Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

93results about How to "Should not be blocked" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

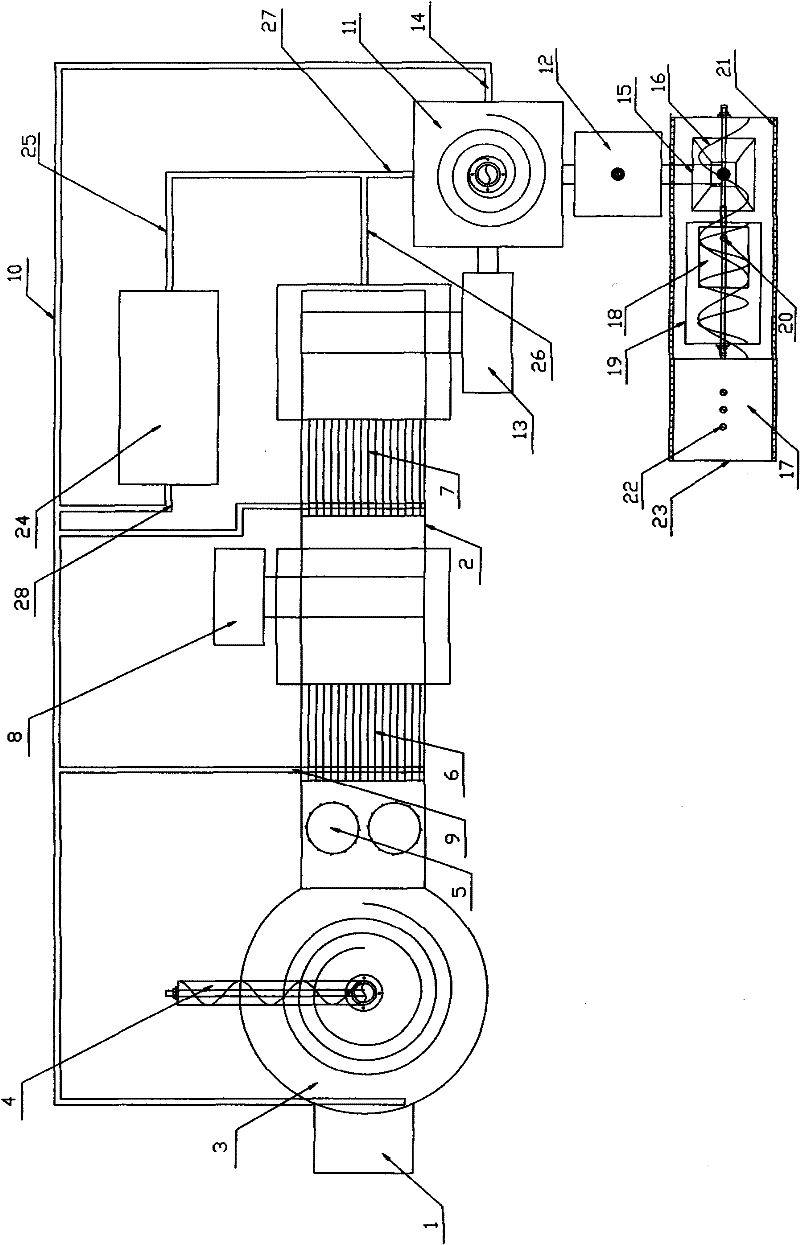

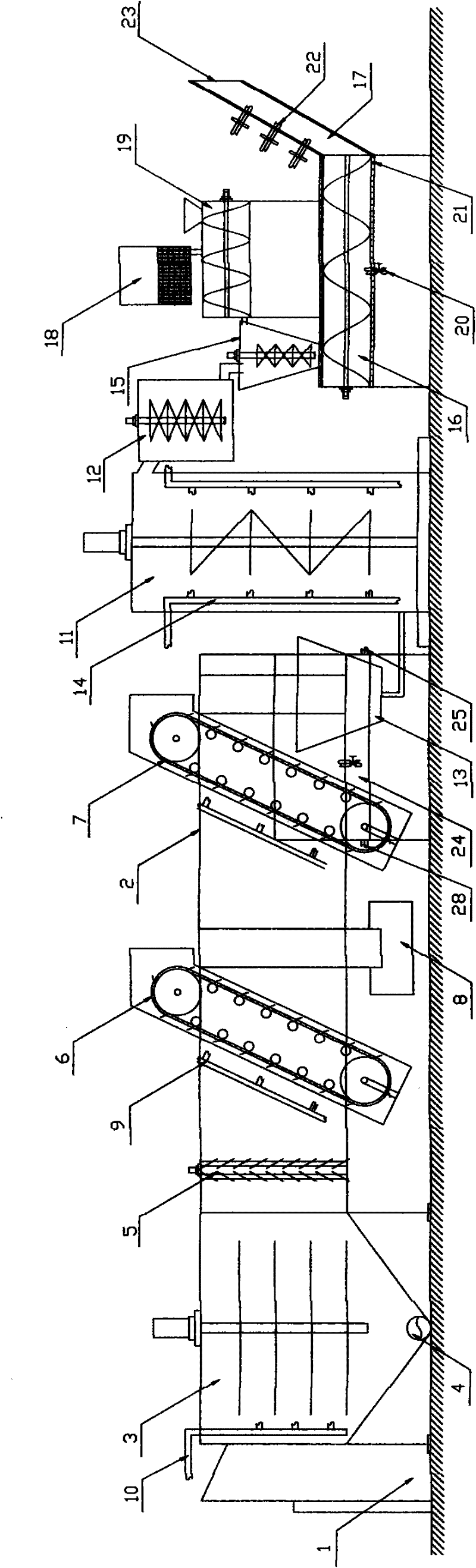

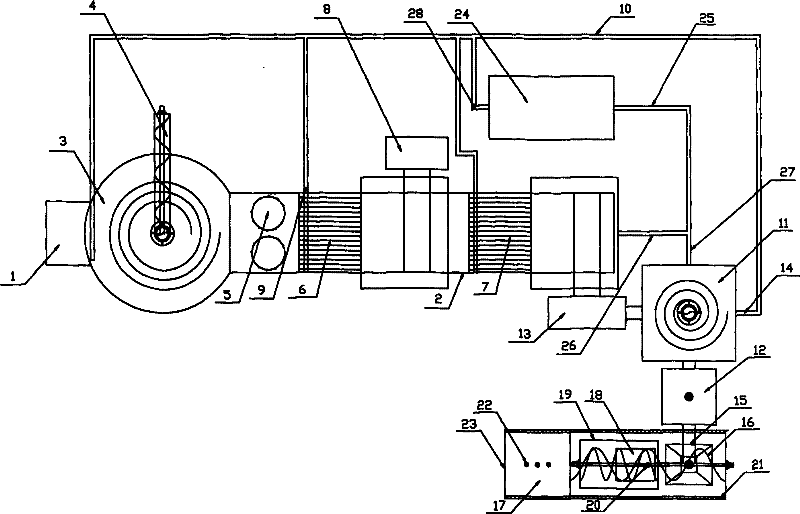

Processing method and processing system for kitchen garbage resourcilization

InactiveCN102690134AReduce moisture contentWater content automatic controlBio-organic fraction processingSolid waste disposalOil and greaseWater use

The invention relates to a processing method and a processing system for kitchen garbage resourcilization. The processing method comprises waterpower decomposition, fragmentation, sorting, dehydration, crushing, anaerobic fermentation and oil-water separation; the processing system comprises a feeding device, a waterpower conveying decomposition tank, a fragmentation preselection apparatus, a dehydration crushing apparatus, an anaerobic fermentation mixing apparatus and an oil-water separation apparatus. The method and system provided in the invention adopt sorting by using water. Advanced treatments of sorting to remove impurity, fragmentation, dehydration, desalination, oil removing and the like are automatically carried out to substances of different properties in the kitchen garbage by using water as a carrier combining with mechanization equipment, according to dissolvability and different proportion of the substances; organic substances separated from the kitchen garbage are fermented and prepared into organic fertilizers; and grease in separated oil-contained sewage is recycled by oil-water separating. The method and the system in the invention thoroughly remove substances of oil, salinity, soy sauce, vinegar and the like in the kit garbage that against fermentation composting. The method and the system have the characteristics of high removal rate of salinity and grease, high dehydration efficiency, good automatic sorting effect, realization of resource regeneration and no secondary pollution.

Owner:焦社杰 +2

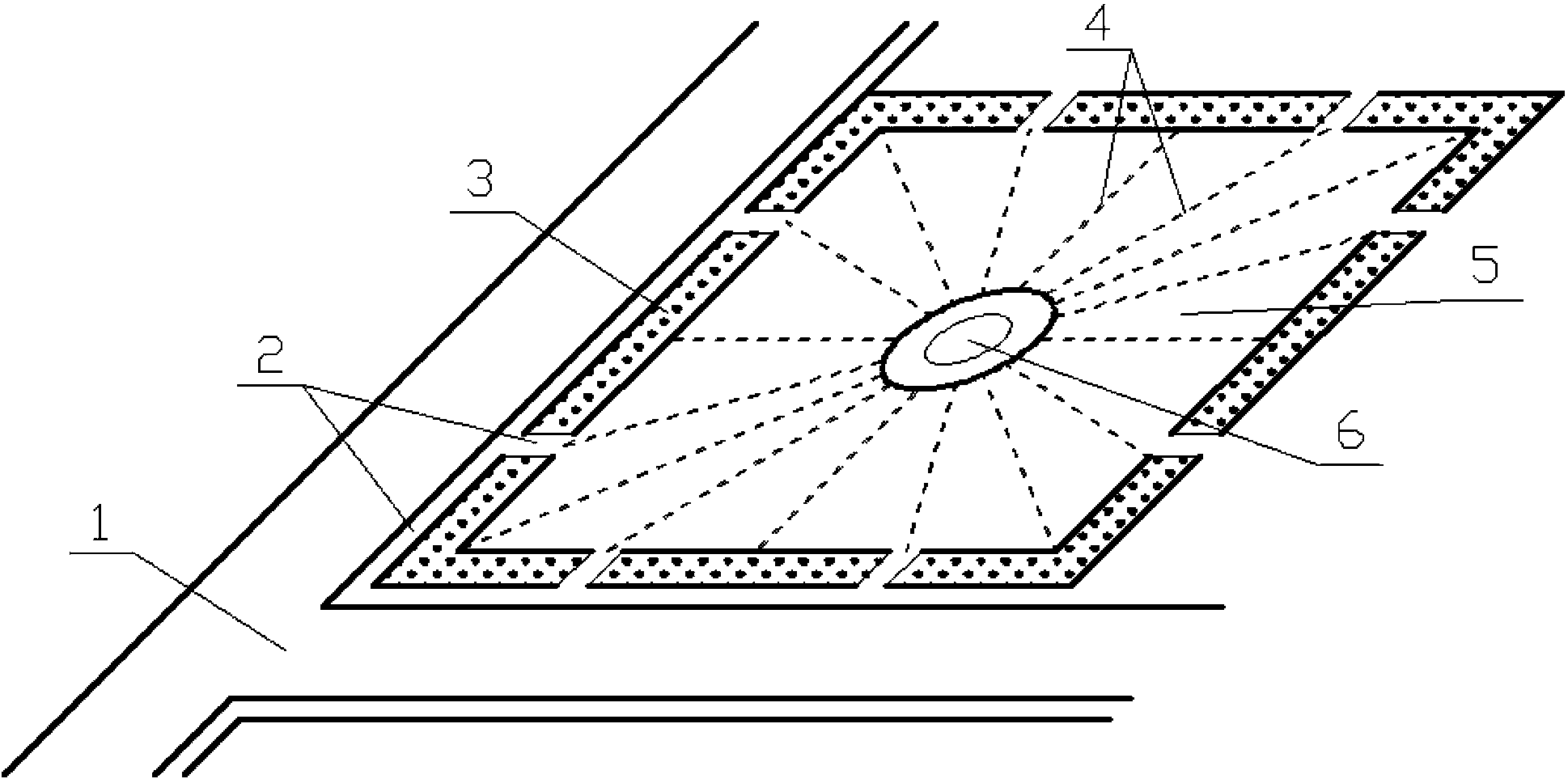

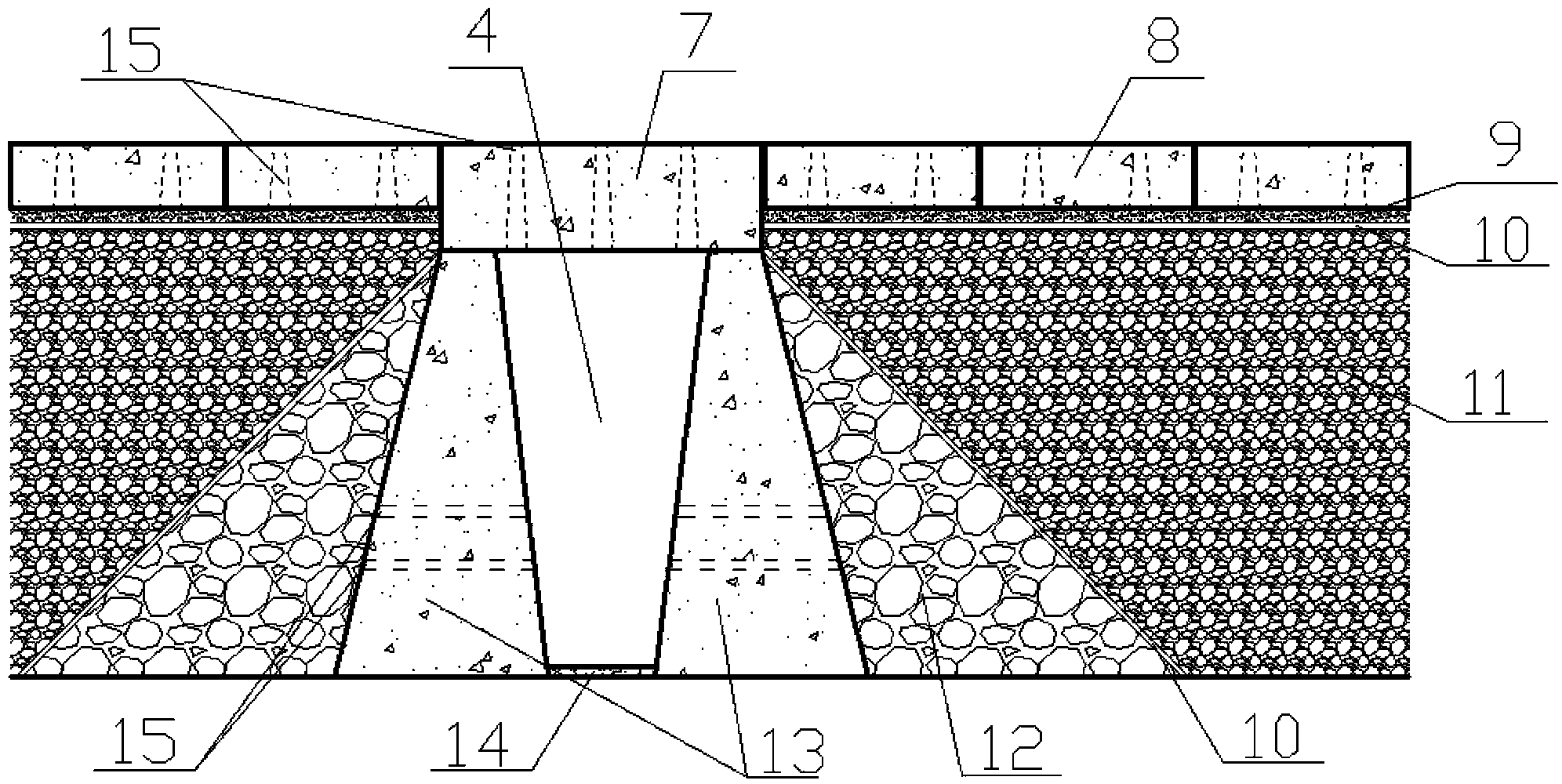

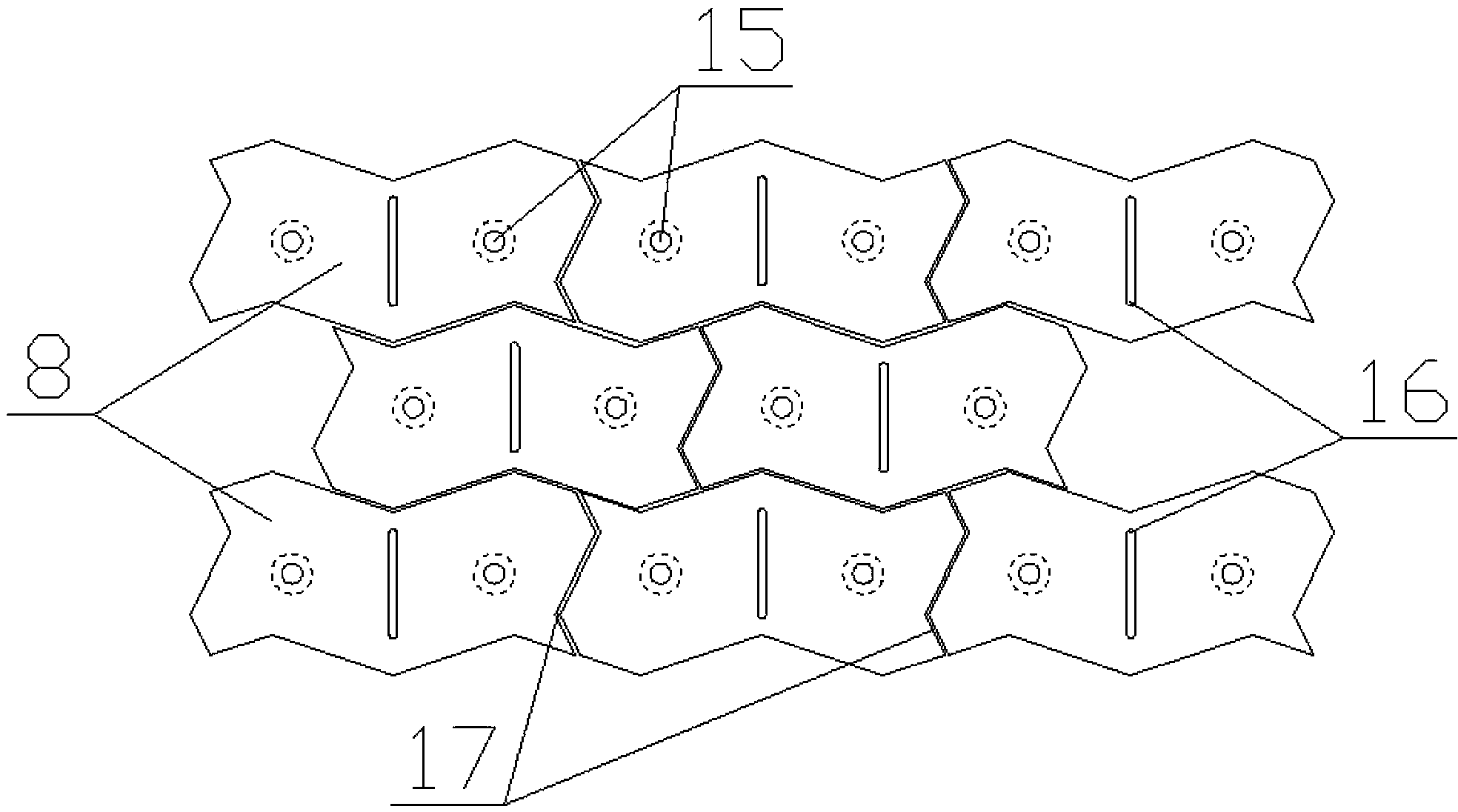

Rainwater penetration collection device based on concrete-sand-based water-permeable bricks

InactiveCN103352411AHigh strengthIncreased durabilityGround-workGeneral water supply conservationBrickAdhesive

The invention relates to a rainwater penetration collection device based on concrete-sand-based water-permeable bricks. The invention belongs to the field of construction design. The invention is characterized in that: pedestrian walkways and squares are paved by using concrete-sand-based water-permeable bricks; rainwater enters the concrete-sand-based pavement water-permeable bricks and cover-plate water-permeable bricks, and is filtered by a gravel bedding layer and a crushed stone bedding layer; rainwater enters a rainwater collection ditch through the water-permeable bricks of a ditch wall of a rainwater-collection thin ditch side wall; the rainwater is then gathered to a water storage tank on the square and is used as a landscape or used for irrigation. The device is characterized in that screened and processed desert sand is used as a main aggregate; high-grade cement is adopted as an adhesive; and proper additives are added. Frustum-shaped water-permeation holes are provided on brick bodies, and anti-slip stripes are arranged on the brick body. The device provided by the invention has the advantages that: desert sand is sufficiently utilized; the strength is high, and cost is low; the water permeability is good, and the water-permeation holes are prevented from blockage; the device is safe and comfortable; a good rainwater collection plane which is the square is sufficiently utilized; and rainwater processing is simple and feasible.

