Industrialized culture energy-saving filth suction device

A factory-made, cover-body technology, applied in fish farming, application, animal husbandry, etc., can solve the problems of passive means of preventing clogging, easy clogging of the filter, not easy clogging, etc., to reduce the particle size of dirt and facilitate operation , the effect of small damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

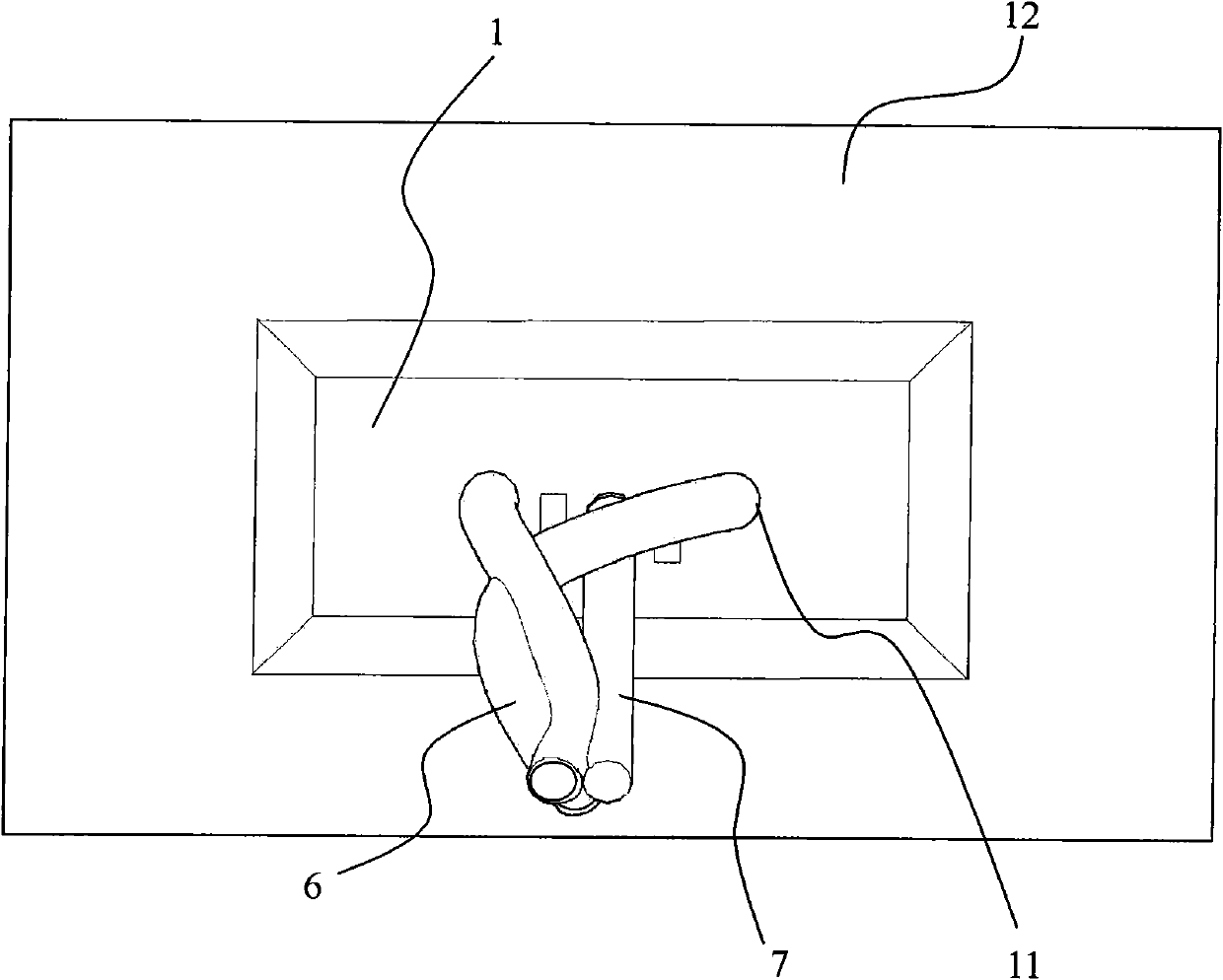

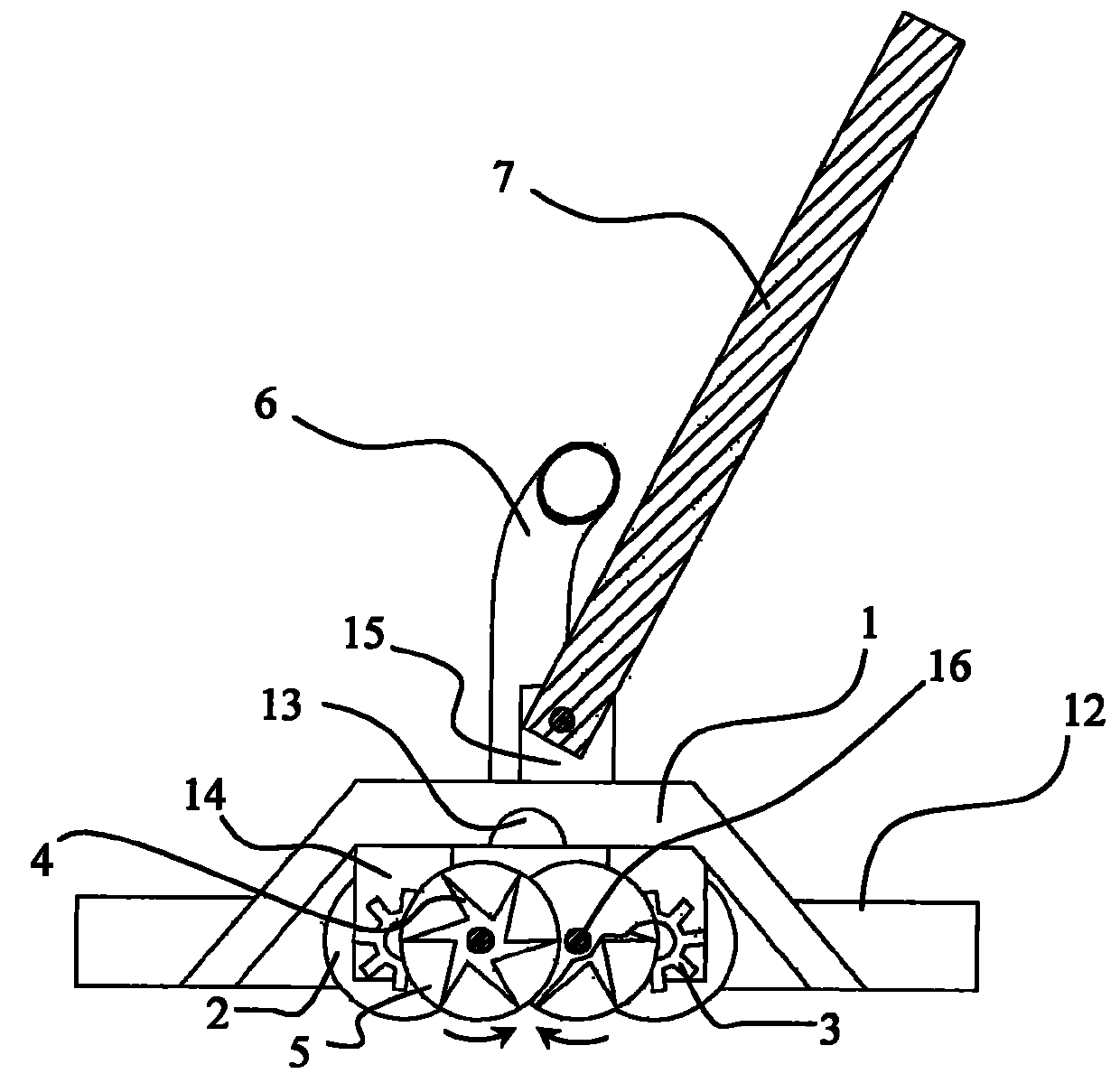

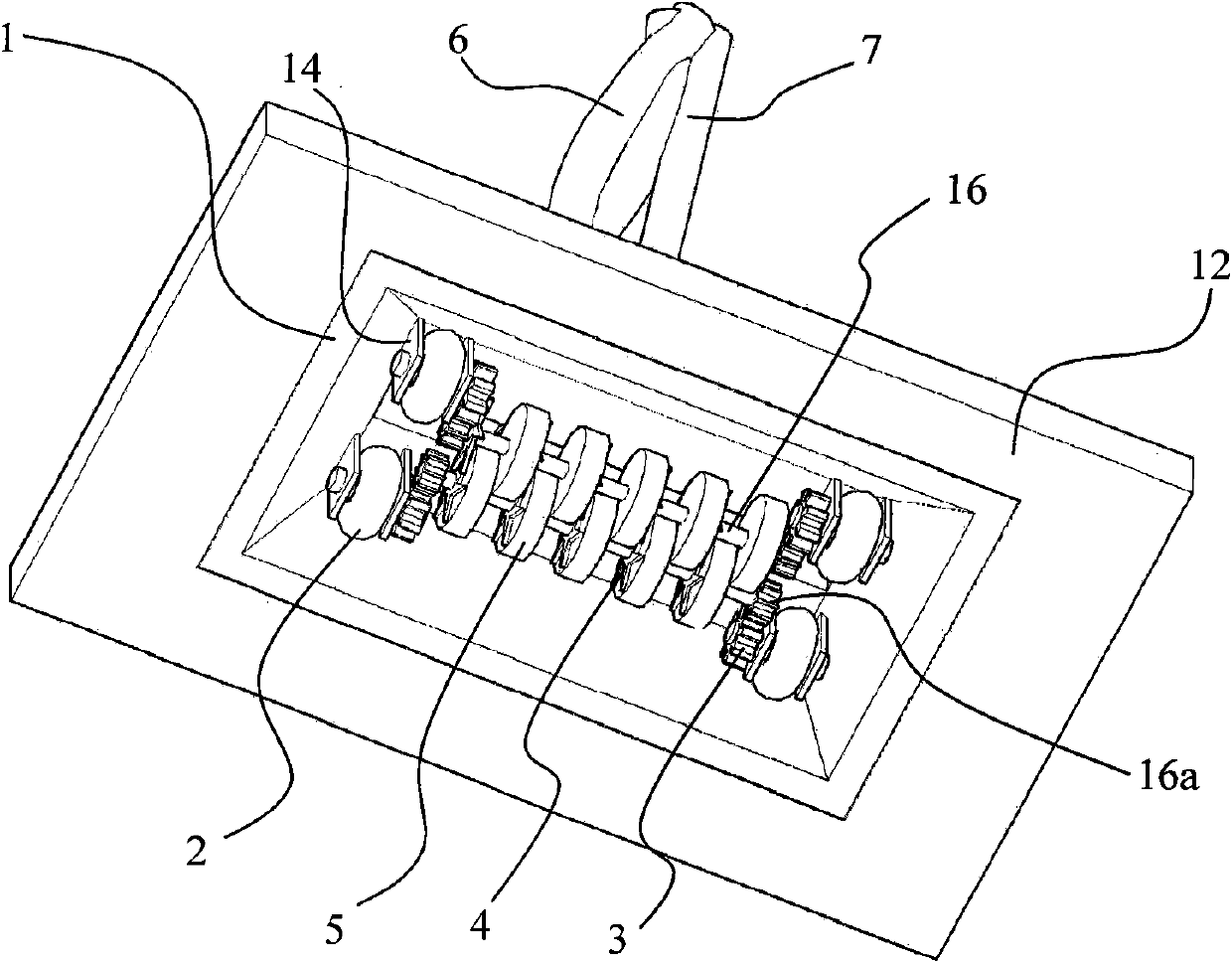

[0014] Example: refer to Figure 1 to Figure 3 , an energy-saving sewage suction device for factory farming, including a cover body 1 provided with a handle 7, characterized in that: the cover body 1 has a concave structure, and a diversion ditch 13 is formed in the middle of the concave body; the top of the cover body 1 runs through the There are two through holes 11, and are connected with the external siphon 6; four roller brackets 14 are formed in the cover body 1, and the rollers 2 are installed on the roller brackets 14; the rollers 2 are connected with the driving gear 3; the cover body 1 Two rollers 16 are installed inside, and each roller 16 is equipped with a hob 4 and a cleaning brush 5 at intervals; a driven gear 16a is installed near the end of the roller 16 and the driven gear 16a and the driving gear 3 meshing connection; the outer side of the cover body 1 is provided with a protective body 12 . The roller 2 is rubbing against the bottom of the culture pond and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com