Fe-based nanocrystalline soft magnetic alloy with strong amorphous forming ability and preparing method of Fe-based nanocrystalline soft magnetic alloy

A technology of iron-based nanocrystals and soft magnetic alloys, which is applied in the direction of magnetic materials, magnetic objects, electrical components, etc., and can solve problems such as extremely strict requirements for process and heat treatment processes, restrictions on the application field of nanocrystals, and difficulties in the production and preparation of nanocrystals.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

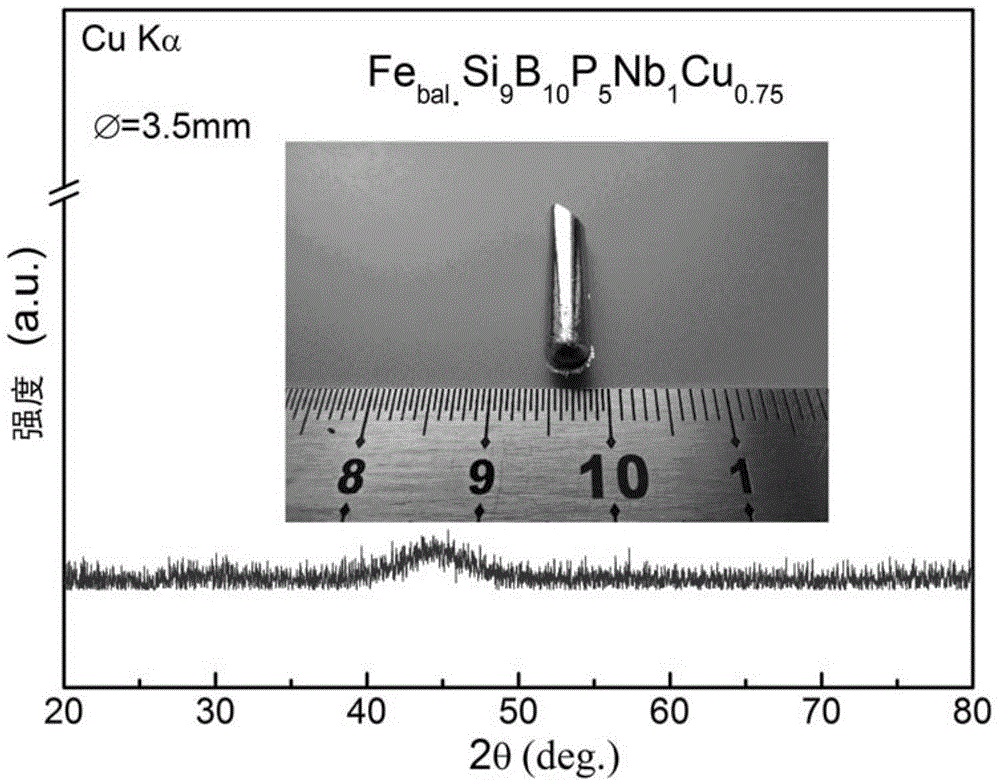

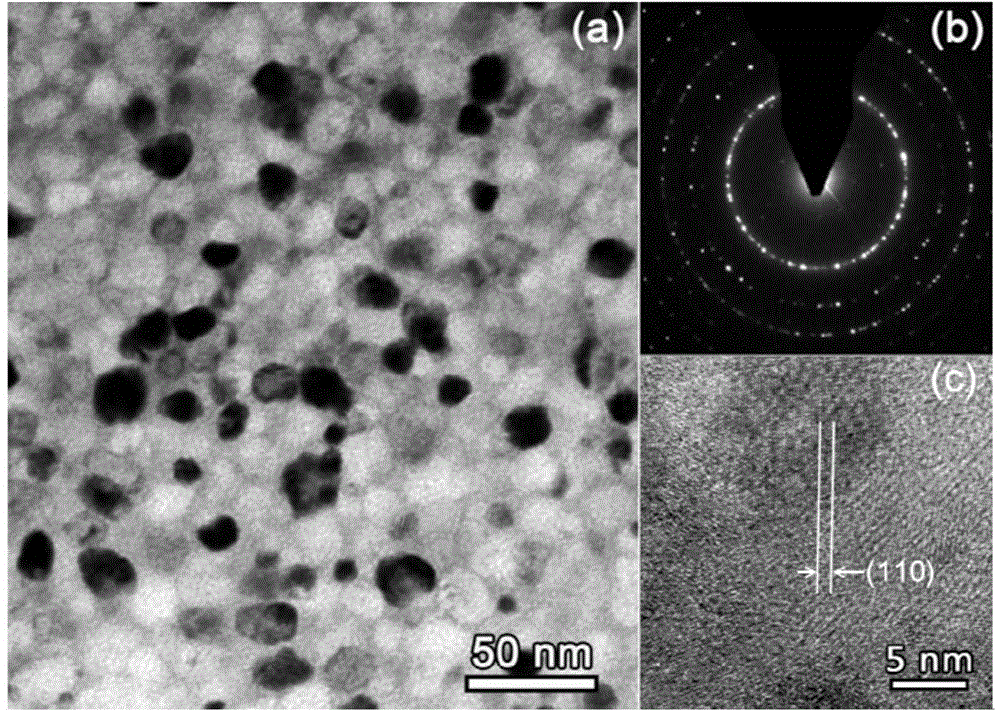

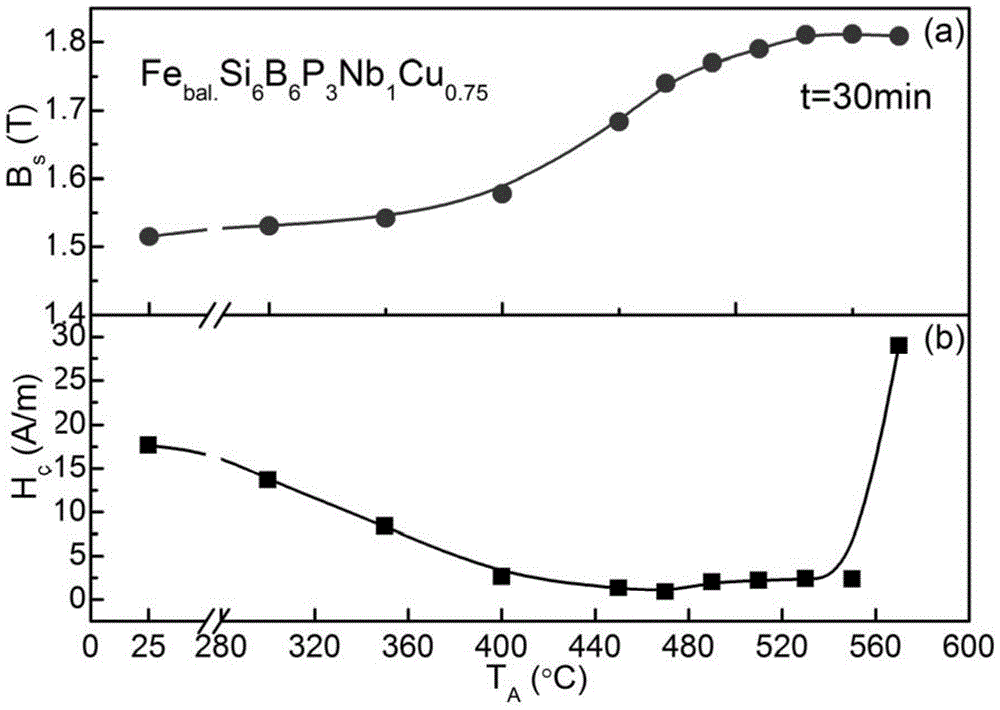

[0059] According to the composition range of the iron-based nanocrystalline alloy of the present invention, we have done a series of experiments. Dosing according to the composition of the present invention, see Table 1 (serial number 1-20) for the specific composition and atomic percentage content, put the raw materials with good ratio into induction melting furnace or electric arc melting furnace, and vacuumize to 5×10 -3Below Pa, then fill with argon atmosphere to protect, completely melt and then keep warm for 30 minutes to melt the alloy raw materials into a uniform molten steel, pour into the mold to cool to obtain a master alloy ingot with uniform composition; then break the master alloy ingot; Put it into a quartz tube and melt it into molten steel. The melting temperature is about 1300°C. Spray the tape at a speed of 35m / s in the air. The temperature of the spray tape is 1200°C. is 1mPas, the cooling rate is 10 2 °C / s, the amorphous alloy strips with a width of 1mm a...

Embodiment 2

