Asymmetrical polyvinyl chloride dry-wet reversible ultrafiltration/microfiltration membrane, preparation method and application thereof

A polyvinyl chloride, asymmetric technology, applied in ultrafiltration, chemical instruments and methods, membrane technology, etc., can solve problems such as difficult cleaning, affecting service life, easy clogging of sponge-like pore structure microporous membranes, etc., and achieve porosity High, performance dry and wet reversible, high strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

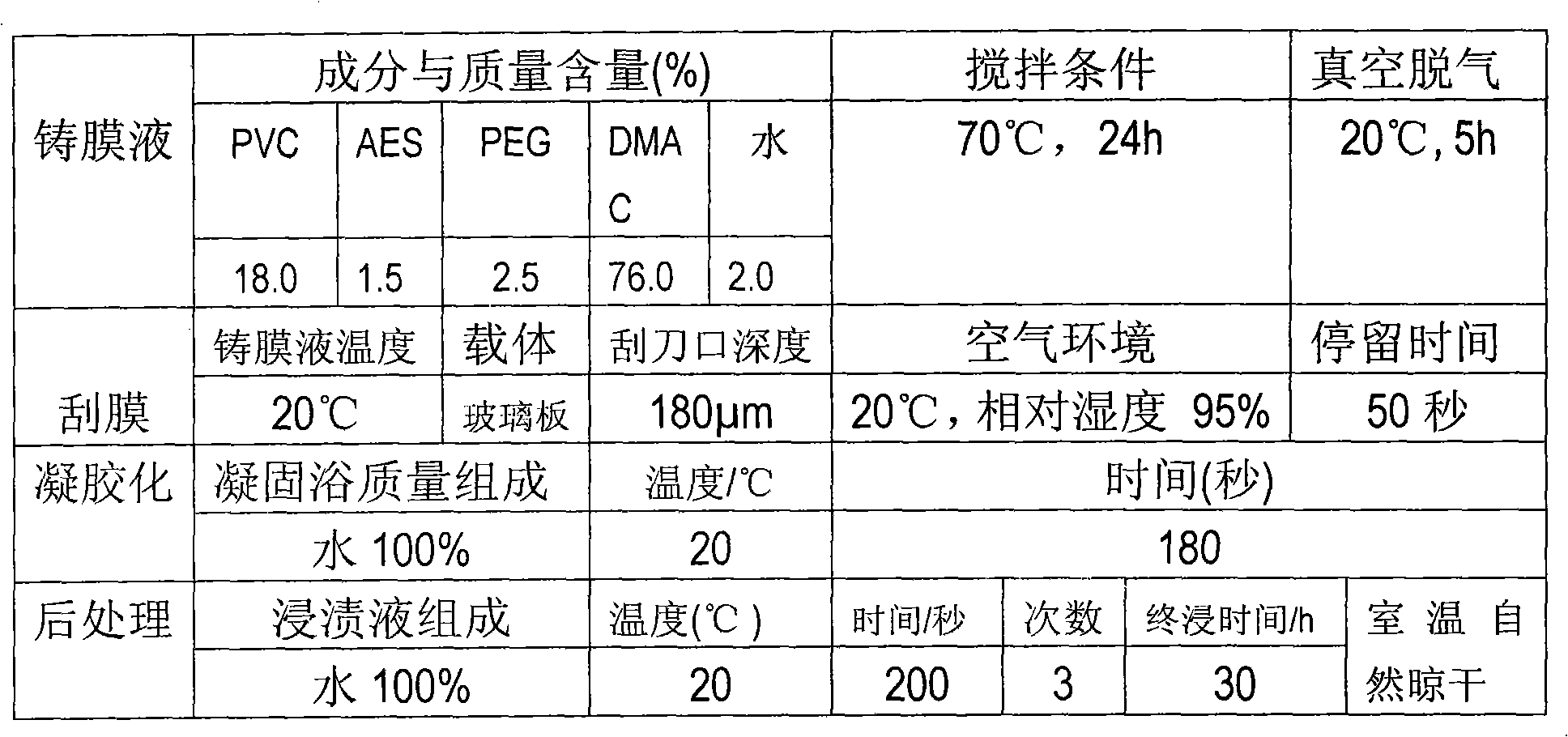

[0077] The various implementation conditions of embodiment 1 are as shown in table 1:

[0078] Table I

[0079]

[0080] Main raw materials: PVC is Tianjin Bohua Group Tianjin Chemical Factory, PEG is 20000, China Pharmaceutical Group Shanghai Chemical Reagent Company; DMAC is Shanghai Jingwei Chemical Co., Ltd.

Embodiment 2

[0081] The various implementation conditions of embodiment 2 are as shown in table two:

[0082] Table II

[0083]

Embodiment 3

[0084] The various implementation conditions of embodiment 3 are as shown in table three:

[0085] Table three

[0086]

[0087] Wherein: PVP, K90, China Pharmaceutical Group Shanghai Chemical Reagent Company; other raw materials are the same as in Example 1. The various implementation conditions of embodiment 4 are as shown in table four:

[0088] Table four

[0089]

[0090] Raw material is with embodiment 3.

[0091] In each embodiment, the structure and performance situation of polyether iron microporous membrane sample are shown in Table 5, wherein:

[0092] The water flux test uses a sample with a diameter of φ10cm, and tests it under the static pressure of a water column of 1m;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com