Owner:DALIAN UNIV OF TECH

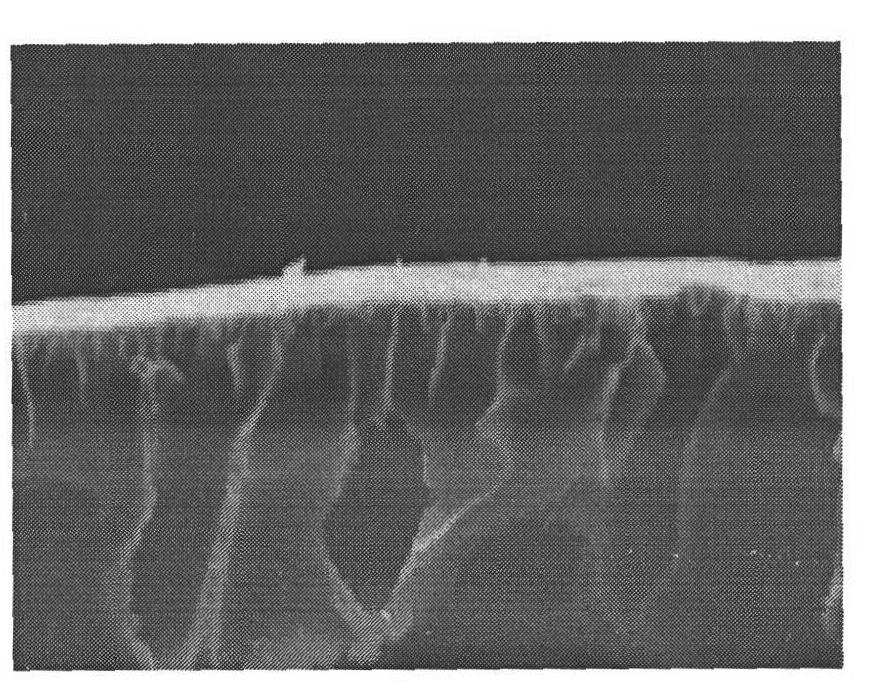

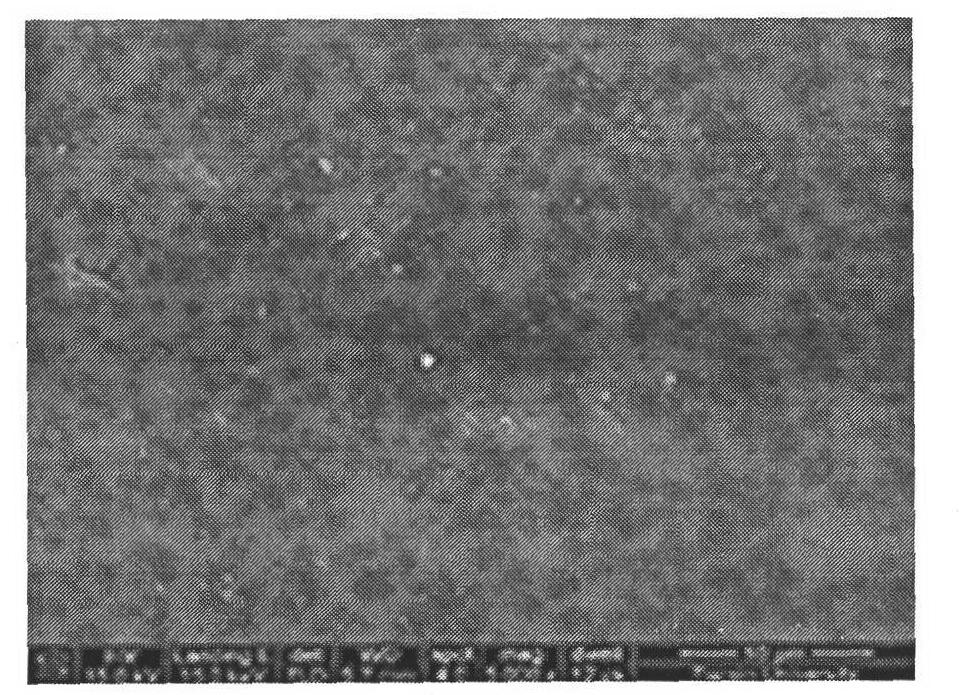

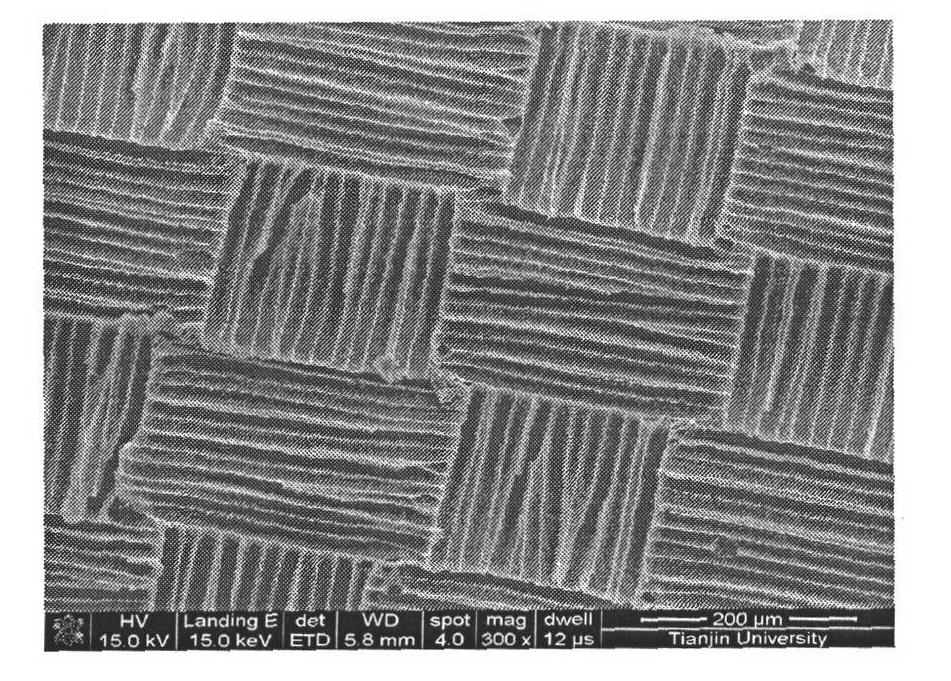

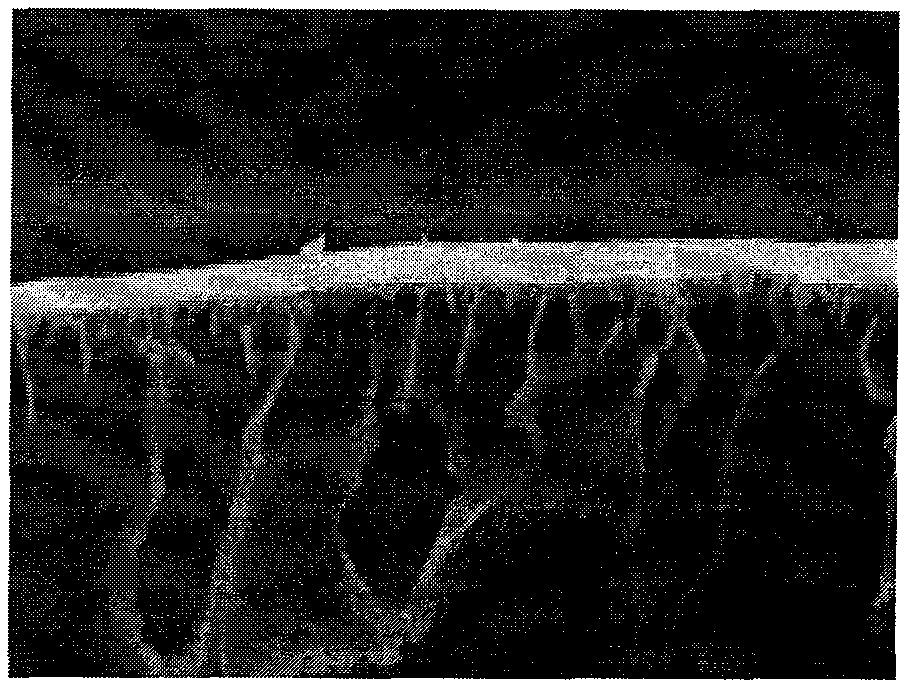

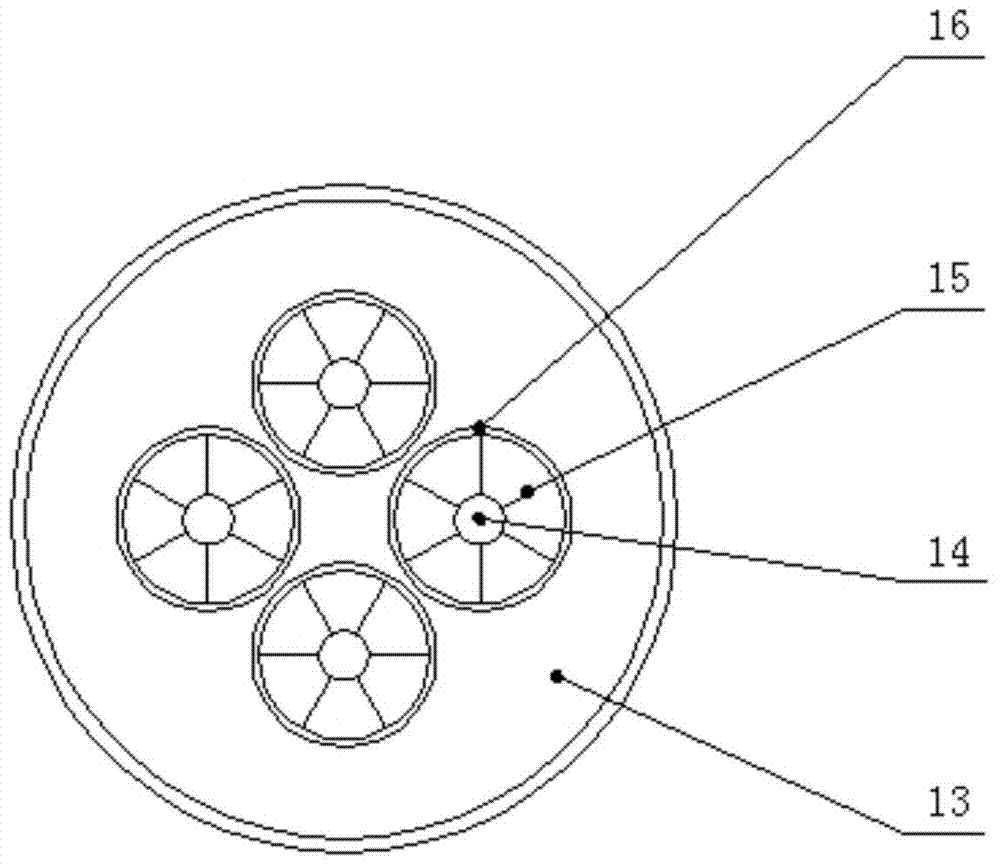

Non-woven fabric and woven fabric support ultra/micro-filtration membrane, preparation thereof and tubular composite filtration membrane

InactiveCN102371125AHigh porosityHigh strengthSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisPolymer scienceFiltration

The invention relates to a non-woven fabric and woven fabric support ultra / micro-filtration membrane, a preparation method thereof and a tubular composite filtration membrane, belonging to the field of polymer microporous membranes. PVC (polyvinyl chloride) is taken as main raw materials for preparing membrane forming liquid, a primary support liquid membrane is prepared on non-woven fabric and is gelatinized in solidification liquid, and then is subjected to water-washing and extraction and finally dried to obtain the support membrane, and the support membrane is coated with a PE (polyethylene) tube for forming the tubular composite filtration membrane. The surface layer of the membrane is in the shape of a finger, one side in the membrane, which is close to a support layer, is in a high asymmetric pore structure with sponge-like pores, and the membrane is reversible in dry and wet performances, can hardly be blocked, has high bursting strength and excellent pollution resistance, and can be back-cleaned and regenerated easily; in addition, the pore diameter of the membrane is adjustable between 0.01 mu m and1.0 mu. The member is suitable for being used as membrane material for precision filtration, reclaimed water treatment, security filtration before RO (reverse osmosis), terminal precision filtration, direct drinking filtration of tap water, sewage treatment and liquid purification and filtration.

