Electric sewage suction device for factory farming

A factory-like, electric technology, applied in applications, fish farming, animal husbandry, etc., can solve the problems of passive means of preventing clogging and easy clogging of the filter net, and achieve the goal of reducing the particle size of dirt, convenient operation, and unsuitable for clogging Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

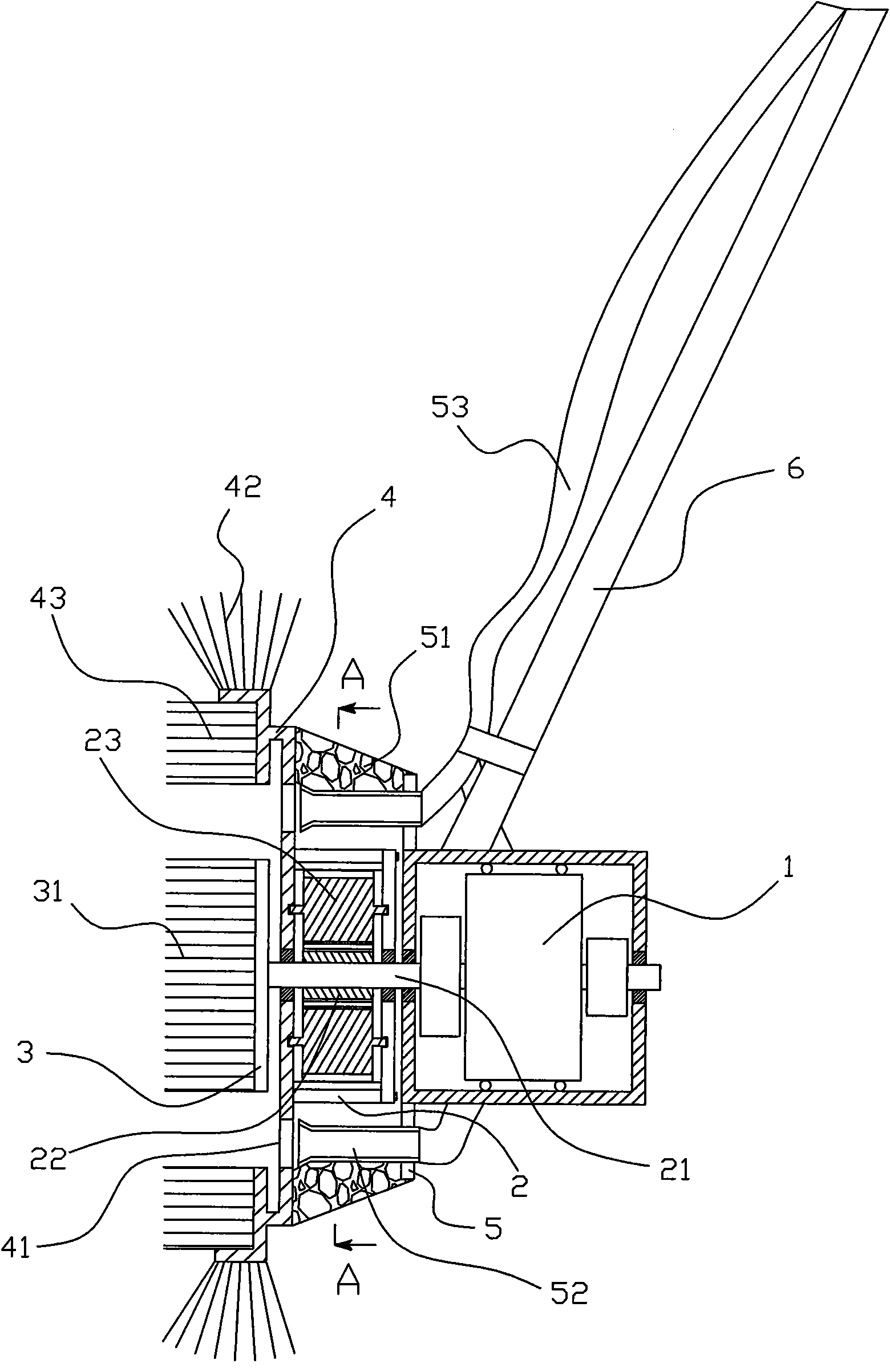

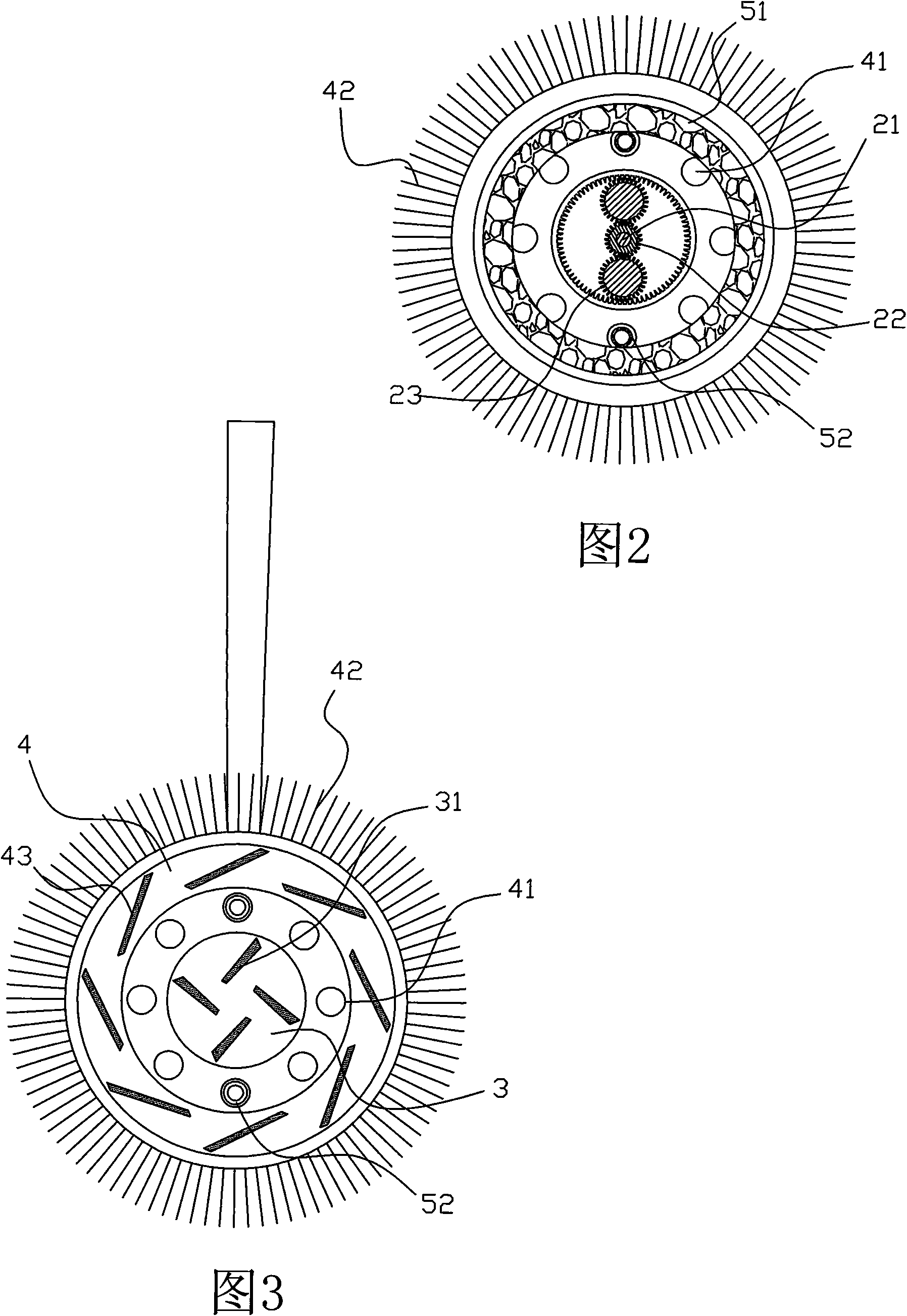

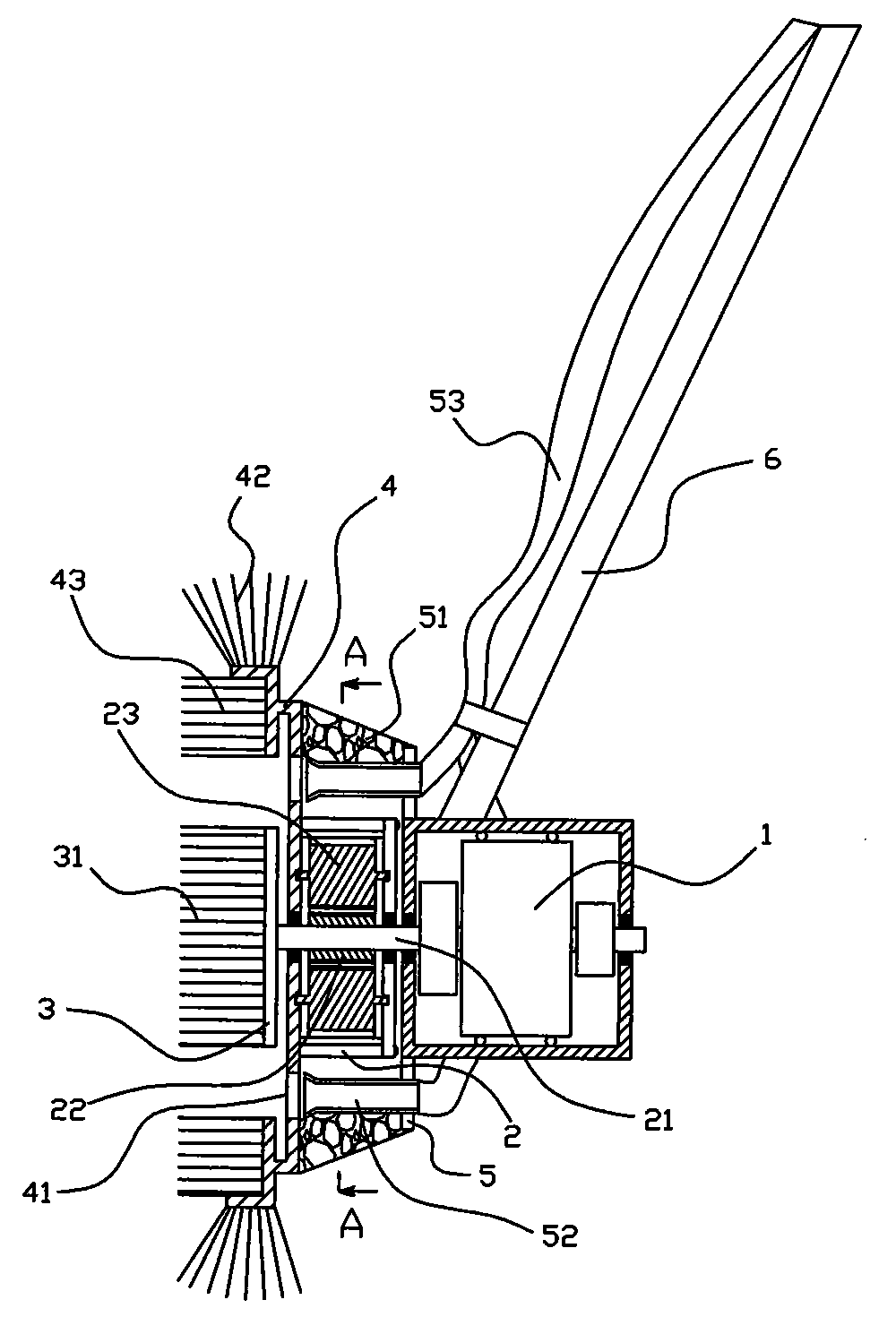

[0013] Example: refer to Figure 1 to Figure 3 , an electric sewage suction device for industrialized farming, including a waterproof motor 1 provided with a handle 6, wherein: the waterproof motor 1 is connected to an outer turntable 4 through a rotating shaft 21; the outer turntable 4 is formed with a gear cover 2; the gear cover 2 is provided with a planet Gear train; the free end of the rotating shaft 21 is connected to the center turntable 3; the planetary gear train can make the rotation direction of the center turntable 3 and the outer turntable 4 opposite; the center turntable 3 is provided with four radial inner brushes 31; the outer turntable 4 is provided with There are six radially arranged outer brushes 43, and there is a gap of 5 cm between the outer brushes 43 and the inner brushes 31; the part of the outer turntable 4 located inside the outer brushes 43 is formed with eight drain holes 41, and the center of the drain holes 41 is symmetrical Arrangement; the sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com