Preparation method and luminescent glass capable of efficiently extracting size-controllable Ag nano particles under low-concentration AgNO3 doping condition

A technology of nanoparticles and luminescent glass, which is applied in the field of transparent luminescent glass, can solve the problems of uneven distribution of materials, harsh requirements of preparation process, unfavorable optical device design, etc., and achieve adjustable size distribution, simple annealing process and short time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) According to the following molar ratio ingredients:

[0038] Sample 1 (G1):

[0039] SiO 2 (66)% B 2 o 3 (8)%

[0040] Na 2 O(10)% NaF(8)%

[0041] SrF 2 (4)% YF 3 (4)%

[0042] Ag(0.1)%

[0043] (2) After fully grinding and mixing the two groups of ingredients in step (1), they are melted at 1450°C for 45 minutes under air atmosphere, pressed and annealed at 450°C for 2 hours to obtain silver-containing nano Particles of glass.

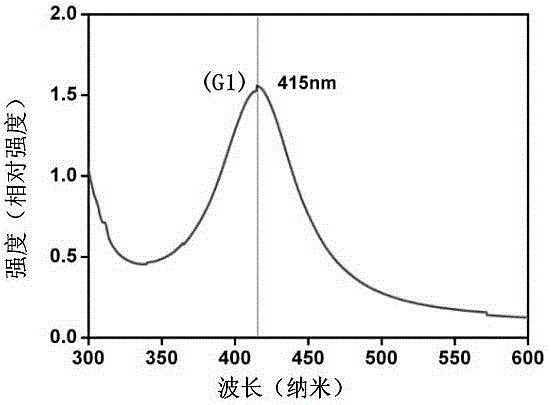

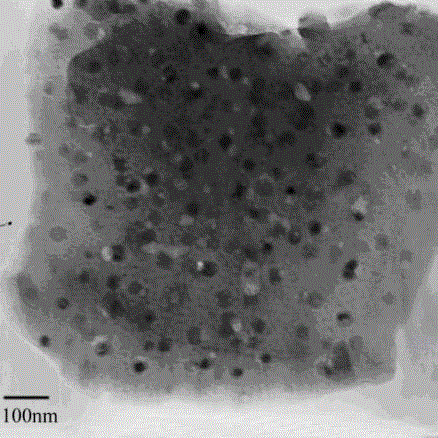

[0044] Its absorption spectrum is as figure 1As shown, there is a strong broadband plasmon resonance absorption peak at 415nm. Its TEM image as figure 2 As shown, it can be estimated that the average particle size of Ag nanoparticles precipitated in the glass is 25nm.

Embodiment 2

[0046] (1) According to the following molar ratio ingredients:

[0047] Sample 1 (G2):

[0048] SiO 2 (69)% B 2 o 3 (5)%

[0049] Na 2 O(10)% NaF(8)%

[0050] SrF 2 (8)%Ag(0.3)%

[0051] Sample 2 (G3):

[0052] SiO 2 (69)% B 2 o 3 (5)%

[0053] Na 2 O(10)% NaF(8)%

[0054] YF 3 (8)%Ag(0.3)%

[0055] (2) After fully grinding and mixing the two groups of batch materials in step (1), they are melted at 1500°C for 45 minutes in an air atmosphere, pressed and molded, and annealed at 450°C for 2 hours to obtain silver-containing nanoparticles. Granular glass, respectively named G2, G3.

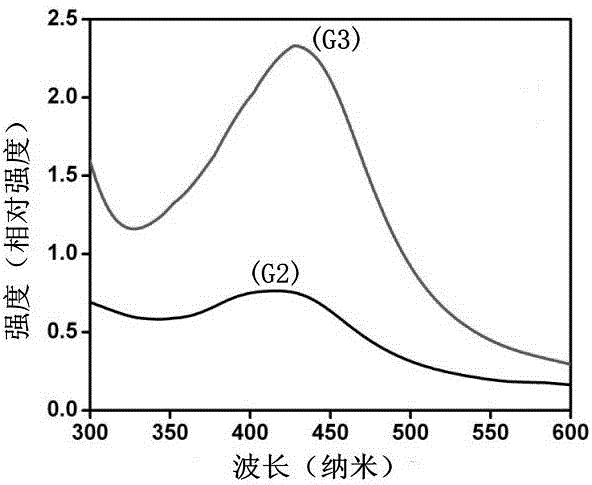

[0056] Its absorption spectrum is as image 3 As shown, there is a broadband plasmon resonance absorption peak. Among them, the absorption peak intensity of G3 is much higher than that of G2, and the center position of the SPR peak is red-shifted from 417nm to 430nm, indicating that the size of Ag nanoparticles precipitated in G3 glass is larger than that in G2.

Embodiment 3

[0058] (1) According to the following molar ratio ingredients:

[0059] Sample 1 (G4):

[0060] SiO 2 (64)% B 2 o 3 (10)%

[0061] Na 2 O(6)% NaF(12)%

[0062] YF 3 (8)%Ag(0.2)%

[0063] Sample 2 (G5):

[0064] SiO 2 (64)% B 2 o 3 (10)%

[0065] Na 2 O(12)% NaF(6)%

[0066] YF 3 (8)%Ag(0.2)%

[0067] (2) After fully grinding and mixing the two groups of batch materials in step (1), they are melted at 1450°C for 45 minutes in an air atmosphere, pressed and formed, and annealed at 400°C for 2 hours to obtain silver-containing nanoparticles. Granular glass, respectively named G4, G5.

[0068] Its absorption spectrum is as Figure 4 As shown, there is a broadband plasmon resonance absorption peak centered at 425 nm. Among them, the absorption peak intensity of G4 is greater than that of G5, indicating that in F - / O 2 -The average particle size of Ag nanoparticles precipitated in G4 glass with a higher proportion is larger than that in G5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com