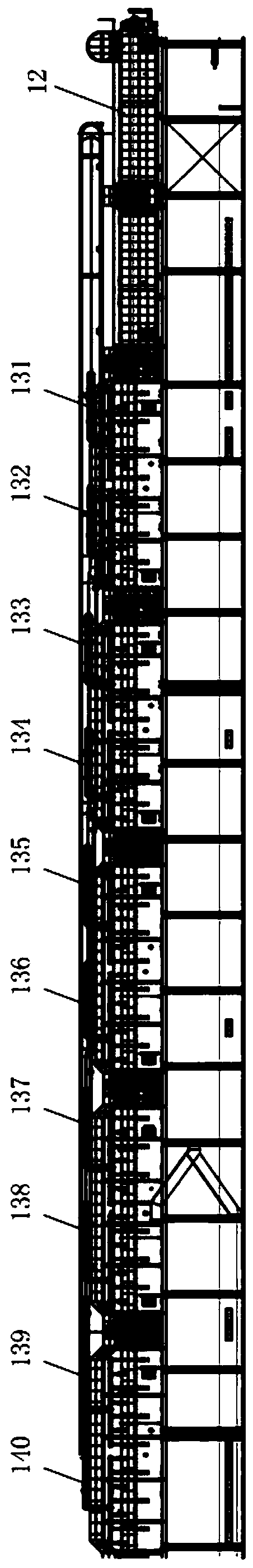

Annealing and pickling system for stainless steel strip

PendingCN109628944AImprove mechanical propertiesImprove flatnessFurnace typesHeat treatment furnacesThermal energyFlue gas

The invention discloses an annealing and pickling system for a stainless steel strip. The annealing and pickling system comprises a heating mechanism, an air cooling mechanism, a water cooling mechanism, a drying mechanism, a first electrolytic cell, a first pickling tank, a second pickling tank, a third pickling tank, rinsing equipment and drying equipment, wherein the heating mechanism comprisesan inlet seal section, a preheating zone, a heating zone and an outlet seal section, a heating nozzle is arranged on the heating zone, and the heating nozzle sprays out the flame to heat the stainless steel strip and produce the flue gas; and the preheating zone pre-heats the stainless steel strip through the convection and radiation of the flue gas, the heat source of the drying mechanism is theflue gas and residual heat generated for the heating mechanism, and the first electrolytic cell, the first pickling tank, the second pickling tank and the third pickling tank conduct electrolytic andthree-stage pickling treatment on the stainless steel strip. By means of the annealing and pickling system, the structure is simple, the traditional annealing and pickling process is simplified, themechanical properties of the finished product of the stainless steel strip are high, the heat energy consumption is lower, and the energy saving effect is significant.

Owner:佛山市诚德新材料有限公司

Thin gauge high-manganese high-aluminum steel with ultra-fine grain sizes and production method

The invention relates to thin gauge high-manganese high-aluminum steel with ultra-fine grain sizes. The thin gauge high-manganese high-aluminum steel with ultra-fine grain sizes is prepared from the components in percentage by weight: 0.91-1.35% of C, 0.21-0.53% of Si, 8.5-16.2% of Mn, 13.7-22.4% of Al, 0.11-0.23% of Nb, 0.15-0.32% of V, less than or equal to 0.018% of P, less than or equal to 0.008% of S, and less than or equal to 0.008% of N. A production method of the thin gauge high-manganese high-aluminum steel with ultra-fine grain sizes comprises the steps of smelting and continuous casting to form a blank; heating of the cast blank; scale removal; finish rolling; laminar cooling; reeling up; naturally cooling to room temperature; cold rolling; and continuous annealing. According tothe thin gauge high-manganese high-aluminum steel with ultra-fine grain sizes and the production method, a structure of the high-manganese high-aluminum steel is fully refined through reasonable composition and process control combined with Nb microalloying technology; meanwhile, under the combined action of strengthening modes such as precipitation strengthening of Nb and V microalloys, the yield strength of the high-manganese high-aluminum steel is 1653-1721 MPa, the tensile strength is 2035-2119 MPa, the elongation is 52-62%, and the thickness is thinner; and the annealing process is simpler and the annealing time is shorter.

Owner:WUHAN UNIV OF SCI & TECH

A method of improving yield strength of copper wire

The invention discloses a method for improving the yield strength of a copper wire. The method comprises the following processes: melting copper with an electric furnace; hot-rolling the smelted copper with a continuous casting and rolling machine; cooling the hot-rolled copper wire Finally, it is extruded with an extrusion molding machine; the extruded copper wire is then subjected to cold rolling and stretching treatment; the stretched copper wire is annealed through an annealing furnace; the annealed copper wire is then The stretching process is performed by a stretching machine. After the processing technology is processed, the internal stress of the copper wire can be effectively eliminated, and the yield strength of the wire can be improved. Under the premise of not changing the material composition and smelting process, the yield strength of the wire can be increased from the original 200-230MPa to 265MPa. , and can also reduce the surface hardness of the wire, wherein the annealing process is simple, easy to operate, low processing cost, and has a significant effect on improving the yield strength of the copper wire.

