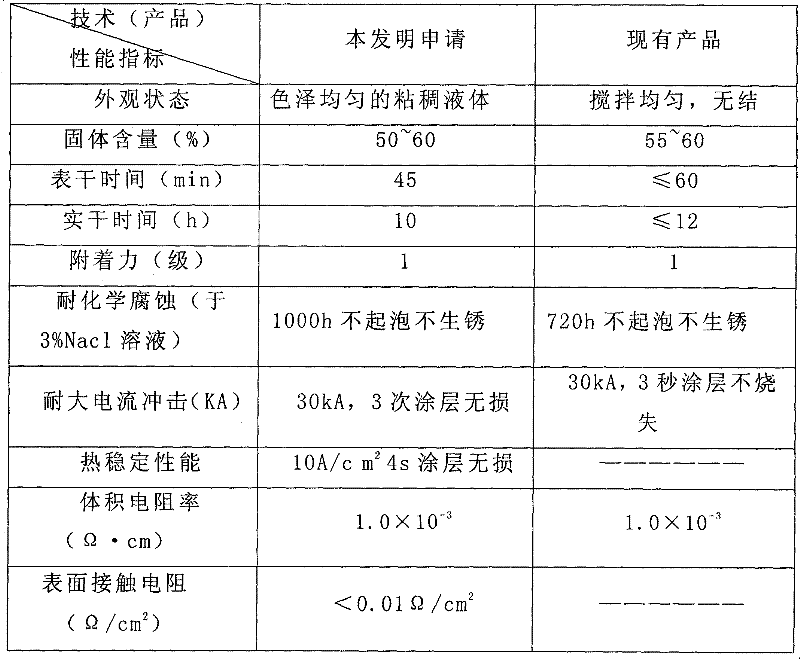

Conductive anti-corrosion coating of electric power grounding grid and preparation method thereof

A conductive anti-corrosion and grounding grid technology, applied in anti-corrosion coatings, conductive coatings, coatings, etc., can solve the problems of unsatisfactory chemical corrosion resistance and thermal stability, and achieve excellent electrical grounding anti-corrosion performance, low surface contact resistance, Good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

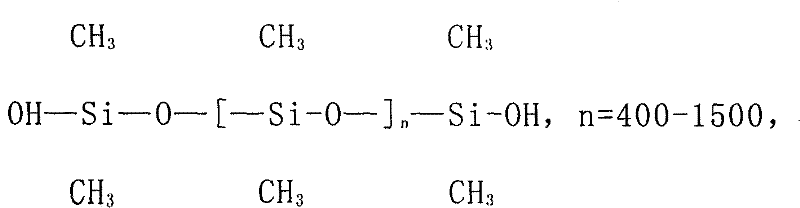

[0014] The raw material composition of the conductive anti-corrosion coating for the power grounding grid includes: 35 parts of room temperature vulcanized silicone rubber or 107 rubber, 50.6 parts of at least one of xylene or petroleum ether as a diluent, 3.0 parts of nano-conductive carbon black, carbon black dispersion 3.0 parts of agent, 5.0 parts of silver-coated glass balls, 0.4 parts of titanate-based chelate as catalyst and 3.0 parts of methyltrialkoxysilane as crosslinking agent.

Embodiment 3

[0016] The raw material composition of the conductive anti-corrosion coating for the power grounding grid includes: 40 parts of room temperature vulcanized silicone rubber or 107 rubber, 47 parts of at least one of xylene or petroleum ether as a diluent, 4.0 parts of nano-conductive carbon black, carbon black dispersion 4.0 parts of agent, 0.5 parts of titanate-based chelate as catalyst and 4.5 parts of methyltrialkoxysilane as crosslinking agent.

[0017] The components of the above three groups of embodiments are manufactured step by step according to the following preparation method: the room temperature vulcanized silicone rubber or 107 glue, diluent and carbon black dispersant are dispersed and mixed according to the stated amount, and then nano-conductive carbon black is added to continue Disperse for about 30 minutes until uniformly dispersed; in order to make the particle size of the fixed substance in it not greater than 30 μm, send the above mixture into a grinder to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com