Construction waste sieving device

A screening device and a technology for construction waste, applied in centrifuges with rotating drums, centrifuges, etc., can solve problems such as easy blockage, and achieve the effects of fast feeding speed, speeding up efficiency, and uniform suspension and strengthening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

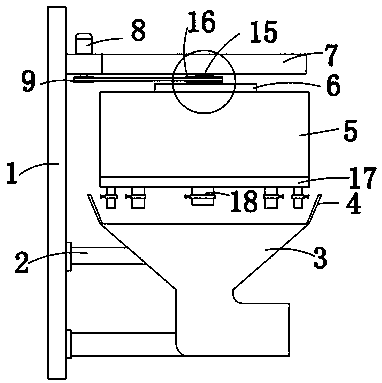

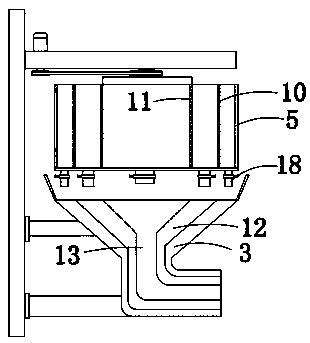

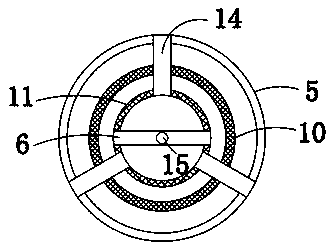

[0024] First implementation: see Figure 1-4 , the present invention provides a technical solution: a construction waste screening device, including a bracket 1, the lower end of the right side wall of the bracket 1 is welded with a third material guide bin 3 through a support rod 2, and the third material guide bin 3. A second material guide bin 12 is arranged inside, and a first material guide bin 13 is arranged inside the second material guide bin 12. A cylinder 5 is arranged at the upper end of the third material guide bin 3. The cylinder 5 The bottom of the cylinder 5 is provided with an end cover 17, and the inside of the cylinder 5 is provided with a second screening cylinder 10 and a first screening cylinder 11, and the first screening cylinder 11 is located on the second screening cylinder. 10, the tops of the cylinder 5, the second screening cylinder 10 and the first screening cylinder 11 are welded through three connecting plates 14, and the top of the first screeni...

no. 2 approach

[0032]The second embodiment: as shown in claim 1, a construction waste screening device includes a bracket 1, and the inside of the bracket 1 is provided with a first air duct connected to an external electric control fan along its axial direction, The lower end of the right side wall of the bracket 1 is welded to the outer surface of the third material guide bin 3 through two horizontal hollow support rods 2 and runs through it. The first air duct communicates with the two support rods 2. The inside of the third guide bin 3 is provided with a second guide bin 12, the inside of the second guide bin 12 is provided with a first guide bin 13, and the upper end of the third guide bin 3 is provided with a cylinder 5 , the three material guide bins 3, 12, and 13 are separated by the shared warehouse walls, the walls of the three material guide bins are made of flexible material, the bottom of the cylinder 5 is provided with an end cover 17, and the circular The inside of cylinder 5 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com