Owner:江阴华电新材料有限公司

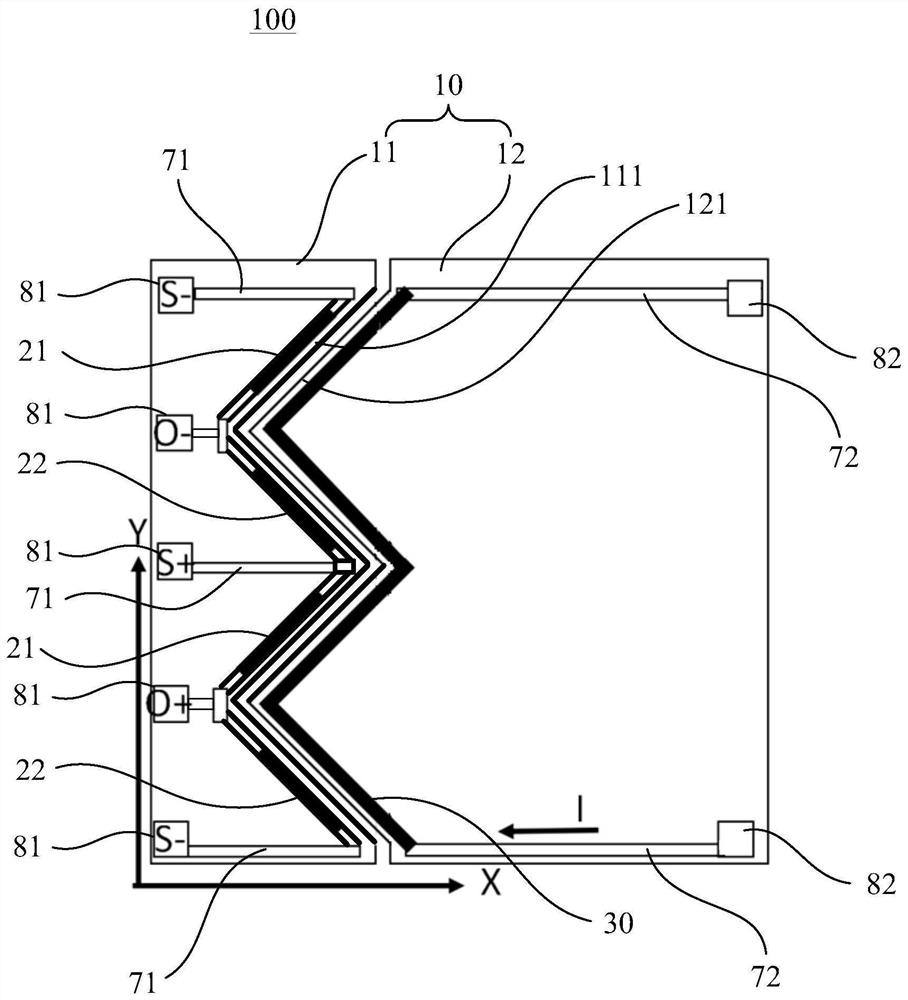

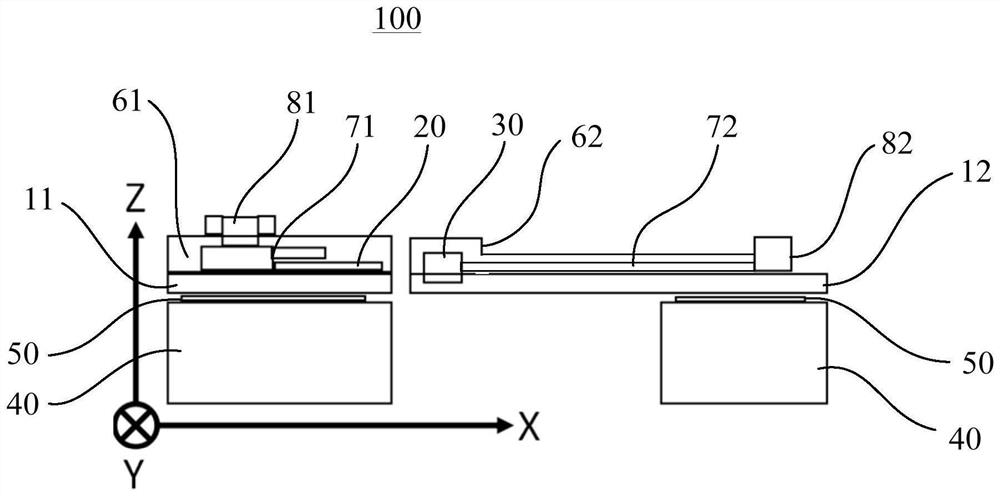

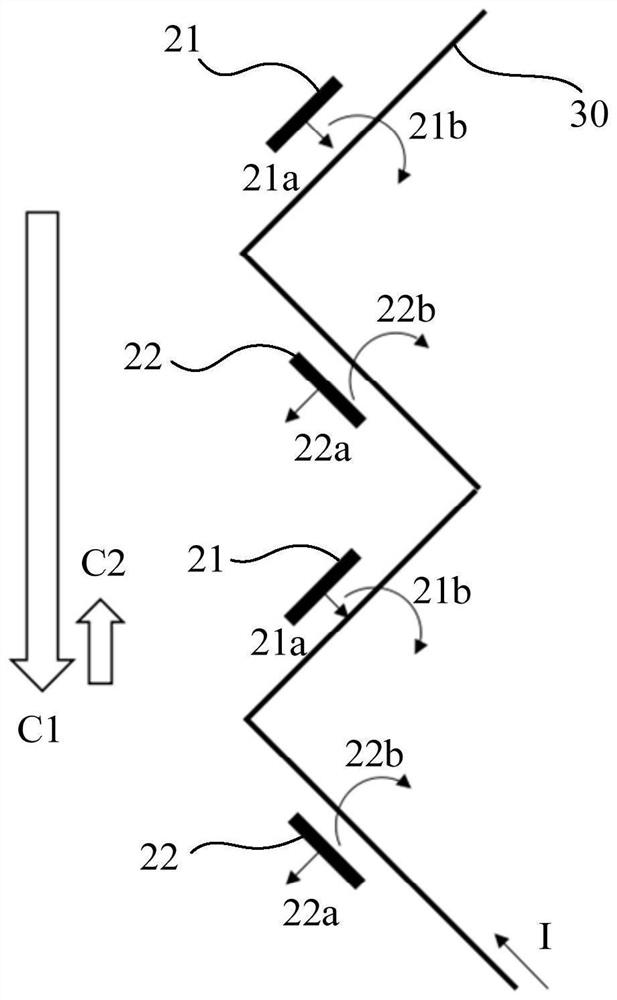

MEMS sensor and electronic device

ActiveCN112995871AReduce high costSimple designMicrophonesLoudspeakersMagnetic reluctanceEngineering

The invention discloses an MEMS sensor and electronic equipment, and the MEMS sensor comprises: a vibrating diaphragm layer which comprises a fixed part and a sensitive part which can vibrate relative to the fixed part; a detection piece which comprises a first magnetic resistance unit and a second magnetic resistance unit which are connected in sequence, an included angle is formed between the long axis direction of the first magnetic resistance unit and the long axis direction of the second magnetic resistance unit, and the included angle is smaller than 180 degrees; a wire, of which the extension direction is parallel to the arrangement direction of the first magnetic resistance unit and the second magnetic resistance unit; wherein the detection piece and the wire are respectively fixed on the fixed part and the sensitive part, the magnetization direction of the reference layer of the first magnetic resistance unit is vertical to the long axis direction of the first magnetic resistance unit and faces the wire, and the magnetization direction of the reference layer of the second magnetic resistance unit is vertical to the long axis direction of the second magnetic resistance unit and is back to the wire. According to the technical scheme, the production cost and the circuit design complexity can be reduced, implementation and manufacturing are easy, and the detection sensitivity can be improved.

