Filling material cyclone composite stripping tower and application thereof

A technology of stripping tower and swirl cylinder, which is applied in distillation desorption reaction tower, packed swirling compound stripping tower and other application fields, can solve the problems of undiscovered patent publications, etc., and achieve strong single-layer mass transfer effect and wide operating range Big, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Hereinafter, the present invention will be further described in detail by taking the embodiment of the accompanying drawings as an example. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

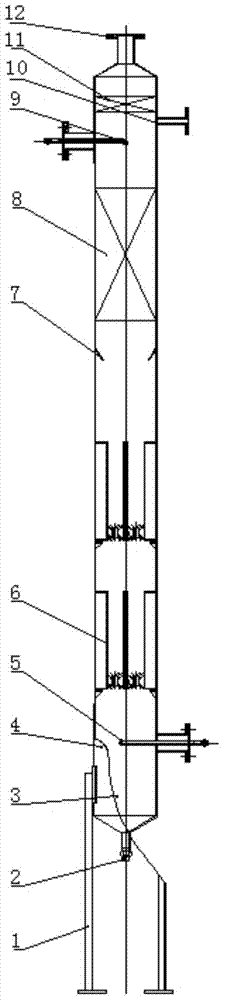

[0031] A packing swirl compound stripper, such as figure 1 As shown, the tower body 4 of the composite stripping tower is a hollow vertical tower, the lower part of the tower body is equipped with a leg 1, and a tower bottom liquid outlet 2 is connected and installed in the bottom of the tower body.

