Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Reduce surface contact resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

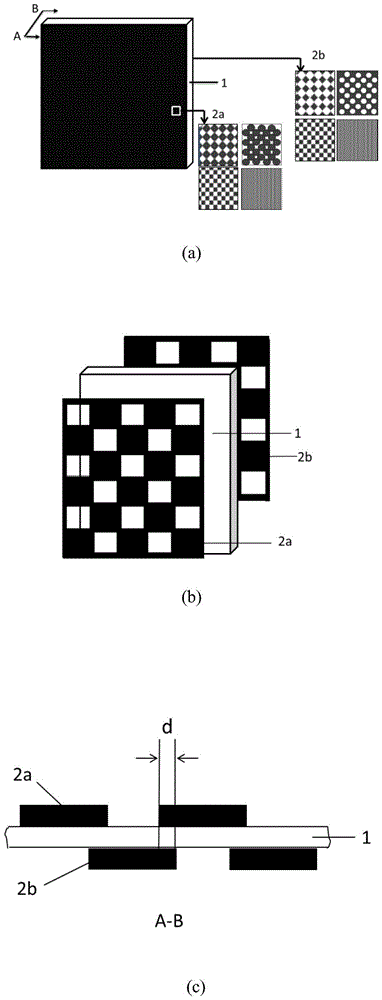

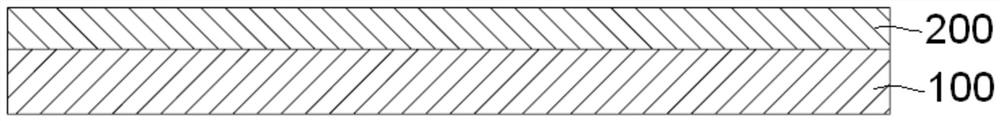

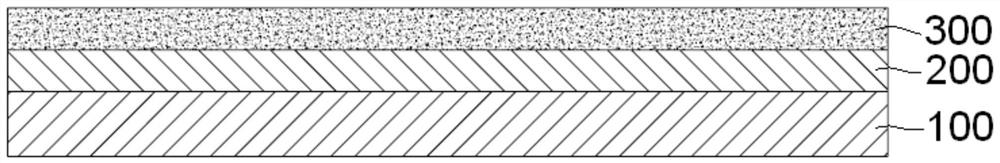

Bipolar current collector and preparation method thereof

ActiveCN104577132AEffectively hinder the passage ofPrevent leakageElectrode carriers/collectorsElectrolyte accumulators manufactureSurface chargesContact resistance

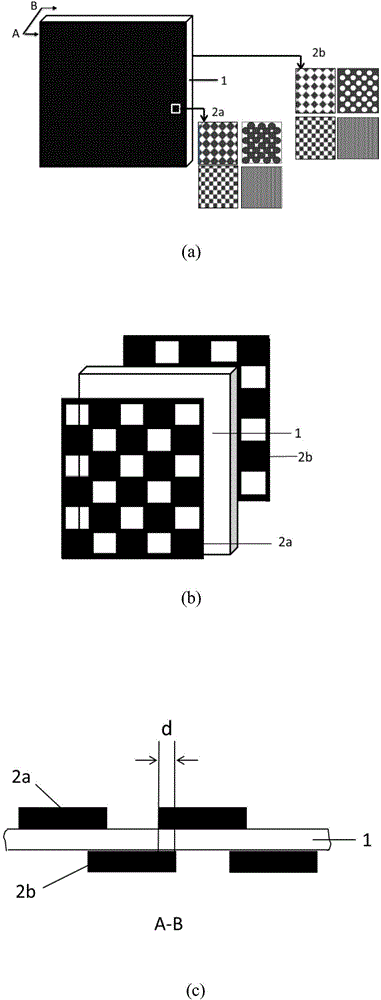

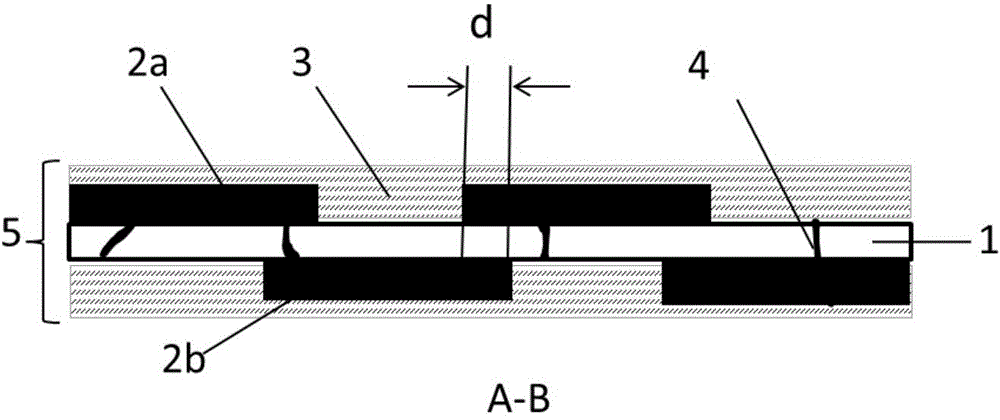

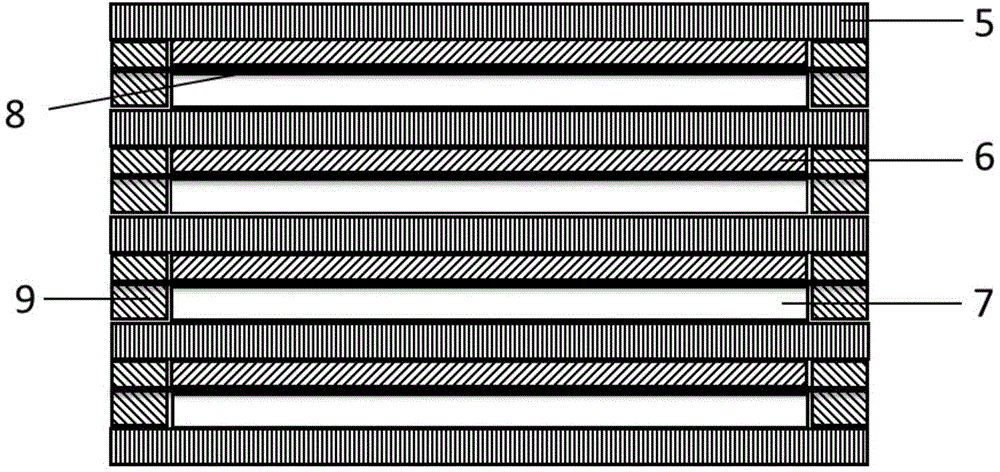

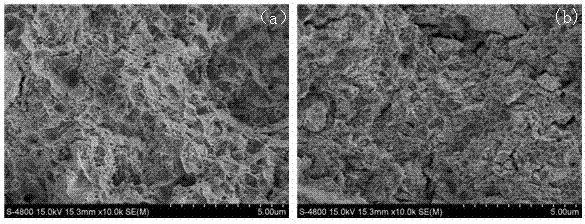

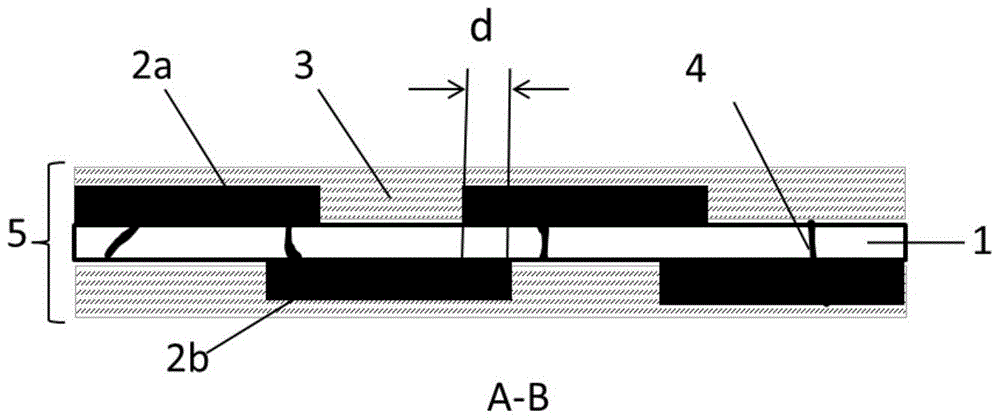

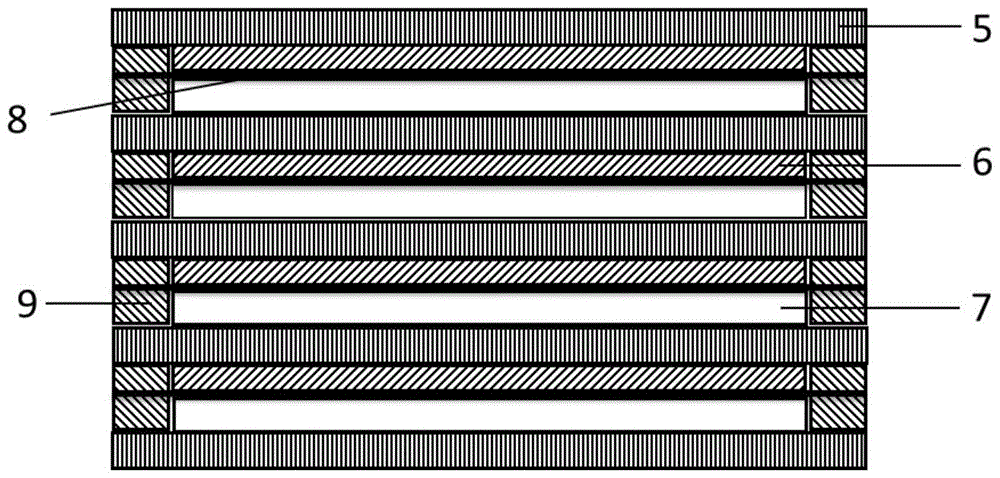

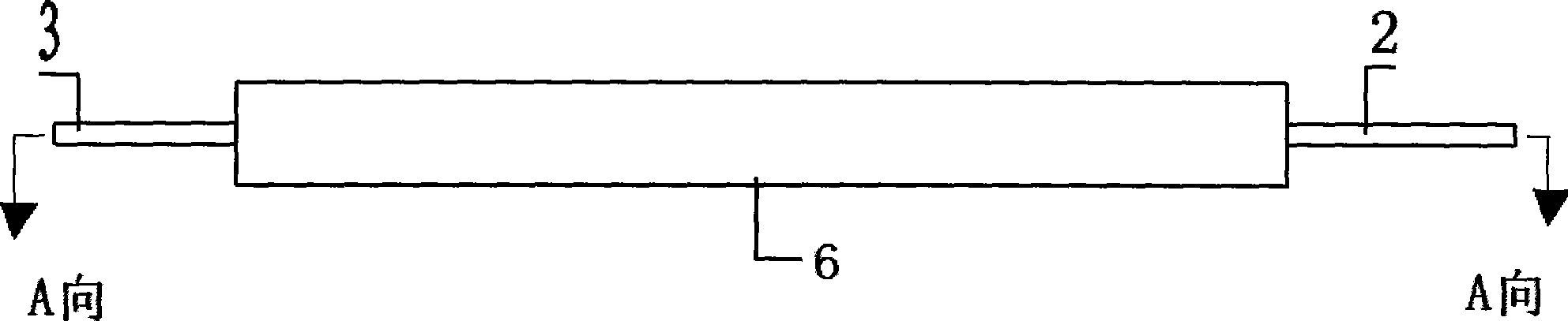

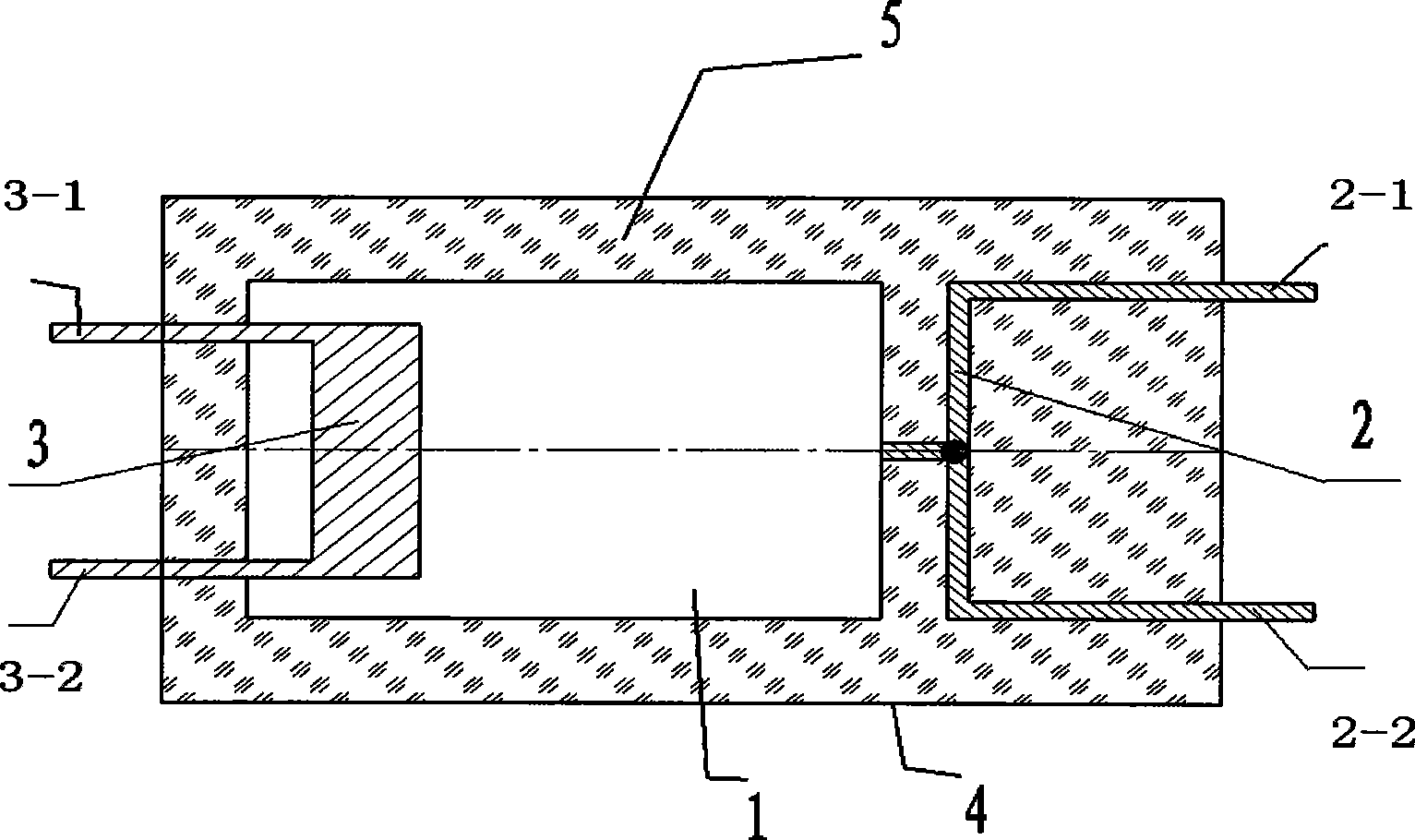

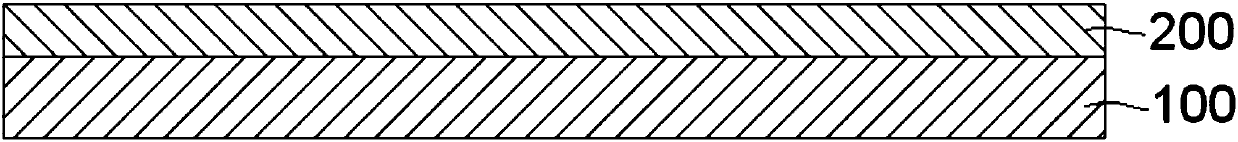

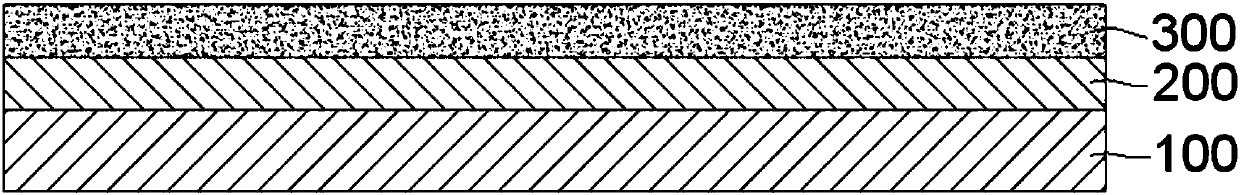

The invention provides a bipolar current collector and a preparation method thereof. The bipolar current collector comprises a conductive substrate film, polymer barrier film layers and conductive shunting layers, wherein upper and lower surfaces of the conductive substrate film are covered with the polymer barrier film layers and the conductive shunting layers, and the polymer barrier film layers are located between the conductive substrate film and the conductive shunting layers and cover upper and lower surfaces of the conductive substrate film in a staggered and complementary manner. The polymer barrier film layers can effectively prevent an electrolytic solution or a gel electrolyte from leaking in the bipolar current collector and prevent short circuits of a battery. Under the synergistic effect of two-sided complementary staggered covering structures of the polymer barrier film layers and the conductive shunting layers, the uniformity of the surface charge distribution of the bipolar current collector is improved, weakening caused by the polymer barrier film layers to the conductivity of the bipolar current collector is reduced to the greatest extent, and the surface contact resistance of the current collector is decreased; the bipolar current collector is prepared with an ink-jet printing method, and the method is efficient, energy-saving, clean and applicable to industrial production.