Owner:WEIFANG GOERTEK MICROELECTRONICS CO LTD

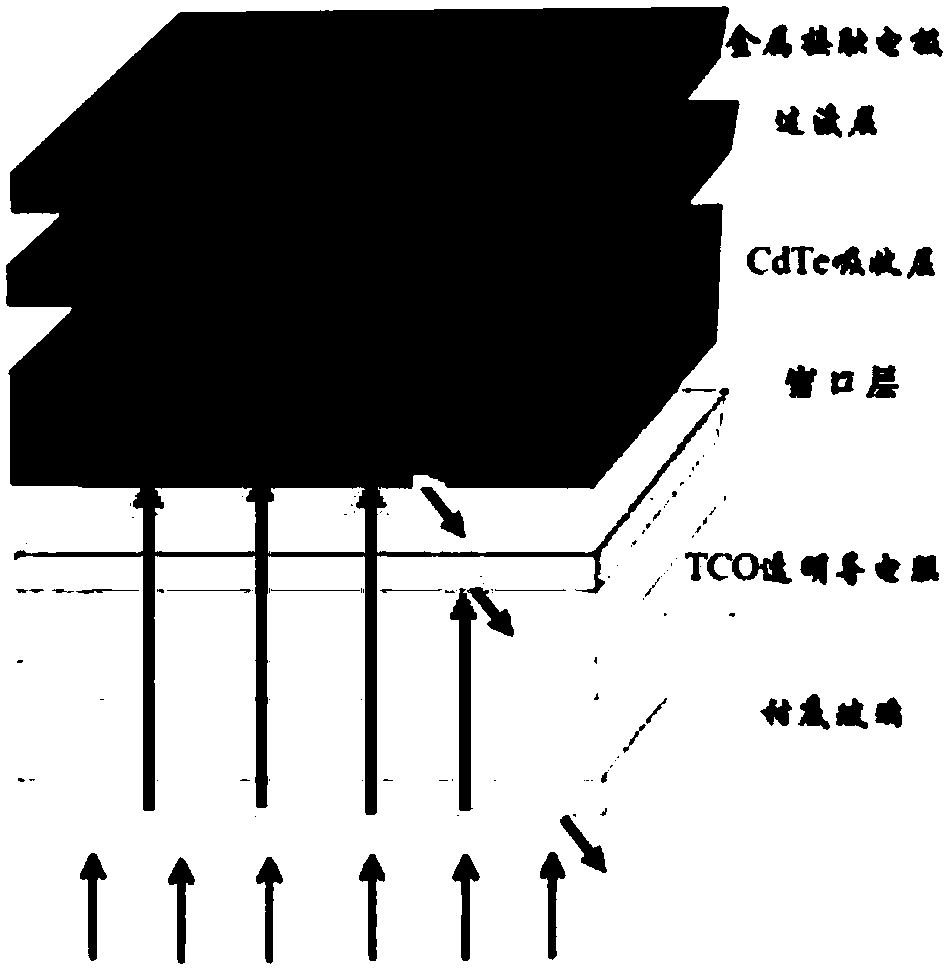

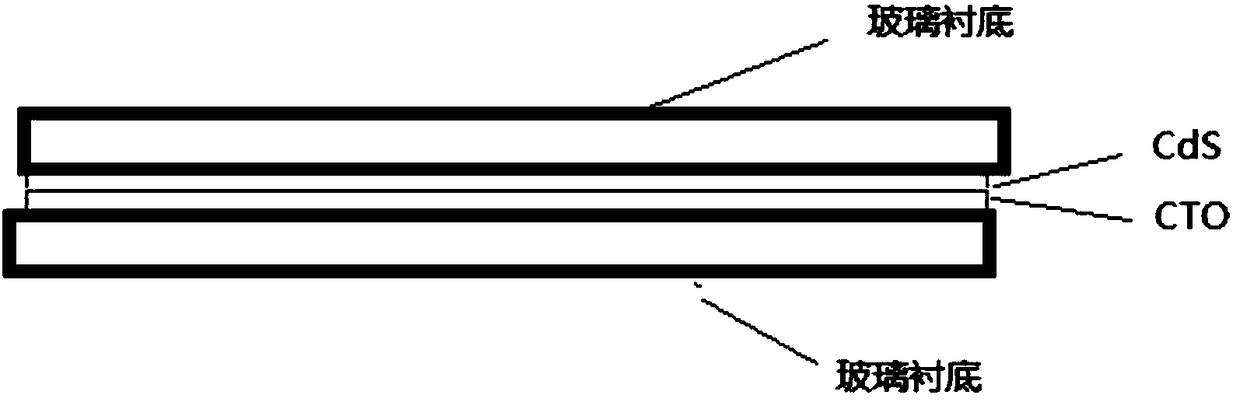

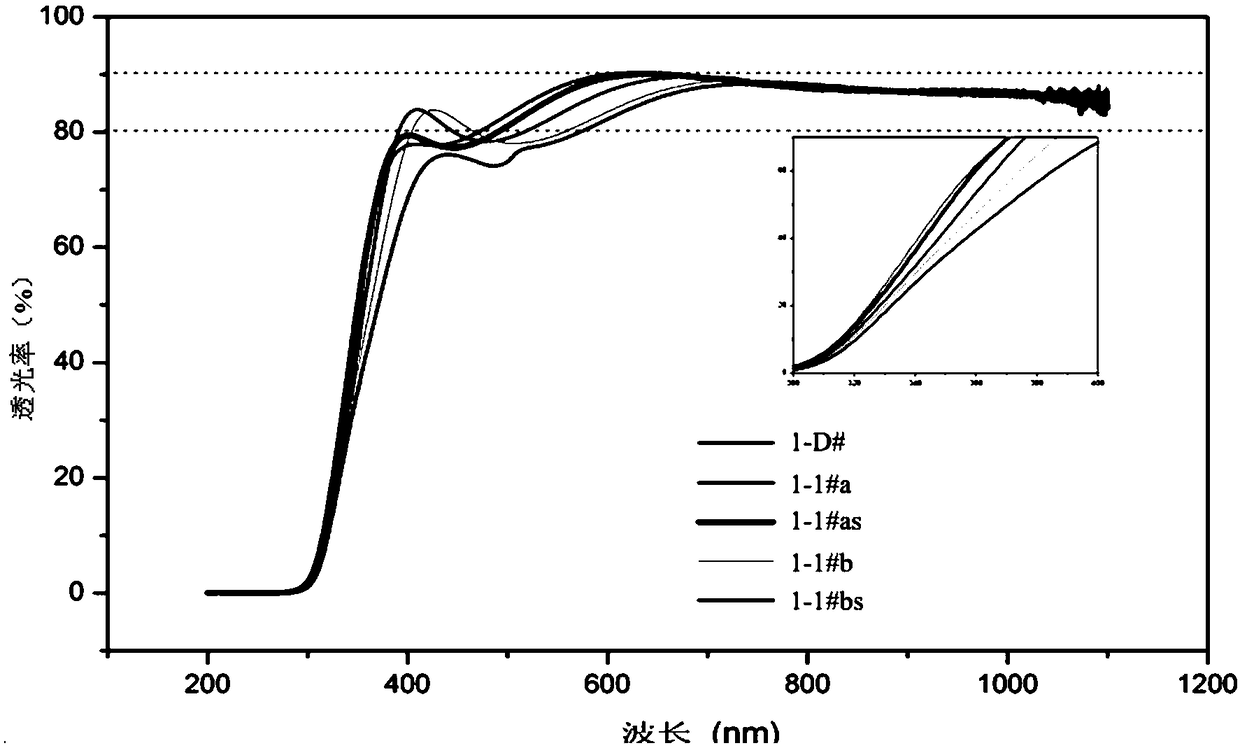

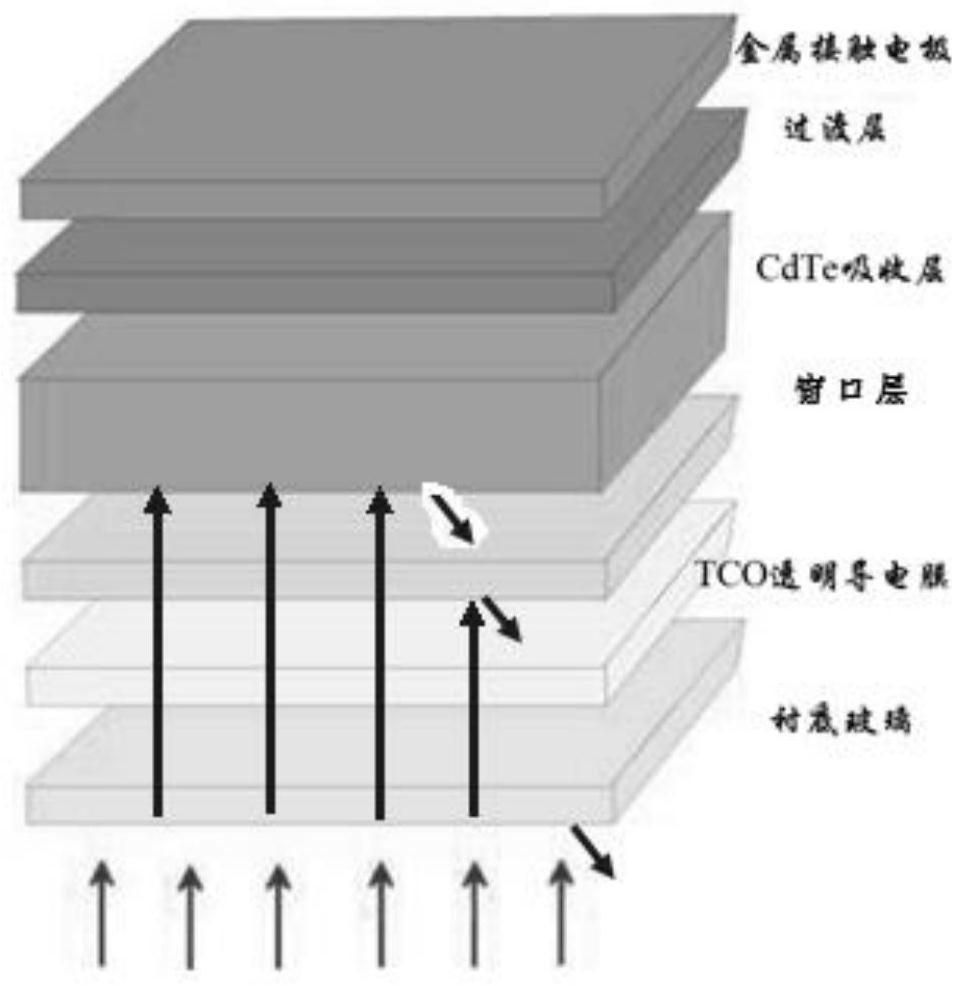

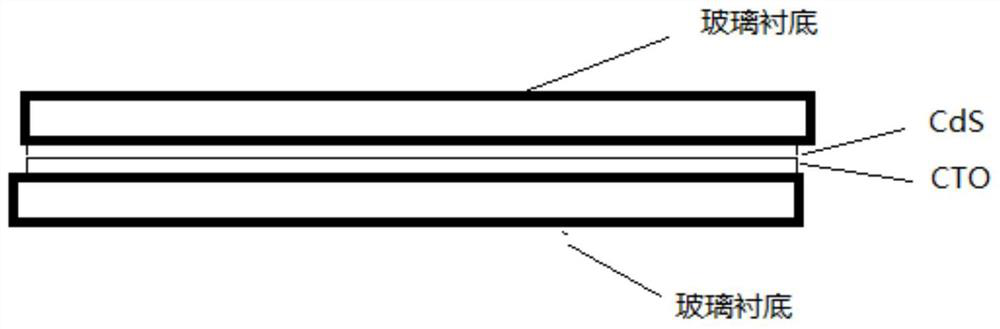

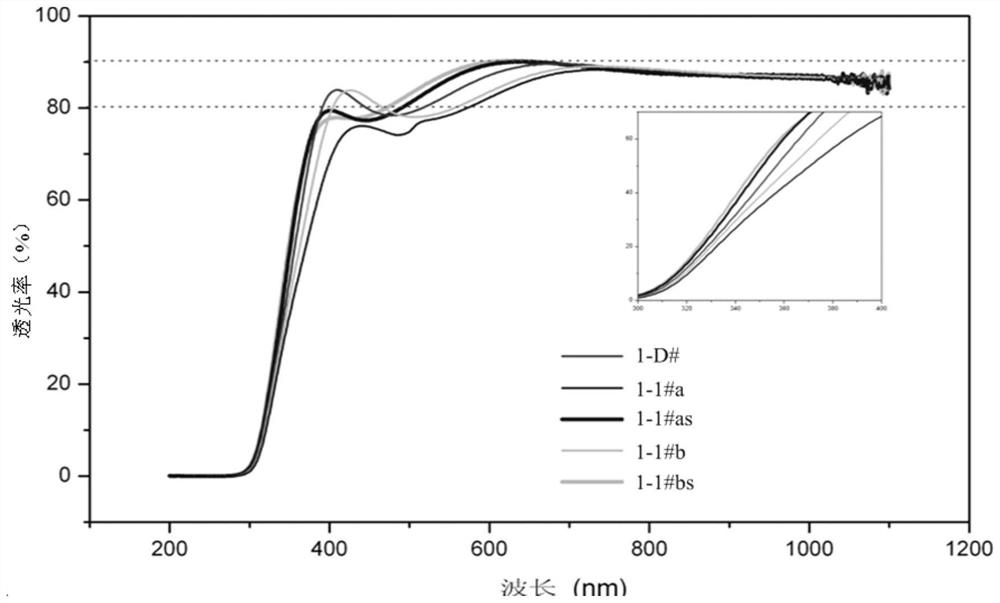

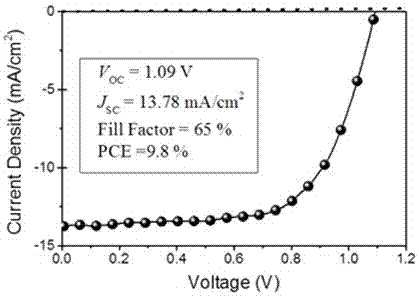

Cadmium stannate-based transparent conductive film, production process thereof and solar cell

ActiveCN109037390AGood for industrial grade productionSimple annealing processFinal product manufacturePhotovoltaic energy generationSputteringOptical property

The present application provides a cadmium stannate-based transparent conductive film, production process thereof and solar cell. In the production process of the present application, first a target material is subjected to magnetron sputtering in an oxygen-containing gas environment, then a transition film layer is composited, and is then annealed in a protective atmosphere. The preparation method according to the invention can be directly annealed in a protective atmosphere without a close-to-annealing mode, thus greatly simplifying the annealing process and realizing industrialized large-scale production. The invention also provides a cadmium stannate-based transparent conductive film and a solar cell comprising the cadmium stannate-based transparent conductive film, wherein the electric and optical properties of the cadmium stannate-based transparent conductive film provided by the invention are obviously improved compared with an existing commercial TCO film.

