A kind of cadmium stannate-based transparent conductive film, its production process and solar cell

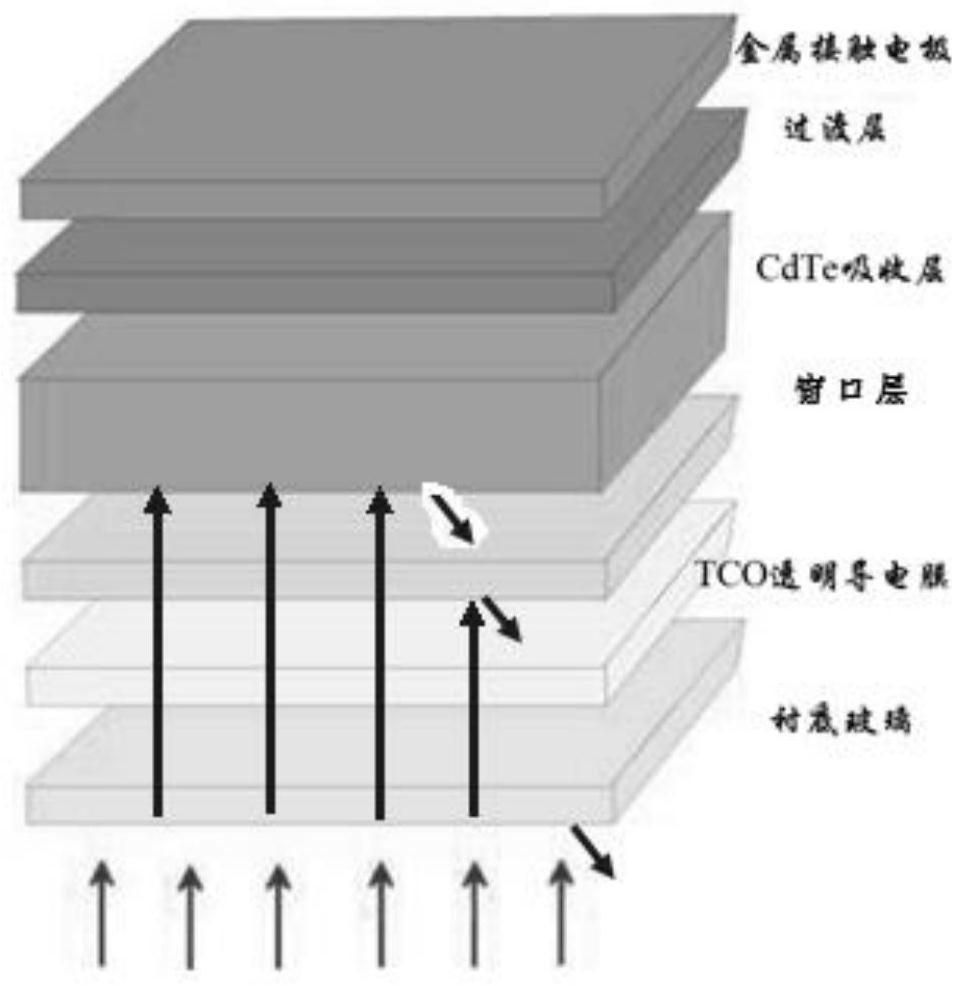

A transparent conductive film and solar cell technology, applied in the field of solar cells, can solve the problems of increasing the cost of film material production, increasing the difficulty, and polluting the CTO film layer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