Owner:BEIJING HAWAGA POWER STORAGE TECH

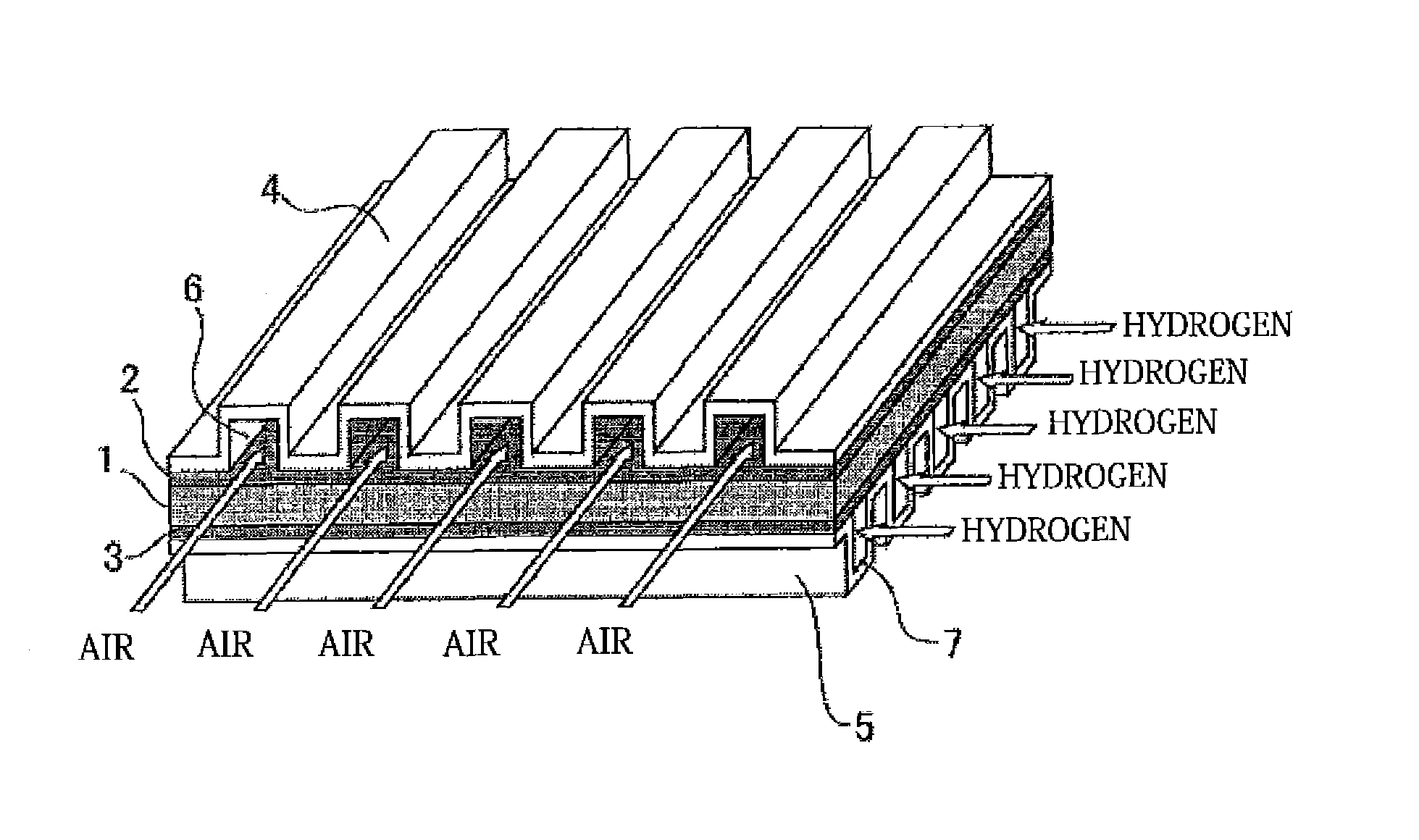

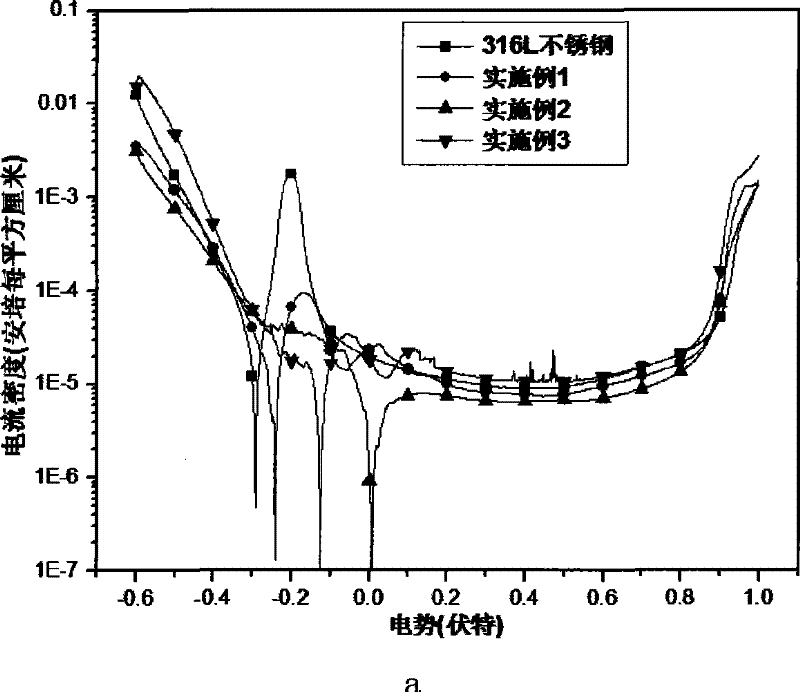

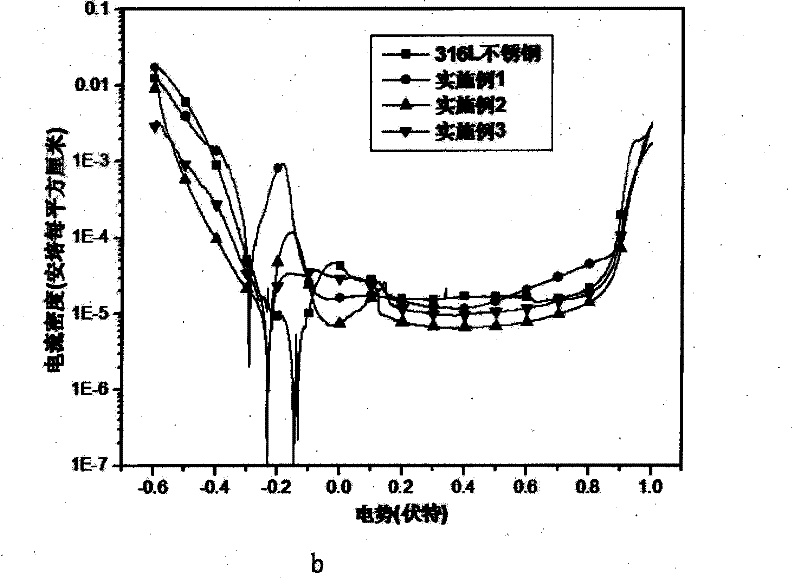

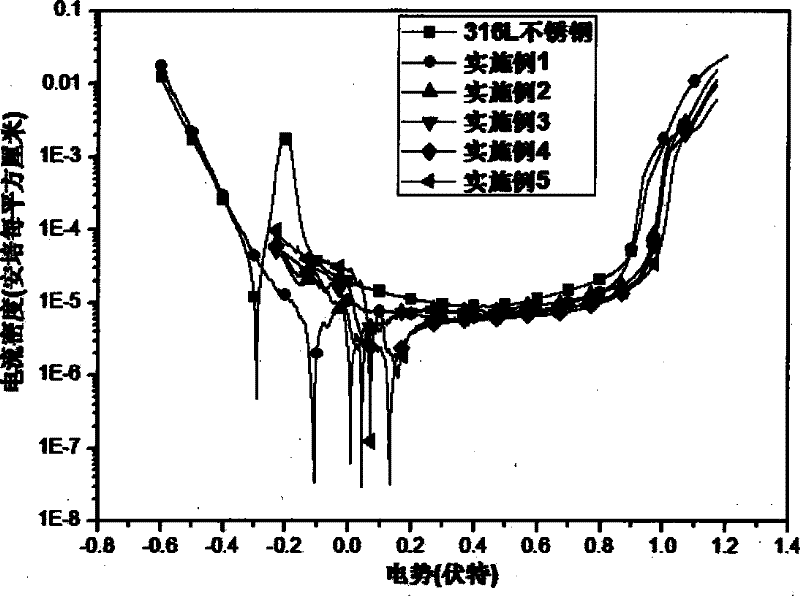

Metal bipolar plate for fuel cell and fabrication method of metal bipolar plate

ActiveCN105047975AImprove corrosion resistanceExtended service lifeCell electrodesSolid electrolyte fuel cellsThermal sprayingFuel cells

The invention discloses a metal bipolar plate for a fuel cell. The metal bipolar plate comprises a stainless steel substrate and a surface modification layer, wherein the surface modification layer comprises a continuous insulating layer and discontinuous conductive particles; and the continuous insulating layer and the discontinuous conductive particles are attached to the surface of the stainless steel substrate. According to the metal bipolar plate for the fuel cell disclosed by the invention, through a surface treatment technology of depositing the continuous insulating layer and the discontinuous conductive particles in combination on the surface, a compact protection layer can be formed; the corrosion rate of the metal bipolar plate is greatly reduced; the contact resistance can be reduced; and the service life of the metal bipolar plate is prolonged. The discontinuous conductive particles are deposited through a plasma thermal spraying technique; micro metallurgic bonding can be formed by the conductive particles and the stainless steel substrate; the adhesive force of the discontinuous conductive particles is improved; and the fabrication cost is reduced.

Owner:北京长征天民高科技有限公司

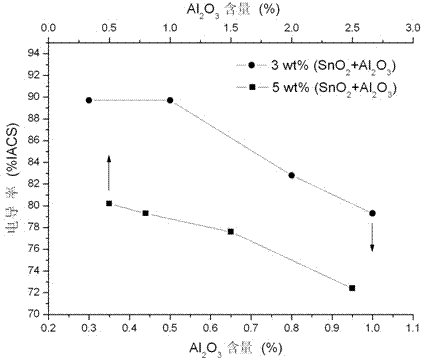

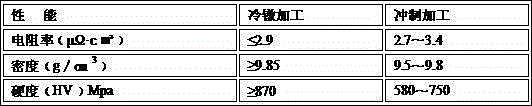

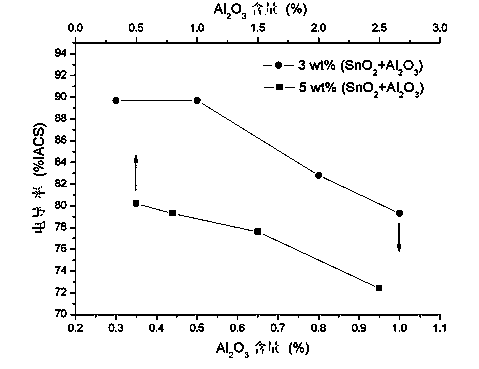

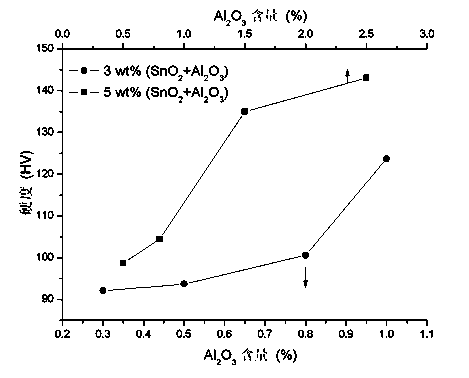

Preparation method for diphasic nanometer particle dispersion strengthening copper matrix composite material

ActiveCN102787250AReduce surface contact resistanceExcellent anti-arc burning performanceAlcoholPolyethylene glycol

The invention relates to a preparation method for diphasic nanometer particle dispersion strengthening copper matrix composite material and relates to the copper matrix composite material. A sol-gel process is combined with a wet powder mixing and powder metallurgic method in the preparation method, and the preparation method comprises the following steps: Ti4+ ion doped Sn(OH)4 dry powder and Al(OH)3 dry powder are prepared; SnO2-TiO2 nanometer powder and Al2O3 nanometer powder are prepared by calcination; a dispersing agent polyethylene glycol-20000 is added into the two powders to prepare turbid liquid in absolute ethyl alcohol, then electrolytic Cu powder is added and mixed in the turbid liquid to form a heavy paste mixture, and then the mixture is dried to prepare (0.3wt%-2.5wt% of Al2O3 + 0.7wt%-4.5wt% of SnO2-TiO2) / Cu composite powder; and finally the diphasic nanometer particle dispersion strengthening copper matrix composite material with high strength, high conductivity, good high temperature softening resisting performance and electric arc burning loss resisting performance and low surface contact resistance is obtained through pressing and sintering.