Owner:ADVANCED SOLAR POWER HANGZHOU

A kind of method for preparing copper-zinc-tin-sulfur film by sulfuration annealing in air

ActiveCN109802011BLow costIncrease profitFinal product manufactureSemiconductor devicesTube furnaceSulfidation

Owner:FUJIAN NORMAL UNIV

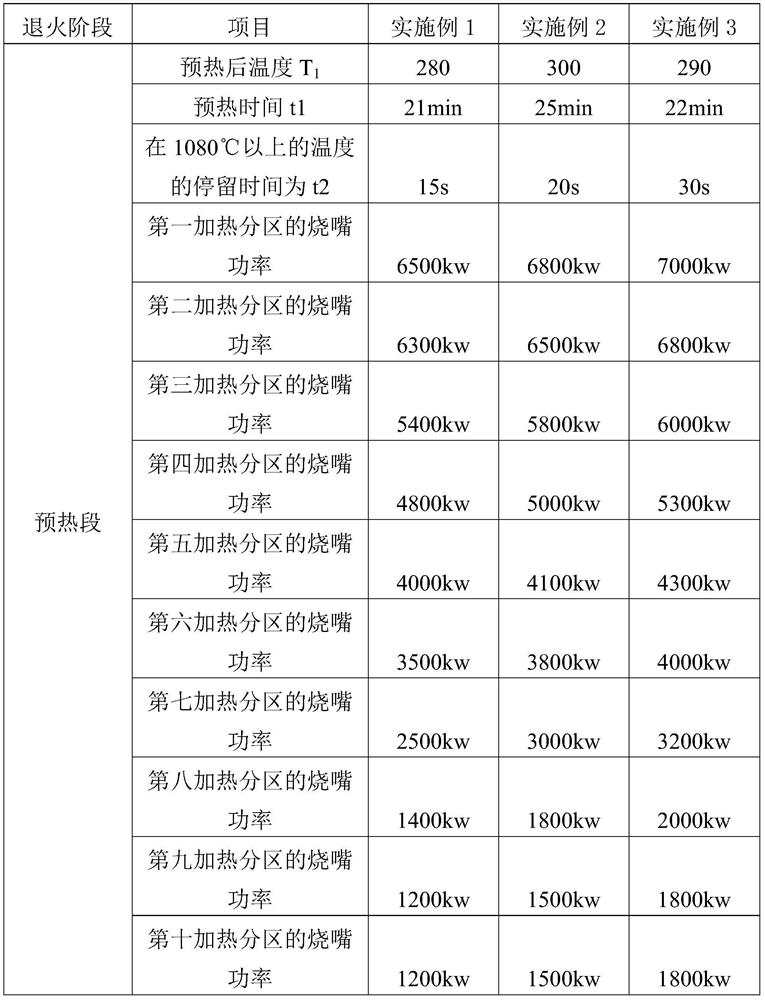

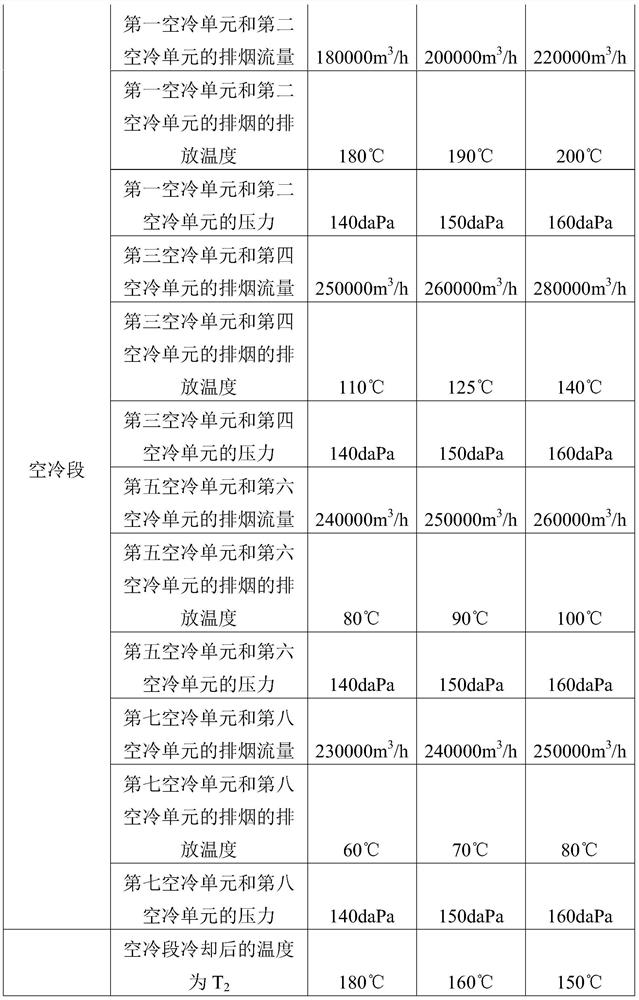

A kind of annealing method of stainless steel strip

ActiveCN109628709BImprove mechanical propertiesImprove flatnessFurnace typesHeat treatment process controlFlue gasSS - Stainless steel

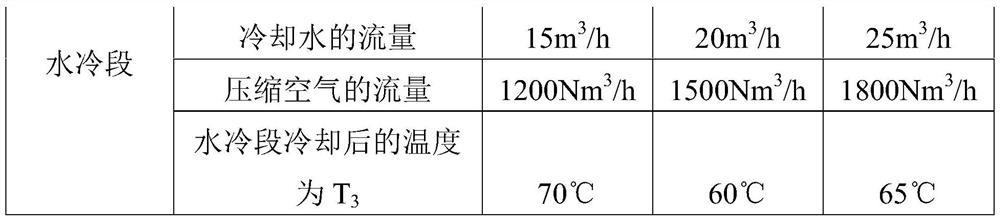

The invention discloses an annealing method for stainless steel strips, which includes: (1) transferring the cold-rolled stainless steel strips to the heating section of the annealing furnace, and directly performing heat treatment on the stainless steel strips, so that the stainless steel strips are heated from 30°C to 1160°C, and the stainless steel strip is at a temperature above 1080°C for at least 15 seconds; (2) cooling the heated stainless steel strip to below 180°C through the air-cooling section; (3) cooling the air-cooled stainless steel strip through the water-cooling section to Below 70°C; (4) Pass the water-cooled stainless steel strip through a squeeze roller to remove moisture on the surface of the stainless steel strip; (5) Dry the stainless steel strip using the flue gas and waste heat generated in the heating zone. The invention simplifies the traditional annealing process, and the finished stainless steel strip has good mechanical properties, good flatness, uniform hardness, small roughness, bright and high-grade appearance.