Owner:天津市宝钜净化设备工程有限公司

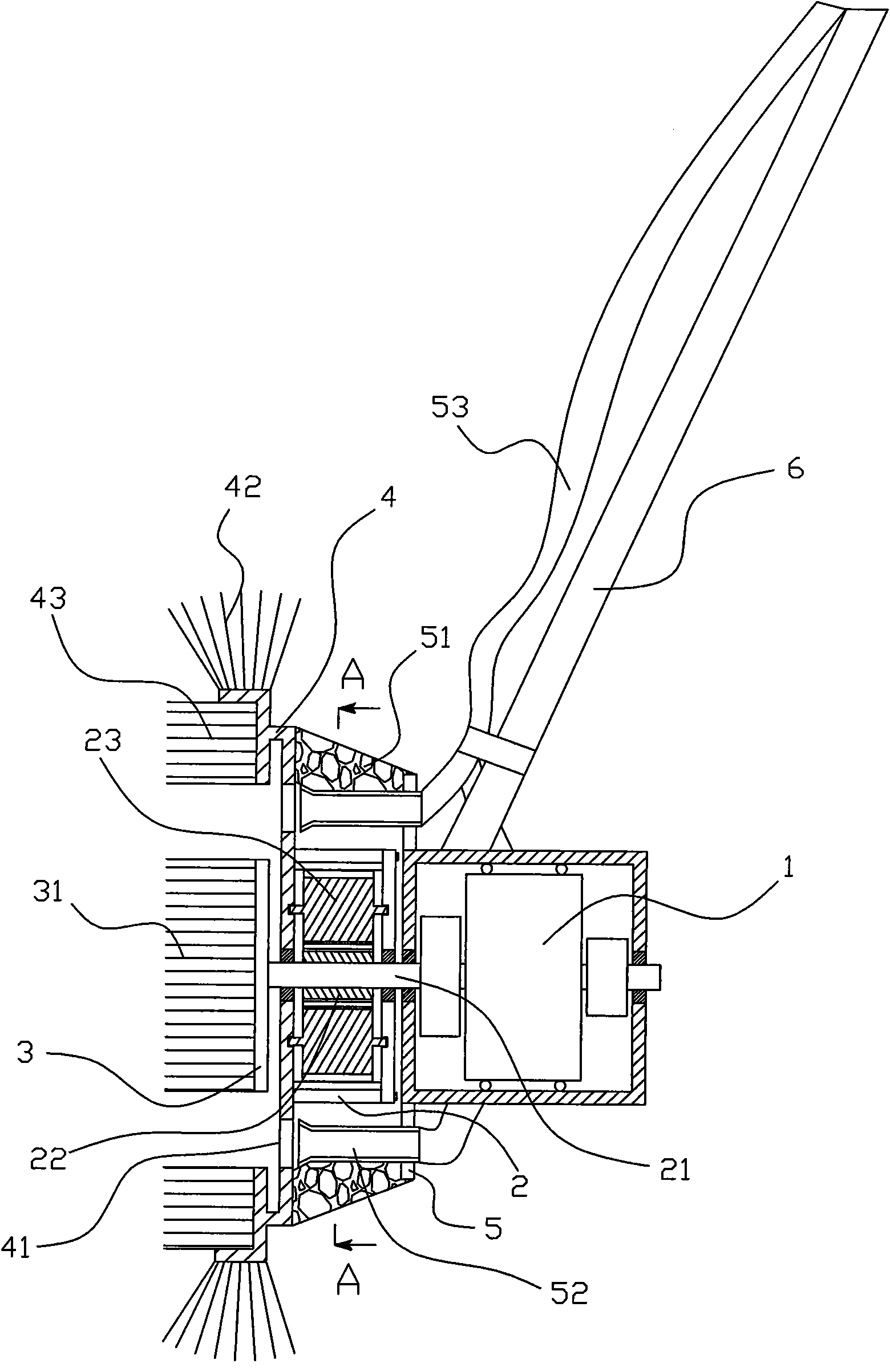

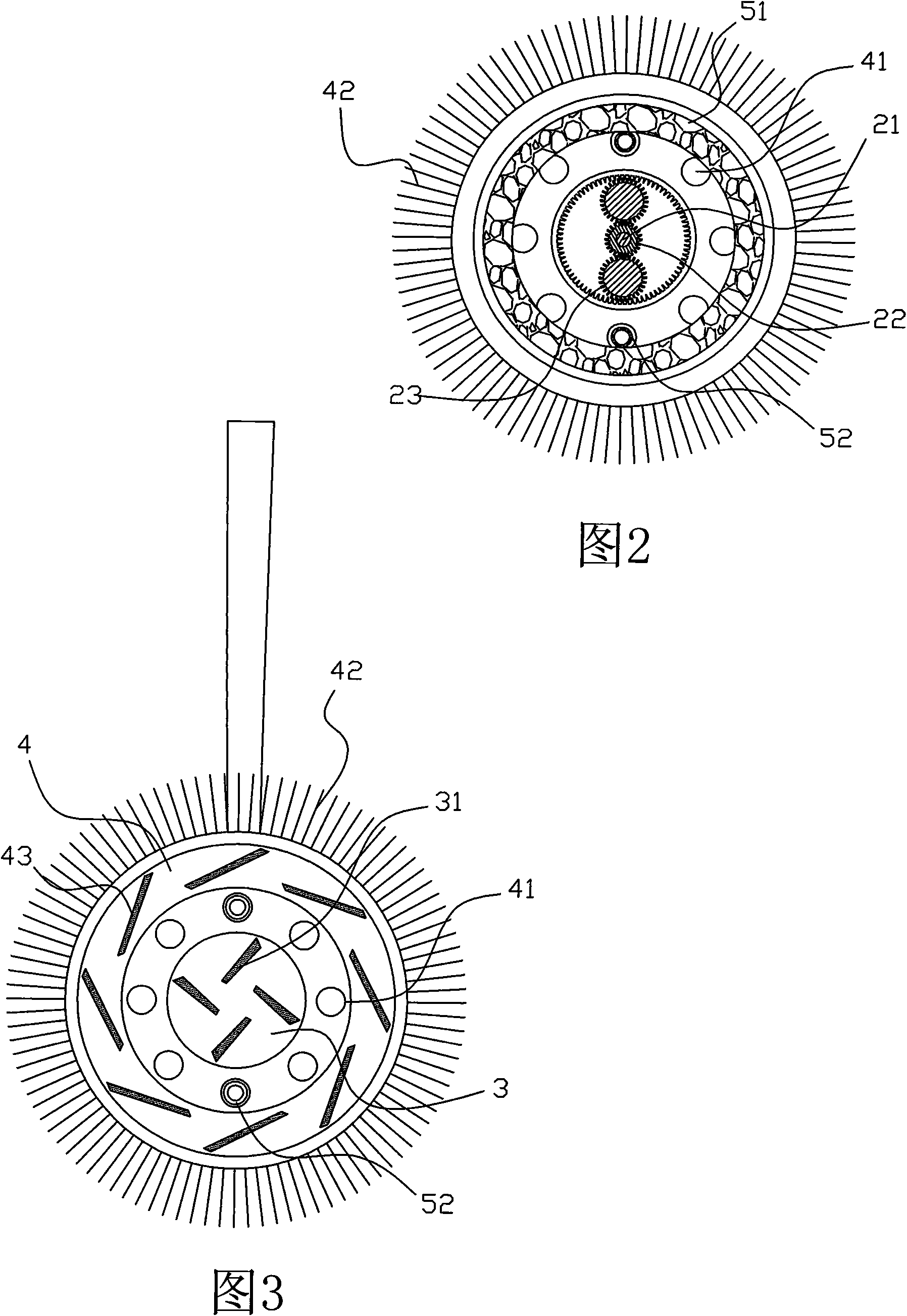

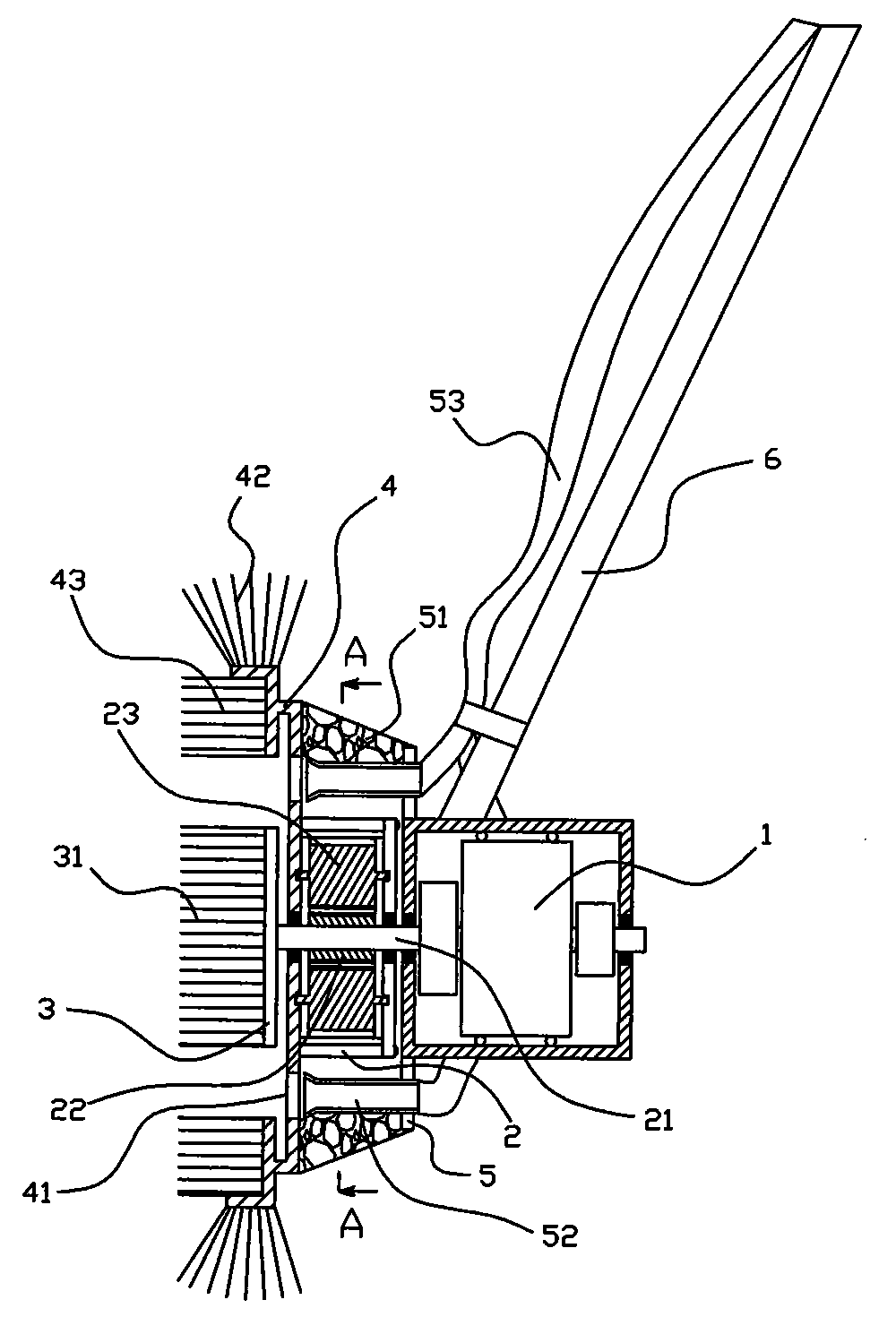

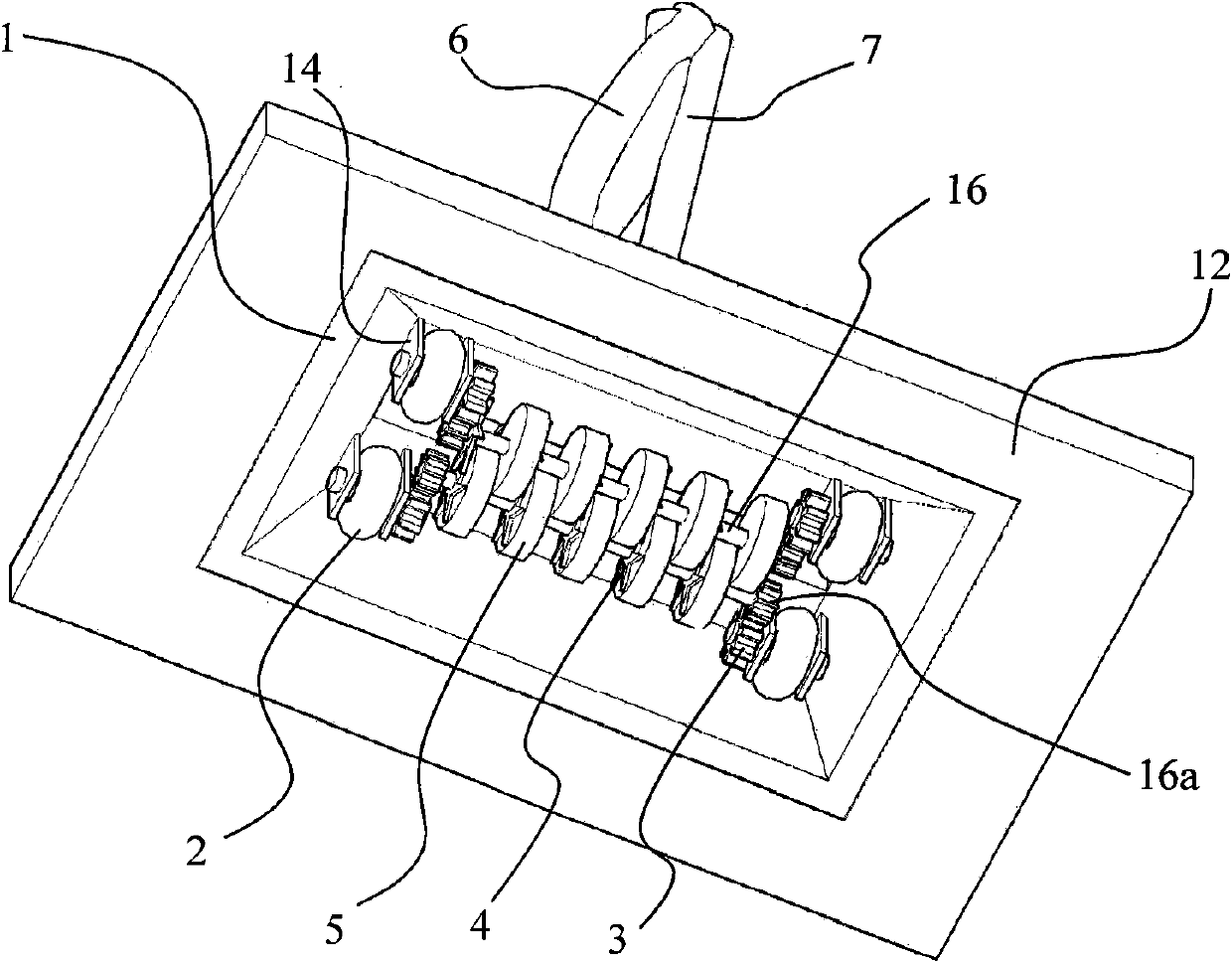

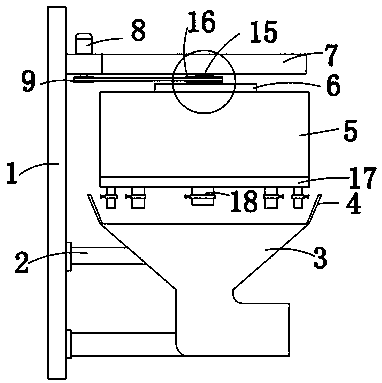

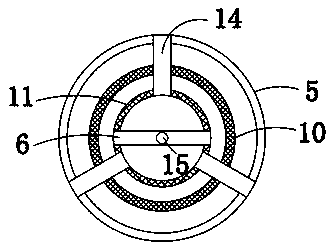

Electric sewage suction device for factory farming

InactiveCN101933490AEasy to operateShould not be blockedPisciculture and aquariaElectric machineryGear system

The invention discloses an electric sewage suction device for factory farming. A water-proof motor is connected with an outer turntable through a rotating shaft; the outer turntable is provided with a gear hood; a planet gear system is arranged in the gear hood; the free end of the rotating shaft is connected with a central turntable; the planet gear system ensures that the central turntable and the outer turntable rotate oppositely; the central turntable is provided with at least three radial inner brushes; the outer turntable is provided with at least six radial outer brushes, and a gap between the outer brush and the inner brush is at least 5cm; and part of the outer turntable on the inner side of the outer brush is provided with at least six central symmetric sewage holes. The side surface of the water-proof motor is connected with a ring-shaped outer cover sheet. The outer edge of the outer cover sheet is provided with a flexible catch, the opening of which is matched with the outer turntable in a sliding way; the outer cover sheet is also provided with a sewage conduit, the nozzle of which is close to the sewage hole; and the tail end of the sewage conduit is connected with a siphon fixed on a handle. The side surface of the outer turntable is provided with a protecting brush and other structures. The electric sewage suction device has the advantages of convenient operation, no block, high sewage suction efficiency and small damage to farmed population.

Owner:ZHEJIANG OCEAN UNIV

Non-contact dustless sweeping vehicle

A non-contact dustless sweeping vehicle includes a blow-suction device and a dust collector. The vehicle is characterized in that the dust collector is fixed on a fixed platform; the blow-suction device is fixed on the fixed platform; an air inlet of the blow-suction device is connected with an air outlet of the dust collector; an air outlet of the blow-suction device is connected with an air inlet of the dust collector. The vehicle has advantages that no ground-contact-type mechanical sweeping device is needed when the sweeping vehicle is used for sweeping and no water spraying is needed; the ground can be cleaned completely, no dust rising is caused and no secondary pollution is caused. Besides, a filter net of the sweeping vehicle is not easy to get blocked by dust, so that cleaning maintenance is reduced and the dust removal effect is good. Air after dust removal can be recycled in use and serves as an air source blowing air to the ground in a directional manner.

Owner:康海增

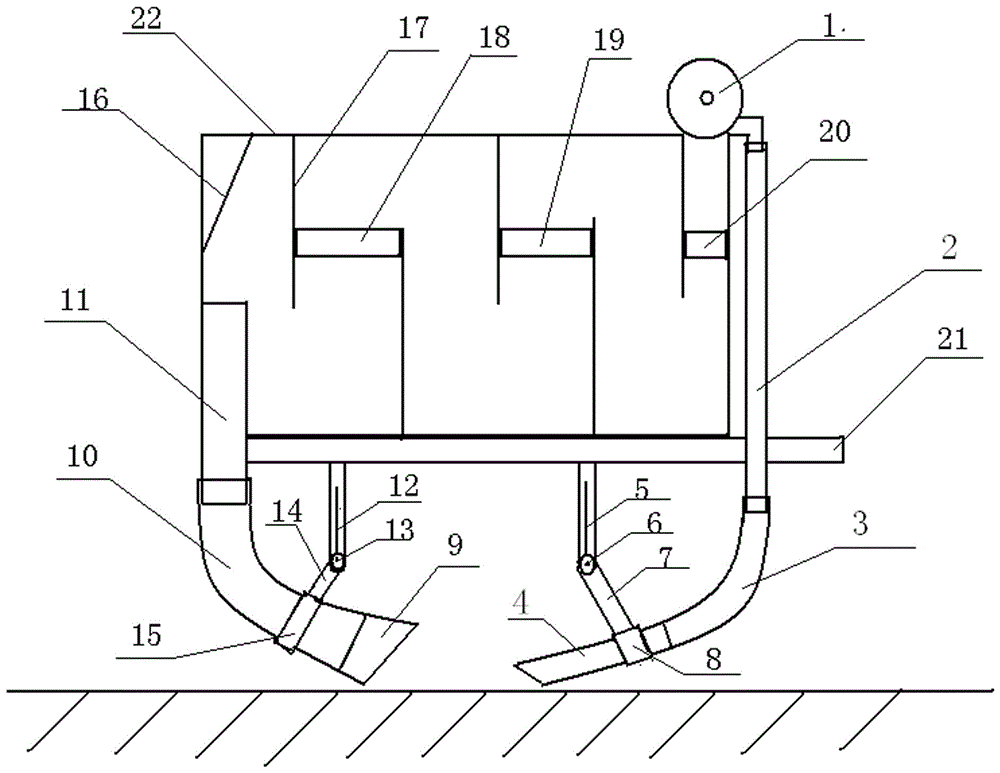

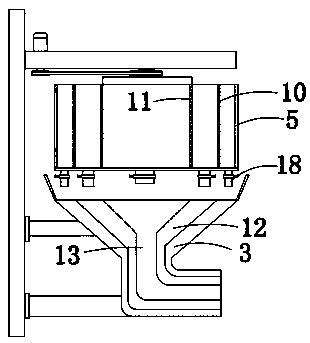

Industrialized culture energy-saving filth suction device

The invention discloses an industrialized culture energy-saving filth suction device which adopts a sunken cover body structure. A diversion groove is arranged in the middle part of the sunken structure; at least one through hole penetrates through the top part of the cover body, and the top part of the cover body is connected with a siphon arranged outside; at least three roller brackets are made in the cover body, and a roller is installed on each roller bracket; each roller is connected with a drive gear; two rolling shafts are installed in the cover body, and a hob and a filth cleaning brush are arranged on each rolling shaft alternately; a driven gear is installed near the end of each rolling shaft and is meshed with the drive gear; and structures, such as a protective body and the like, are arranged outside the cover body. The invention has the advantages of convenient operation, difficult blocking, high filth suction efficiency, little damage to a cultured object and energy saving and can pre-crush filth to reduce the particle size of the filth under the drive of manpower before filth is sucked into a pipeline.

Owner:ZHEJIANG OCEAN UNIV

Self-drying glass ink and preparation thereof

InactiveCN101412864AShould not be blockedReduce the frequency of cleaning the screenInksPolymer scienceEthylene glycol monoethyl ether acetate

The invention discloses a self-drying glass ink and a preparation method thereof. The self-drying glass ink comprises the following compositions in weight portion: 8 to 16 portions of gulf red nanometer paint, 15 to 20 portions of gulf red micron paint, 60 to 75 portions of modified splicing material, 0.5 to 1.5 portions of unsaturated carboxylate, 0.8 to 1.8 portions of modified polyacrylic ester, 0.8 to 3 portions of modified acrylic polymer, 0.5 to 1 portion of modified polydimethylsiloxane, 1 to 3 portions of modified microcrystalline polyethylene, 0.2 to 1 portion of 3-glycidol triethoxypropylsilane and 8 to 14 portions of ethylene glycol monoethyl ether acetate. The preparation method comprises the procedures of paint preparation, mixing and ink preparation. Compared with the prior art, the method adopts a nanometer level paint filler in order that the ink is uneasy to block meshes, reduces the times for cleaning a net, improves production efficiency, has good adhesive force and erosion resistance and high hardness, and does not need to roast.

Owner:芜湖力特尔涂料制造有限公司

Water-resistant abrasive base paper and production method thereof

ActiveCN105297526AGood waterproof and oil-proof performanceImprove toughnessWater-repelling agents additionPaper coatingSolventPaper sheet

The invention discloses water-resistant abrasive base paper and a production method thereof. The water-resistant abrasive base paper is prepared from the following raw materials in parts by weight: 32-35 parts of softwood pulp fibers, 32-35 parts of hardwood pulp fibers, 5-10 parts of polyester fibers, 10-15 parts of modified thermoplastic resin, 3-5 parts of a water-proofing agent and 3-5 parts of an oil-proofing agent. The preparation method comprises the following steps: (1) mixing, crushing, pulping and repulping the softwood pulp fibers, the hardwood pulp fibers and the polyester fibers in parts by weight; (2) starching by a fourdrinier machine; (3) molding and drying a paper sheet on the fourdrinier machine, and carrying out gumming treatment once online, wherein the glue quantity is 10%-15%; (4) after drying the glue obtained in the step (3), carrying out secondary gumming on the front surface of the paper sheet, wherein the glue quantity is 6%-10%; and (5) calendaring the paper sheet which is gummed for the second time in the step (4) by a soft calendar. The Water-resistant abrasive paper prepared from the water-resistant abrasive base paper has the advantages of good waterproofness, softness, solvent resistance, dimension stability, high dry strength, good high temperature resistance and good weathering resistance.

