Pneumatic atomizing nozzle with function of adjusting sizes of atomizing particles

A pneumatic atomization and particle size technology, applied in the direction of spraying devices, single handheld devices, etc., can solve the problems of complex structure, easy blockage, etc., and achieve the effect of large speed regulation range, not easy to block, and good atomization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

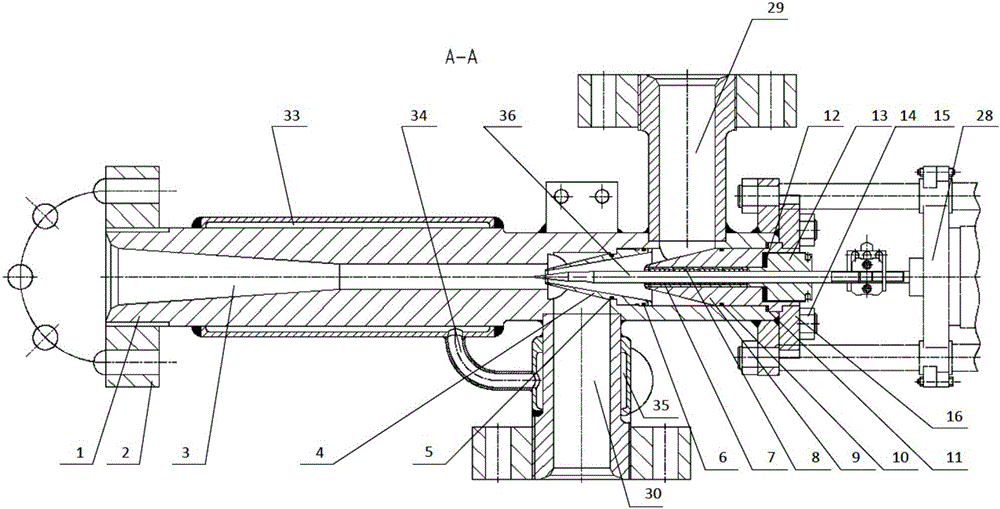

[0041] The present invention will be further described in detail below in conjunction with the accompanying drawings.

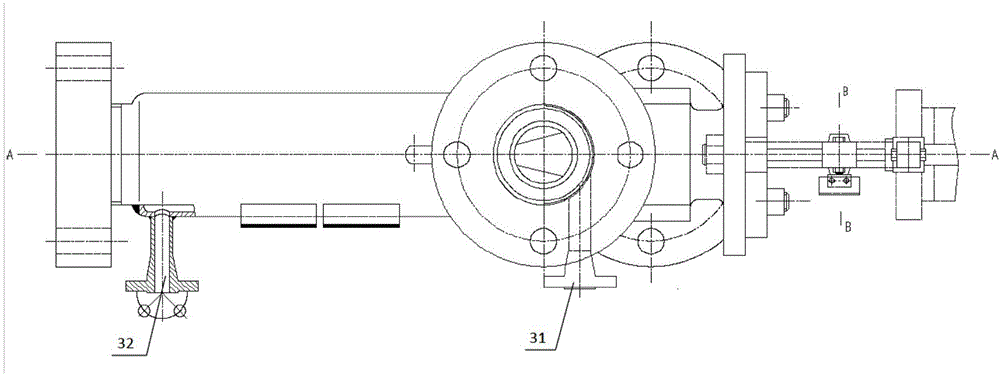

[0042] The invention relates to a pneumatic atomizing nozzle capable of adjusting the size of atomized particles, which is installed on mechanical equipment of chemical production and used in the production of chemical products such as chemical fertilizers and medicines. Such as figure 1 As shown, its structure includes: nozzle main body 1, which mainly plays the role of supporting and connecting various parts; flange plate 2, which mainly plays the role of connecting the outlet end of nozzle main body 1 with the production equipment pipeline; tapered nozzle 3. It is the outlet end of the liquid raw material after atomization. It uses the guiding effect of its conical surface to make the atomized liquid droplets sprayed out at high speed more dispersed; Nozzle 4. The compression effect of its internal conical surface can compress the incoming gas. Secondary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com