Owner:佛山市诚德新材料有限公司

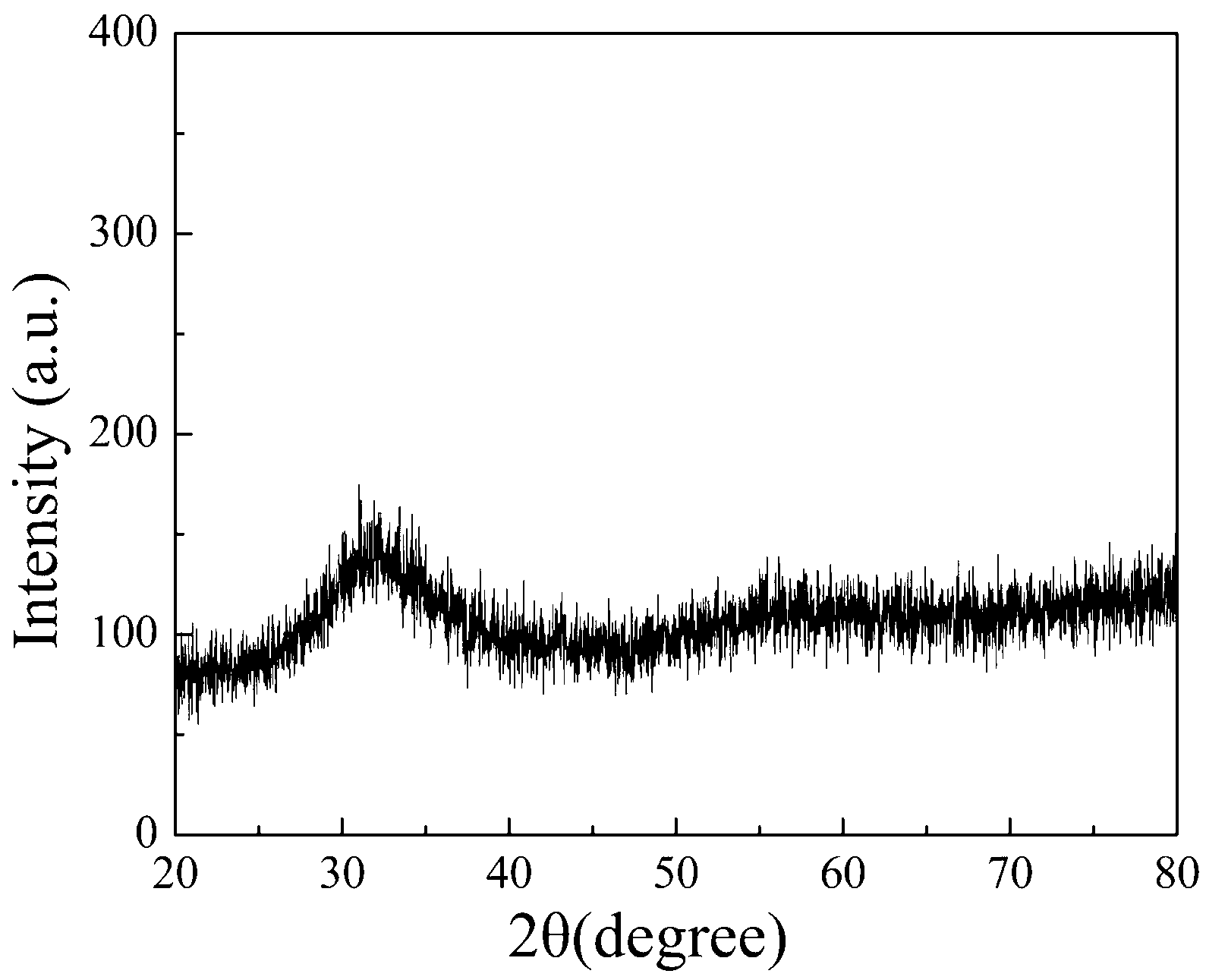

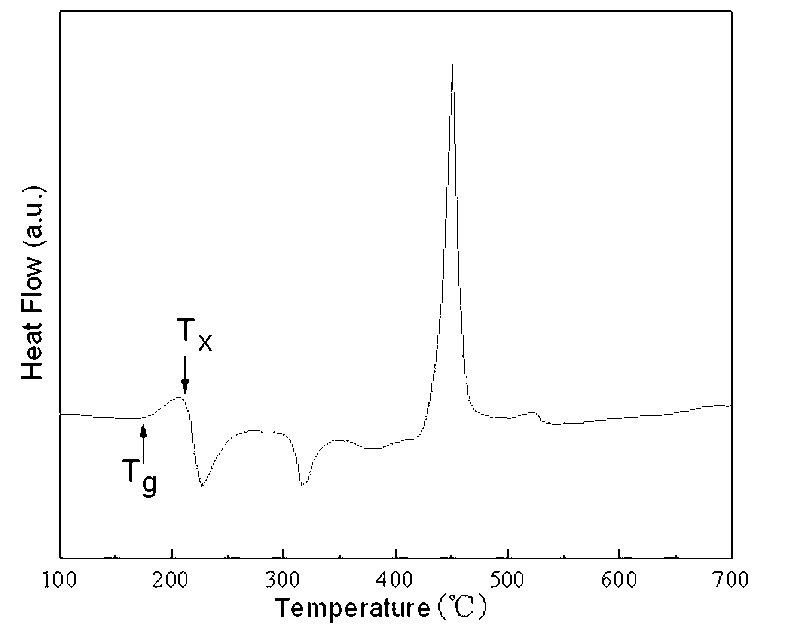

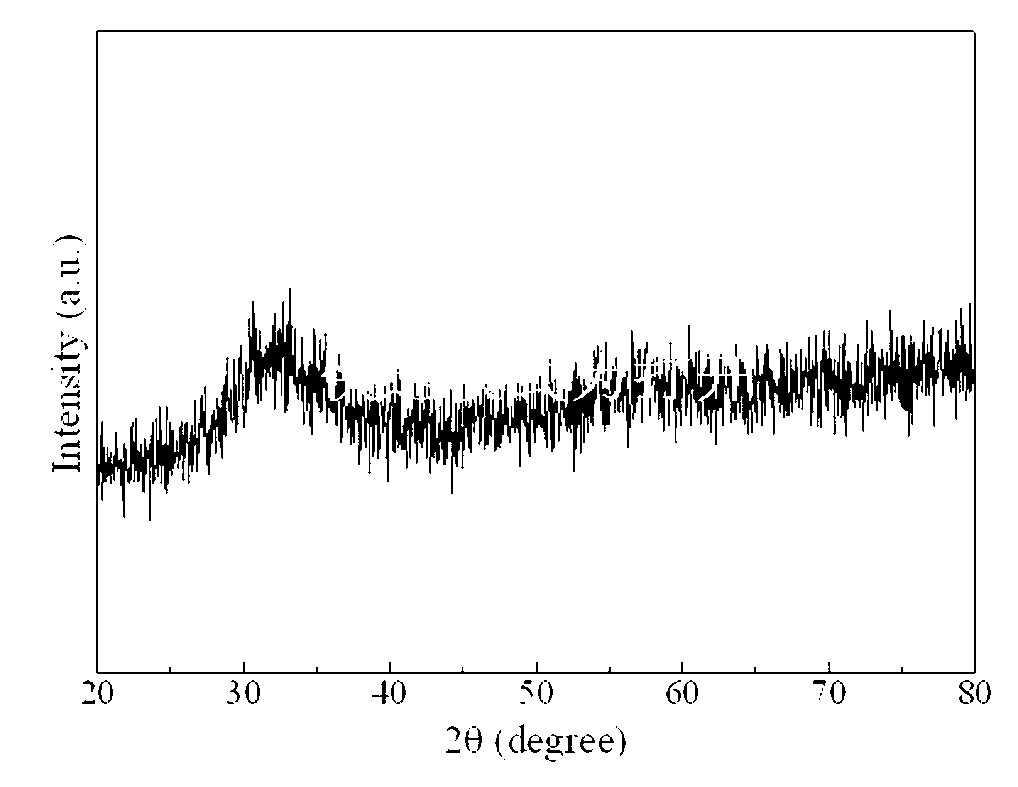

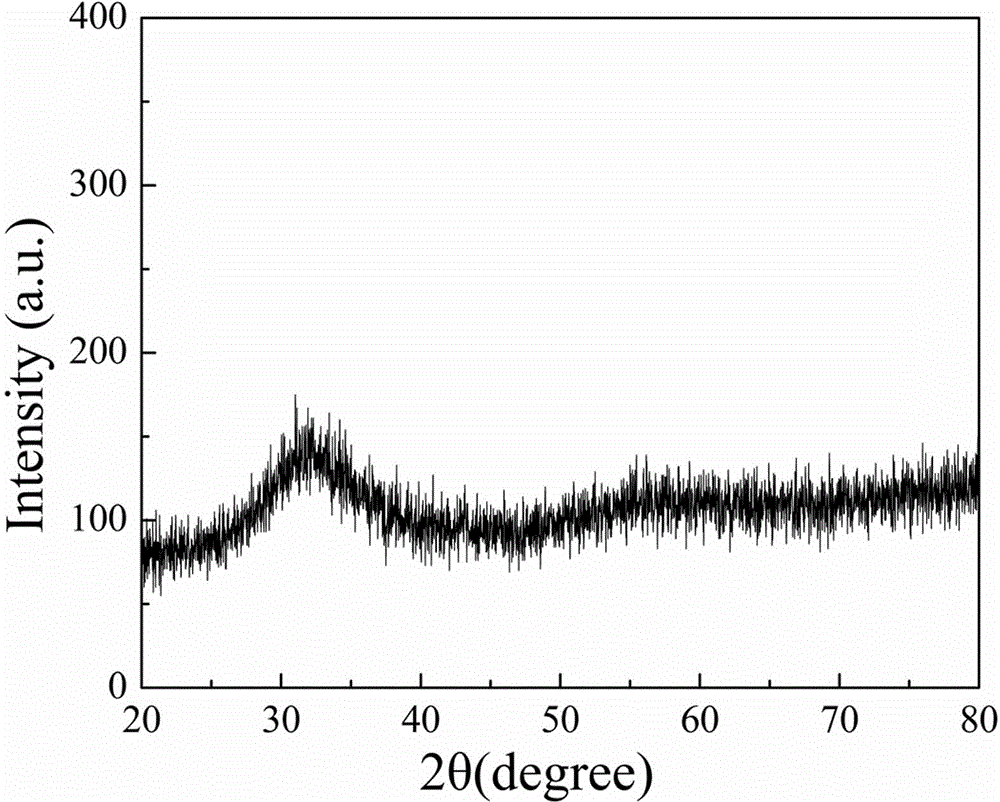

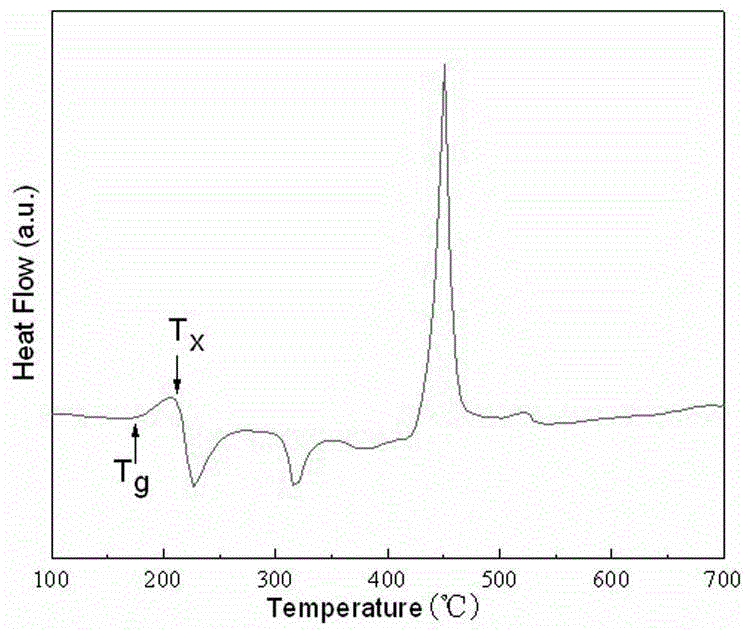

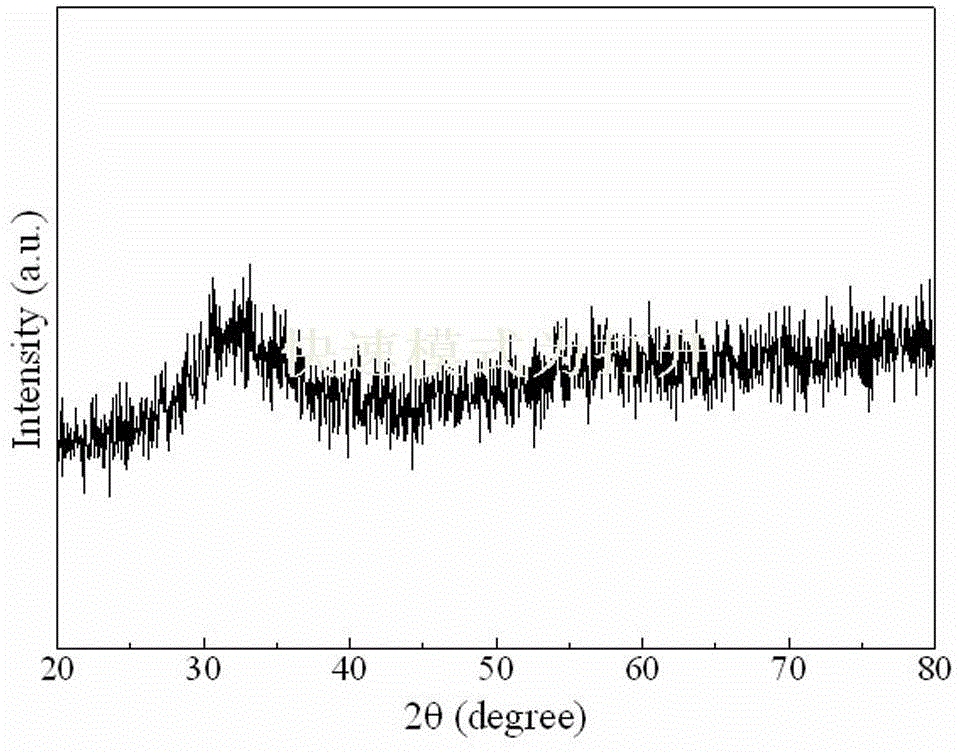

Anti-corrosion block rare earth-based metal glass and annealing method thereof

The invention relates to anti-corrosion block rare earth-based metal glass and an annealing method thereof, belonging to the technical field of preparation of amorphous alloy materials. Specific to the problem of poor crystallization resistance of the existing metal glass, the invention provides an anti-corrosion block rare earth-based metal glass with good crystallization resistance; and the composition is CexLayPrzSmsGdtComAln, wherein x, y, z, s, t, m and n represent the atom percentage content; x is 29.31%, y is 21.83%, z is 3.53%, s is 7.08%, t is 3.25%, m is 25% and n is 10%. The anti-corrosion block rare earth-based metal glass provided by the invention is a single amorphous phase and has strong amorphous forming ability; the anti-corrosion block rare earth-based metal glass after annealing treatment is still in an amorphous state; the corrosion resistance is obviously enhanced by 49.5%; and the hardness is remarkably improved.

Owner:UNIV OF JINAN

A kind of cadmium stannate-based transparent conductive film, its production process and solar cell

ActiveCN109037390BGood for industrial grade productionSimple annealing processFinal product manufacturePhotovoltaic energy generationSputteringOptical property

The application provides a cadmium stannate-based transparent conductive film, its production process and a solar cell. In the production process of the present application, the target is first subjected to magnetron sputtering in an oxygen-containing gas environment, and then a transition film layer is compounded, and then annealed in a protective atmosphere. According to the preparation method of the present invention, it is not necessary to carry out close annealing, and it is sufficient to directly anneal under the protective atmosphere, which greatly simplifies the annealing process and can realize industrialized large-scale production. The present invention also provides a cadmium stannate-based transparent conductive film and a solar cell comprising the cadmium stannate-based transparent conductive film. Compared with the existing commercialized TCO film, the cadmium stannate-based transparent conductive film provided by the invention has The electrical and optical properties are significantly improved.

Owner:ADVANCED SOLAR POWER HANGZHOU

Fire-resistant case for annealing sapphire and production method thereof

Owner:湖南华联特种陶瓷有限公司

