Thermal treatment method for improving type N polycrystal Bi2Te3thermoelectricity capability

A heat treatment method and thermoelectric performance technology, which is applied in post-treatment, post-treatment details, polycrystalline material growth, etc., to achieve the effects of simple annealing process, strong practicability, and short synthesis and preparation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

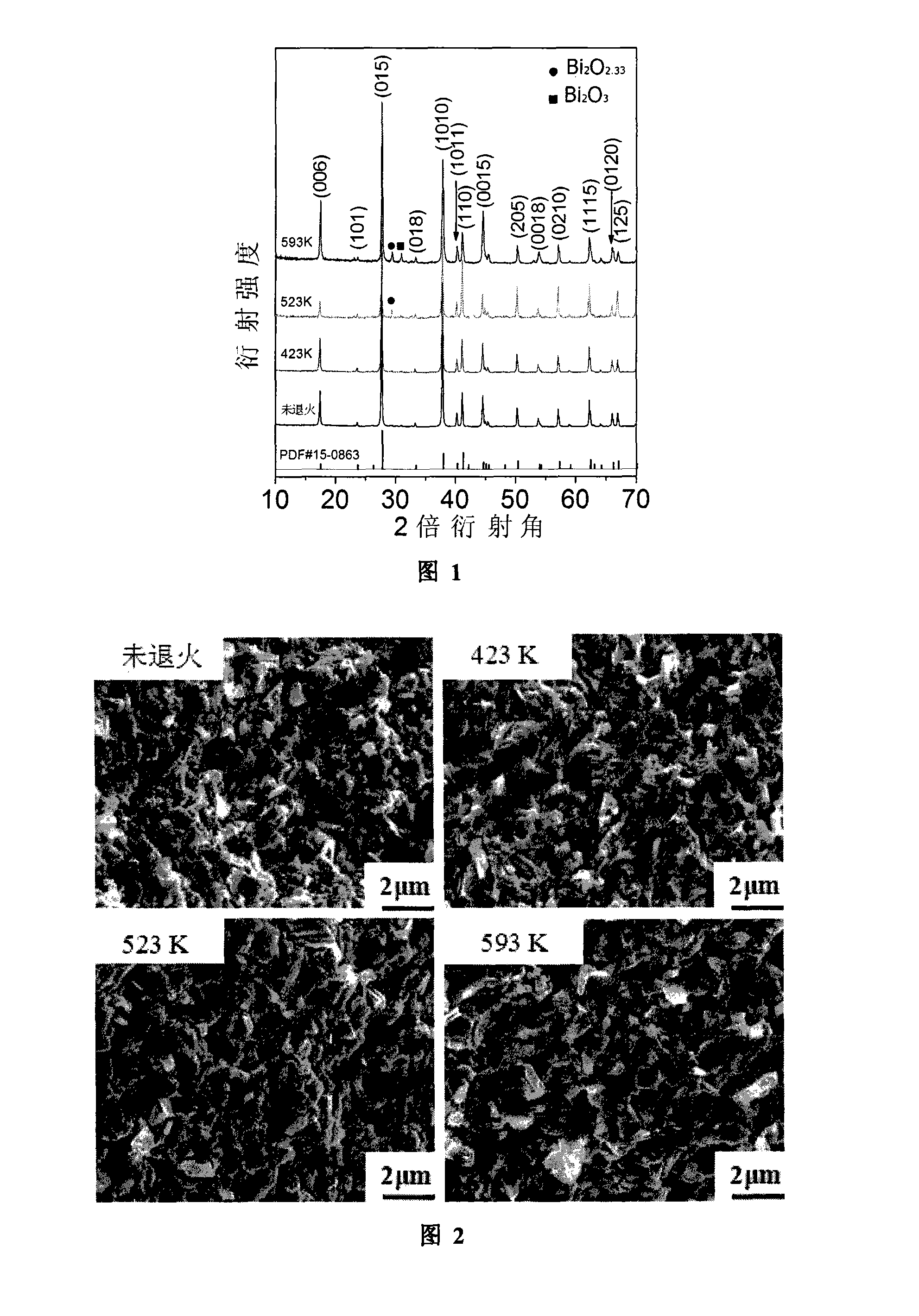

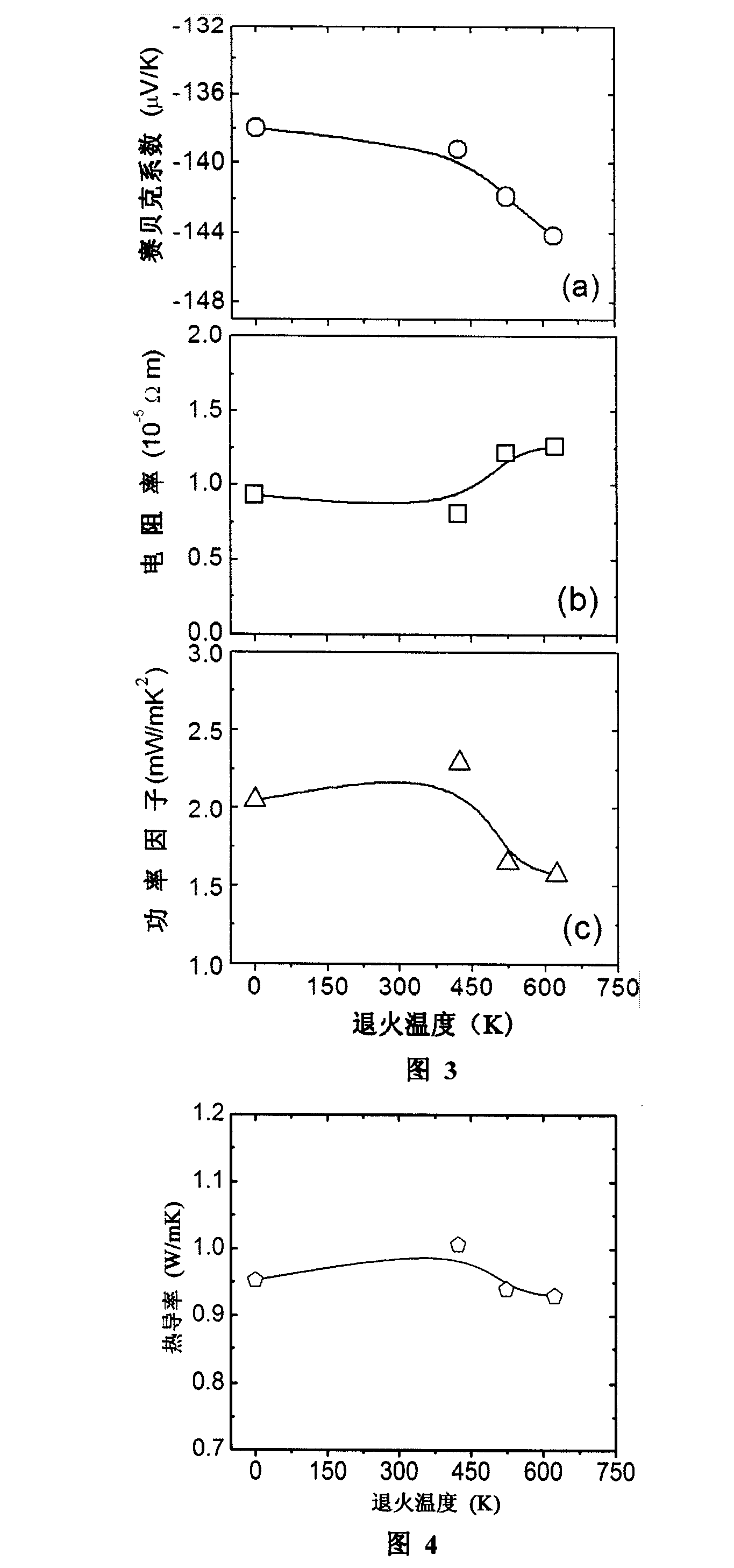