Owner:HEBEI UNIV OF TECH

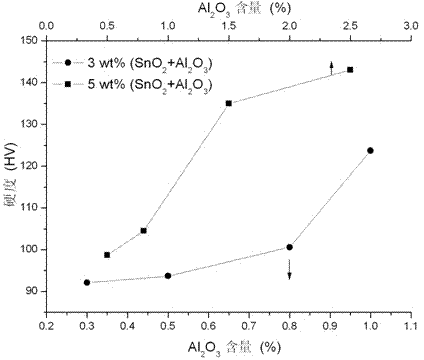

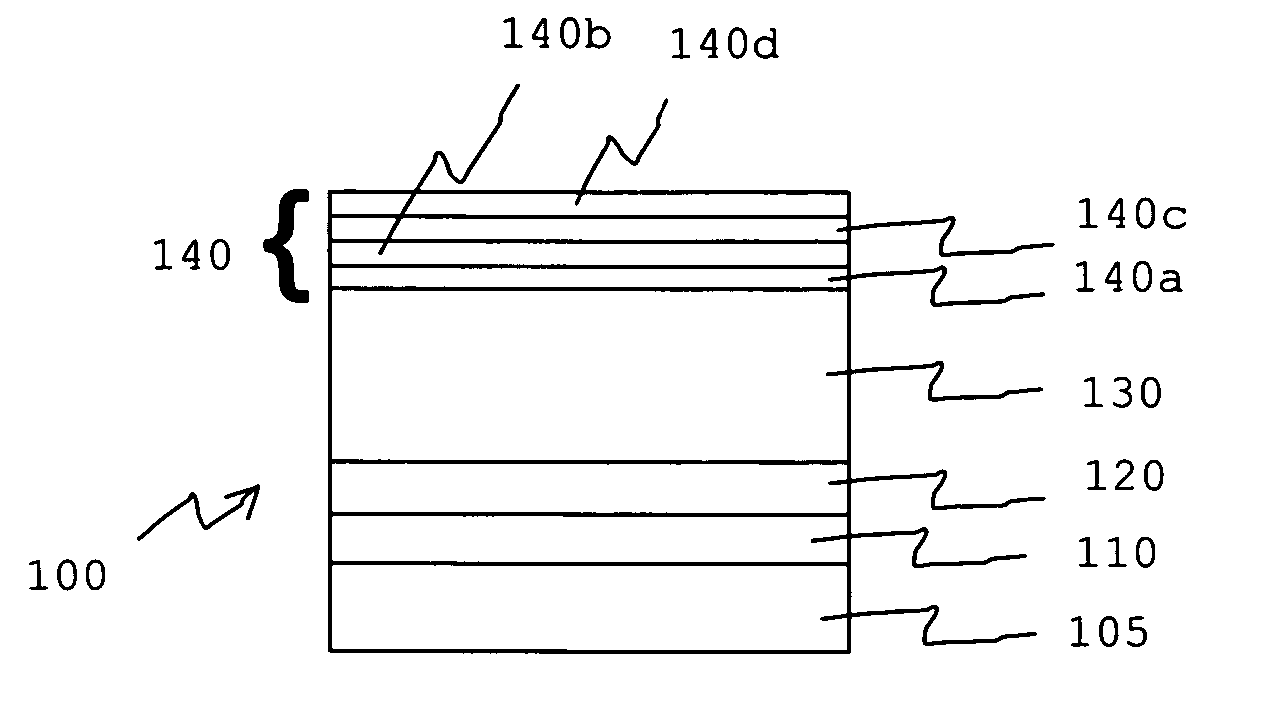

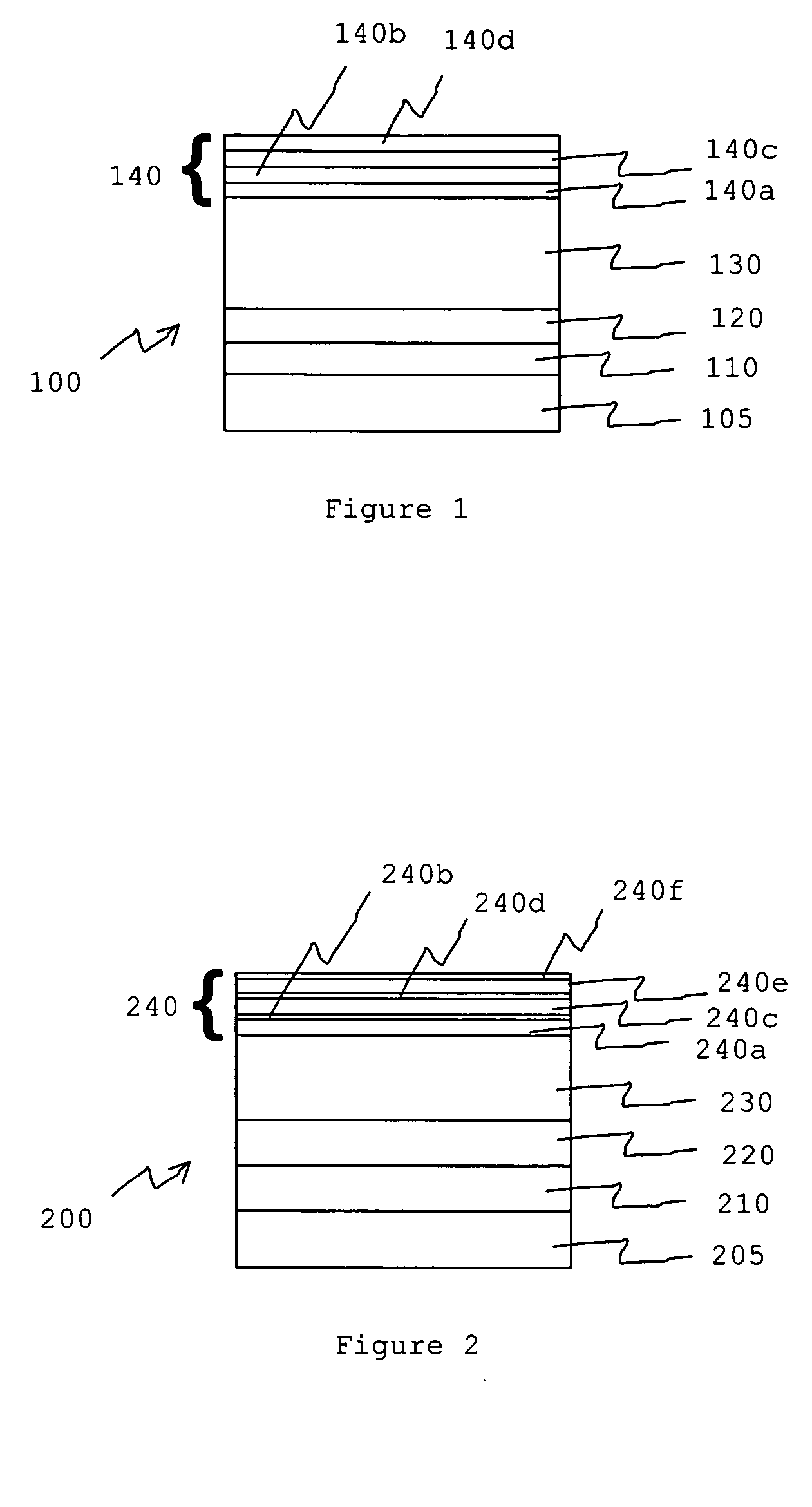

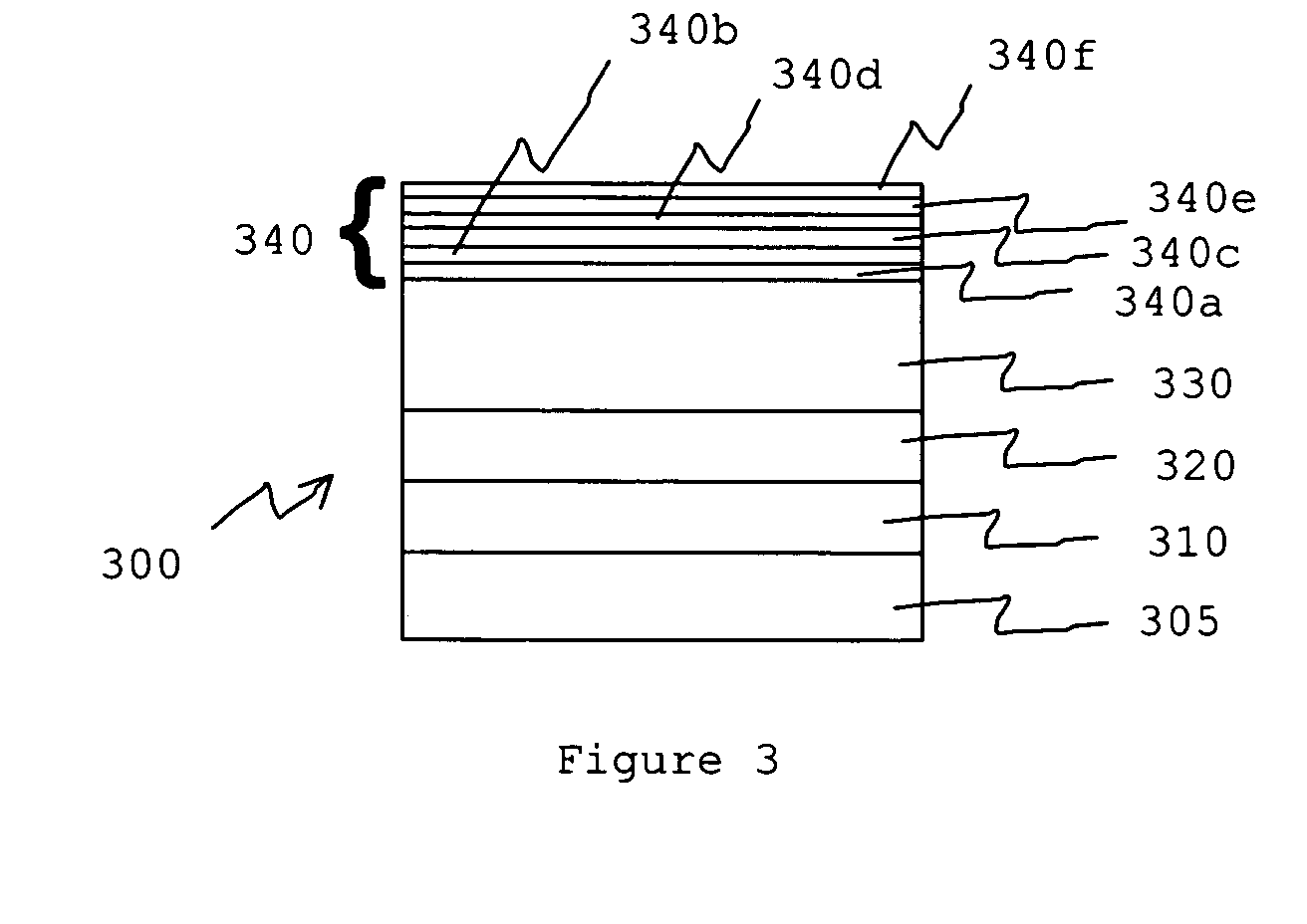

Conductive anti-reflection coating

ActiveUS20060023131A1Reduce surface contact resistanceNon-linear opticsOptical elementsElectrical resistance and conductanceThin layer

A conductive anti-reflection coating has a surface quarterwave layer that is broken up into smaller portions by inserting one or more thin layers of conductive material in the dielectric material. The resulting stack of alternating layers of a dielectric material and an electrically conductive material provides a solid electrical contact to the buried conductive layer and exhibits a low surface contact resistance.

Owner:VIAVI SOLUTIONS INC

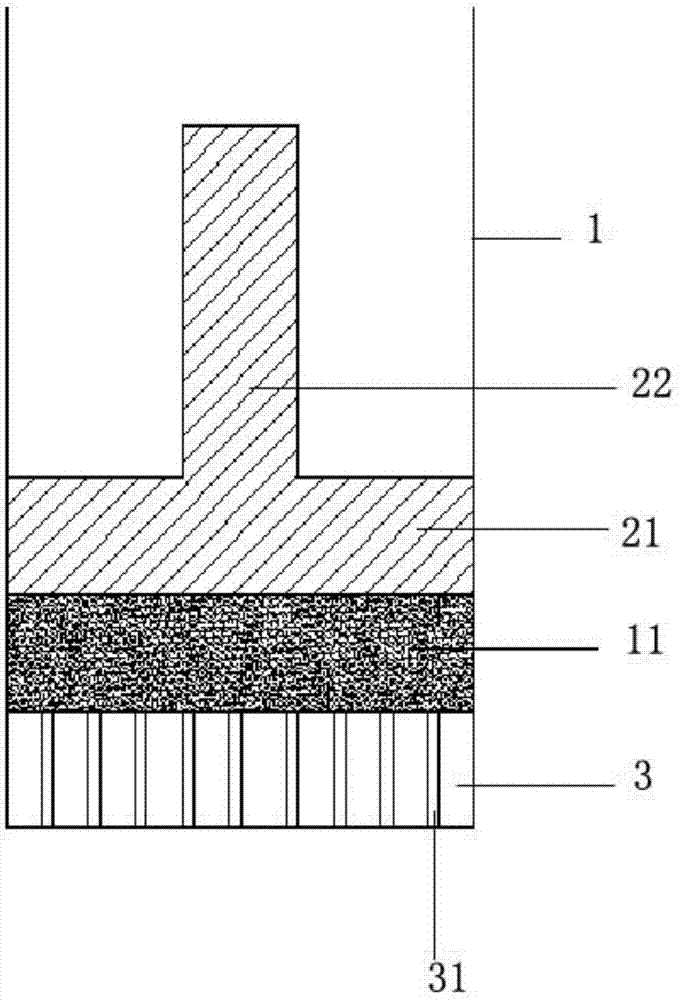

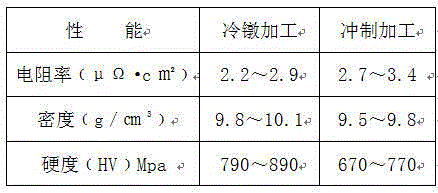

Preparation method of surface composite coating based on metal bipolar plate of proton exchange membrane fuel cell

PendingCN110364749AReduce surface contact resistanceExcellent self-healing performanceElectrolytic coatingsFinal product manufactureMetal substrateCorrosion

The invention relates to the technical field of fuel cells, and specifically relates to a preparation method of a surface composite coating based on a metal bipolar plate of a proton exchange membranefuel cell. The invention adopts an electrochemical method to deposit a conductive polymer intelligent composite coating doped with carbon powder on the metal surface. The metal bipolar plate, which is modified by the conductive polymer intelligent composite coating doped with carbon powder, of the proton exchange membrane fuel cell has the advantages that the corrosion current density is reduced,the long-term corrosion resistance is greatly improved, and the surface contact resistance is low. Meanwhile, the conductive polymer intelligent composite coating doped with carbon powder has strongadhesion, chemical stability and conductivity on the surface of the metal substrate. The preparation method has the advantages of simple operation, low manufacturing cost, safety, environmental protection and simple and easily obtained synthetic raw materials, and is widely applicable to protecting the metal bipolar plate of the proton exchange membrane fuel cell.

Owner:NANJING UNIV OF TECH

Surface treatment method of rivet electric contact, grinding material and grinding material preparation method

InactiveCN107378741AReduce contact resistanceRp decreasesEdge grinding machinesPolishing machinesEpoxyElectricity

The invention discloses a surface treatment method of a rivet electric contact, a grinding material and a grinding material preparation method. The surface treatment method comprises the following steps that mixed powder and epoxy resin are mixed according to the ratio and then placed in a stirring machine; gel is taken out after stirring is conducted for a period of time and then squeezed to obtain a blank; after being subjected to cold storage for a period of time, the blank is taken out, and then the cylindrical grinding material is obtained; and through the grinding material, rammer-making burrs and ring marks of the rivet electric contact can be rapidly removed, and the contact resistance can be decreased. According to the grinding material and the grinding material preparation method, the rammer-making burrs and ring marks of the rivet electric contact can be simultaneously removed, and the contact resistance is decreased; and meanwhile the grinding time is shortened, the testing cost is saved, and technological support is provided for development of the low-voltage electrical apparatus industry.