Well type cyclic annealing process for bare copper flat wire

ActiveCN102936642BWide range of annealing specificationsSolve the problem of uneven annealingFurnace typesCable/conductor manufactureShielding gasProduct gas

The invention provides a well type cyclic annealing process for a bare copper flat wire of a pot type hot-air cyclic annealing furnace with a patent number of ZL201120172272.1. The well type cyclic annealing process comprises the following steps: 1) feeding materials into the furnace; 2) pumping to reach a vacuum state; 3) feeding protective gas; 4) heating and carrying out heat preservation; 5) discharging the materials out of the furnace, and cooling; and 6) discharging the finished product from the furnace. The well type cyclic annealing process for the bare copper flat wire is simple, and the bare copper flat wire annealing specification scope is wide; and the protective gas is supplied and cycled in the annealing furnace, so that the problem that the bare copper flat wire cannot be uniformly annealed due to different temperatures in the upper part, the middle part and the lower part of the annealing furnace can be effectively solved.

Owner:GOLD CUP ELECTRIC APP CO LTD

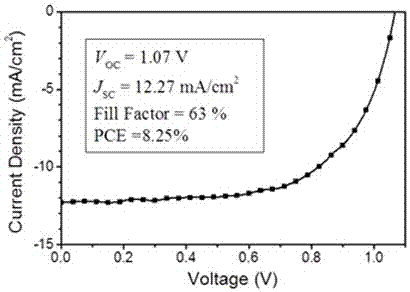

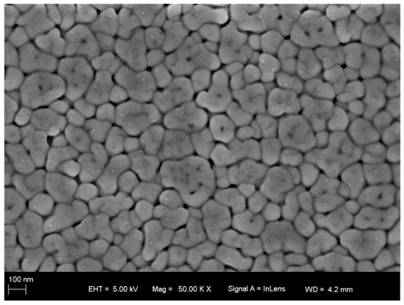

A non-annealing perovskite solar cell and its preparation method

ActiveCN104993060BLow costSimple preparation processSolid-state devicesSemiconductor/solid-state device manufacturingOrganic solar cellRoom temperature

The invention belongs to the field of solar cells, and discloses a non-annealing perovskite solar cell and a preparation method thereof. In the preparation method, indium chloride is added to the perovskite precursor, and the method is spin-coated, soaked or pulled The thin film is obtained by the method, and the crystalline perovskite crystal is directly formed at room temperature, and then the electron transport layer is obtained by a non-annealing treatment method. The preparation method of the present invention adopts spin coating, inkjet printing or roll-to-roll printing method to process perovskite solar cells, has the advantages of simple preparation process, low preparation temperature, etc., and is conducive to greatly reducing the cost of organic solar cells; There are no strict requirements on the substrate, which is more conducive to the preparation of large-area, flexible and bendable devices; it avoids the status quo of poor repeatability of device efficiency caused by different degrees of crystallization during the annealing process of the perovskite layer, and the non-annealing process is simple and easy to repeat , improve the uniformity of device efficiency, and facilitate industrial production.