[0070] According to the composition range of the iron-based nanocrystalline alloy of the present invention, we have done a series of experiments. Fe with high saturation magnetic induction of the present invention x Si a B b P c Nb d Cu e An alloy in which Cu is partially or completely replaced by at least 3 atomic % of at least one element among Ag and Au. Table 2 is according to the composition of the present invention to carry out batching, and the raw material of proportioning is put into induction melting furnace or electric arc melting furnace, and vacuumizes to 5 * 10 -3 Pa below, then filled with nitrogen atmosphere protection, after melting, keep warm for 30 minutes to melt the alloy raw materials into a uniform molten steel, pour into the mold to cool down to obtain an alloy ingot with uniform composition; break the master alloy ingot; put small pieces of master alloy into a quartz tube and melt it into a For molten steel, the melting temperature is about 1500°...

Embodiment 3

[0076] According to the composition range of the iron-based nanocrystalline alloy of the present invention, we have done a series of experiments. Fe with high saturation magnetic induction of the present invention x Si a B b P c Nb d Cu e An alloy, wherein Nb is partially or completely replaced by at least 3 atomic % of at least one element among Zr, Ti, Ta, Hf, V, W, Mo, Mn, Cr, and Zn. Table 3 carries out batching according to the composition of the present invention, puts the raw material of ratio into induction melting furnace or electric arc melting furnace, vacuumizes to 5 * 10 -3 Pa below, then filled with nitrogen atmosphere protection, after melting, keep warm for 30 minutes to melt the alloy raw materials into a uniform molten steel, pour into the mold to cool down to obtain an alloy ingot with uniform composition; break the master alloy ingot; put small pieces of master alloy into a quartz tube and melt it into a Molten steel, the melting temperature is about ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com