Owner:SHANDONG LUNAN NEW MATERIALS

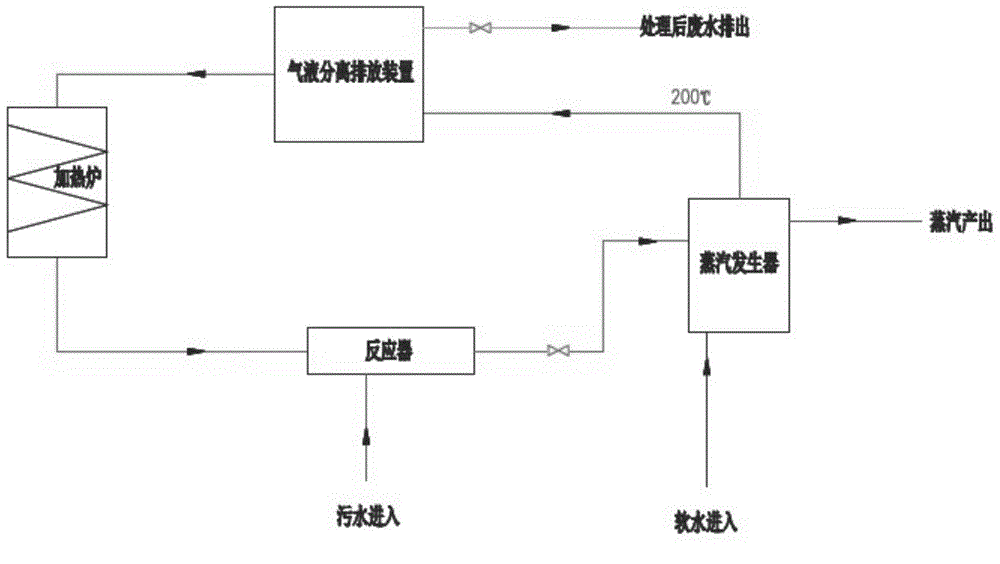

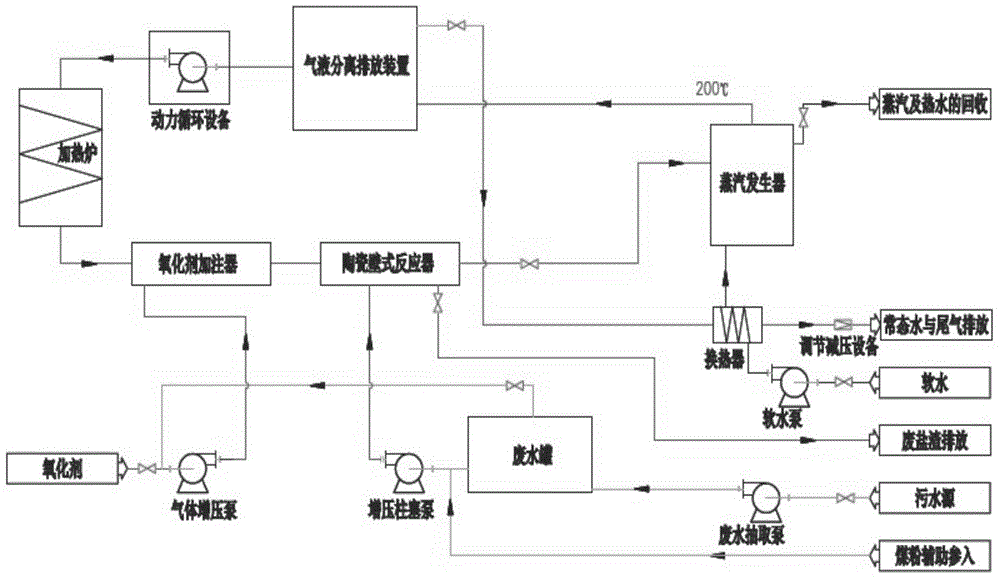

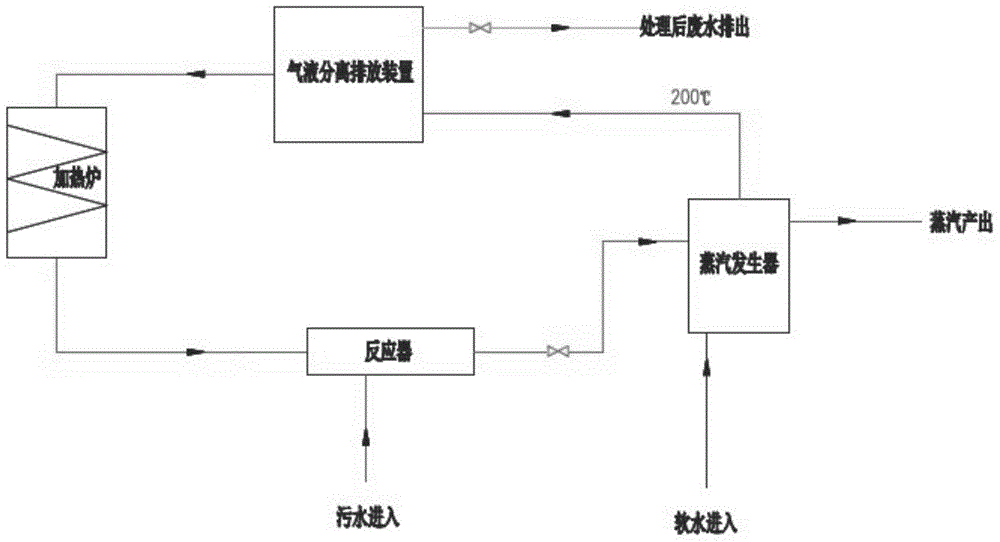

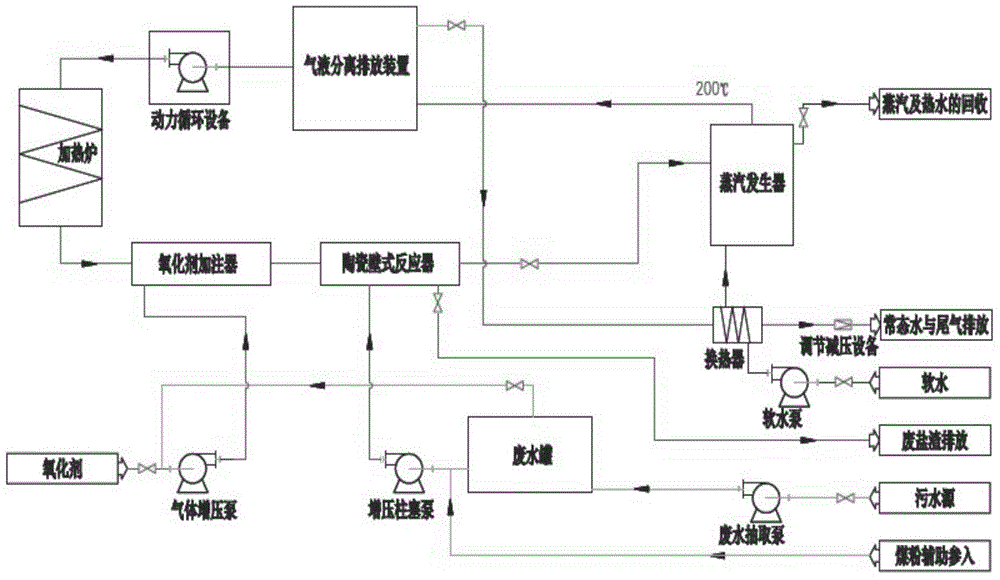

Process for waste oxidation treatment and steam co-production by using supercritical circulating water

ActiveCN103553202AReduce excess spaceShorten the timeSteam generation using hot heat carriersWater/sewage treatment by oxidationInorganic saltsChemical oxygen demand

The invention provides a process for waste oxidation treatment and steam co-production by using supercritical circulating water. A treatment system is a circulating treatment system. The process comprises the steps of filling circulating water into a supercritical circulating water oxidation treatment system, heating the circulating water in a heating device, driving the circulating water to circularly operate in the system, and controlling the temperature to be raised to 395-450 DEG C and the pressure to be higher than 22.1Mpa; inputting sewage and an oxidizing agent to a reactor, and enabling the sewage and the oxidizing agent to react in a supercritical state; enabling the water after reacting to enter a steam generator for heat recovery, and outputting steam; carrying out gas-liquid separation on the water subjected to heat exchange through the steam generator, and discharging inorganic salt gas and a part of water; inputting the other part of water after gas-liquid separation as the circulating water to the heating device. In the process, the sewage is up to the supercritical state through being mixed with the circulating water, a sewage preheating device in traditional sewage treatment is omitted, and the sewage with a high-concentration COD (Chemical Oxygen Demand) value can be directly treated.

Owner:NANJING TECH UNIV

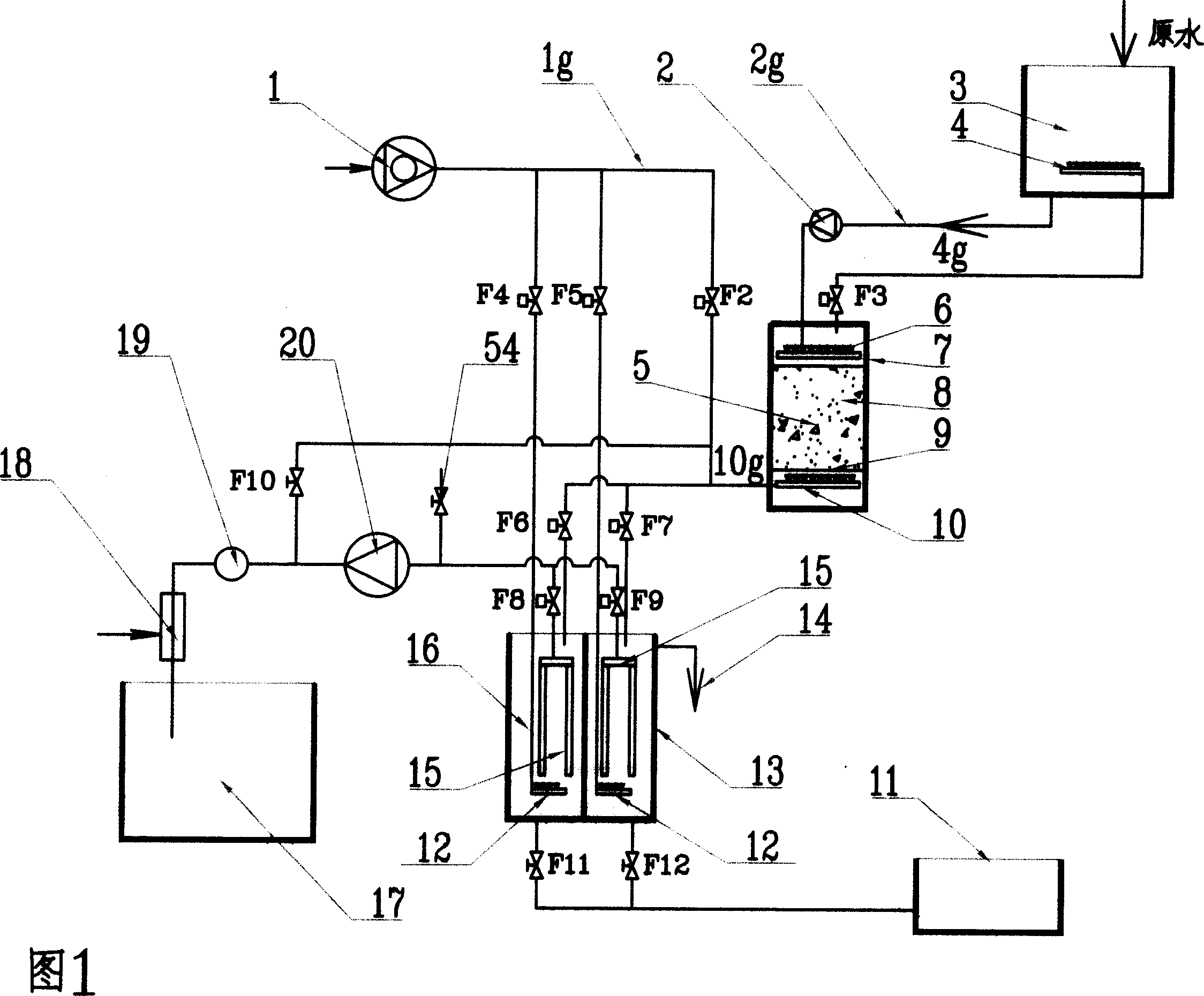

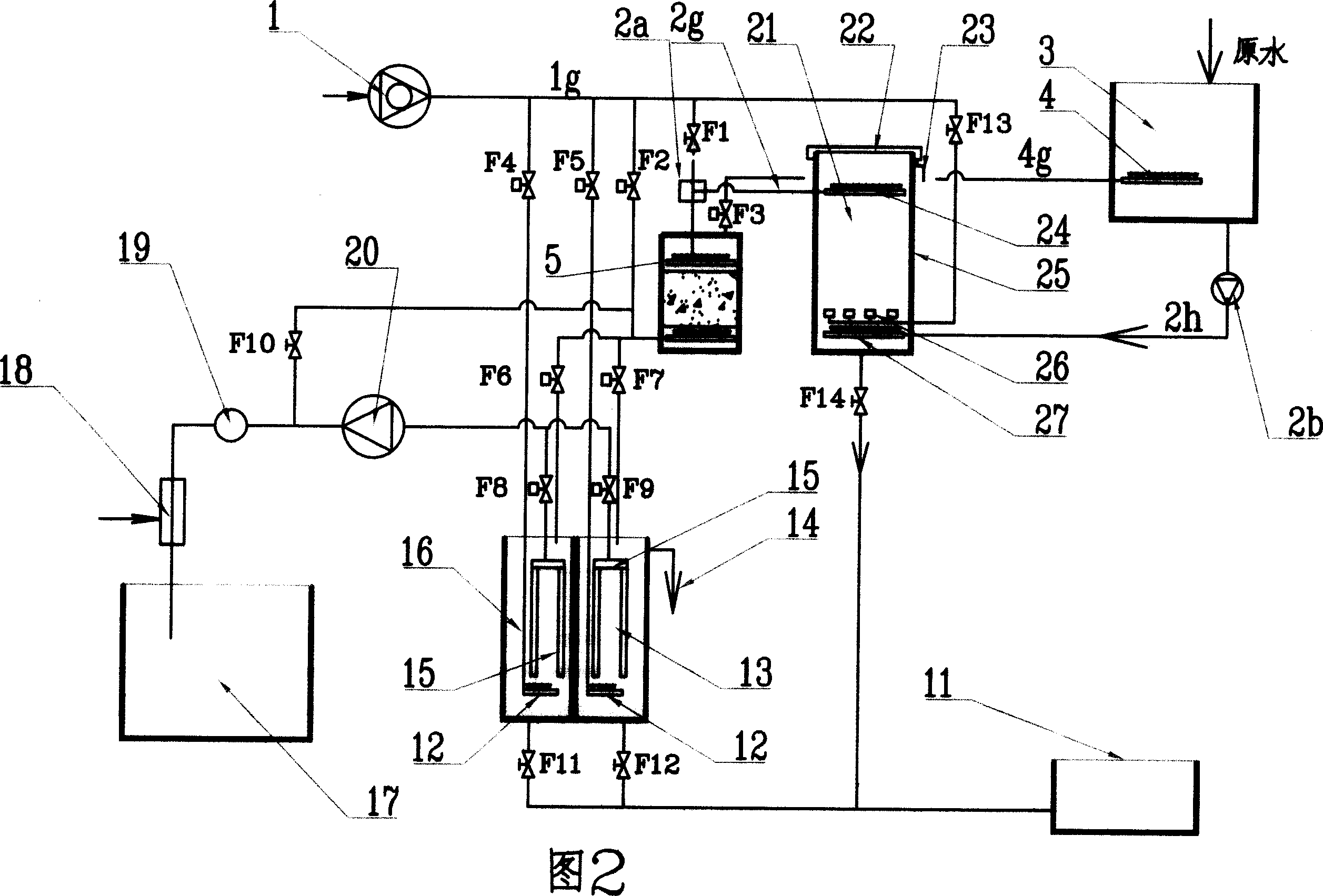

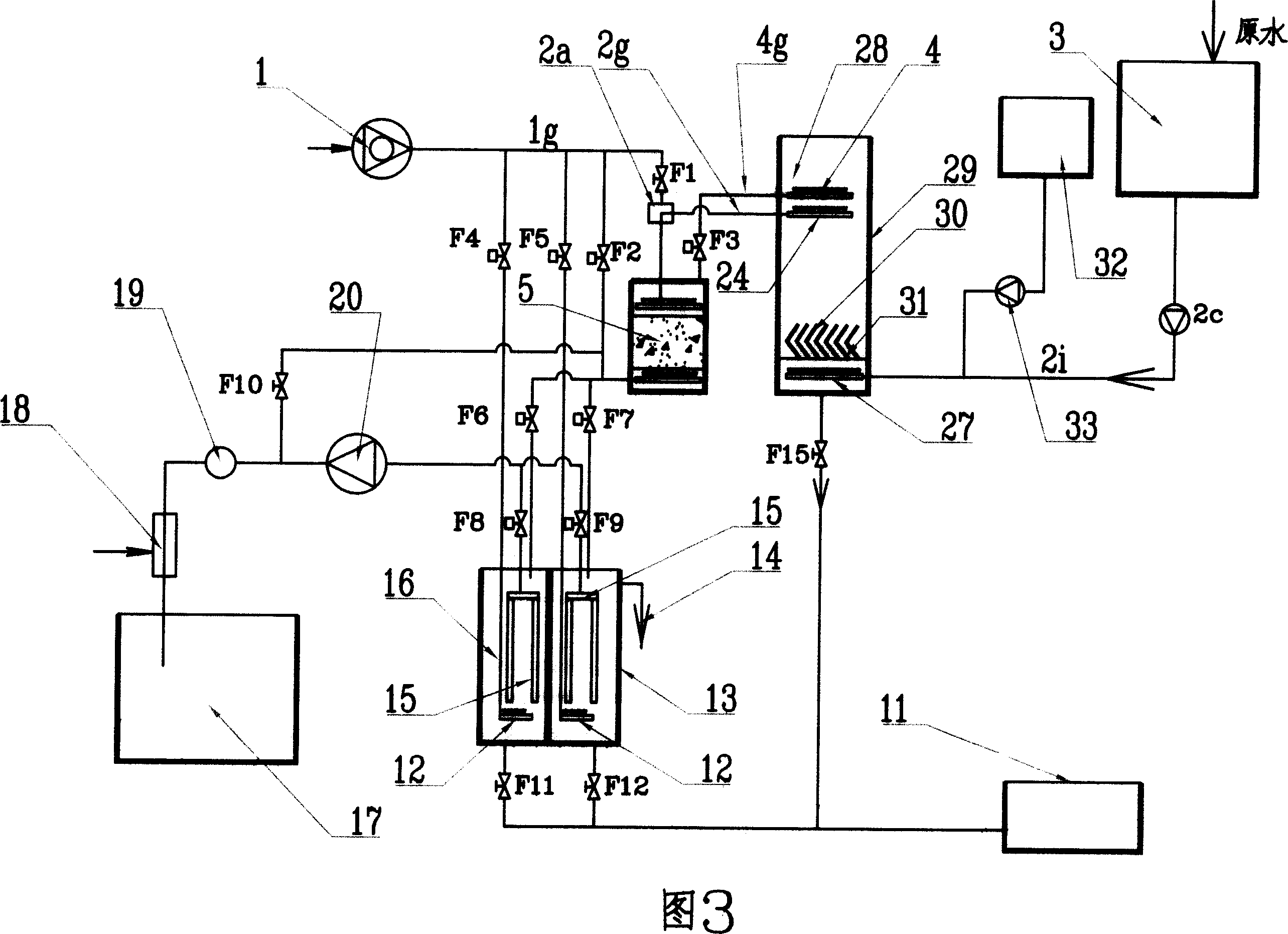

Separator and immersion membrane bioreactor combined water purifying device and system

InactiveCN101033107AAvoid stickingImprove anti-pollution performanceMultistage water/sewage treatmentWaste water treatment from bathing facilitiesFiberAeration system

This invention relates to a clean water device and a system including an immerged film bio-reactor, water, an aeration system, a separator, a technics flow and pipelines, a water safeguarding system, a chemical flush system and a program control system, in which, at least a separator is connected between an original pump of an adjusting basin and the original pipe of the reaction basin of the immerged film bio-reactor, which is suitable for poor water quality with many combos of oil and waste-soap solution with humanbody fat in particular and increases the ability of anti-pollution of the immerged hollow fiber film bio-reactor, and this filter separator can be taken as a generator for collecting and growing biochemical films.