Owner:SUZHOU UNIV

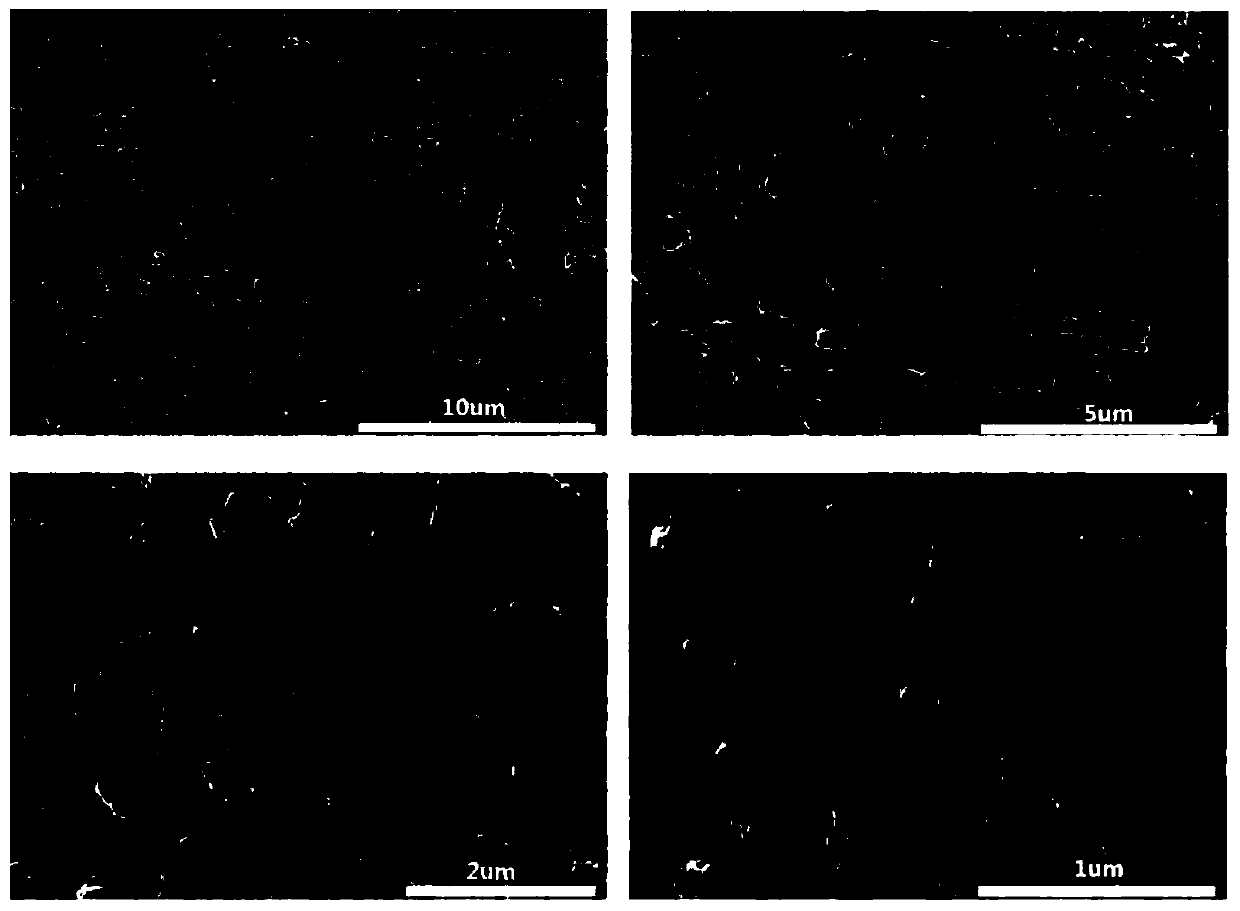

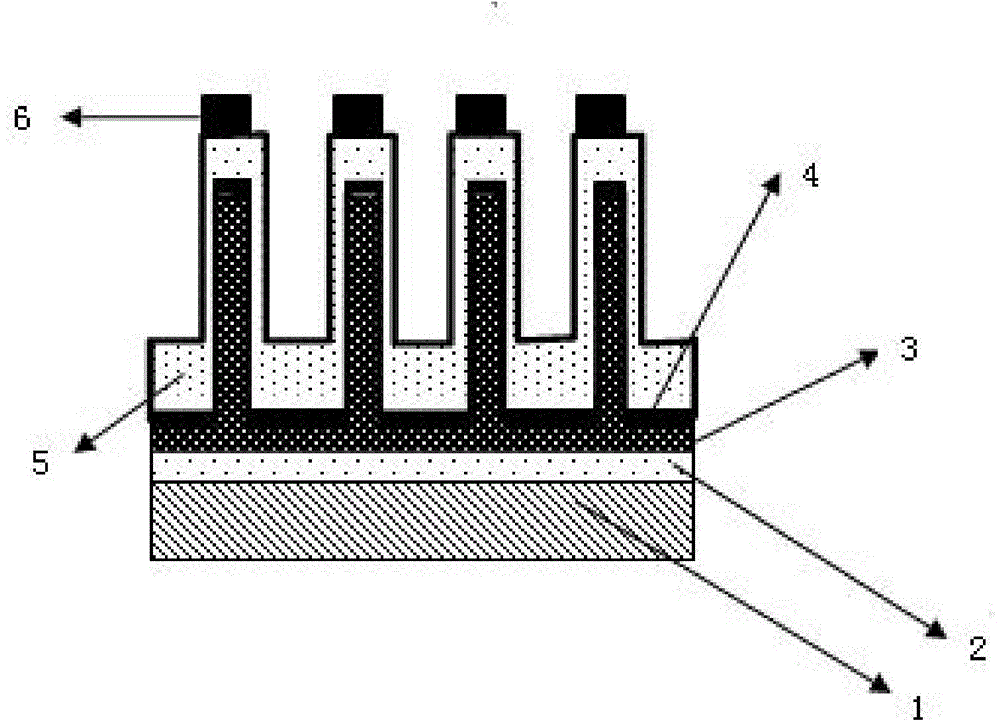

A kind of czts nanoarray thin film solar photovoltaic cell and preparation method thereof

ActiveCN104465807BImprove photoelectric conversion efficiencyEasy to prepareFinal product manufacturePhotovoltaic energy generationDot matrixNanostructure

The invention belongs to the field of solar photovoltaic cells, and particularly relates to a CZTS nanometer array thin film solar photovoltaic cell and a manufacturing method thereof. According to the solar photovoltaic cell of a nanometer structure, the characteristics that the diameter of nanowire arrays is small, light rays are absorbed in the axial direction of the nanowire arrays and the distance between the nanowire arrays is smaller than the wavelength of light waves are utilized at the same time, and therefore light absorption is improved; by means of the preferred orientation of the nanowire arrays, the dot matrix distortion is reduced, and the light reflection is reduced; by means of the characteristic that the specific surface area of the nanowire arrays is large, the probability of carrier generation is increased; due to the fact that carriers are conveyed in the radial direction, the probability of electron holes and electron recombination is lowered, and the photoelectric conversion efficiency of the solar photovoltaic cell is greatly improved.

Owner:SHANGQIU NORMAL UNIVERSITY

Anti-corrosion block rare earth-based metal glass and annealing method thereof

InactiveCN103290341BStrong Amorphous Formation AbilityImprove corrosion resistanceAmorphous phaseAlloy

The invention relates to anti-corrosion block rare earth-based metal glass and an annealing method thereof, belonging to the technical field of preparation of amorphous alloy materials. Specific to the problem of poor crystallization resistance of the existing metal glass, the invention provides an anti-corrosion block rare earth-based metal glass with good crystallization resistance; and the composition is CexLayPrzSmsGdtComAln, wherein x, y, z, s, t, m and n represent the atom percentage content; x is 29.31%, y is 21.83%, z is 3.53%, s is 7.08%, t is 3.25%, m is 25% and n is 10%. The anti-corrosion block rare earth-based metal glass provided by the invention is a single amorphous phase and has strong amorphous forming ability; the anti-corrosion block rare earth-based metal glass after annealing treatment is still in an amorphous state; the corrosion resistance is obviously enhanced by 49.5%; and the hardness is remarkably improved.