Owner:FUDA ALLOY MATERIALS

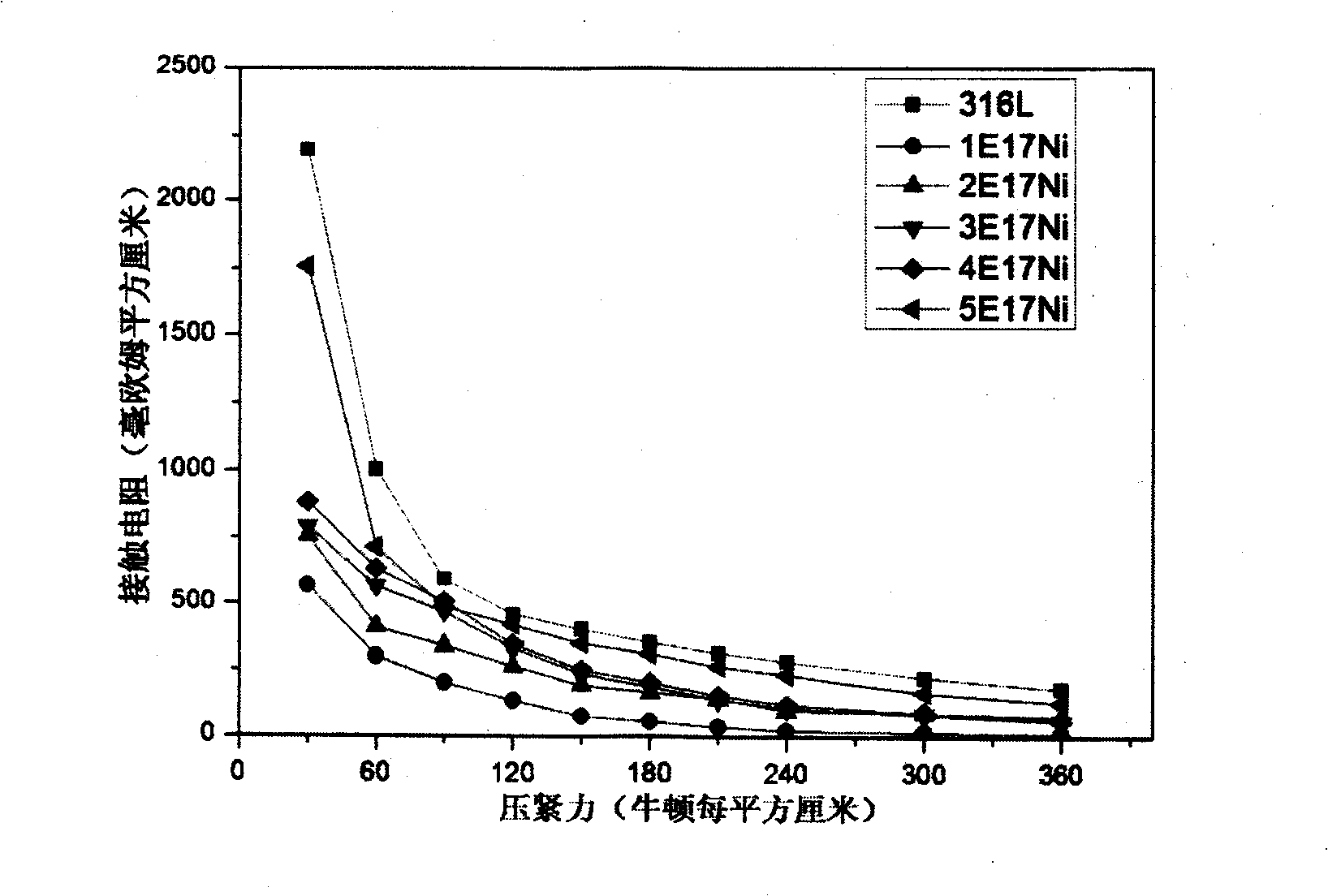

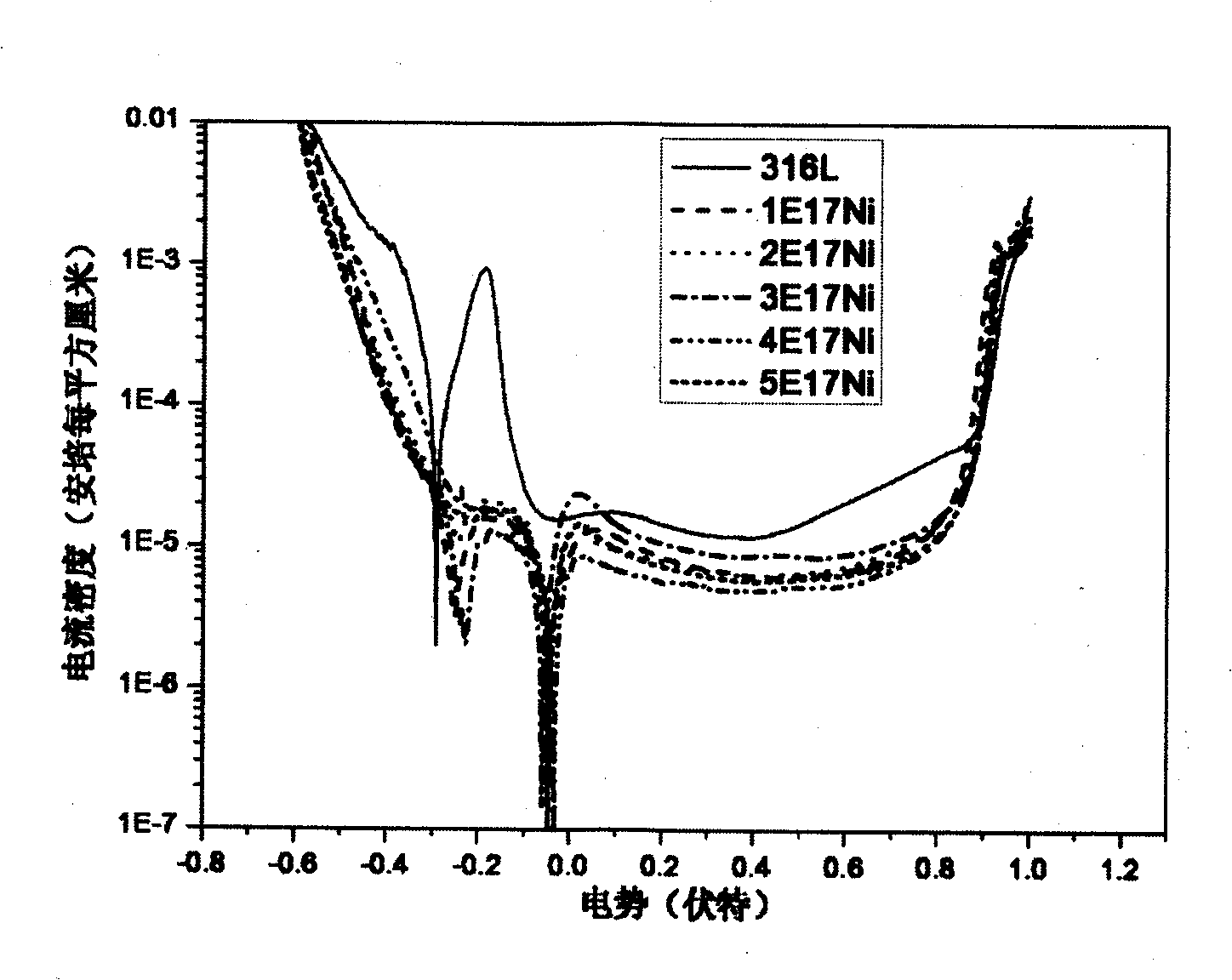

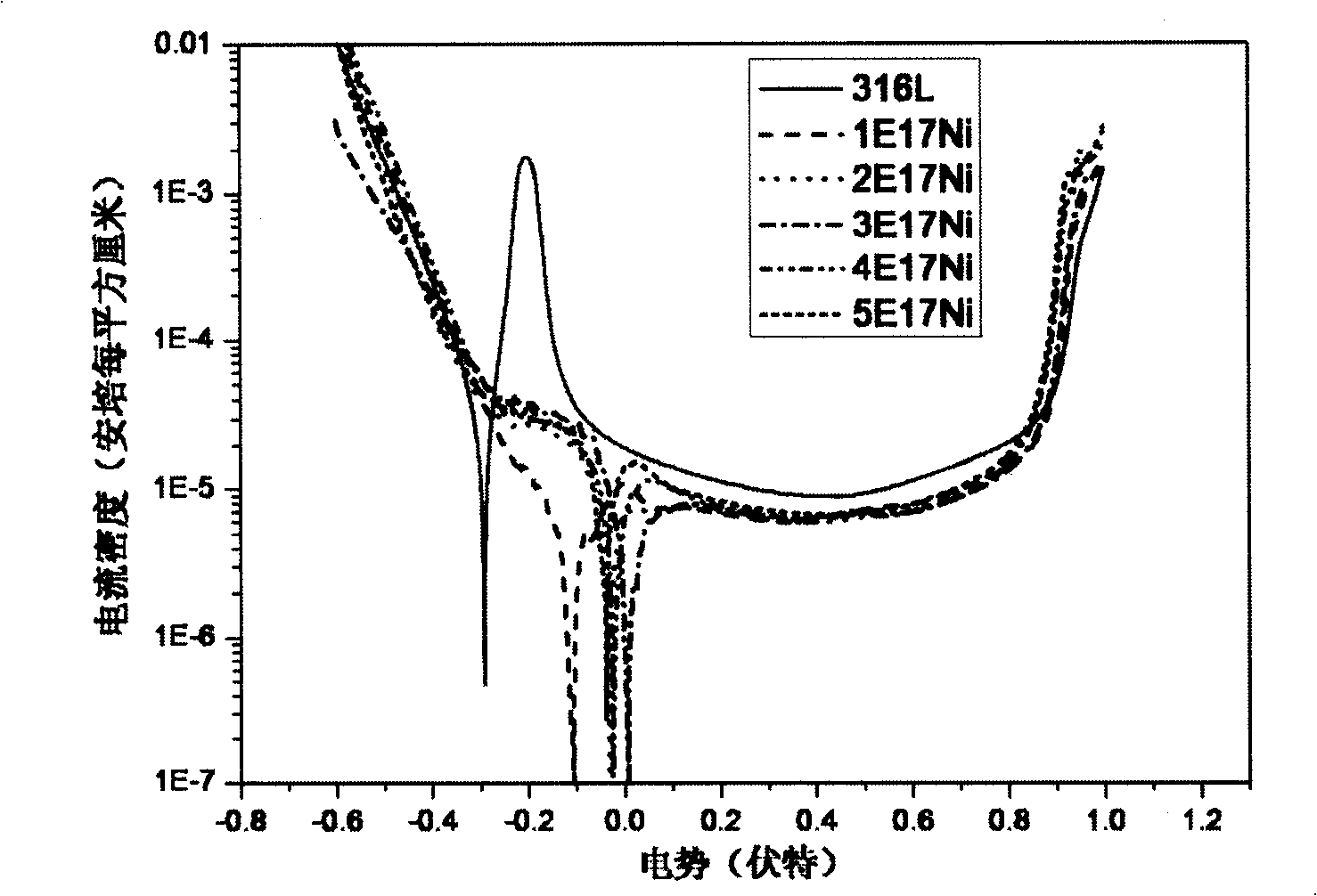

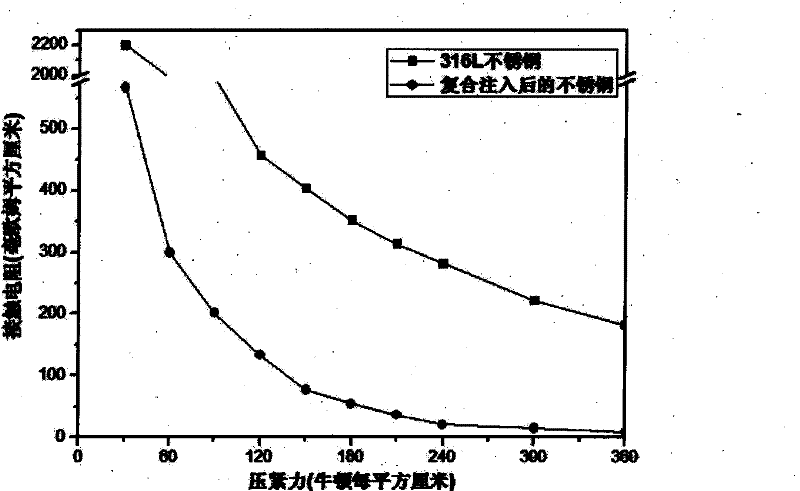

Composite ion injection method for dual polar plates of proton exchange membrane fuel cell

InactiveCN101393990AReduce material costsPrevent thermal reboundCell electrodesCollectors/separatorsCopperIon implantation

The invention relates to a method for injecting compound ions of a bipolar plate of a proton exchange membrane fuel cell in the technical field of fuel cells. The bipolar plate is composed of a surface modification layer and substrate stainless steel. By adopting the method of the ion injection, the ions in arbitrary combination of two elements of nickel, chromium and copper or of all three elements are injected into a stainless steel thin plate, and an injection layer is formed on the surface of the stainless steel thin plate within the range of dozens of nanometer, so as to obtain a modified stainless steel bipolar plate. The invention has the advantages that the corrosion resistance performance of a metallic bipolar plate can be further improved, the contact resistance of the metallic bipolar plate with a gas diffusion layer (carbon paper) can be reduced, a thinner bipolar plate can be produced, and the weight ratio energy and the volume ratio energy of a fuel cell can be increased, so as to satisfy the development requirement on the proton exchange membrane fuel cell.

Owner:SHANGHAI JIAO TONG UNIV

Manufacturing process for silver zinc oxide copper oxide electrical contact and electrical contact product

InactiveCN104201019AUniform metallographic structureFine grainContactsElectrical resistance and conductanceIngot casting

The invention discloses a manufacturing process for a silver zinc oxide copper oxide electrical contact and an electrical contact product. In the manufacturing process, the electrical contact product is manufactured through smelting, ingot casting, hot extrusion, drawing into ally wires, forming of required specification of sheet through cold heading, then diffusion annealing and oxidation treatment. The electrical contact product produced by adopting the preparation method is characterized in that the electrical contact product is low in surface contact resistance, good in electrical property and arc extinguishing performance, high in welding resistance and good in combination property. The processing method is simple, the material utilization rate is high, the detrimental impurity is few, the production cost is low, and the production cycle is low. The economic benefit and social benefit are particularly obvious.