Owner:天津市石化通用机械研究所有限公司 +1

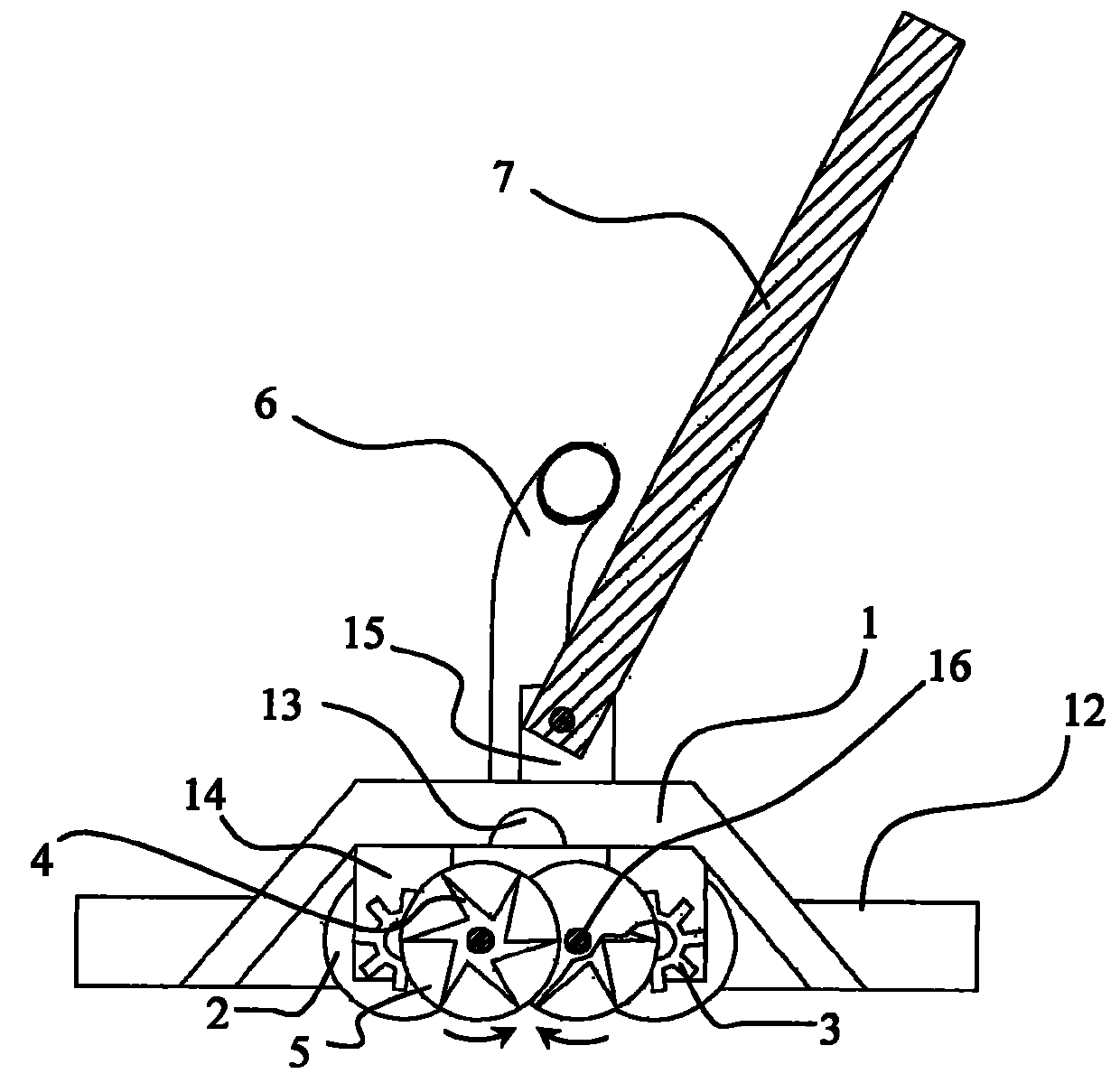

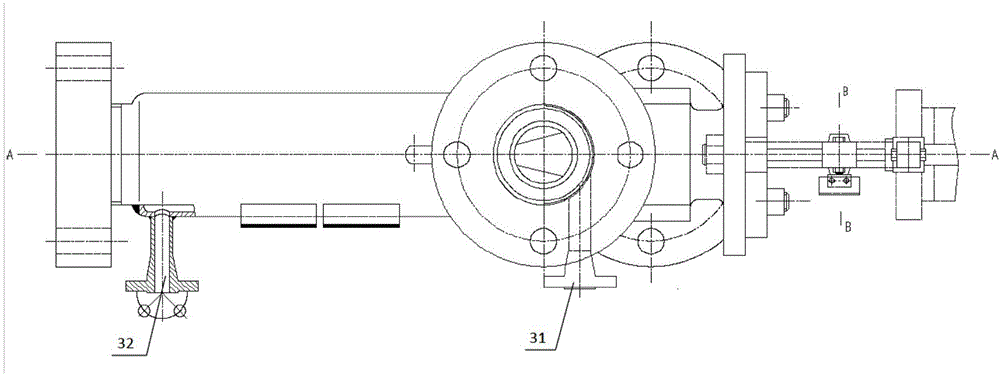

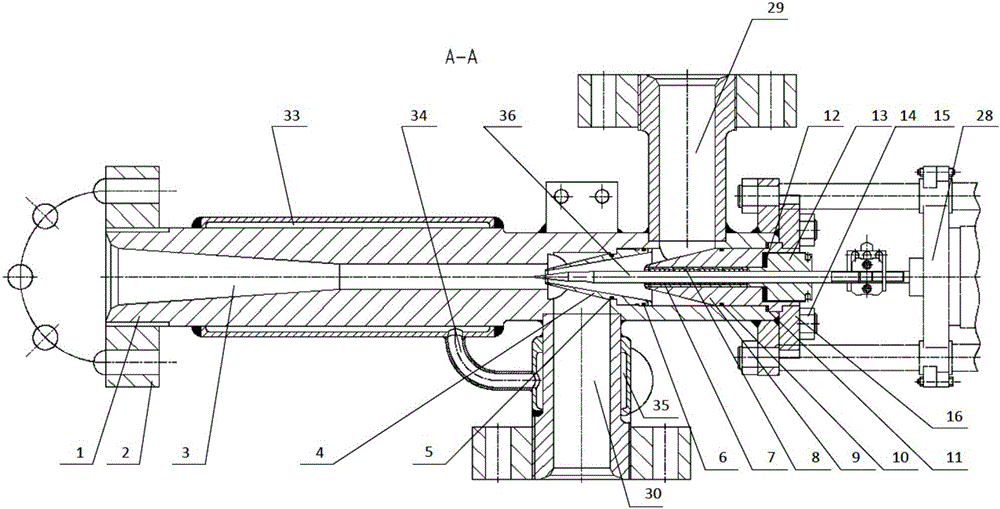

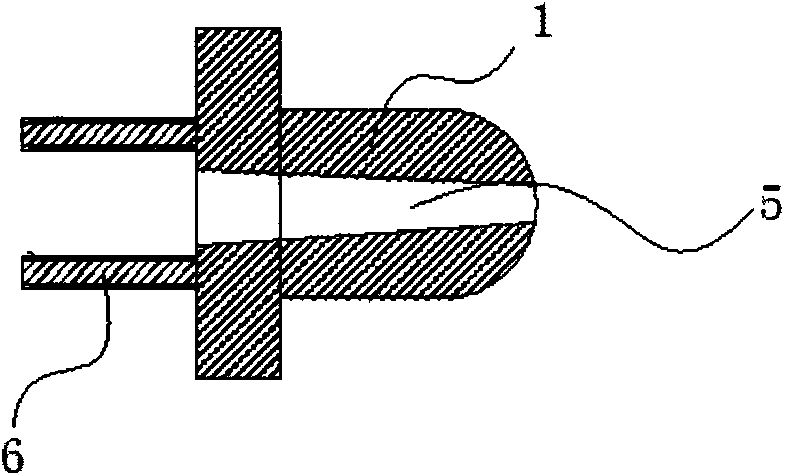

Pneumatic atomizing nozzle with function of adjusting sizes of atomizing particles

The invention provides a pneumatic atomizing nozzle with the function of adjusting the sizes of atomizing particles. The pneumatic atomizing nozzle comprises a nozzle body. An air inlet and a liquid inlet are formed in the outer side of the nozzle body. A tapered nozzle orifice is formed in one end of a hollow cavity of the nozzle body. The aperture of the tapered nozzle orifice is increased from inside to outside. A cylindrical cavity is formed in the middle of the nozzle body. A tapered spray nozzle and a tapered bushing are sequentially arranged at the other end of the hollow cavity. A part between the outer part of the tapered spray nozzle and the inner wall of the nozzle body is sealed. A cavity between an outer taper surface of the tapered spray nozzle and the inner wall of the hollow cavity communicates with the liquid inlet. A cavity defined by the inner taper surface of the tapered spray nozzle, the inner wall of the hollow cavity and the outer side of the tapered bushing communicates with the air inlet. A part between the tapered bushing and the inner wall of the hollow cavity is sealed. A cylindrical through hole is formed in the center of the tapered bushing. A core shaft capable of moving in the axial direction to adjust the size of an air outlet of the tapered spray nozzle is arranged in the cylindrical through hole through a bushing and a sealing sleeve. A fastening sleeve is mounted on the core shaft to fix the bushing in the axial direction. A gland, which has an axial pressing effect, is arranged on the end surface of the tapered bushing. According to the pneumatic atomizing nozzle provided by the invention, the air spraying rate is adjusted by adjusting the core shaft so as to adjust the sizes of sprayed liquid drops. The pneumatic atomizing nozzle is suitable for various productions.

Owner:厦门精世环保科技有限公司

System for wastewater oxidation treatment by using supercritical circulating water

InactiveCN103553254AReduce excess spaceShorten the timeMultistage water/sewage treatmentChemical oxygen demandSewage

The invention provides a system for wastewater oxidation treatment by using supercritical circulating water. The system comprises a heating device, a reactor, a steam generator and a gas-liquid separation device which are sequentially connected end to end through pipelines to form a circulating treatment system, wherein the heating device is used for heating circulating water. In the system, the heating device is used for heating the circulating water to promote the whole treatment process to operate, sewage is up to a supercritical state through being mixed with the circulating water, a sewage preheating device in traditional sewage treatment is omitted, and the sewage with a high-concentration COD (Chemical Oxygen Demand) value can be directly treated.

Owner:NANJING TECH UNIV

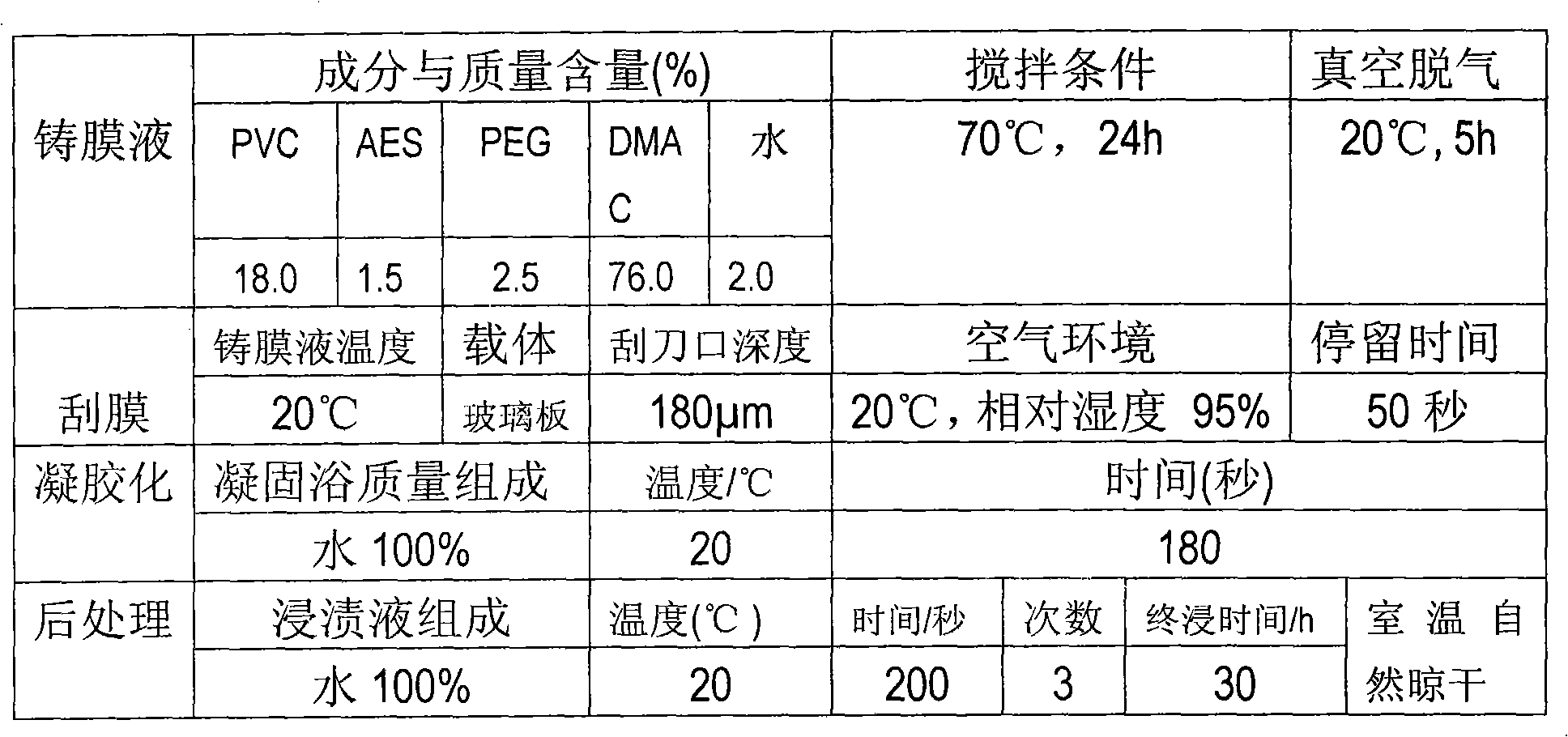

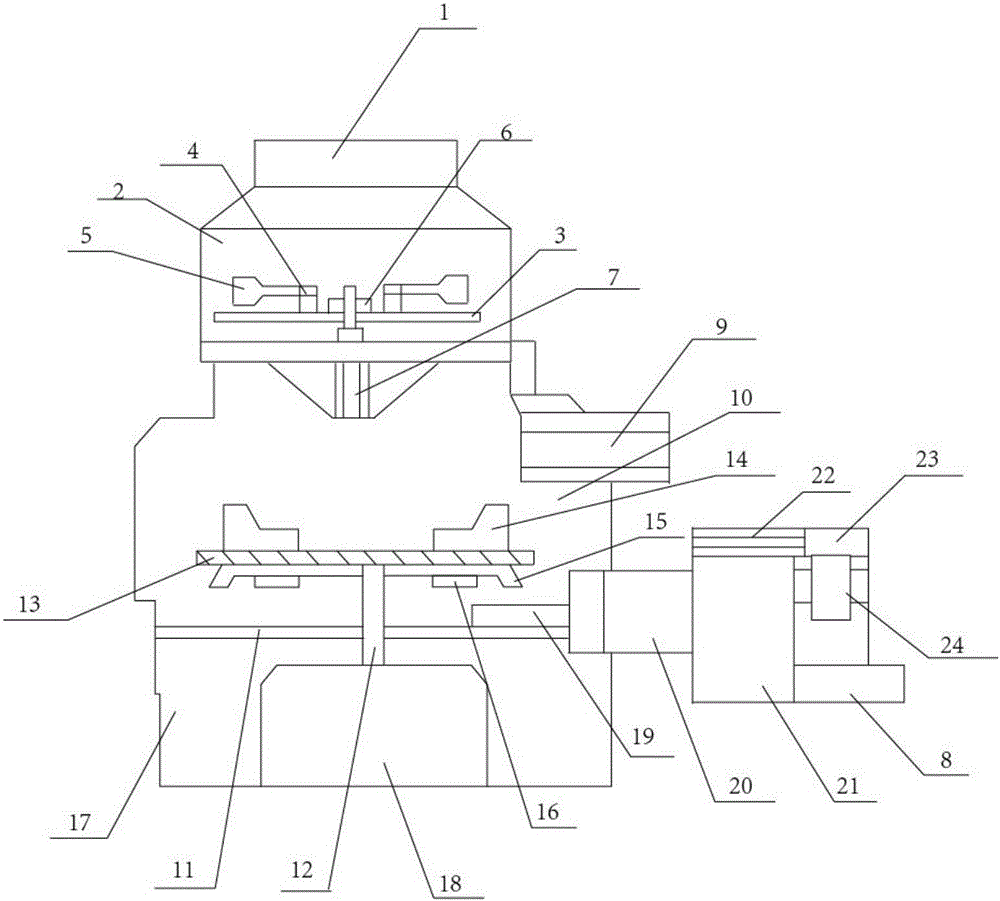

Preparation method of non-woven fabric or weaving cotton cloth supporting ultra-filtration/micro-filtration composite membrane

The invention relates to a preparation method of a non-woven fabric or weaving cotton cloth supporting ultra-filtration / micro-filtration composite membrane, belonging to the field of membrane materials; the preparation method comprises the following steps of: preparing a casting membrane solution by using PVC (PolyVinyl Chloride) as a main raw material, scraping a primary supporting liquid membrane on a non-woven fabric or a weaving cotton cloth, gelating the primary supporting liquid membrane in a solidifying liquid, washing and leaching, and finally drying into finished products. The composite membrane prepared by the method is finger-shaped on the surface; one side of the interior of the membrane, which is close to a supporting layer, is a high asymmetrical hole structure with spongy holes; the supporting membrane is reversible in terms of dry and wet, is not easy to block, has high bursting strength and excellent soiling resistance and is easy to wash reversely and regenerate; bore diameters are in the range of 0.01mum to 1.0mum and can be adjusted; and therefore, the non-woven fabric or weaving cotton cloth supporting ultra-filtration / micro-filtration composite membrane is suitable for secondary filter, recycled water treatment, cartridge filtration before RO (Reverse Osmosis), terminal secondary filter, direct drinking filtration of running water, sewage treatment and liquid purification and filtration.

Owner:天津市宝钜净化设备工程有限公司

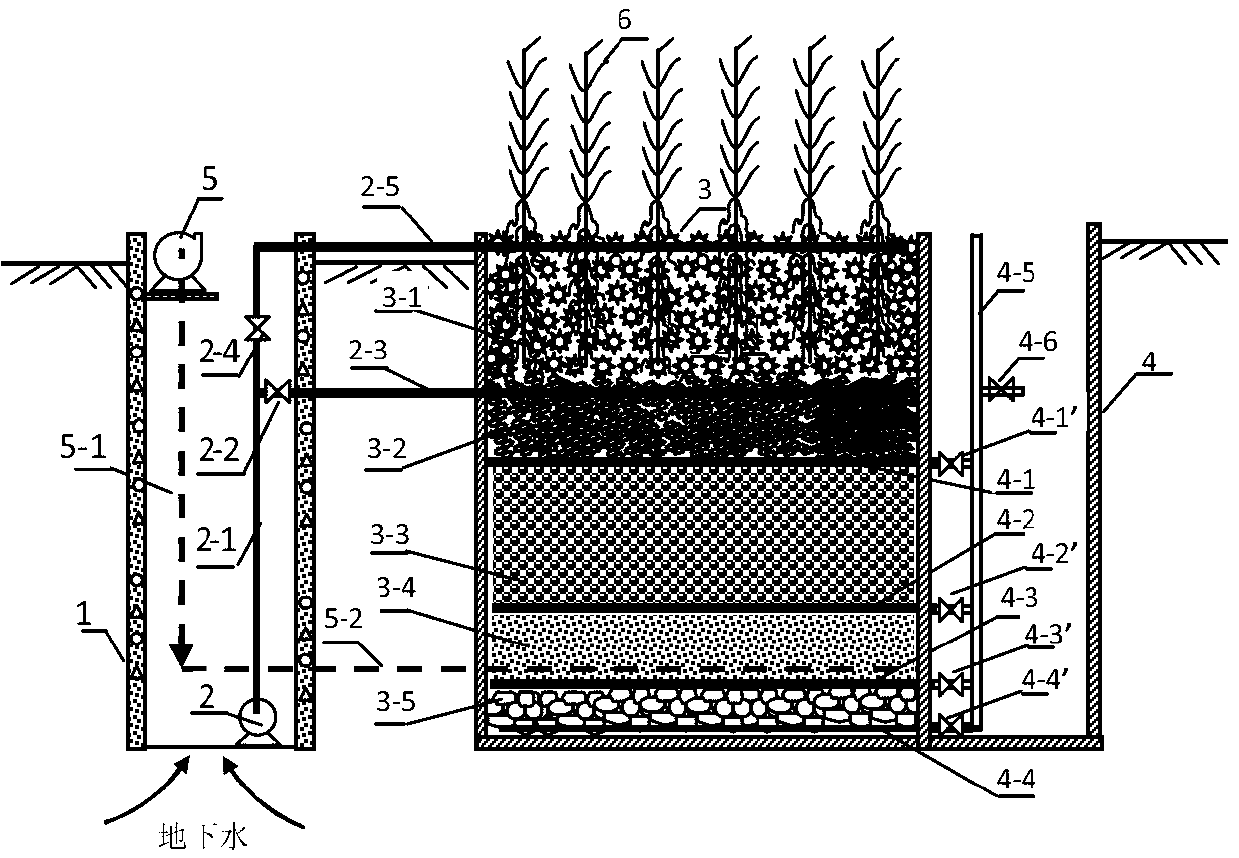

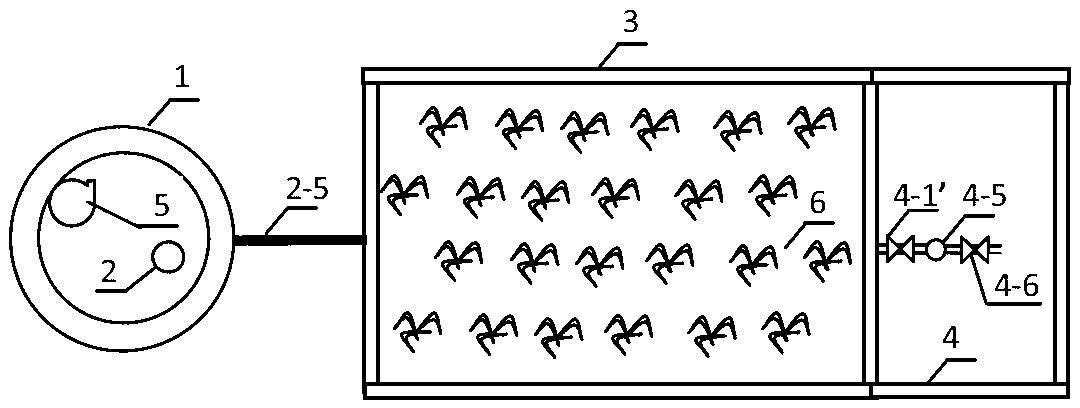

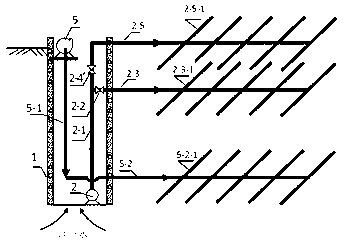

Constructed wetland system for treating high-concentration nitrate nitrogen in groundwater efficiently