Owner:UNIV OF JINAN

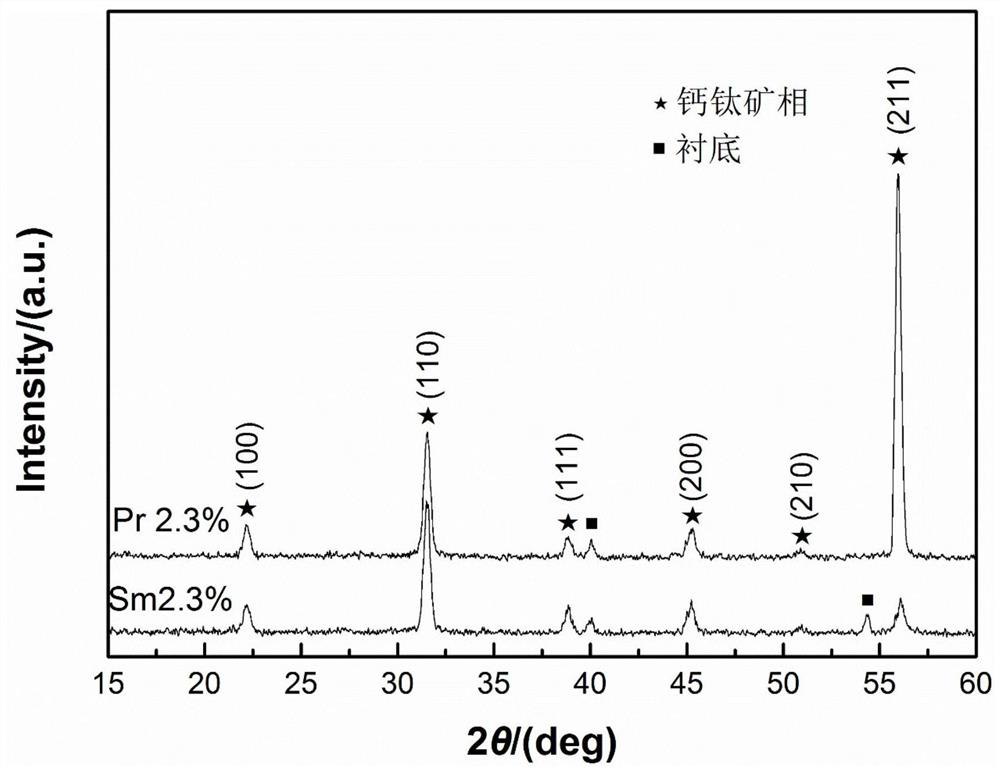

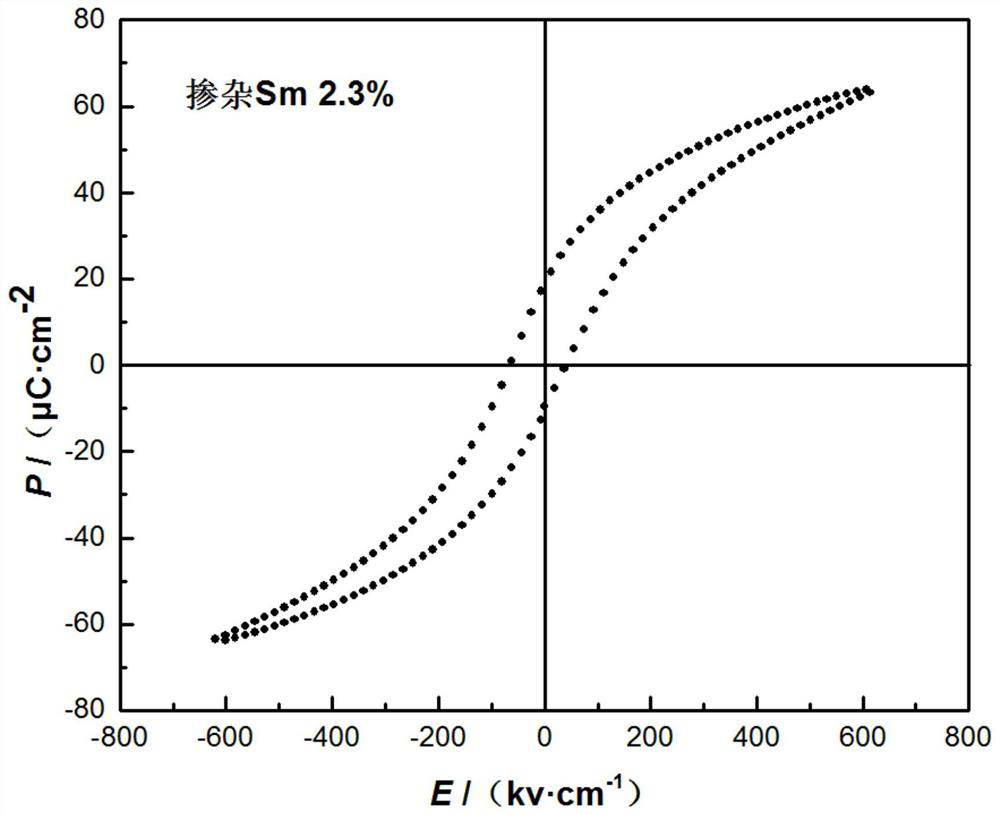

A method to improve the dielectric and pyroelectric properties of relaxor ferroelectric thin films

The invention relates to a method for improving the dielectric and pyroelectric properties of a relaxor ferroelectric thin film. The dielectric and pyroelectric properties of the existing ferroelectric thin film are not high, and the dielectric and pyroelectric properties of the relaxor ferroelectric thin film are improved by A / B site doping modification. The present invention comprises the following steps in turn: 1. Prepare PMN-PT precursor solution: 2. Utilize rare earth elements to prepare PMN-PT precursor solution uniformly doped with rare earth elements; 3. Dope PMN-PT precursor solution with rare earth elements On Pt / TiO 2 / SiO 2 Spin coating on the / Si substrate evenly, and the film is annealed and crystallized to obtain PMN‑PT film doped with rare earth elements. The invention remarkably improves the dielectric and pyroelectric properties of the relaxor ferroelectric PMN-PT thin film through the doping of rare earth elements.

Owner:XIAN TECH UNIV

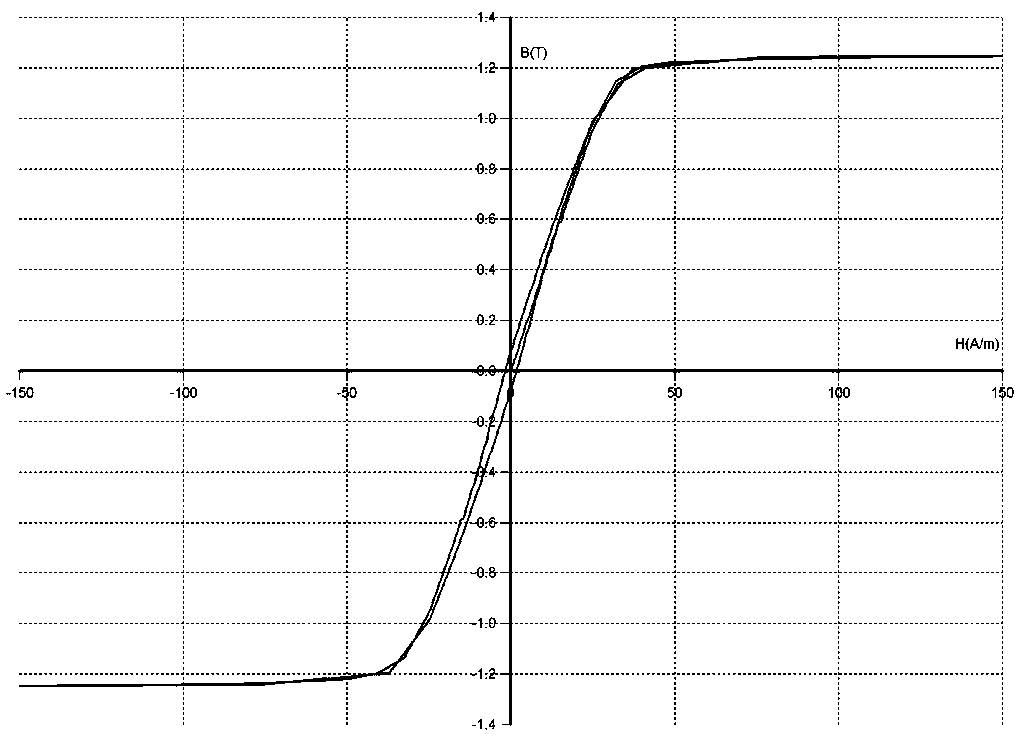

A magnetic core with a linear hysteresis loop

ActiveCN107464649BExcellent anti-DC component performanceThe output is stable and does not changeTransformers/inductances magnetic coresMagnetic materialsNiobiumMagnetic flux

The invention discloses a magnetic core with a linear hysteresis loop. The magnetic core comprises a magnetic core body, wherein the magnetic core body is made of iron-based nanocrystal soft magnetic alloy, and the iron-based nanocrystal soft magnetic alloy comprises the following constituents according to atomic ratios: 72-76 parts of iron, 12-16 parts of silicon, 5.2-7.5 parts of boron, 1.5-3 parts of niobium, 1-1.8 parts of vanadium, 0.8-1.1 parts of copper and 0.2-3 parts of rare metal. The magnetic core is provided with the linear hysteresis loop, the residual magnetic flux density Br is smaller than 0.02T, the coercivity is smaller than 1.5A / m, the saturation flux density is larger than 1.1T, and the linear magnetic conductivity of different magnetic cores which are produced can be controlled between 1,500 and 35,000.

Owner:NEW MATERIALS TECH JIANGSU AMORPHD

A kind of ultra-fine grain size thin gauge high manganese high aluminum steel and production method

A high-manganese and high-aluminum steel with ultra-fine grain size and thin gauge, its composition and wt% are: C: 0.91~1.35%, Si: 0.21~0.53%, Mn: 8.5~16.2%, Al: 13.7~22.4% , Nb: 0.11~0.23%, V: 0.15~0.32%, P: ≤0.018%, S: ≤0.008%, N: ≤0.008%; production method: smelting and continuous casting into slab; heating the slab, descaling ; Finish rolling; Laminar cooling; Coiling; Natural cooling to room temperature; Cold rolling; Continuous annealing. The present invention fully refines the microstructure of the high-manganese and high-aluminum steel through reasonable composition and process control combined with Nb microalloying technology, and at the same time, under the joint action of strengthening methods such as precipitation strengthening of Nb and V microalloys , so that the yield strength of the high manganese and high aluminum steel is 1653~1721MPa, the tensile strength is 2035~2119MPa, the elongation is 52~62%, and the thickness is thinner; the annealing process is simpler and the annealing time is shorter.

Owner:WUHAN UNIV OF SCI & TECH

A rolling process favorable for spheroidizing annealing of cr and mo steel

InactiveCN103350116BInhibit growthImprove segregationTemperature control deviceTemperature controlCarbide

The invention belongs to the technical field of metallurgy and particularly relates to a rolling process beneficial to spheroidizing annealing of a Cr and Mo steel. The rolling process is carried out according to the following steps of: carrying out cogging, rolling and spinning on a continuously cast steel billet; then always carrying out heat preservation to about 300 to 350 DEG C on a roll table cooling line and carrying out coil collection so as to obtain a Cr and Mo steel rolled product. According to the invention, by cogging heating control, steel rolling temperature control and after-rolling cooling control, segregation at the position of one second of R and center segregation are improved, grains are refined and growth of abnormal grains is avoided. Meanwhile, generation of large granular ferrite and pearlite is controlled, martensite is controlled below 35 percent; tissues mainly comprising bainite is formed, and carbide of the tissues is more uniformly distributed on a matrix. Moreover, according to a product produced by using the process, time of spheroidizing annealing is greatly shortened, an annealing process is simplified and spheroidized cementite is more dispersively and finely distributed.

Owner:NORTHEASTERN UNIV LIAONING +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com