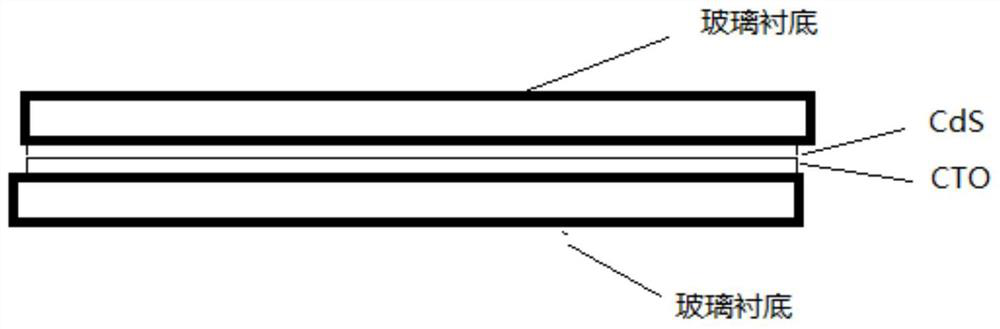

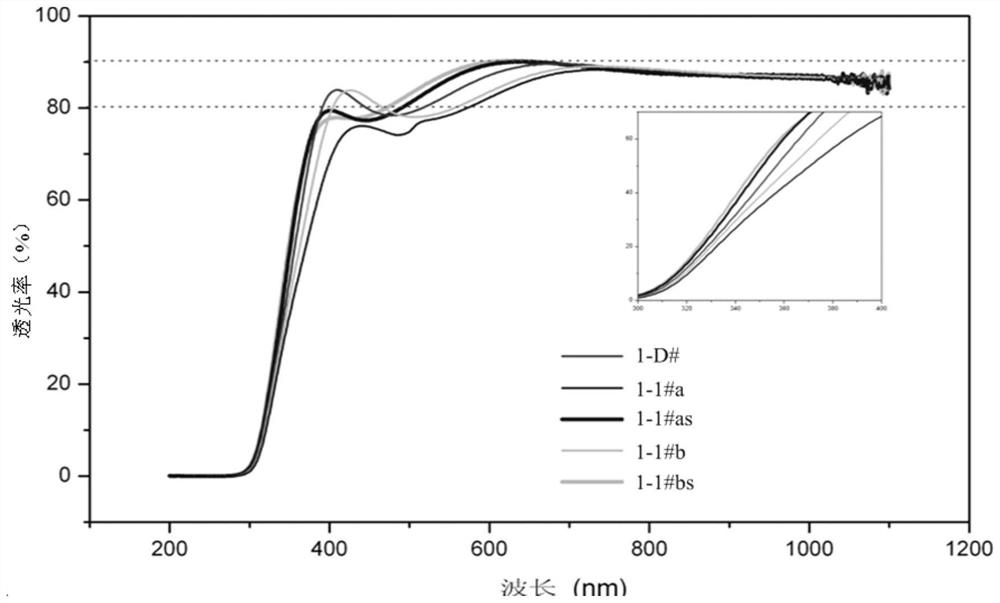

[0067] 1.1 Preparation of cadmium stannate-based transparent conductive film (CTO-CdS):

[0068] (1)a. With SnO 2 -CdO as the target (SnO 2 The molar ratio to CdO is 33:67), the glass substrate is placed in the magnetron sputtering chamber, and the sputtering distance between the target and the substrate is adjusted to be 6.7cm;

[0069] b. Vacuum the sputtering chamber until the vacuum degree is ≤2.5E-6Torr;

[0070] c. Introduce gas (Ar and O) into the sputtering chamber 2 ), Ar flow is 72sccm, O 2 The flow rate is 8sccm, so that the air pressure in the sputtering chamber is kept at 10mTorr;

[0071] d. Using radio frequency sputtering, the sputtering power is 484W, the radio frequency is 13.56MHz, and the sputtering is 9.5min, and the precursor CTO base film is deposited on the glass substrate (denoted as 1-0#);

[0072] e. Replace the target material and use CdS as the target material;

[0073] f. Vacuum the sputtering chamber to a vacuum degree ≤2.5E-6Torr;

[0074] ...

Embodiment 2

[0092] 1.1 Preparation of cadmium stannate-based transparent conductive film (CTO-Al):

[0093] (1)a. With SnO 2 -CdO as the target (SnO 2 The molar ratio to CdO is 33:67), the glass substrate is placed in the magnetron sputtering chamber, and the sputtering distance between the target and the substrate is adjusted to be 6.7cm;

[0094] b. Vacuum the sputtering chamber until the vacuum degree is ≤2.5E-6Torr;

[0095] c. Introduce gas (Ar and O) into the sputtering chamber 2 ), Ar flow is 72sccm, O 2 The flow rate is 8sccm, so that the air pressure in the sputtering chamber is kept at 10mTorr;

[0096] d. Using radio frequency sputtering, the sputtering power is 485W, the radio frequency is 13.56MHz, and the sputtering is 9.5min, and the precursor CTO base film is deposited on the glass substrate (denoted as 2-0#);

[0097] e. Replace the target material and use the Al target as the target material;

[0098] f. Vacuum the sputtering chamber to a vacuum degree ≤ 1.5E-4Pa; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com