ActiveCN103145304AAchieve removalLow running costWater contaminantsMultistage water/sewage treatmentInsulation layerSmall footprint

The invention relates to a constructed wetland system for treating high-concentration nitrate nitrogen in the groundwater efficiently and belongs to the field of groundwater pollution control. The constructed wetland system is used for removing the high-content NO3<-1>-N which is a pollutant in the groundwater and recycling source water. The polluted groundwater is accumulated in a water well, surface water distribution main and branched pipes or deep water distribution main and branched pipes are uniformly in the constructed wetland by using a submersible pump according to the change of seasons, and the NO3<-1>-N in the groundwater is removed under the physical, chemical and biological actions of the soil layer, the heat insulation layer, the NO3<-1>-N conversion layer, the ion-exchange biological layer and the water accumulation layer in the constructed wetland. In winter, by filling nitrogen into the constructed wetland and adjusting the water outlet amount of the water collection well, the multifunctional composite fillers in the constructed wetland fully play a role of reducing the NO3<-1>-N and the microorganisms in the constructed wetland fully play a role of nitrifying and decomposing the NH3<-1>-N. The constructed wetland system provided by the invention is compact in structure, high in treatment efficiency and low in operation cost, occupies a small land area, can operate stably, is free from blocking, can not cause secondary pollution and ensures that the quality of the treated water completely meets the requirement of the quality of the source water.

Owner:BEIJING JIAOTONG UNIV

Asymmetrical polyvinyl chloride dry-wet reversible ultrafiltration/microfiltration membrane, preparation method and application thereof

The invention relates to an asymmetrical polyvinyl chloride dry-wet reversible ultrafiltration / microfiltration membrane, a preparation method and application thereof, which belong to the field of polymer microporous membranes. The asymmetrical polyvinyl chloride dry-wet reversible ultrafiltration / microfiltration membrane is prepared by the following steps of: striking membrane casting liquid which is prepared from polyvinyl chloride (PVC) serving as a major raw material on a carrier substrate so as to obtain an initial liquid producing membrane; gelling in coagulating liquid consisting of a mixed solvent; washing with water and soaking; and drying so as to obtain a finished membrane. The PVC ultrafiltration / microfiltration membrane prepared by a method has a finger-shaped structure on the surface, highly asymmetrical spongy porous structures on a mold stripping side and inside the membrane, has reversible dryness and wetness membrane performance and high stain resistance, is blocked difficultly, is easy to clean and regenerate, has a pore diameter which is adjustable between 0.01 and 1.0 mu m, is suitable for precision filtration, recycled water treatment, R0 pre-cartridge filtration, terminal precision filtration, tapped water direct drinking filtration, sewage treatment and liquid purification and filtration.

Owner:天津市宝钜净化设备工程有限公司

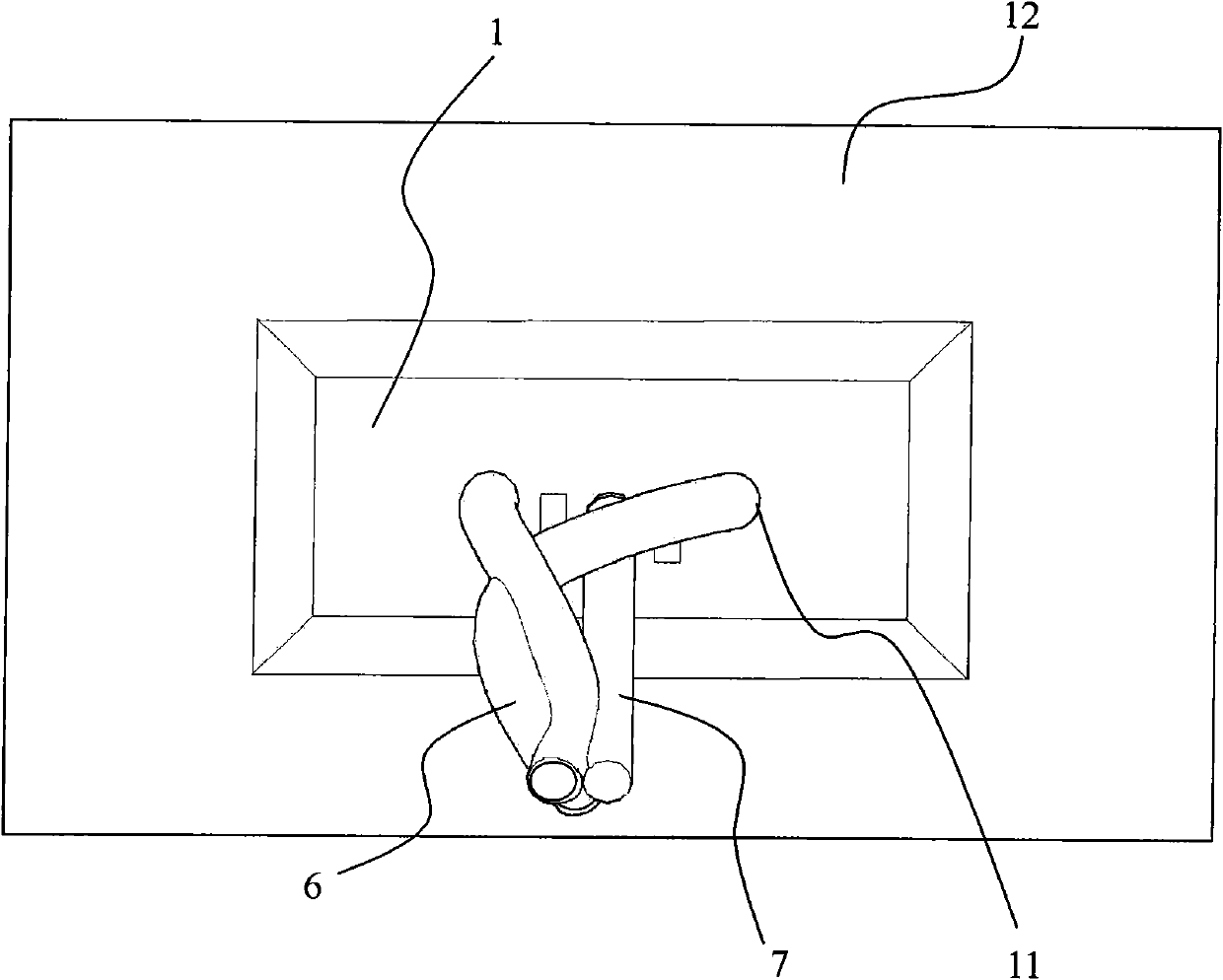

Kitchen waste treatment device

InactiveCN106111280AReduce energy consumptionImprove processing efficiencyGrain treatmentsRadiationMicrowaveDrive motor

The invention discloses a kitchen waste treatment device. The kitchen waste treatment device comprises a feeding port, a first grinding cavity, a cutter head, hinge shafts, crushing beat blocks, a drive device, a discharging port, a second discharging pipe, a protection cover, a second grinding cavity, a transverse partition plate, a connecting rotary shaft, a grinding disc, rotation impact heads, a pushing cutter bit, guiding blocks, a motor cavity, a drive motor, a guiding plate, a first discharging pipe, a microwave sterilizing cavity, a heating pipe, a control device and a microwave generation device. The first grinding cavity is formed in the lower end of the feeding port. The cutter head is arranged in the first grinding cavity. The drive device is arranged at the upper end of the cutter head and fixedly connected with the cutter head. The crushing beat blocks are arranged on one side of the drive device and connected with the cutter head through the hinge shafts. The discharging port is formed in the lower end of the cutter head, and formed in the second grinding cavity. The kitchen waste treatment device has the beneficial effects that blockage is not likely to happen, safety and sterility are achieved, and cost is low.

Owner:霍普科技(天津)股份有限公司

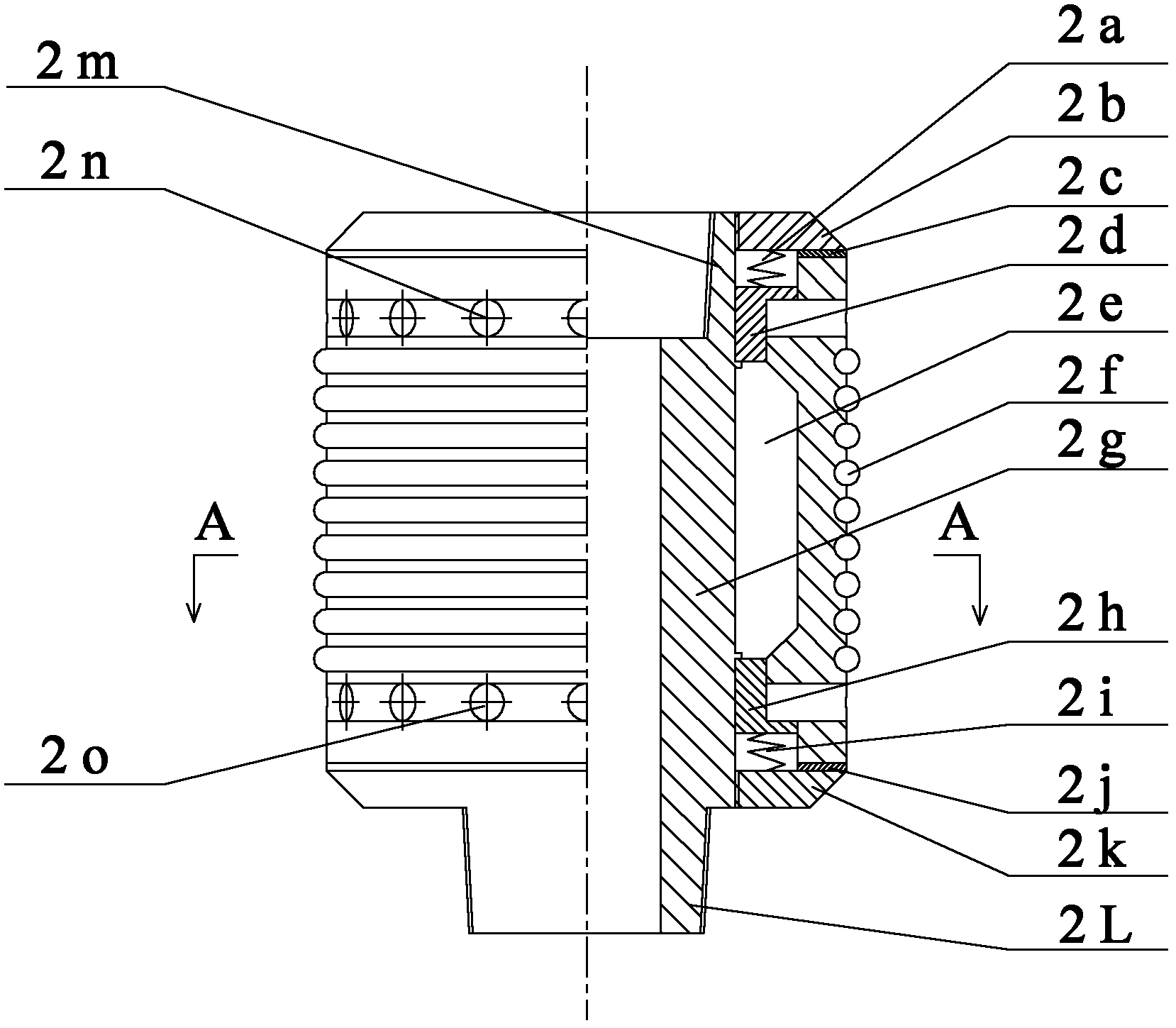

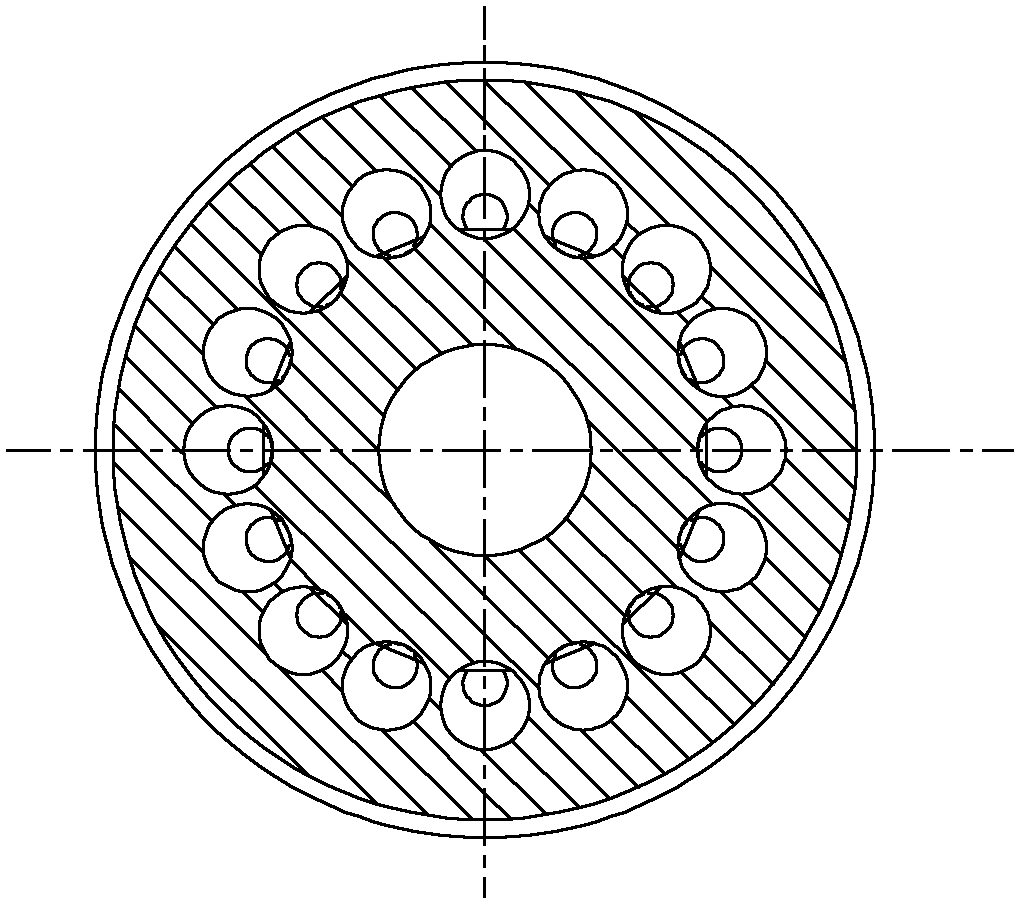

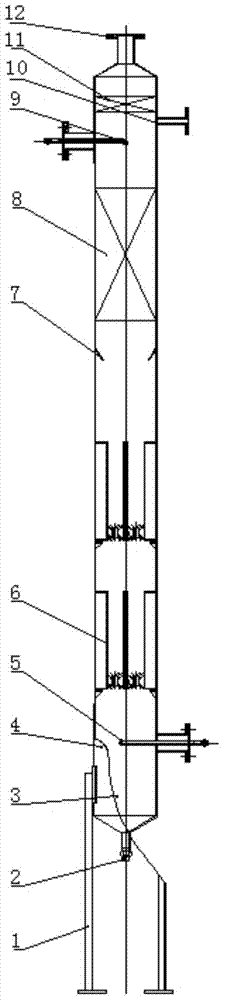

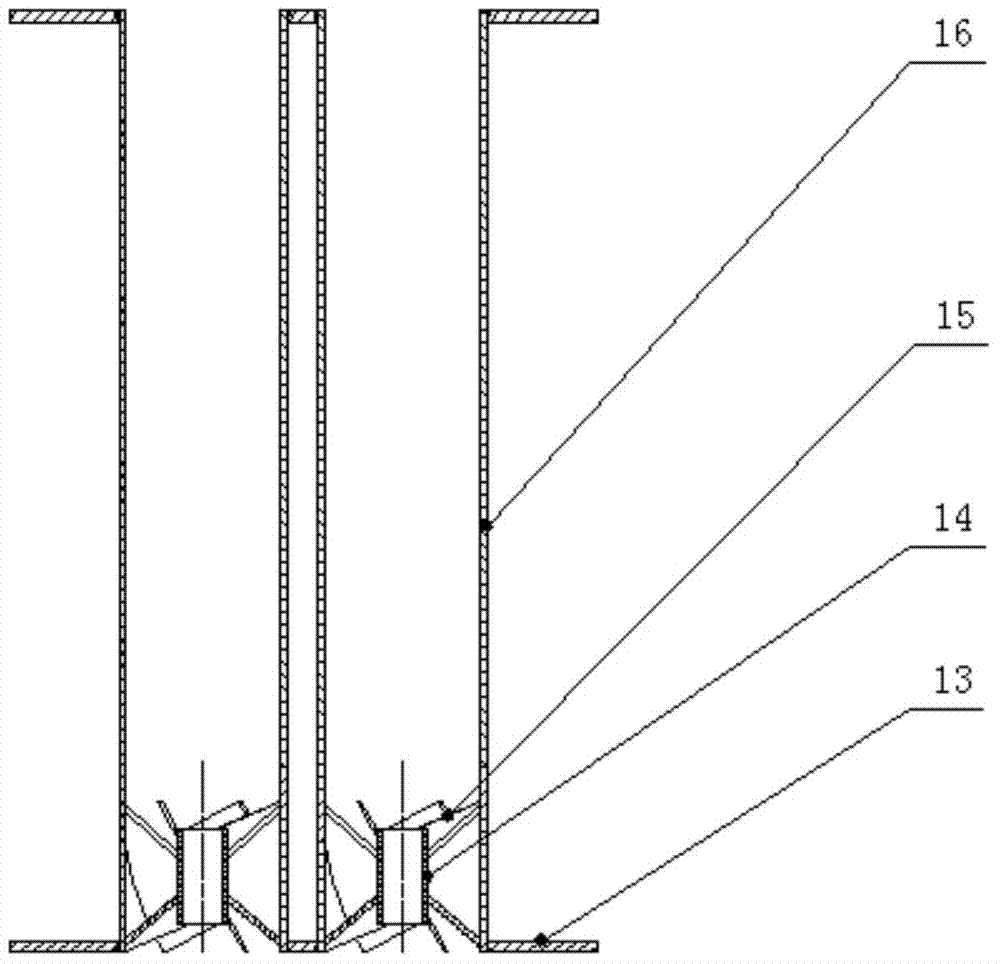

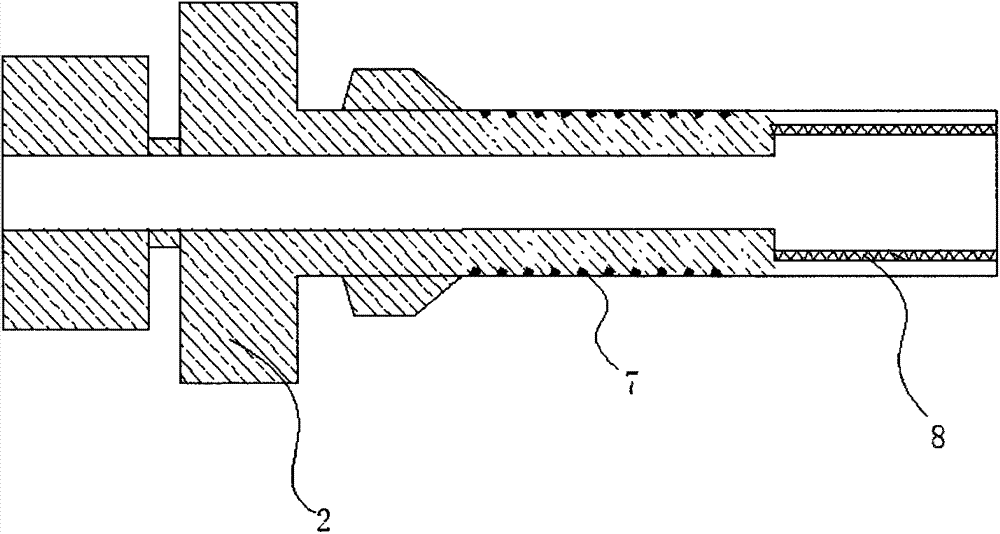

Two-stage two-section separate-injection pipe column capable of back-flushing well and protected by insert seal sleeve and separate-injection method of two-stage two-section separate-injection pipe column

