Preparation method of non-woven fabric or weaving cotton cloth supporting ultra-filtration/micro-filtration composite membrane

A technology of non-woven fabrics and composite membranes, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of low strength, difficult cleaning, easy clogging of homogeneous microporous membranes, etc., and achieve high porosity , high-strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

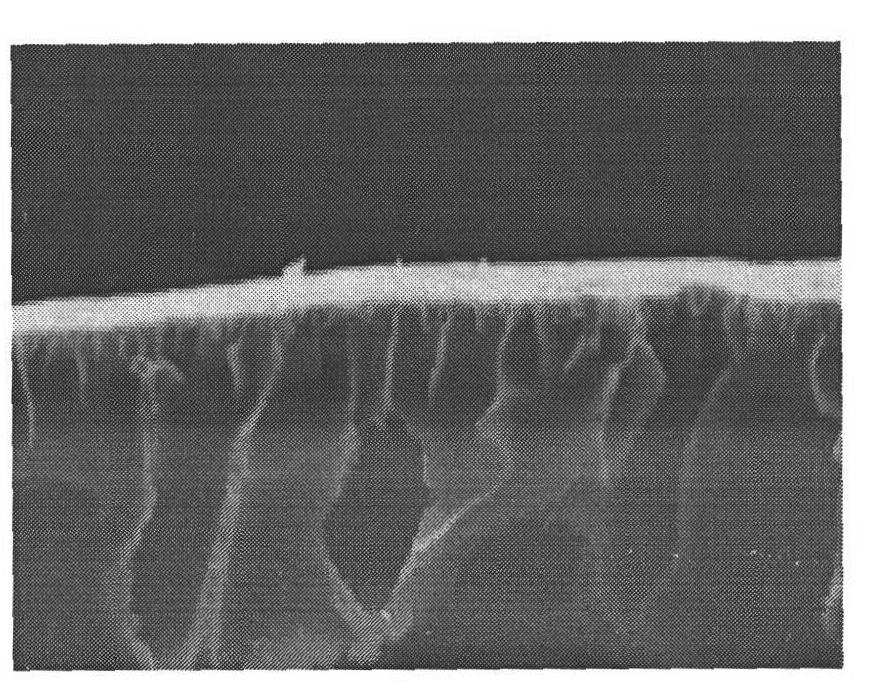

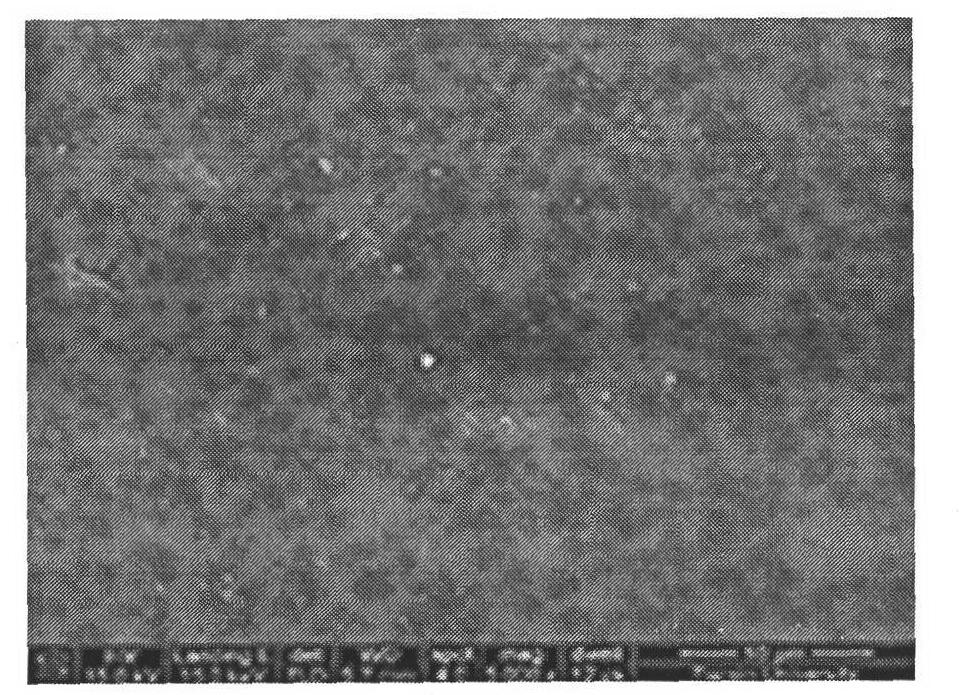

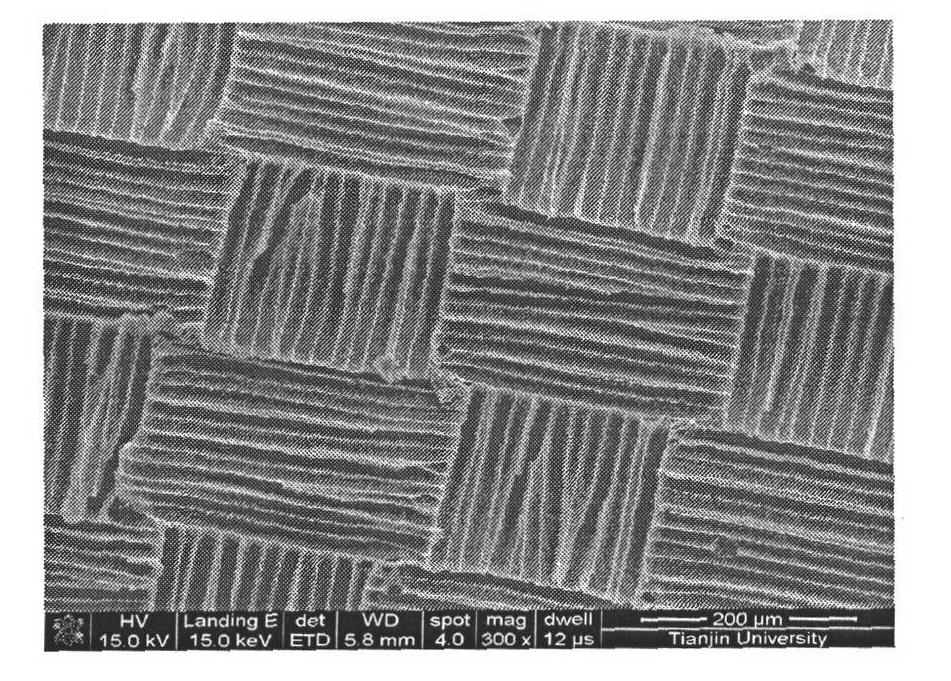

[0071] Embodiment 1: making the average pore size is 0.1 μ m non-woven fabrics, and the implementation conditions of the ultra / microfiltration composite membranes supported by woven fabrics are as shown in Table 3:

[0072] Table I

[0073]

[0074]

[0075] Main raw materials: PVC is Tianjin Bohua Group Tianjin Chemical Factory, PEG is 20000, China Pharmaceutical Group Shanghai Chemical Reagent Company; DMAC is Shanghai Jingwei Chemical Co., Ltd.

Embodiment 2

[0076] Embodiment 2: making the average pore size is 0.03 μm non-woven fabric, woven fabric supporting ultra / microfiltration composite membrane. The various implementation conditions are as shown in Table 3:

[0077] Table II

[0078]

[0079] Wherein: PVP, K60, are China Pharmaceutical Group Shanghai Chemical Reagent Company; other raw materials are the same as in Example 1.

Embodiment 3

[0080] Embodiment 3: making average pore diameter is 1.0 μ m non-woven fabrics, woven fabric support ultra / microfiltration composite membrane Various implementation conditions are as shown in Table 3:

[0081] Table three

[0082]

[0083]

[0084] Wherein: PVP, K90, China Pharmaceutical Group Shanghai Chemical Reagent Company; other raw materials are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com