Owner:张树堂

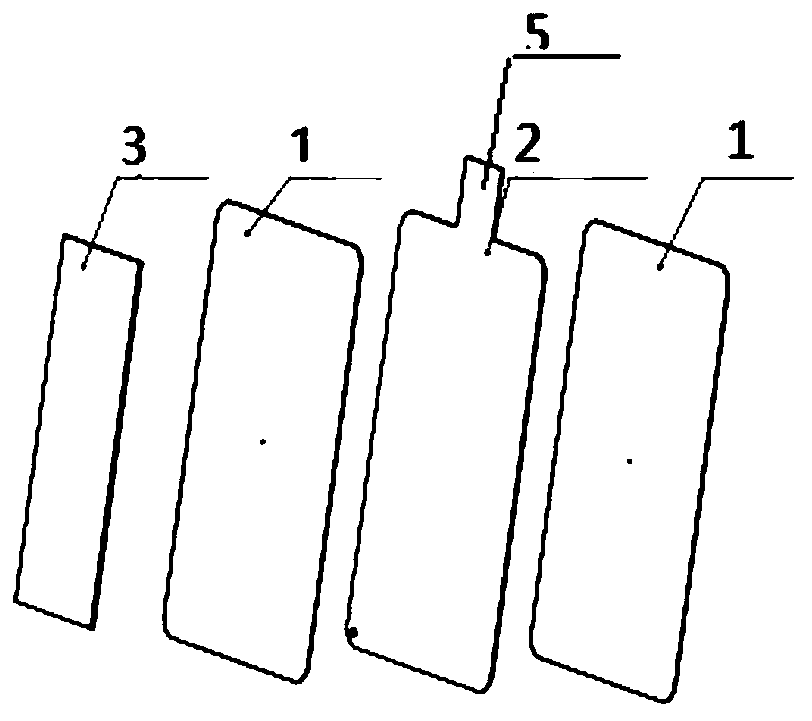

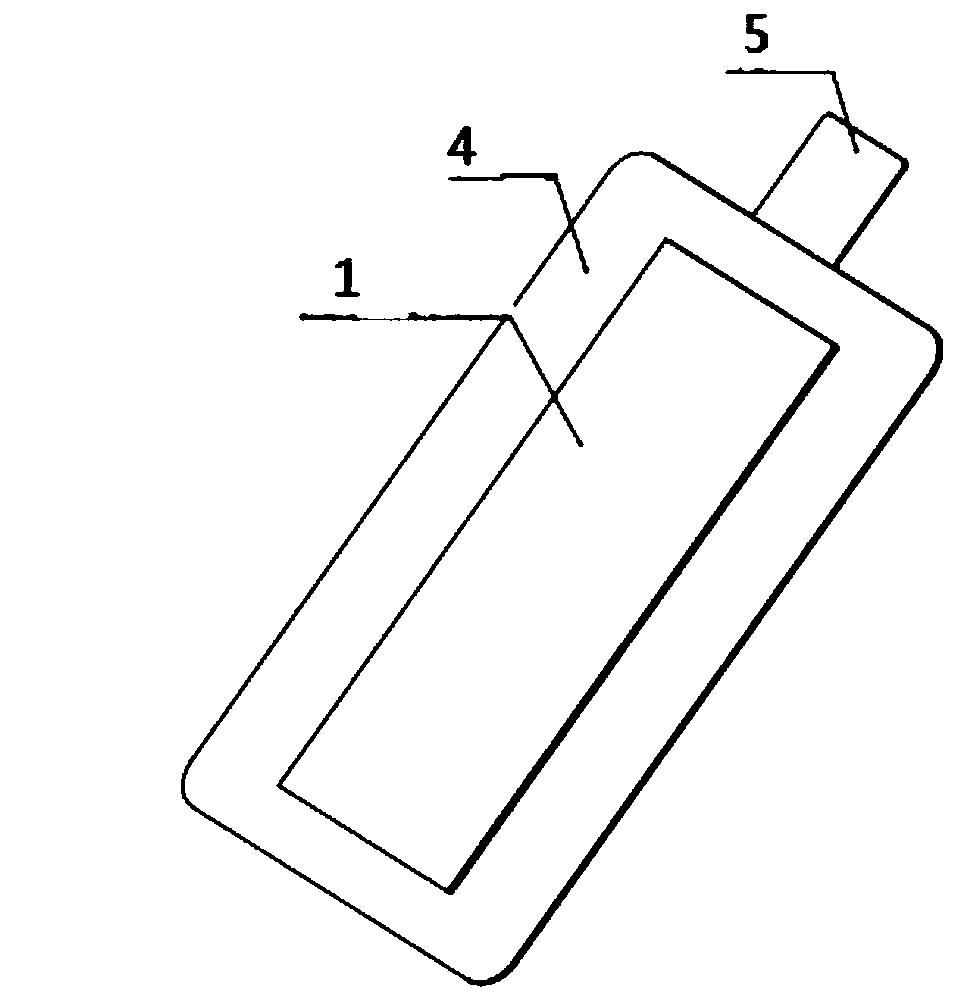

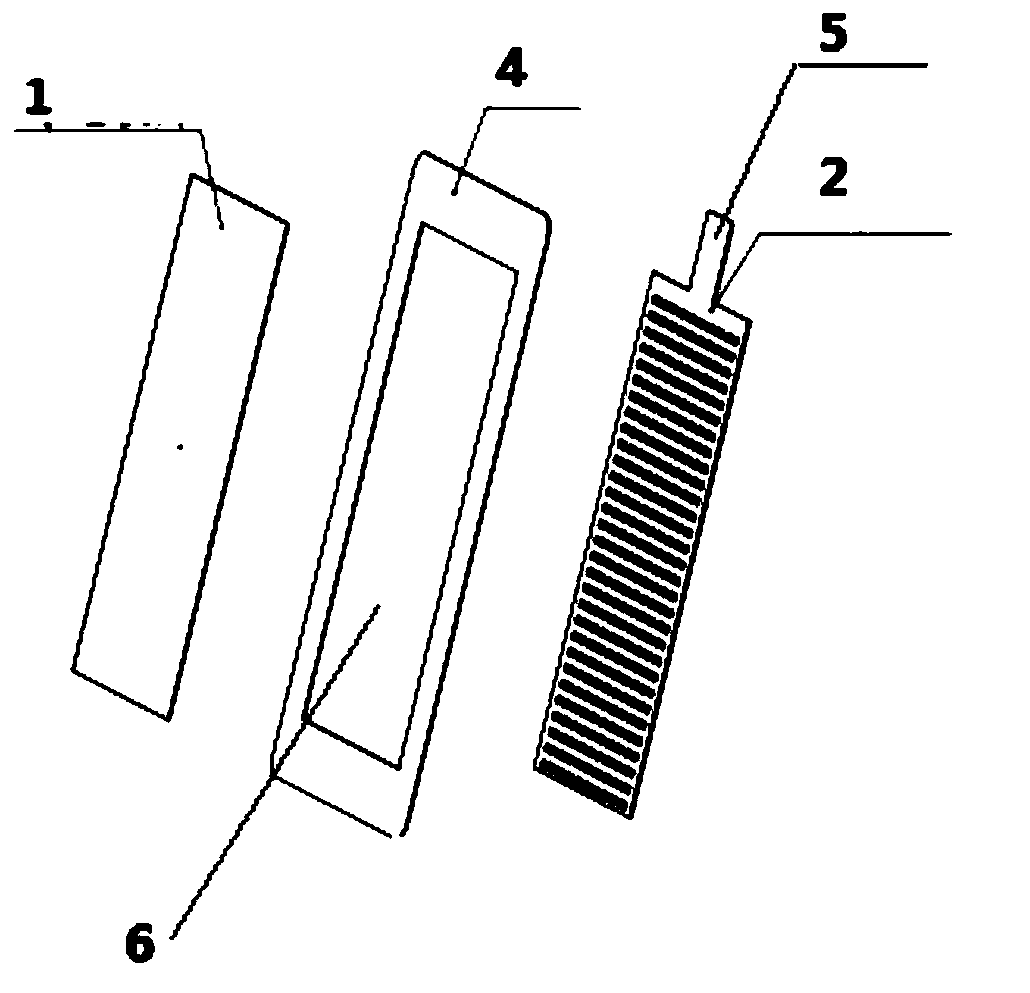

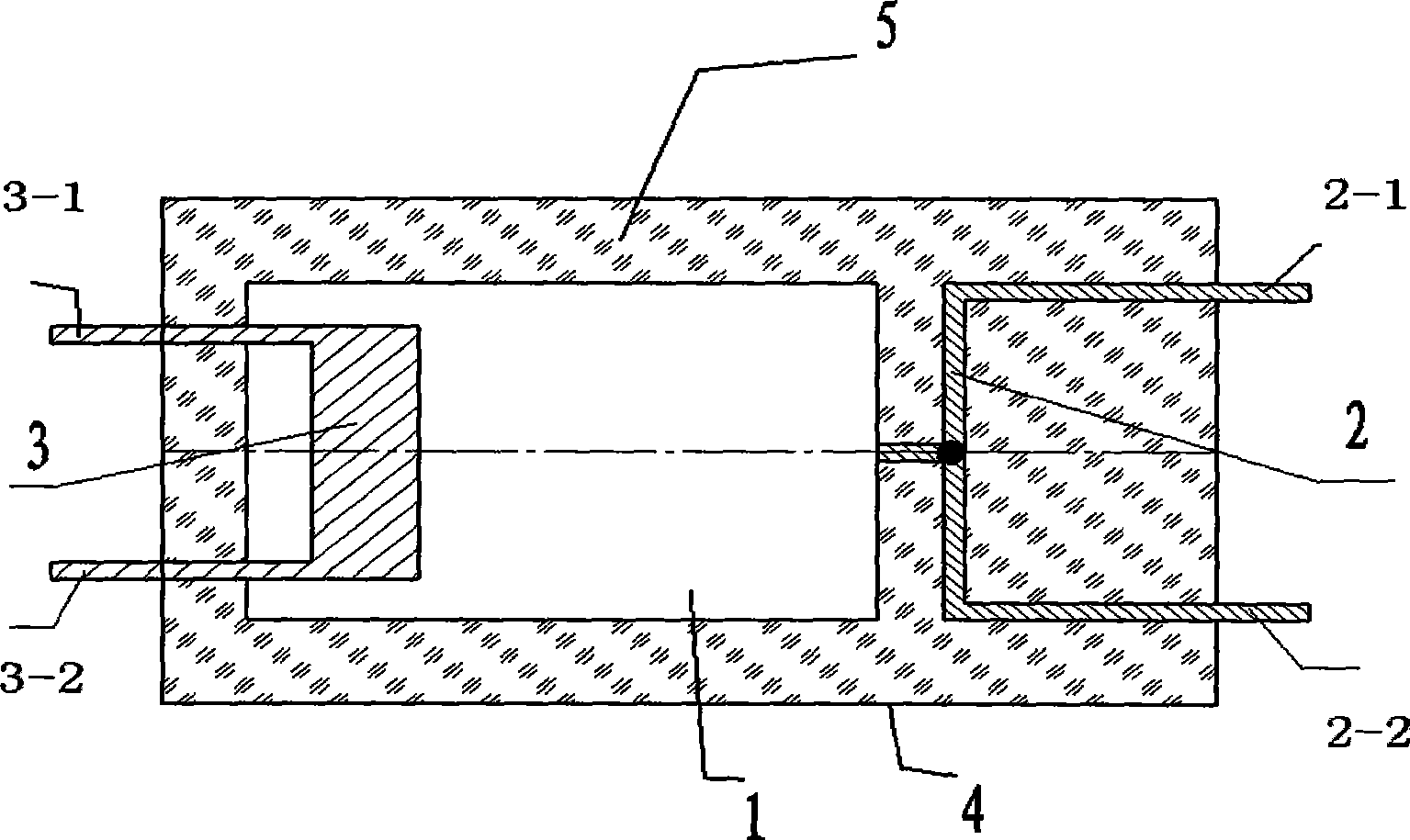

All-vanadium redox flow battery composite terminal electrode and preparation method thereof

ActiveCN110600750AImprove voltage efficiencyReduce surface contact resistanceCell electrodesRegenerative fuel cellsOxidation-Reduction AgentCopper electrode

The invention discloses an all-vanadium redox flow battery composite terminal electrode and a preparation method thereof. The composite terminal electrode comprises a carbon felt, an electrode slice,an insulating plate outer frame slice and a copper electrode slice. A hollow cavity which is through front and back is formed in the middle of the insulating plate outer frame slice; the electrode slice is fused in the hollow cavity of the insulating plate outer frame slice; the electrode slice, the insulating plate outer frame slice, the copper electrode slice, the insulating plate outer frame slice and the electrode slice are sequentially stacked in an inner cavity of the die; a hot pressing die is used for preparing a terminal electrode blank; and the carbon felt is welded on the surface ofthe electrode slice on the terminal electrode blank through a resistance welding machine. The preparation method comprises the following steps of: cutting and preparing the terminal electrode blank assembly, carrying out hot press molding on the terminal electrode blank, machining a terminal electrode blank, and welding the carbon felt layer to prepare the composite terminal electrode. The surface contact resistance is effectively reduced, the voltage efficiency of the flow battery is improved, the assembly process is simplified, and the assembly sealing risk is reduced.

Owner:江苏恒安储能科技有限公司

Stainless steel for fuel cell separators

ActiveUS9531014B2Reduce surface contact resistanceGood surface contact resistance characteristicResistance/reactance/impedenceCell component detailsElectrical resistance and conductanceFuel cells

Owner:JFE STEEL CORP

Alloy powder for silicon solar cell aluminum paste

ActiveCN103617820AImprove conductivityImprove wettabilityNon-conductive material with dispersed conductive materialPhotovoltaic energy generationSilicon solar cellContact resistance

The invention belongs to the technical field of electrode paste of solar cells, and particularly relates to alloy powder for silicon solar cell aluminum paste. The alloy powder comprises at least one type of first silicon aluminum alloy and at least one type of second silicon aluminum alloy. The mass content of silicon in the first silicon aluminum alloy is smaller than 12.73%, the mass content of the silicon in the second silicon aluminum alloy is larger than or equal to 12.73%, and both the melting point of the first silicon aluminum alloy and the melting point of the second silicon aluminum alloy are lower than 660 DEG C. Compared with the prior art, the alloy powder is added to the aluminum paste, so that conductive particles are firmly sintered together, surface contact resistance among aluminum particles is reduced, and the conductive performance of a thick film is excellent; formation of a deep doped p+ zone on a silicon wafer is facilitated and the conversion efficiency of a solar cell is improved; a sintering temperature window section is expanded, the manufacturability of a product is good, the technology sensibility of the defects such as aluminum beads, aluminum bubbles and dust generation in the sintering process of the aluminum paste is reduced, and the performance stability is improved.

Owner:DONGGUAN HYPER TECH COMPANY

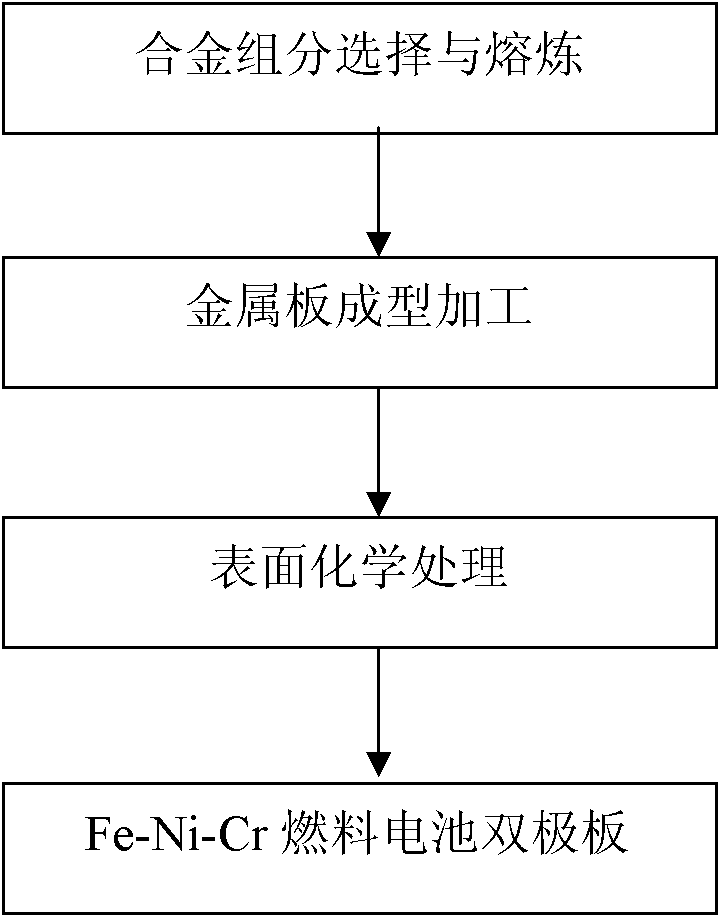

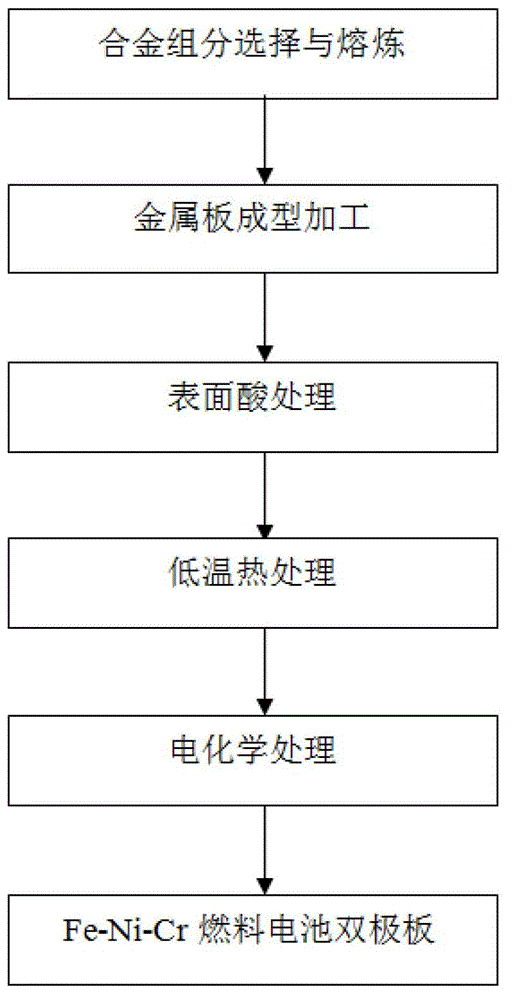

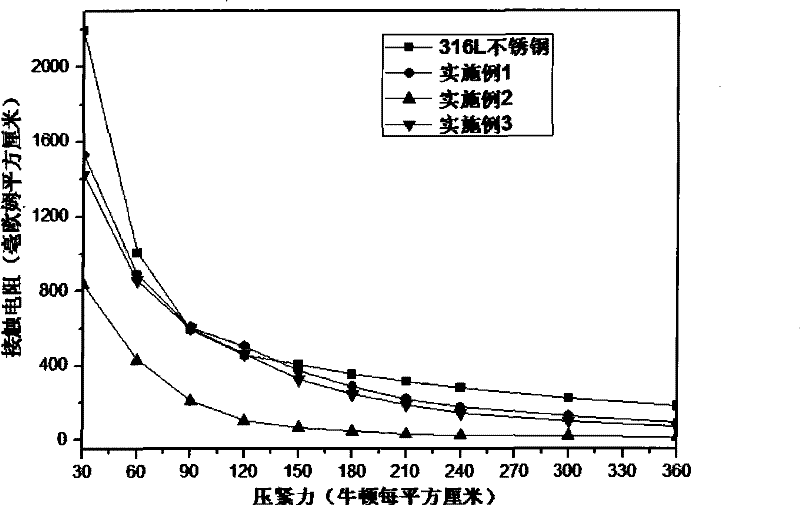

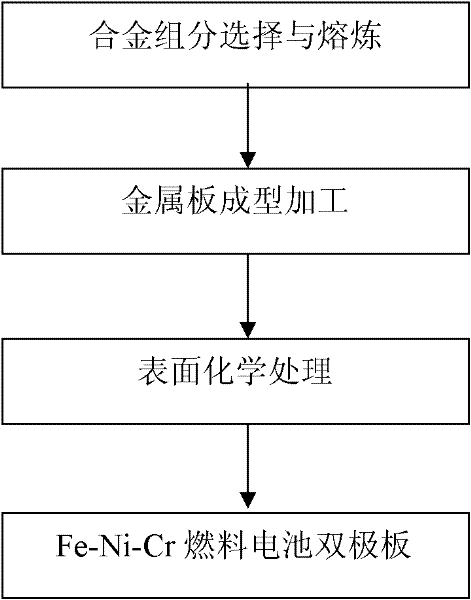

Manufacturing method of Fe-Ni-Cr alloy fuel cell bi-polar plate

InactiveCN101859904AChange surface propertiesImprove conductivityCell electrodesFuel cellsNi cr alloy

The invention belongs to the technical field of fuel cells, and relates to a manufacturing method of a Fe-Ni-Cr alloy fuel cell bi-polar plate. The method comprises the following steps of: mixing materials, wherein the materials comprise Fe with the content of x (atomic percentage), Ni with the content of y (atomic percentage) and Cr with the content of z (atomic percentage), x is equal to 37-39 percent, y is equal to 32-34 percent, z is equal to 28-30 percent, and the sum of x, y and z is 100 percent; smelting FexNiyCrz alloy by utilizing vacuum induction; molding and machining a metal plate; carrying out surface chemical treatment; placing the metal plate with a flow field in an HF water solution with the volume concentration of 45-50 percent under 20-30 DEG C and soaking for 7-9 min, taking out, cleaning and drying. The fuel cell bi-polar plate prepared by the method has the advantages of excellent corrosion resistance and conductivity, simple manufacturing process, low operation temperature, no easy deformation of the plate, suitability for assembly of a fuel cell pile and low cost.