The invention provides a two-stage two-section separate-injection pipe column capable of back-flushing a well and protected by an insert seal sleeve and a separate-injection method of the separate-injection pipe column. The separate-injection pipe column comprises an insert sealer (2), a sleeve prefabricated sealing cylinder (3), a first-stage water injection layer section (14), and the like; the sleeve prefabricated sealing cylinder (3) is arranged on the upper part of the top boundary of the first-stage water injection layer section (14); a sleeve prefabricated sealing cylinder (6) is arranged between the first-stage water injection layer section (14) and a second-stage water injection layer section (15); the sleeve prefabricated sealing cylinder (6) is simultaneously arranged between a water distributor (4) and a water distributor (7); the insert sealer (2) is arranged in the middle of the sleeve prefabricated sealing cylinder (3); and an insert sealer (5) is arranged in the sleeve prefabricated sealing cylinder (6). With the adoption of the separate-injection pipe column, the channeling phenomenon is effectively avoided, the successful ratio of removing sand blockage is high, and the successful ratio of drop-dipper measuring and dosing is high; and the pipe column has high adaptability to the a high-temperature and high-pressure deep deflecting well with high water injection pressure and obvious difference between layers and is long in period of validity.

Owner:PETROCHINA CO LTD

Treatment method applied to chemical industrial wastewater

InactiveCN106007207ASolve processing problemsReduce the content of harmful substancesWater treatment parameter controlTreatment using aerobic processesHazardous substanceTherapeutic effect

The invention discloses a treatment method applied to chemical industrial wastewater. The treatment method comprises the following treatment steps of (a) chemical industrial wastewater pretreatment, (b) biochemical treatment of chemical industrial wastewater and (c) physical treatment of chemical industrial wastewater. According to the treatment method, the chemical industrial wastewater is sequentially subjected to the chemical industrial wastewater pretreatment, the biochemical treatment of chemical industrial wastewater and the physical treatment of chemical industrial wastewater, and the chemical industrial wastewater reaching the discharge standard is obtained. The treatment method is especially suitable for treatment of organic chemical industrial wastewater having strong biological toxicity and poor biochemical properties and can deeply treat chemical industrial wastewater, the harmful matter content in the treated wastewater is reduced to the most degree, the lower treatment degree is avoided, and accordingly the problem that treated wastewater still cause large environmental pollution is solved. In addition, in the wastewater treatment process, all links can be performed in order, the treatment method is simple in structure, scientific, convenient, strong in pertinence, high in automation degree, low in actural application cost, advanced in technology and good in treatment effect, and the chemical industrial wastewater treatment problem is well solved.

Owner:衢州市协成化工有限公司

Filling material cyclone composite stripping tower and application thereof

ActiveCN103537111AImprove separation efficiencyReduce the overall heightSteam distillationCycloneDesorption

The invention relates to a filling material cyclone composite stripping tower. The tower body of the composite stripping tower is a hollow vertical tower device. A tower bottom liquid outlet is communicatively arranged in the tower bottom. A liquid storage section is arranged on the bottom of tower body of a desorption tower. A heating device is arranged in the liquid storage section. A through cyclone section is arranged coaxially in the tower body above the liquid storage section. A liquid re-distribution section is coaxially arranged above the cyclone section. A filling material section is arranged coaxially above the liquid re-distribution section. A hollow liquid distribution section is arranged in the tower body coaxially above the filling material section. A tower top liquid phase reflux inlet communicating with the internal side of the tower body is arranged on the tower body outer surface above the liquid distribution section. A foam-removing section is coaxially arranged in the tower body above the tower top liquid phase reflux inlet. A tower top steam outlet is arranged on the top in the tower body above the foam-removing section. According to the stripping tower provided by the invention, with the cyclone principle, desorption strength is enhanced, reaction tower height is reduced, space and material are saved, and desorption effect of the reaction tower is improved.

Owner:北京航天环境工程有限公司

Method for preparing ceramsite adsorbing material from manganese slag

InactiveCN109759033AImprove use valueLow costOther chemical processesWater contaminantsSlagHeavy metals

The invention discloses a method for preparing a ceramsite adsorbing material from manganese slag. The method comprises the following steps: the manganese slag is cleaned with a cleaning solution which is a mixed solution of alkali and carbonate, an adhesive is added to the cleaned manganese slag, the materials are mixed uniformly and pressed into particles, the particles are dried, calcined an cooled, and the ceramsite adsorbing material is obtained. The manganese slag is successfully used for adsorbing heavy metals in wastewater, the use value of the manganese slag can be increased, the costcan be reduced, further, waste can be changed into wealth, and environmental pollution can be reduced.

Owner:HUNAN YONKER ENVIRONMENTAL PROTECTION RES INST +1

Nozzle for injection molding machine

The invention discloses a nozzle for an injection molding machine and relates to the field of injection molding machines. The nozzle for the injection molding machine comprises a primary nozzle and a secondary nozzle; both the primary nozzle and the second nozzle are provided with runners and are communicated with each other; the primary nozzle is provided with a first connection end; the secondary nozzle is provided with a second connection end; the primary nozzle is connected with the secondary nozzle; the joint position of the primary nozzle and the secondary nozzle is provided with a filter screen; and the secondary nozzle is provided with a spiral heating wire. According to the nozzle for the injection molding machine, arrangement of the heating wire enables the nozzle for the injection molding machine to be difficult to block; and by arrangement of the filter screen, impurities in raw materials can be effectively filtered, the nozzle is prevented from being blocked, and in case of blockage, blockage can be cleared away after the primary nozzle is disassembled.

Owner:SUZHOU CHANGFA PLASTICS

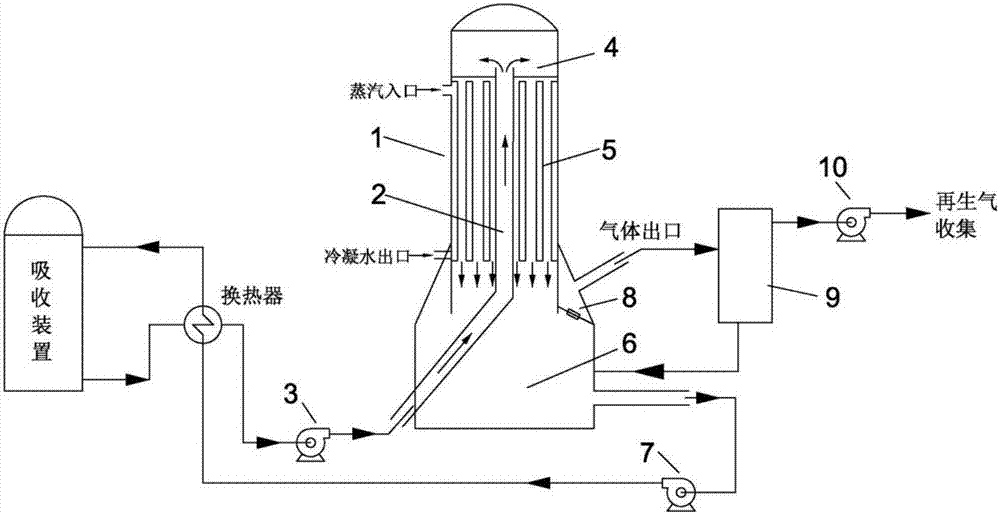

Regeneration device for solution for trapping acidic gases from power plant flue gas and method

PendingCN107243258AFast flowReduce heat transfer resistanceGas treatmentDispersed particle separationVapor–liquid separatorAir pump

The invention relates to a regeneration device for a solution for trapping acidic gases from power plant flue gas and a method. The device comprises a built-in circulating tube which is located at the center of a heating evaporation chamber, wherein a bottom inlet of the built-in circulating tube is connected with a rich solution pump of an absorption device, a top outlet of the built-in circulating tube is located at the upper part of a liquid distributor, the liquid distributor is connected with inlets of heating tubes which are uniformly distributed in the heating evaporation chamber, outlets of the heating tubes directly communicate with a lean solution tank, a bottom lean solution outlet of the lean solution tank is connected with a lean solution pump, a demister is arranged at an upper gas outlet, the gas outlet is connected with an inlet of a gas-liquid separator, a bottom liquid outlet of the gas-liquid separator is connected with the lean solution tank, and a top gas outlet of the gas-liquid separator is connected with a gas pump. According to the device and the method, heated desorption is carried out on a rich solution in a tube-type falling film manner, and a flow direction of rich-solution steam is the same as that of a liquid film, so that the liquid film can be more uniform and thinner and be higher in flow velocity, the lowering of heat transfer resistance is facilitated, the heat efficiency is increased, the regeneration effect is improved, and thus, the device and the method are particularly applicable to absorbent systems with relatively high viscosity.

Owner:HUANENG CLEAN ENERGY RES INST +1

Construction waste sieving device

ActiveCN109569897AFast cutting speedUniform Suspension StrengtheningRotary centrifugesEngineeringArchitectural engineering

The invention discloses a construction waste sieving device. The construction waste sieving device comprises a supporting frame, a cylinder is internally provided with a second sieving meshed cylinderand a first sieving meshed cylinder, wherein the first sieving meshed cylinder is located in the second sieving meshed cylinder; and a rotating shaft is arranged at the upper end of a transverse plate, the top end of the rotating shaft is connected with a supporting plate through a bearing seat, the left side of the supporting plate is welded to the supporting frame, and an electromotor is installed at the left end of the top of the supporting plate. The electromotor is started to drive a first transmission belt wheel to rotate, due to the action of centrifugal force, when the particle size of construction waste brick residues in the first sieving meshed cylinder is smaller than the mesh diameter of the first sieving meshed cylinder, the construction waste brick residues with small particle size are thrown into the second sieving meshed cylinder; and when the particle size of the construction waste brick residues dropping into the second sieving meshed cylinder is smaller than the mesh diameter of the second sieving meshed cylinder, the construction waste brick residues are thrown into the cylinder; and the graded sieving of the construction waste brick residues can be realized byarranging the first sieving meshed cylinder and the second sieving meshed cylinder.

Owner:江苏营特泰克智能环保设备有限公司

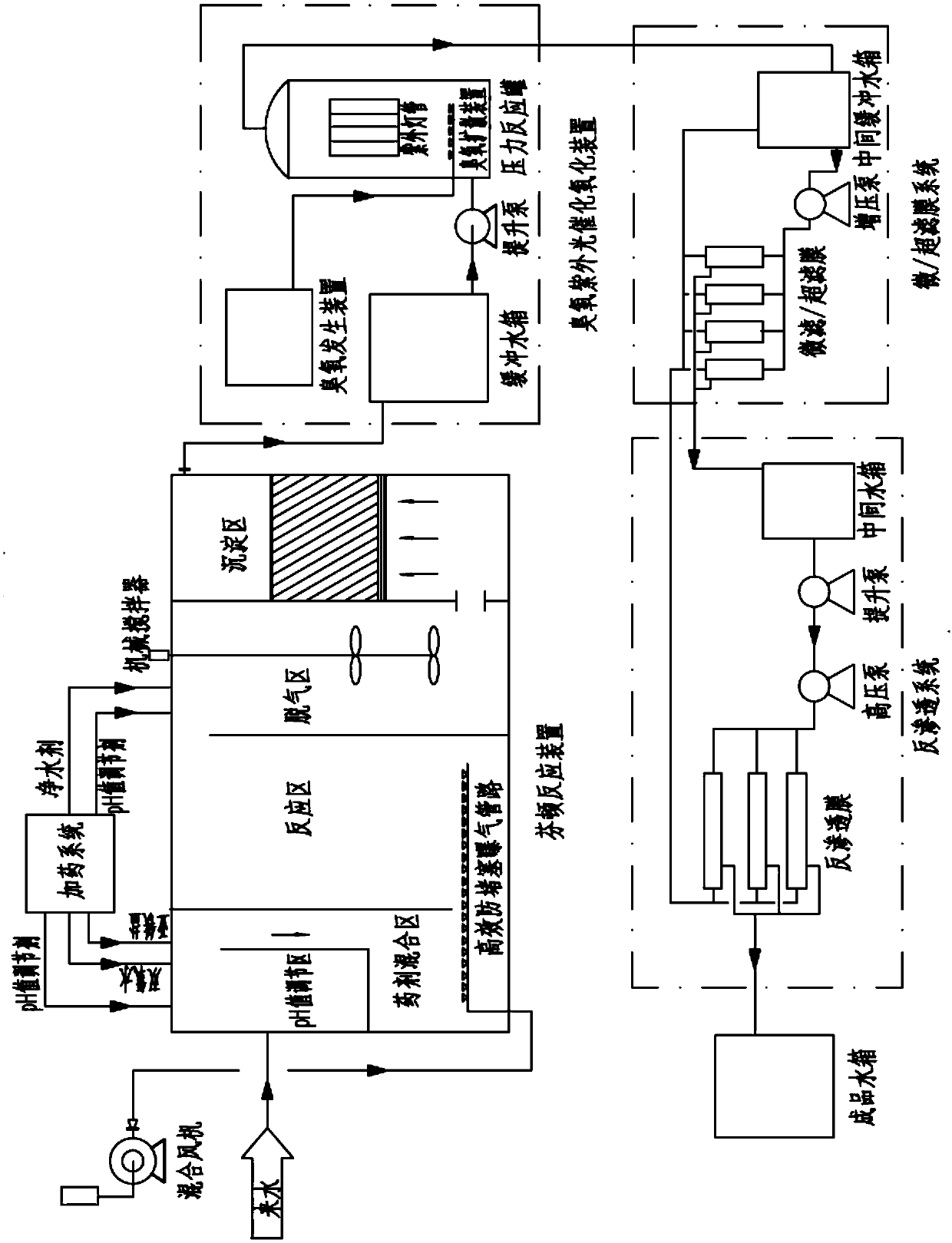

Process method for treating refractory CODs (chemical oxygen demands) in produced water of high-sulfur-content gas field

InactiveCN110563223AReduce dosageReduce outputWaste water treatment from quariesWater/sewage treatment by irradiationVolatile phenolsUltrafiltration

The invention belongs to the technical field of ground engineering of oil and gas fields and in particular relates to a process for removing refractory CODs (chemical oxygen demands) in produced waterof a high-sulfur-content gas field. Aiming at situations that refractory COD components in produced water of a high-sulfur-content gas field and CODs in fed water after pretreatment are generally 1000mg / L and are refractory CODs, and to achieve resource recycling of the produced water of the high-sulfur-content gas field, the invention discloses the process applicable to removal of refractory CODs in produced water of the high-sulfur-content gas field, a treatment process of "Fenton oxidation+ozone ultraviolet photocatalytic oxidation+micro / ultrafiltration membrane+reverse osmosis membrane" is adopted, and organic components such as refractory CODs and volatile phenols in the produced water of the high-sulfur-content gas field can be degraded and removed. In a situation that the CODs of produced water are less than or equal to 1000mg / L, the process is adopted for treatment, and CODs of an effluent after treatment qualification are less than or equal to 50mg / L.

Owner:中石化石油工程技术服务有限公司 +1

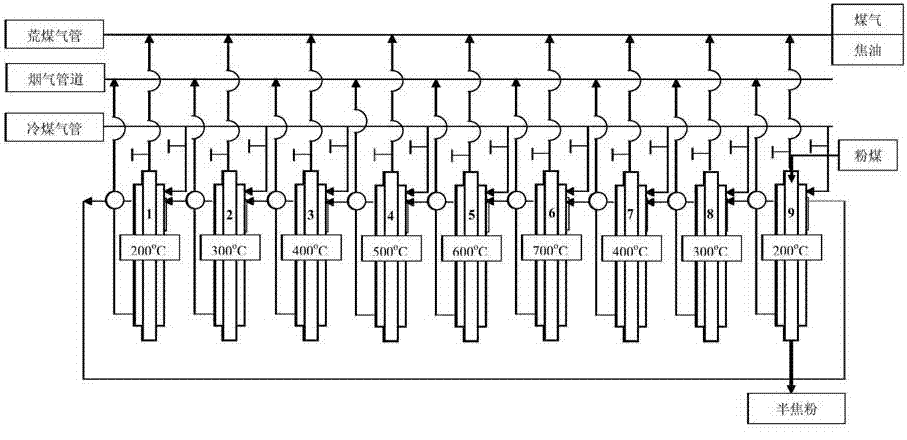

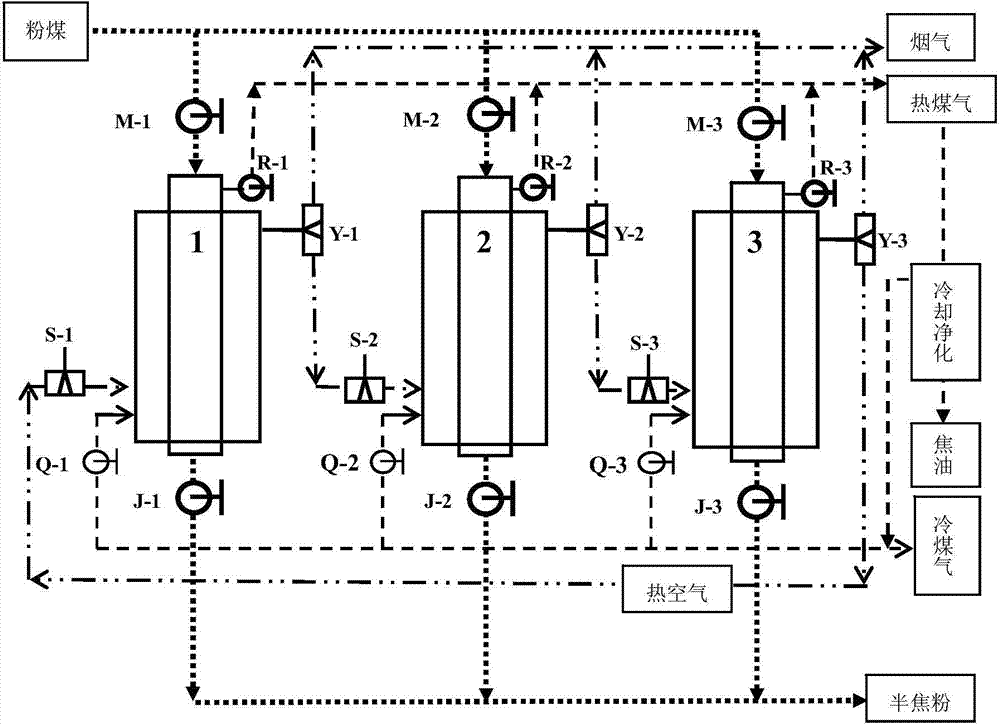

Pulverized coal pyrolysis method and device

InactiveCN104774629AReduce overflow speedReduce dust contentEnergy inputSpecial form destructive distillationFlue gasProcess engineering

The invention relates to a static pulverized coal pyrolysis method. A related pulverized coal dry distillation method needs at least three working units, each of the three working units is provided with a pulverized coal inlet and a semi-coke outlet; after being fed into a pulverized coal pyrolysis unit, the same batch of pulverized coal raw material is sequentially subjected to preheating, dry distillation pyrolysis and cooling and finally discharged from the semi-coke outlet; at the same moment, the three working units are respectively at a preheating working state, a dry distillation pyrolysis working state and a cooling working state, and correspondingly the three working units are respectively a preheating working unit, a dry distillation pyrolysis working unit and a cooling working unit, wherein hot flue gas generated by the dry distillation pyrolysis working unit is used as a heat source of the preheating working unit. A related pulverized coal dry distillation pyrolysis device comprises three pulverized coal pyrolysis furnaces, and the three furnaces work in a circular way to realize the static dry distillation pyrolysis of pulverized coal. The process is simple and rapid, requires simple equipment and small investment, is high in thermal efficiency, and can ensure high coal gas quality, low ash content of semi-coke and high tar yield.