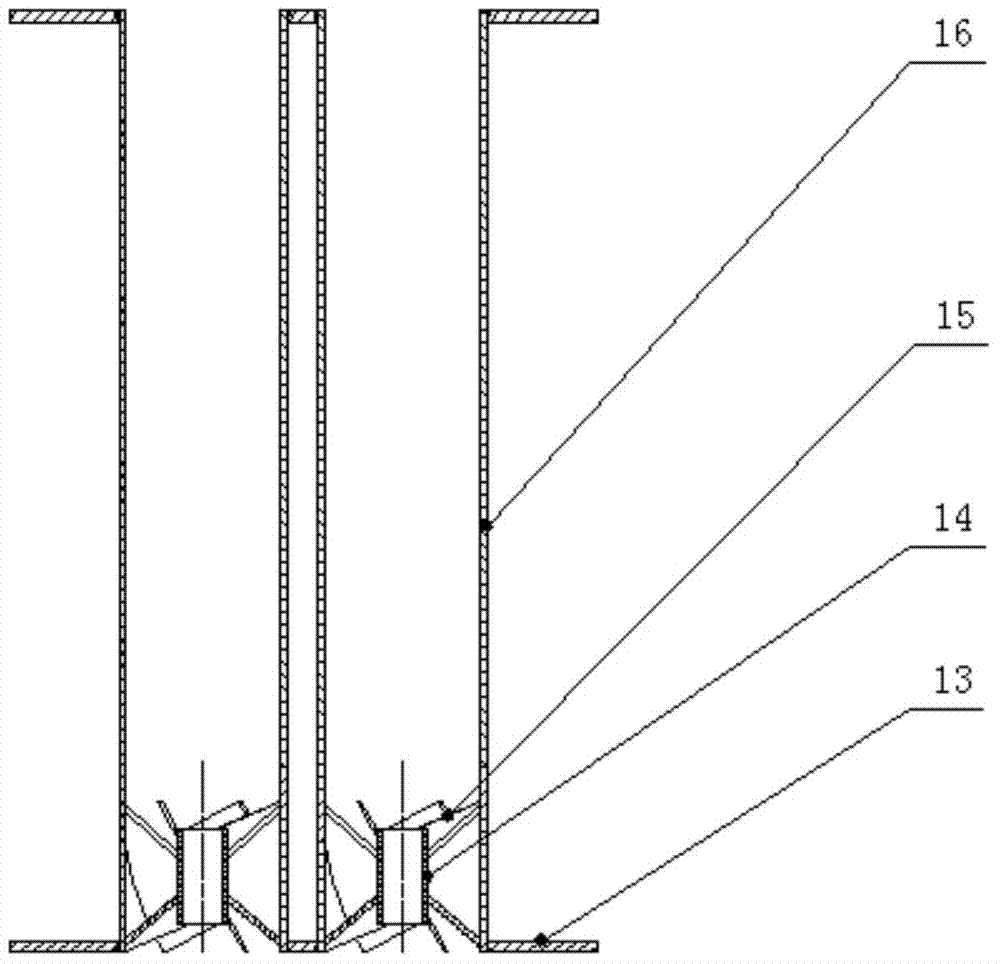

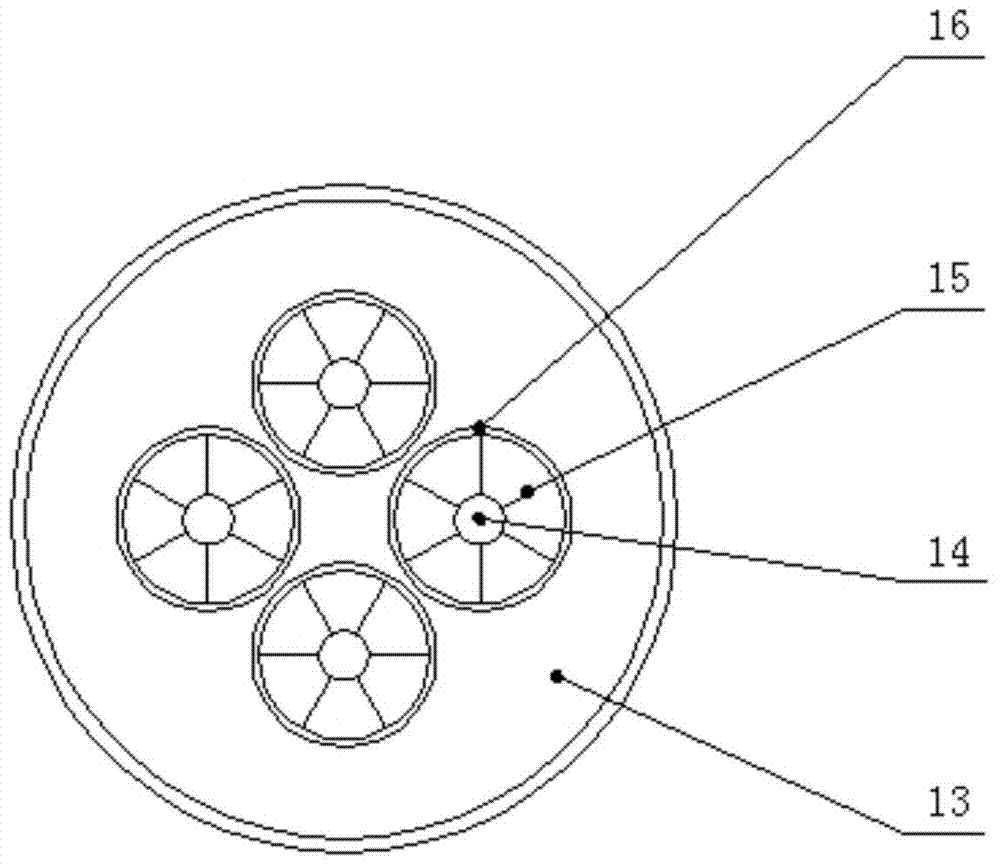

[0032] A hollow liquid storage section 3 is coaxially arranged in the lower part of the compound stripping tower body, and the solution is stored in the liquid storage section. The amount of the storage solution can be set to meet the evaporation capacity of ten minutes. A heating device 5 is installed, and the heating device can use heating devices such as an electric heater, a steam heater or heat transf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com