Owner:WUHAN UNIV OF TECH

Manufacturing process and products of silver cadmium oxide zirconia electric contacts

InactiveCN104201018BUniform metallographic structureFine grainContactsElectrical resistance and conductanceSocial benefits

The invention discloses a manufacturing process for a silver cadmium oxide zirconium oxide electrical contact and an electrical contact product. In the manufacturing process, the electrical contact product is manufactured through smelting, ingot casting, hot extrusion, drawing into ally wires, forming of required specification of sheet through cold heading, then diffusion annealing and oxidation treatment. The electrical contact product produced by adopting the preparation method is characterized in that the electrical contact product is low in surface contact resistance, good in electrical property and arc extinguishing performance, high in welding resistance and good in combination property. The processing method is simple, the material utilization rate is high, the detrimental impurity is few, the production cost is low, and the production cycle is low. The economic benefit and social benefit are particularly obvious.

Owner:周朝贵 +1

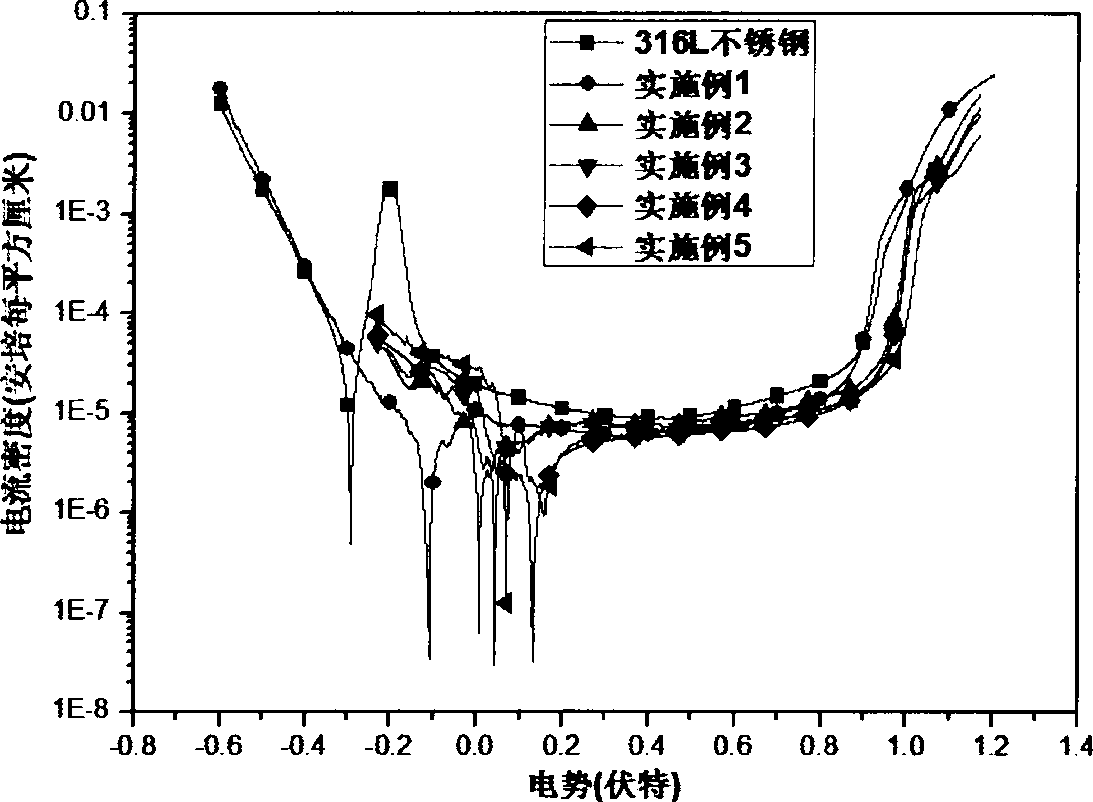

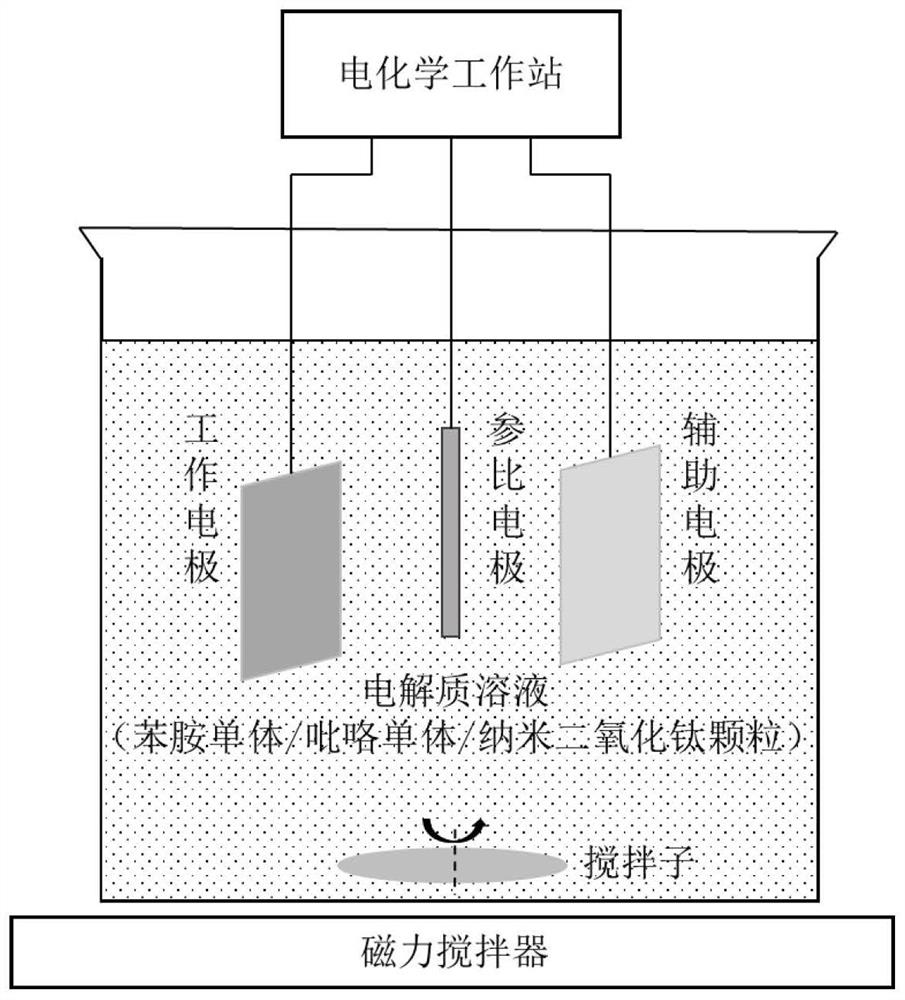

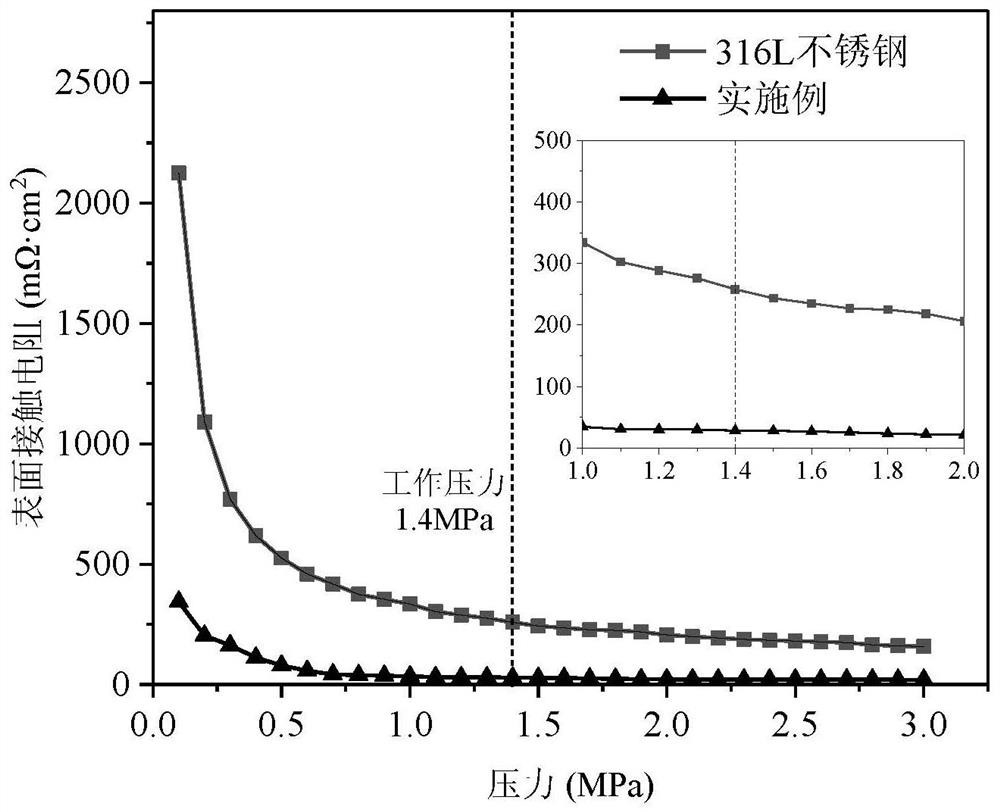

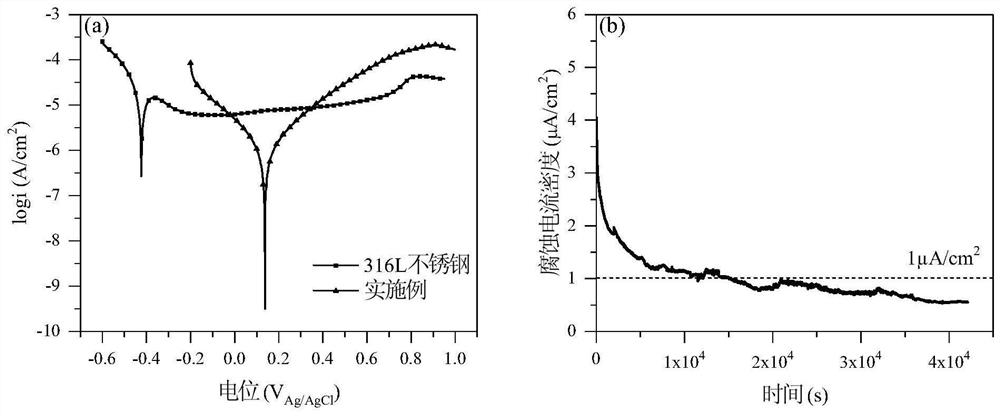

Preparation method of polyaniline-base composite coating applied to stainless steel bipolar plate

PendingCN113403663AReduce surface contact resistanceExcellent corrosion resistance and durabilityElectrolytic coatingsFinal product manufacturePyrroleGalvanic deposition

The invention relates to a preparation method of a high-corrosion-resistance and high-conductivity conductive polymer composite coating applied to a stainless steel bipolar plate of a proton exchange membrane fuel cell. The method comprises the following steps of preparing an aniline-pyrrole mixed solution, adding nano titanium dioxide particles and fully dispersing, preparing an electrolyte, and pretreating a stainless steel base material; and compounding and electrodepositing the polyaniline-base composite coating on the surface of stainless steel. The polyaniline-base composite coating has excellent corrosion resistance and stability and good conductivity, the use efficiency of the proton exchange membrane fuel cell can be improved, the service life of the proton exchange membrane fuel cell can be prolonged, the process is simple, the raw material cost is low, and the coating is suitable for industrial grade production.

Owner:EAST CHINA UNIV OF SCI & TECH

Manufacturing process for silver tin oxide calcium oxide electrical contact and electrical contact product

InactiveCN104201020AUniform metallographic structureFine grainElectric switchesFusion weldingMetallurgy

The invention discloses a manufacturing process for a silver tin oxide calcium oxide electrical contact and an electrical contact product. In the manufacturing process, the electrical contact product is manufactured through smelting, ingot casting, hot extrusion, drawing into ally wires, forming of required specification of sheet through cold heading, then diffusion annealing and oxidation treatment. The electrical contact product produced by adopting the preparation method is characterized in that the electrical contact product is low in surface contact resistance, good in electrical property and arc extinguishing performance, high in welding resistance and good in combination property. The processing method is simple, the material utilization rate is high, the detrimental impurity is few, the production cost is low, and the production cycle is low. The economic benefit and social benefit are particularly obvious.

Owner:周朝贵 +1

Preparation method of PERC battery

PendingCN112635617AReduce tensionIncrease profitFinal product manufactureChemical vapor deposition coatingRefractive indexPhysical chemistry

The invention belongs to the technical field of photovoltaics, and particularly relates to a preparation method of a PERC battery. The method is mainly used for improving the efficiency of the PERC battery. The method comprises a diffusion step, an etching step and a back film step which are carried out in sequence, an etching solution is adopted in the etching step, and chemical components of the etching solution comprise HNO3, HF, H2SO4 and H2O; and in the back film step, SiH4 and NH3 are adopted to carry out film coating deposition on the back surface of the silicon wafer, and the film coating deposition times is twice. Compared with the prior art, the method increases the refractive index of the silicon wafer substrate, increases the light absorption rate of the PERC cell, and increases the efficiency of the PERC cell.