Owner:CHANGAN UNIV

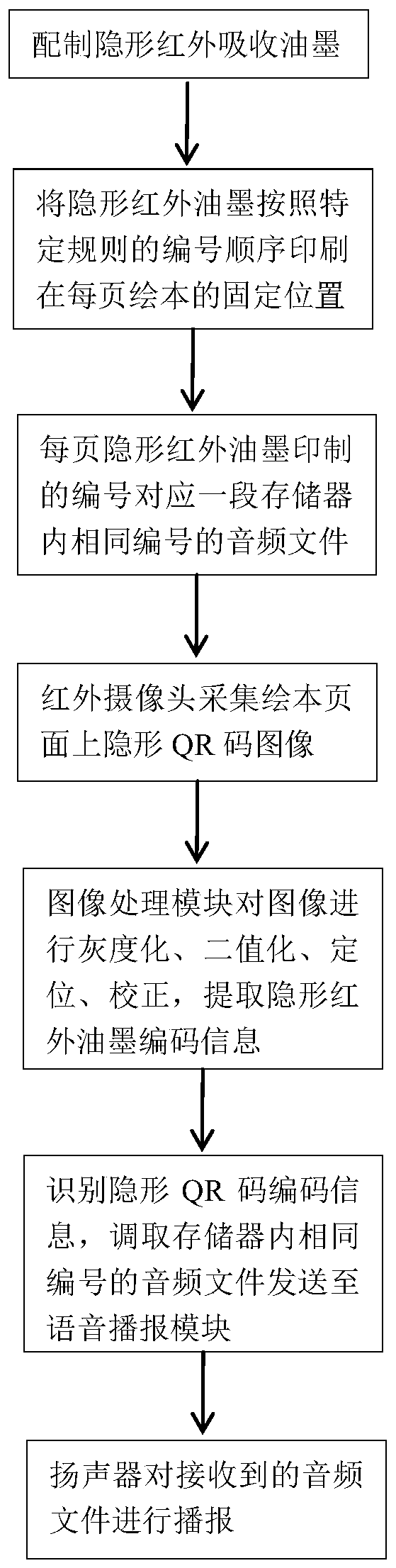

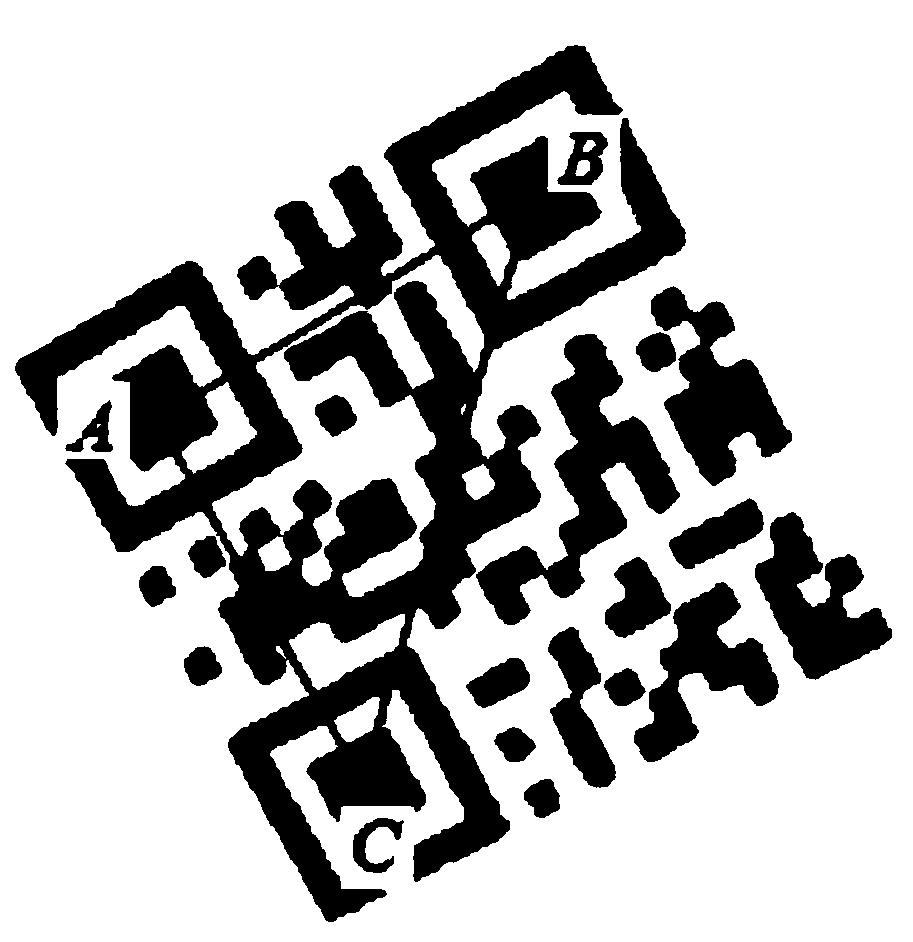

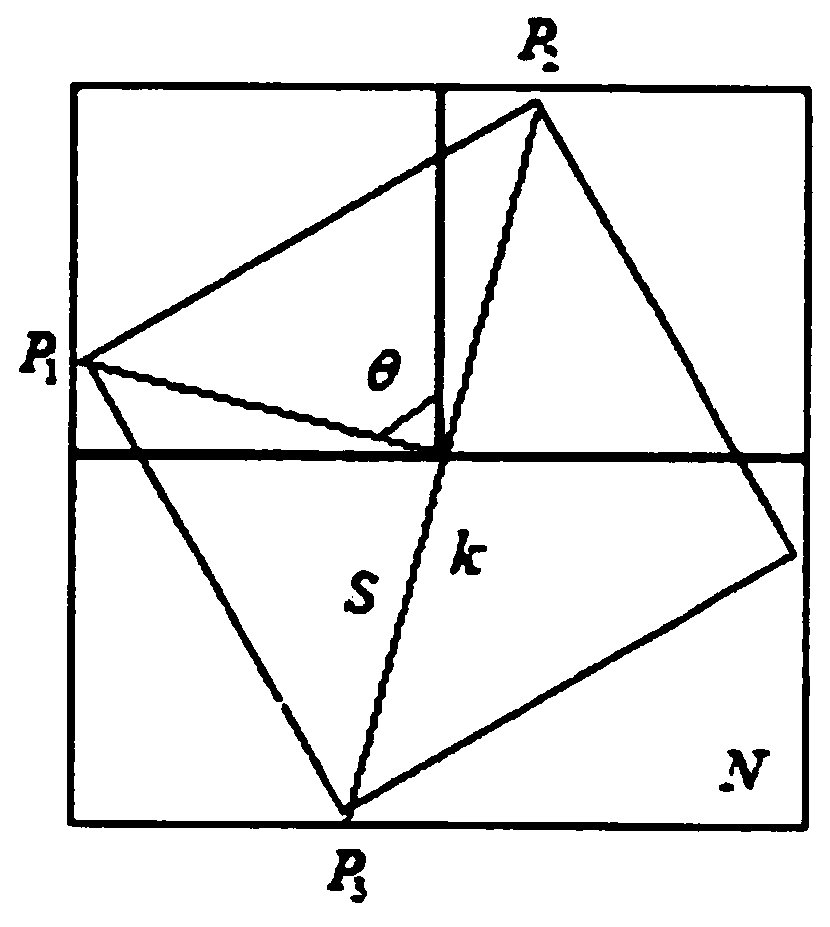

A picture book recognition method based on image recognition and an invisible infrared ink technology

ActiveCN109886372ADoes not affect the normal reading experienceImprove accuracyMetadata audio data retrievalVisual presentation using printersPattern recognitionSpeech sound

The invention discloses a picture book recognition method based on image recognition and an invisible infrared ink technology. The picture book recognition method comprises the following steps of firstly, preparing the invisible infrared ink; 2, printing the invisible infrared ink at a specific position of a picture book; 3, using the camera to collects images; 4, carrying out graying on the acquired image, and removing a noise point effect; 5, carrying out binarization processing on the image; 6, positioning and inclination correction are carried out on the infrared image; 7, performing normalization processing on the QR code image subjected to binarization, positioning and correction; 8, performing error correction verification on the processed QR code image; 9, carrying out voice broadcast on the audio file. By applying the invisible infrared ink technology to picture book image recognition, the image recognition module can be prevented from being interfered by visible light illumination, the number information printed with the invisible infrared ink can be quickly recognized, the normal reading experience of a user is not influenced, and the picture book image recognition method has the comfortable and practical use value.

Owner:深圳市象形字科技股份有限公司

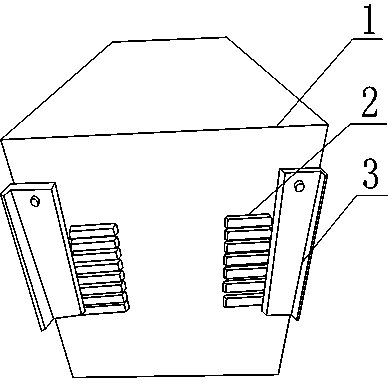

Ventilating mechanism of power distribution cabinet

InactiveCN103683046ASimple structureEasy to implementSubstation/switching arrangement cooling/ventilationElectrical and Electronics engineering

Owner:CHENGDU TIANPAN TECH

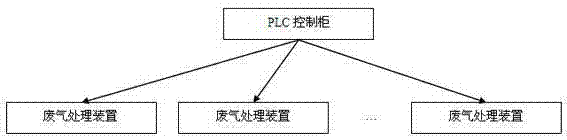

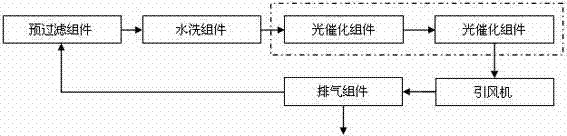

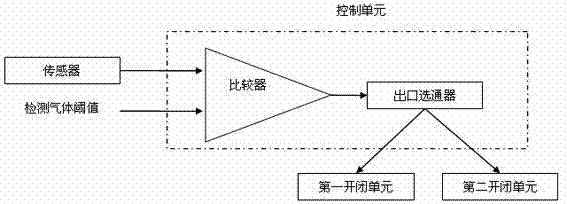

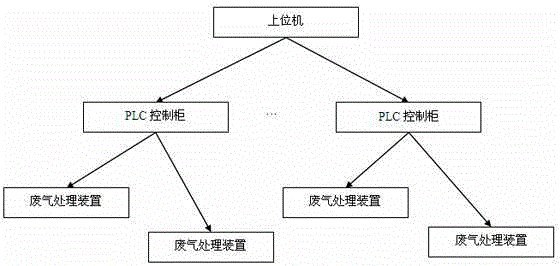

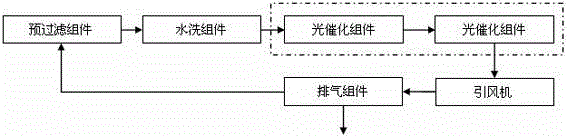

Circulatory rinsing type waste gas treatment system

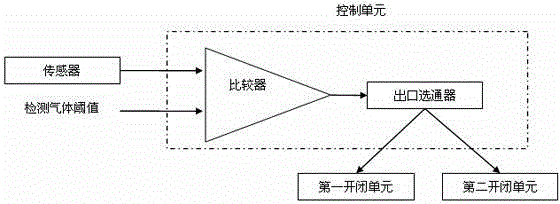

ActiveCN104841233AImprove degradation rateEasy to cleanCombination devicesRemote controlProgrammable logic controller

The invention discloses a circulatory rinsing type waste gas treatment system which comprises a plurality of waste gas treatment devices and a PLC (Programmable Logic Controller) control cabinet, wherein the waste gas treatment devices conduct remote opening-closing control through the PLC control cabinet. Each waste gas treatment device comprises a pre-filtering assembly, a rinsing assembly, a draught fan and an exhausting assembly which are connected through pipes in sequence. Each exhausting assembly comprises two outlets, wherein one is used for exhausting gases, and the other one is connected with the corresponding pre-filtering assembly. Each exhausting assembly comprises a sensor for detecting the gas content, a control unit of a strobe outlet and an opening-closing unit of two outlets. The output end of each sensor is connected with the corresponding control unit which is connected with the corresponding opening-closing unit. The circulatory rinsing type waste gas treatment system controls the waste gas treatment devices through the PLC control cabinet in a remote control way, is safe and reliable and can further improve the quality of exhausted gases due to the provided circulatory detection function.

Owner:CHENGDU HONGHUA ENVIRONMENTAL SCI & TECH CO LTD

Safe and reliable circulating water washing type waste gas treatment system

ActiveCN104857800AEasy to handleImprove degradation rateCombination devicesProgrammable logic controllerTreatment system

The invention discloses a safe and reliable circulating water washing type waste gas treatment system which comprises an upper computer, a plurality of PLC (Programmable Logic Controller) cabinets and a plurality of waste gas treatment devices, wherein the upper computer is connected with the PLC cabinets; the PLC cabinets are connected with the waste gas treatment devices; each waste gas treatment device comprises a pre-filtering component, a water washing component, an induced draft fan and an exhaust component that are sequentially connected by pipelines; each exhaust component comprises a sensor for detecting a gas content, a control unit gating outlets and opening and closing units of the two outlets; the sensors are arranged at inlets of the exhaust components; output ends of the sensors are connected with the control units; and the control units are connected with the opening and closing units. According to the system, the upper computer controls the PLC cabinets, the PLC cabinets remotely control the waste gas treatment devices, and the system is safe and reliable, and can remotely control the organic waste gas treatment devices to improve efficiency.

Owner:四川华赐科技有限公司

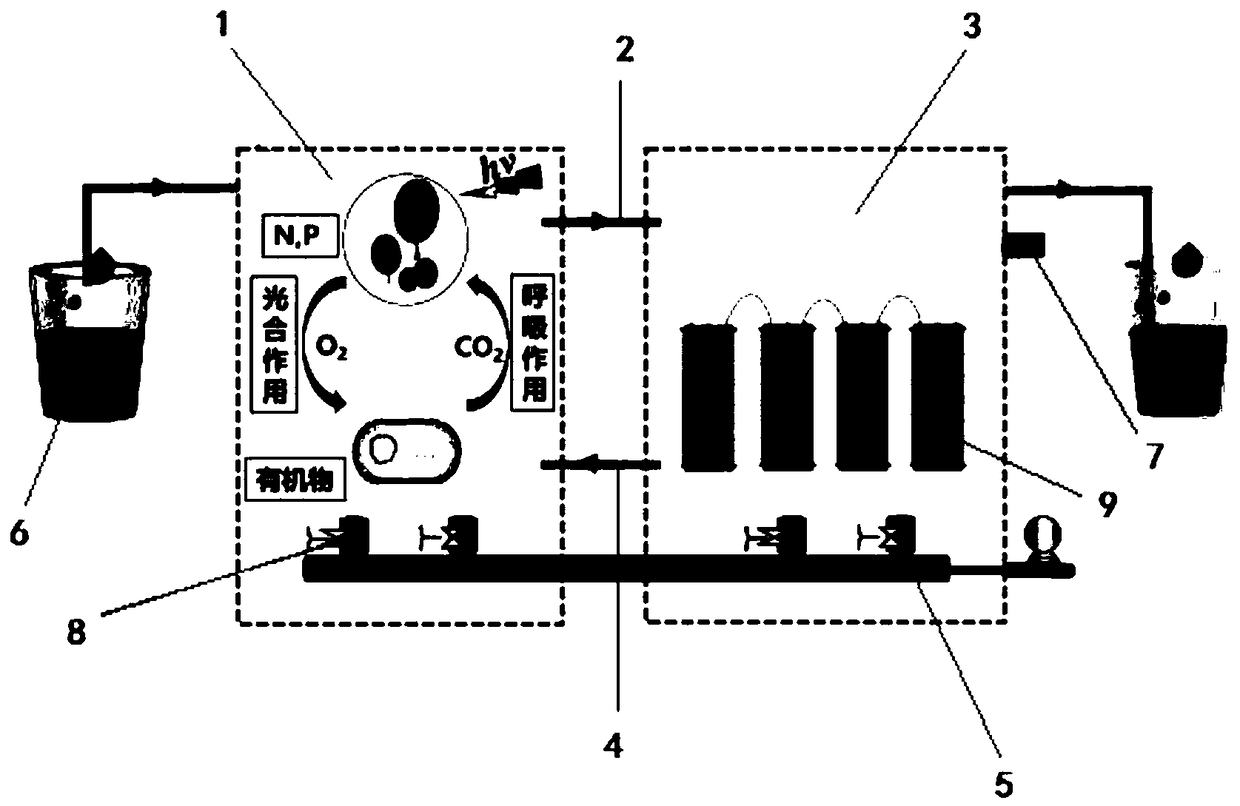

Photoreaction-MBR integrated nitrogen and phosphorus removal equipment

InactiveCN109231486APromote decompositionGood denitrification and phosphorus removalWater/sewage treatment by irradiationWater contaminantsActivated sludgeNitrogen

The invention discloses photoreaction-MBR integrated nitrogen and phosphorus removal equipment, comprising a photobioreactor and an MBR membrane reactor, wherein the left side face of the photobioreactor is provided with a water inlet, the photobioreactor and the MBR membrane reactor are coupled by arranging a first pipeline and a recycling pipeline device, the photobioreactor adopts an air-lift type photobioreactor, the photobioreactor is internally provided with algae and activated sludge, the MBR membrane reactor is formed by aeration assemblies and a membrane assembly, the bottom ends of the inner parts of the photobioreactor and the MBR membrane reactor are respectively provided with a blower device, the aeration assemblies are fixedly mounted on the upper surfaces of the blower devices, the blower device in the photobioreactor and the blower device in the MBR membrane reactor are connected into a whole, and the right side of the MBR membrane reactor is provided with a water outlet and an air outlet. The photoreaction-MBR integrated nitrogen and phosphorus removal equipment has the advantages of realizing a bacteria and algae symbiosis mode, deep treating sewage by a two-stepprocess of the photobioreactor and the MBR membrane reactor, and achieving a high recycling rate and the nitrogen and phosphorus removal effect of 90%.

Owner:NANCHANG HANGKONG UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com