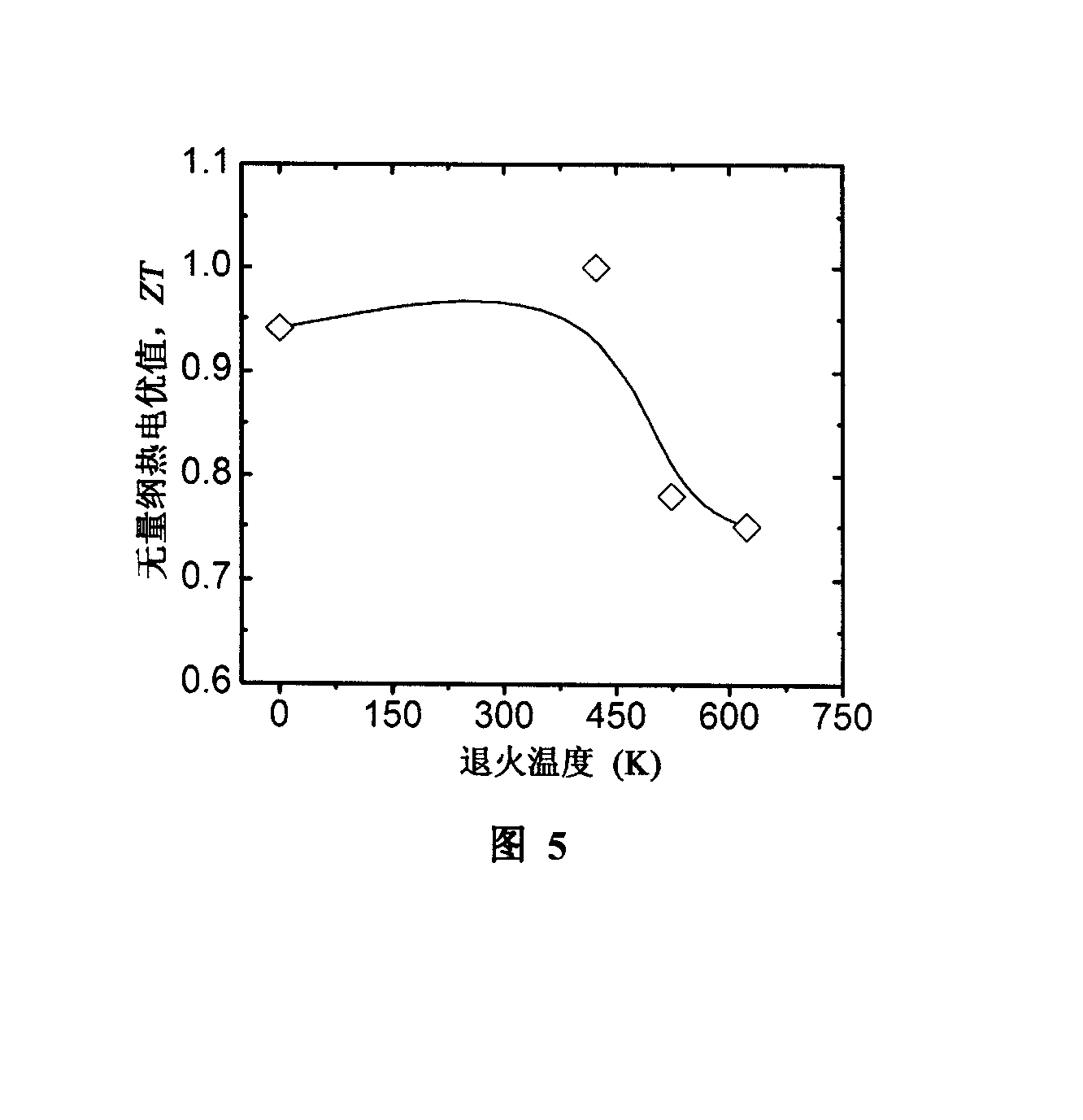

[0018] Bi was first prepared by the mechanical alloying method (MA) 2 Te 3 Precursor fine powder, the method is to mix high-purity Bi and Te elemental powders according to the atomic ratio of 2:3, put them together in a planetary high-energy ball mill for mechanical alloying under the protection of inert gas, and dry-mill the synthetic compound before wet Grind, and finally dry to get Bi 2 Te 3 based fine powder; the Bi 2 Te 3 The powder is prepared into a bulk material, the sintering temperature is 200-500°C, the holding time is 2-8min, and the pressure is 20-60MPa; after the surface of the sintered bulk material is polished, it is put into a glass tube, and then the glass The tube is evacuated, when the pressure inside the tube is less than 10 -3 After Pa, sealing treatment is carried out. Put the sealed glass tube of the sample into a box furnace for annealing treatment, heat it from room temperature to 100-400°C, keep it warm for 1-150 hours and then cool it with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com