Owner:ZHEJIANG BEYONDSUN PV

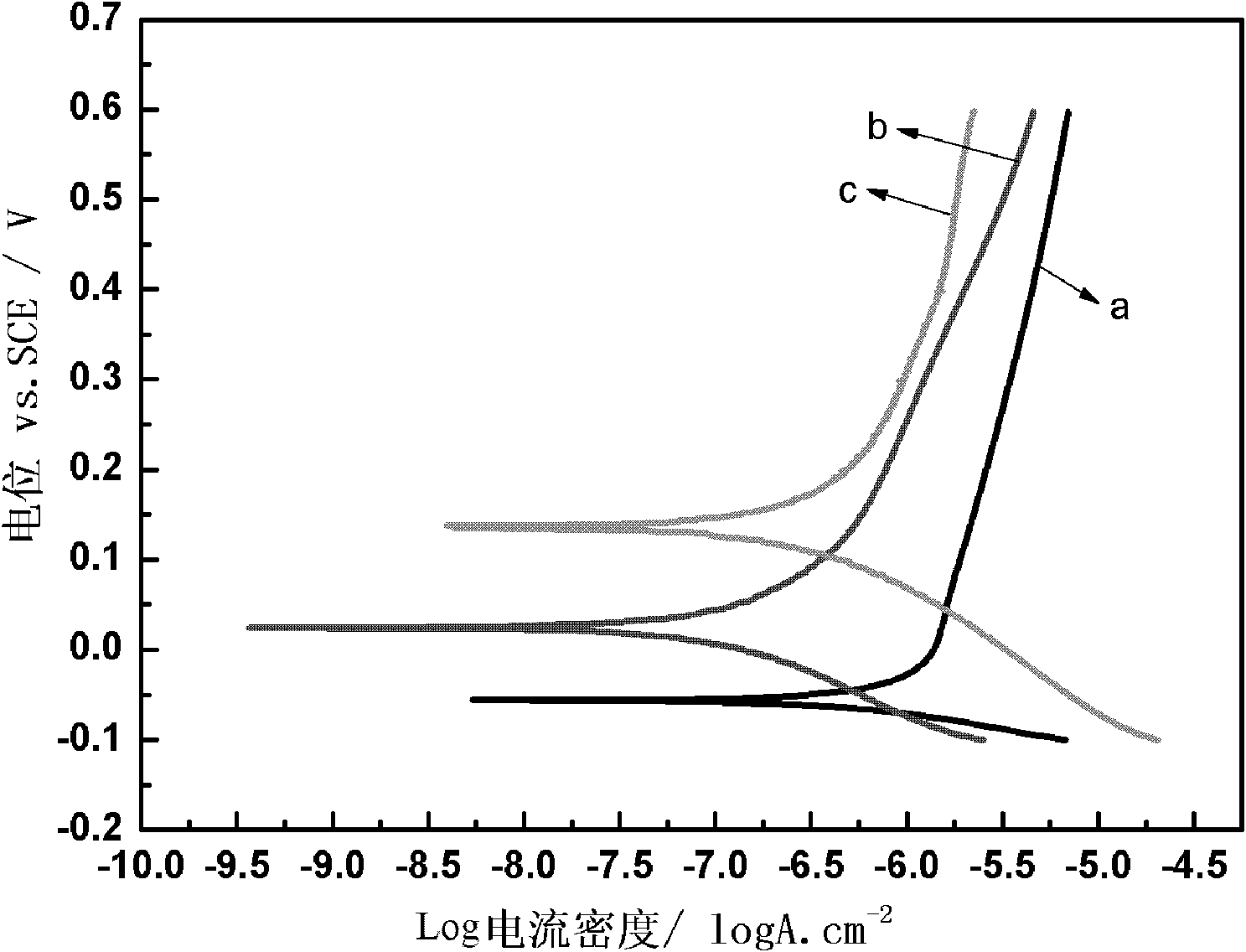

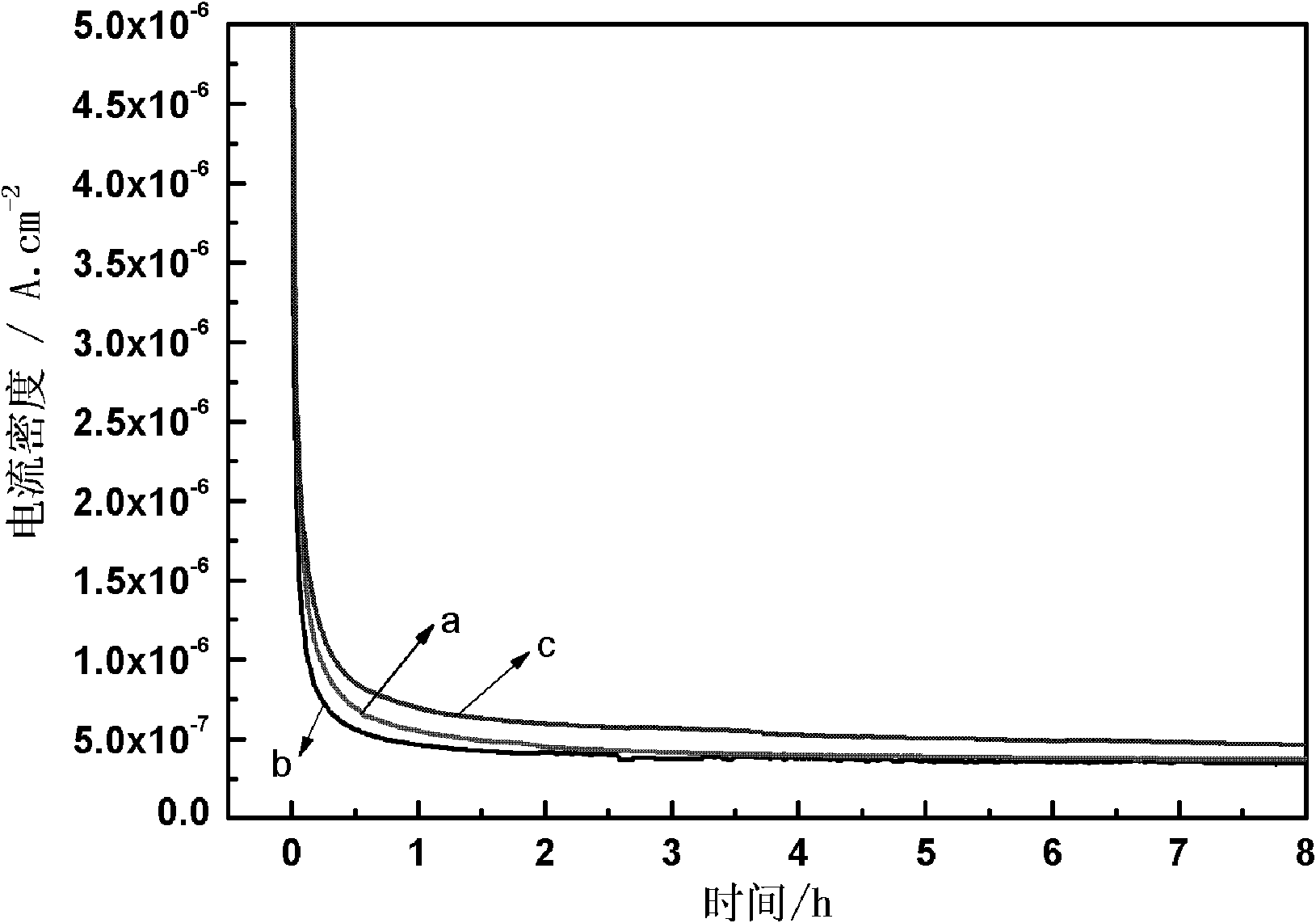

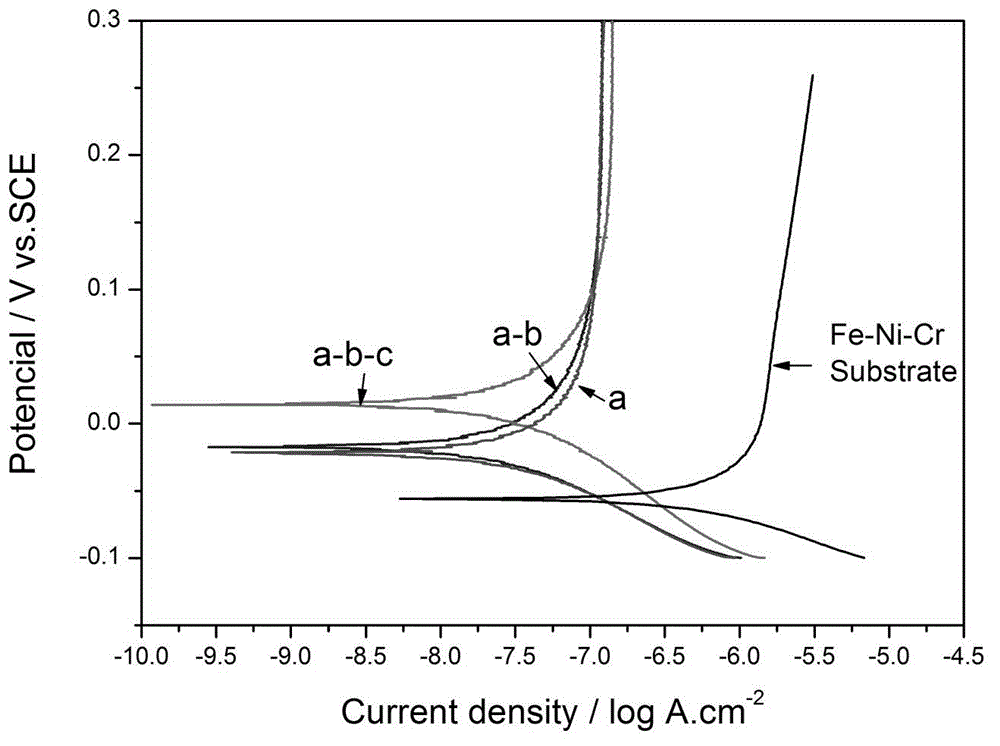

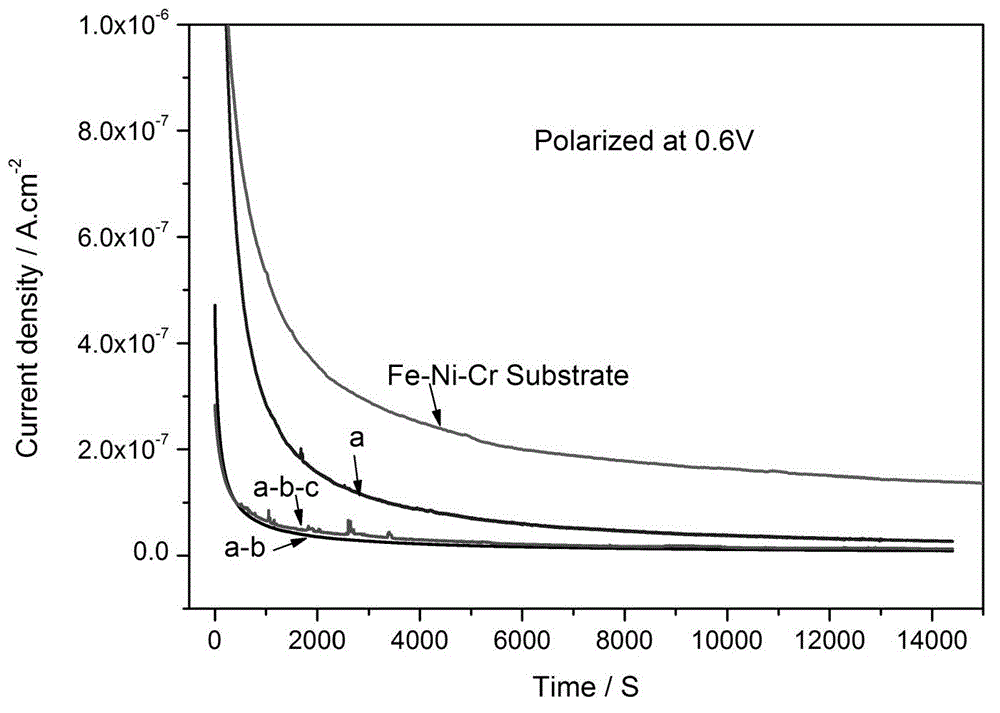

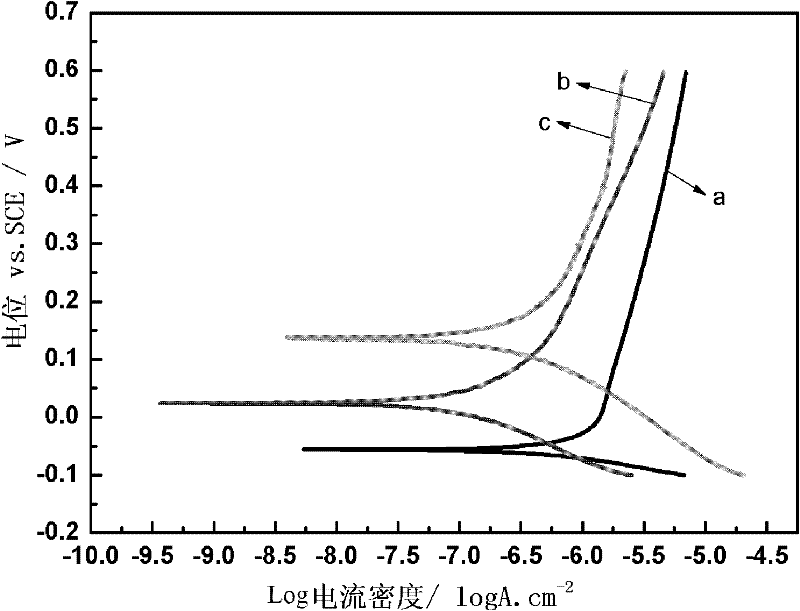

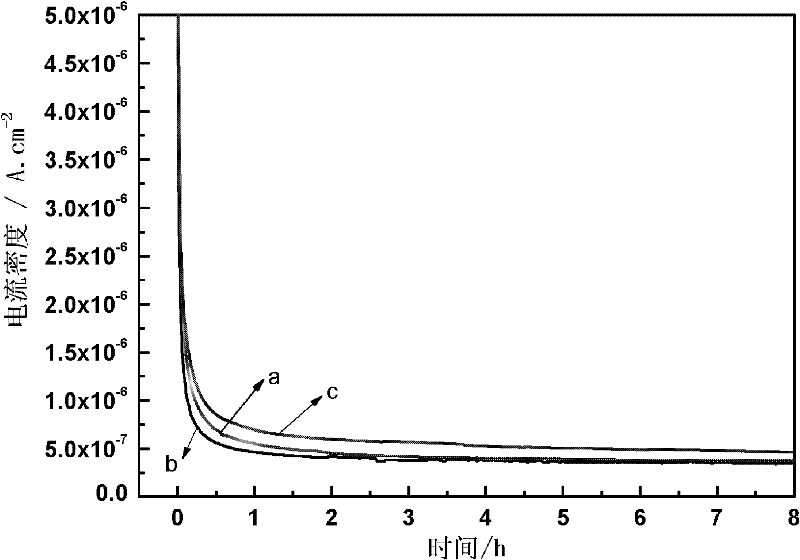

In-situ preparation method of carbonized film on surface of Fe-Ni-Cr bipolar plate

InactiveCN103337638AImprove corrosion resistanceImprove performanceCell electrodesFuel cellsNi cr alloy

The invention belongs to the technical field of fuel cells and provides an in-situ preparation method of a carbonized film on the surface of a Fe-Ni-Cr bipolar plate. The in-situ preparation method is characterized by comprising the following steps of: (1) alloy component selecting and melting, namely, mixing the components based on that the atomic percentage content of the component Fe is x, the atomic percentage content of the component Ni is y and the atomic percentage content of the component Cr is z and carrying out vacuum induction melting on the FexNiyCrz alloy, wherein x is equal to 37-39%, y is equal to 32-34%, z is equal to 28-30% and the sum of x, y and z is 100%; (2) metal plate forming processing, namely, processing the FexNiyCrz alloy into a metal plate with a flow field according to the conventional method; and (3) in-situ surface treatment, namely, carrying out surface acid treatment (a), low-temperature heating treatment (b) and electrochemical treatment (c) on the metal plate with the flow field obtained in the step (2) in sequence, thus obtaining the Fe-Ni-Cr alloy bipolar plate of a fuel cell. The bipolar plate of the fuel cell, prepared by using the method, has excellent corrosion resistance and electrical conductivity, and is simple in manufacturing process, low in cost, not easy to deform and suitable for assembling fuel cell stacks.

Owner:WUHAN UNIV OF TECH

A kind of bipolar current collector and its preparation method

ActiveCN104577132BEffectively hinder the passage ofPrevent leakageElectrode carriers/collectorsElectrolyte accumulators manufactureSurface chargesContact resistance

The invention provides a bipolar current collector and a preparation method thereof. The bipolar current collector comprises a conductive substrate film, polymer barrier film layers and conductive shunting layers, wherein upper and lower surfaces of the conductive substrate film are covered with the polymer barrier film layers and the conductive shunting layers, and the polymer barrier film layers are located between the conductive substrate film and the conductive shunting layers and cover upper and lower surfaces of the conductive substrate film in a staggered and complementary manner. The polymer barrier film layers can effectively prevent an electrolytic solution or a gel electrolyte from leaking in the bipolar current collector and prevent short circuits of a battery. Under the synergistic effect of two-sided complementary staggered covering structures of the polymer barrier film layers and the conductive shunting layers, the uniformity of the surface charge distribution of the bipolar current collector is improved, weakening caused by the polymer barrier film layers to the conductivity of the bipolar current collector is reduced to the greatest extent, and the surface contact resistance of the current collector is decreased; the bipolar current collector is prepared with an ink-jet printing method, and the method is efficient, energy-saving, clean and applicable to industrial production.

Owner:BEIJING HAWAGA POWER STORAGE TECH

Solid tantalum electrolytic capacitor and manufacturing method thereof

InactiveCN101345139BIncrease surface areaReduce surface contact resistanceSolid electrolytic capacitorsElectrolytic capacitorElectron

The invention relates to a solid Ta electrolytic capacitor and a preparation method thereof, comprising a flat cuboid capacitor body which consists of a Ta core, an insulator and a metal shell, and a flat cathode dual-head leading wire and a flat anode dual-head leading wire which are arranged in a C-shape and respectively led out of the anode and cathode of the two ends of the body; in order to prepare the capacitor, firstly, the Ta core in flat cuboid shape is prepared; the C-shaped flat cathode dual-head leading wire and the anode dual-head leading wire are assembled with the Ta core; subsequently, resin is poured so as to form the capacitor by natural solidification. The electrolytic capacitor adopting the structure reduces the surface contact resistance of the product and has obviouseffect on reducing the high frequency ESR value of the product and improving the high frequency characteristic of the product as the capacitor body structure is changed into flat cuboid and the surface area of a Ta block is increased; after two ends of the leading wire are bent to parallel flat dual-head leading wire, most of the generated inductance can be counteracted, and the frequency range of the inductance appearing in the electronic circuit is delayed.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

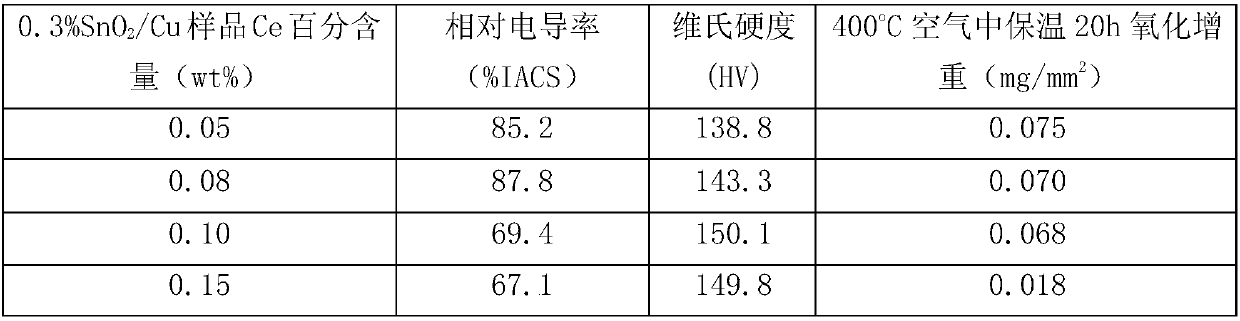

Copper-based electrical contact material for low-voltage electrical appliances and preparation method thereof

InactiveCN106683914BHigh viscosityExcellent anti-arc burning performanceContactsLow voltageOxidation resistant

The invention discloses a copper-based electrical contact material used for a low-voltage electric appliance and a preparation method for the copper-based electrical contact material, and relates to a contact by taking copper as a substrate material. The copper-based electrical contact material is prepared from the following components based on mass percentage: 0.05-0.5% of Ce, 0.1-1.0% of TiO<2>-doped SnO<2> nanoparticles and the balance of Cu, wherein the TiO<2>-doped SnO<2> nanoparticles are taken as a main reinforcing phase, and meanwhile, the rare element Ce is added, so that mechanical performance, antioxidant performance and electrical contact performance are reinforced; and the material is prepared by processes of wet grinding of mixed powder and powder metallurgy under protection of absolute ethyl alcohol, so that the shortcomings of low electrical conductivity, high contact resistance, poor antioxidant performance and arc burning loss resistance and insufficient dispersion distribution degree of the reinforcing phase of a Cu-based composite material used as the contact material and prepared in the prior art can be overcome.

Owner:HEBEI UNIV OF TECH

A kind of alloy powder for aluminum paste of silicon solar cell

ActiveCN103617820BReduce surface contact resistanceImprove conductivityNon-conductive material with dispersed conductive materialPhotovoltaic energy generationState of artSilicon alloy

The invention belongs to the technical field of electrode paste of solar cells, and particularly relates to alloy powder for silicon solar cell aluminum paste. The alloy powder comprises at least one type of first silicon aluminum alloy and at least one type of second silicon aluminum alloy. The mass content of silicon in the first silicon aluminum alloy is smaller than 12.73%, the mass content of the silicon in the second silicon aluminum alloy is larger than or equal to 12.73%, and both the melting point of the first silicon aluminum alloy and the melting point of the second silicon aluminum alloy are lower than 660 DEG C. Compared with the prior art, the alloy powder is added to the aluminum paste, so that conductive particles are firmly sintered together, surface contact resistance among aluminum particles is reduced, and the conductive performance of a thick film is excellent; formation of a deep doped p+ zone on a silicon wafer is facilitated and the conversion efficiency of a solar cell is improved; a sintering temperature window section is expanded, the manufacturability of a product is good, the technology sensibility of the defects such as aluminum beads, aluminum bubbles and dust generation in the sintering process of the aluminum paste is reduced, and the performance stability is improved.

Owner:DONGGUAN HYPER TECH COMPANY

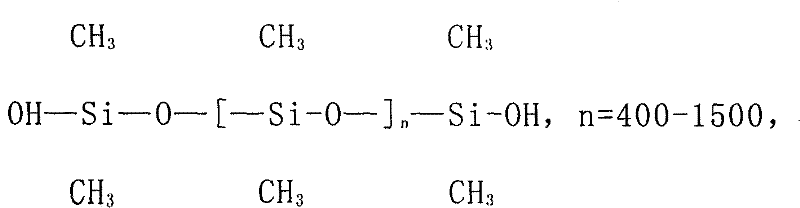

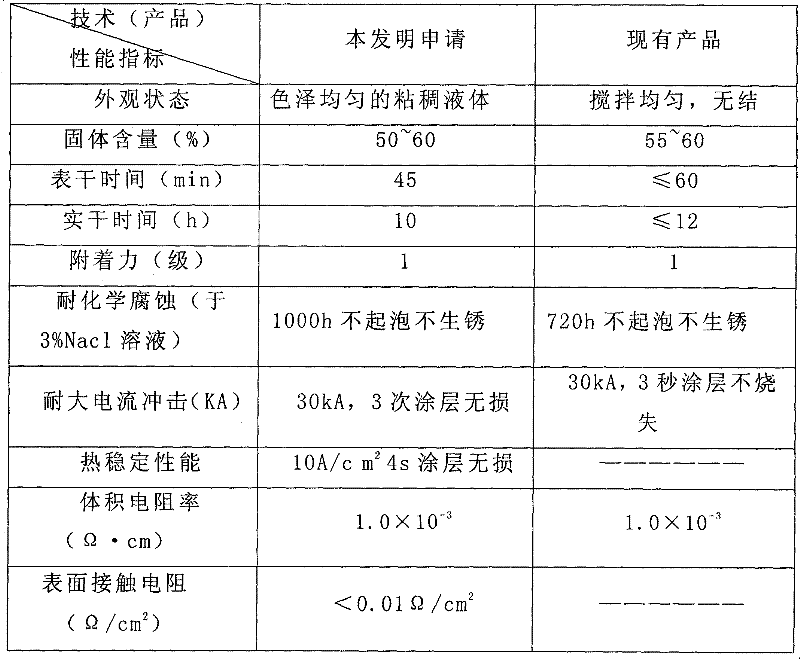

Conductive anti-corrosion coating of electric power grounding grid and preparation method thereof

ActiveCN101717608BExcellent power grounding anti-corrosion performanceGood groundingAnti-corrosive paintsElectrically-conductive paintsCross-linkVulcanization

The invention provides a conductive anti-corrosion coating of an electric power grounding grid and a preparation method thereof. The raw materials in the preparation method comprise the following components: room temperature vulcanization silicone rubber, at least one of dimethylbenzene or petroleum ether used as a thinner, nanometer conductive carbon black, a carbon black dispersant, silver-coated glass spheres, a titanate-based chelate used as a catalyst and methyl trialkoxysilane used as a cross-linking agent. The preparation method comprises the following steps of dispersedly mixing the room temperature vulcanization silicone rubber, the thinner and the carbon black dispersant by metering; adding the nanometer conductive carbon black until homogeneous dispersion is achieved; adding the silver-coated glass microspheres until homogeneous dispersion is achieved; and conveying the mixture into a reactor for reaction and naturally cooling in a vacuum state to obtain the conductive anti-corrosion coating. The comprehensive technical performance indexes of the technical scheme are superior to those of the prior art, and the invention has the advantages of short tack-free time, favorable anti-corrosion performance, high thermal stability and low surface contact resistance.

Owner:LIAONING HUALONG ELECTRIC POWER TECH

Contact protection layer for conductive terminal and formation method thereof

ActiveCN109659738AReduce manufacturing costImprove conductivityContact member manufacturingCoupling contact membersOrganic filmMetal microstructure

The present invention discloses a contact protection layer for a conductive terminal. The contact protection layer for a conductive terminal comprises: a nickel layer formed on an outer surface of base metal of a conductive terminal; and a corrosion-resistant organic film formed on an outer surface of the nickel layer. A microporous structure distributed in a predetermined pattern is formed on thecorrosion-resistant organic film; and the microporous structure of the corrosion-resistant organic film is filled with noble metal to form a noble metal microstructure at the outer surface of the nickel layer. Besides, the present invention further discloses a formation method of the contact protection layer. In the invention, the noble metal microstructure is formed on the contact of the conductive terminal, and a noble metal layer is not formed on the contact of the conductive terminal to reduce the usage amount of the noble metal and reduce the manufacturing cost of the conductive terminal. The noble metal microstructure has good electrical conductivity to improve the electrical conductivity of the conductive terminal. The rest of part without being covered by the noble metal microstructure on the contact of the conductive terminal is covered with the corrosion-resistant organic film so as to improve the corrosion-resistant performance of the conductive terminal.

Owner:TYCO ELECTRONICS (SHANGHAI) CO LTD

Manufacturing process and products of silver tin oxide calcium oxide electrical contacts

InactiveCN104201020BUniform metallographic structureFine grainElectric switchesManufacturing technologyElectric properties

Owner:周朝贵 +1

Stainless steel double-polar plate surface modifying method for proton exchange film fuel battery

InactiveCN101246964BIncrease material costReduce unevennessElectric discharge tubesCell electrodesMetallurgyEngineering

Owner:SHANGHAI JIAO TONG UNIV

Surface modification method for dual polar plates of proton exchange membrane fuel cell

InactiveCN101393991BPrevent thermal reboundImprove corrosion resistanceCell electrodesCollectors/separatorsCopperIon implantation

The invention relates to a method for surface modification for a bipolar plate of a proton exchange membrane fuel cell in the technical field of energy resources. The bipolar plate is composed of a surface modification layer and substrate stainless steel. By adopting a method of ion injection, copper ions are injected into a stainless steel thin plate, an injection layer is formed in a range of dozens of nanometer on the surface of the stainless steel thin plate, and finally a modified stainless steel bipolar plate is obtained. The invention has the advantages that the corrosion resistance performance of a metallic bipolar plate can be further improved, the contact resistance of the metallic bipolar plate with a gas diffusion layer (carbon paper) can be reduced, a thinner bipolar plate can be produced, and the weight ratio energy and the volume ratio energy of a fuel cell can be increased, so as to satisfy the development requirement on the proton exchange membrane fuel cell.

Owner:SHANGHAI JIAO TONG UNIV

Contact protection layer for conductive terminal and method for forming same

ActiveCN109659738BReduce manufacturing costImprove conductivityContact member manufacturingCoupling contact membersOrganic filmMetal microstructure

The invention discloses a contact protection layer of a conductive terminal, comprising: a nickel layer formed on the outer surface of a base metal of the conductive terminal; and an anti-corrosion organic film formed on the outer surface of the nickel layer. A microporous structure distributed in a predetermined pattern is formed on the anti-corrosion organic film; and precious metal is filled in the micro-porous structure of the anti-corrosion organic film, thereby forming a noble metal microstructure on the outer surface of the nickel layer. In addition, the invention also discloses a method for forming the contact protection layer. In the present invention, a precious metal microstructure is formed on the contact of the conductive terminal instead of a noble metal layer, thereby reducing the amount of precious metal used and the manufacturing cost of the conductive terminal. At the same time, since the noble metal microstructure has good electrical conductivity, the electrical conductivity of the conductive terminal can be improved. Moreover, the rest of the contact of the conductive terminal not covered by the noble metal microstructure is covered with an anti-corrosion organic film, so that the anti-corrosion performance of the conductive terminal can be improved.

Owner:TYCO ELECTRONICS (SHANGHAI) CO LTD

Manufacturing method of Fe-Ni-Cr alloy fuel cell bi-polar plate

InactiveCN101859904BChange surface propertiesImprove conductivityCell electrodesFuel cellsNi cr alloy

The invention belongs to the technical field of fuel cells, and relates to a manufacturing method of a Fe-Ni-Cr alloy fuel cell bi-polar plate. The method comprises the following steps of: mixing materials, wherein the materials comprise Fe with the content of x (atomic percentage), Ni with the content of y (atomic percentage) and Cr with the content of z (atomic percentage), x is equal to 37-39 percent, y is equal to 32-34 percent, z is equal to 28-30 percent, and the sum of x, y and z is 100 percent; smelting FexNiyCrz alloy by utilizing vacuum induction; molding and machining a metal plate; carrying out surface chemical treatment; placing the metal plate with a flow field in an HF water solution with the volume concentration of 45-50 percent under 20-30 DEG C and soaking for 7-9 min, taking out, cleaning and drying. The fuel cell bi-polar plate prepared by the method has the advantages of excellent corrosion resistance and conductivity, simple manufacturing process, low operation temperature, no easy deformation of the plate, suitability for assembly of a fuel cell pile and low cost.

Owner:WUHAN UNIV OF TECH

Composite ion injection method for dual polar plates of proton exchange membrane fuel cell

InactiveCN101393990BReduce material costsPrevent thermal reboundCell electrodesCollectors/separatorsCopperIon implantation

The invention relates to a method for injecting compound ions of a bipolar plate of a proton exchange membrane fuel cell in the technical field of fuel cells. The bipolar plate is composed of a surface modification layer and substrate stainless steel. By adopting the method of the ion injection, the ions in arbitrary combination of two elements of nickel, chromium and copper or of all three elements are injected into a stainless steel thin plate, and an injection layer is formed on the surface of the stainless steel thin plate within the range of dozens of nanometer, so as to obtain a modified stainless steel bipolar plate. The invention has the advantages that the corrosion resistance performance of a metallic bipolar plate can be further improved, the contact resistance of the metallic bipolar plate with a gas diffusion layer (carbon paper) can be reduced, a thinner bipolar plate can be produced, and the weight ratio energy and the volume ratio energy of a fuel cell can be increased, so as to satisfy the development requirement on the proton exchange membrane fuel cell.

Owner:SHANGHAI JIAOTONG UNIV

Preparation method for diphasic nanometer particle dispersion strengthening copper matrix composite material

ActiveCN102787250BReduce surface contact resistanceExcellent anti-arc burning performanceAlcoholPolyethylene glycol

Owner:HEBEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com