All-vanadium redox flow battery composite terminal electrode and preparation method thereof

An all-vanadium flow battery and terminal electrode technology, applied in battery electrodes, fuel cells, regenerative fuel cells, etc., can solve the problems of easy defects, complicated assembly, and large contact resistance, so as to reduce the risk of assembly sealing and reduce the surface Contact resistance, the effect of improving battery voltage efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

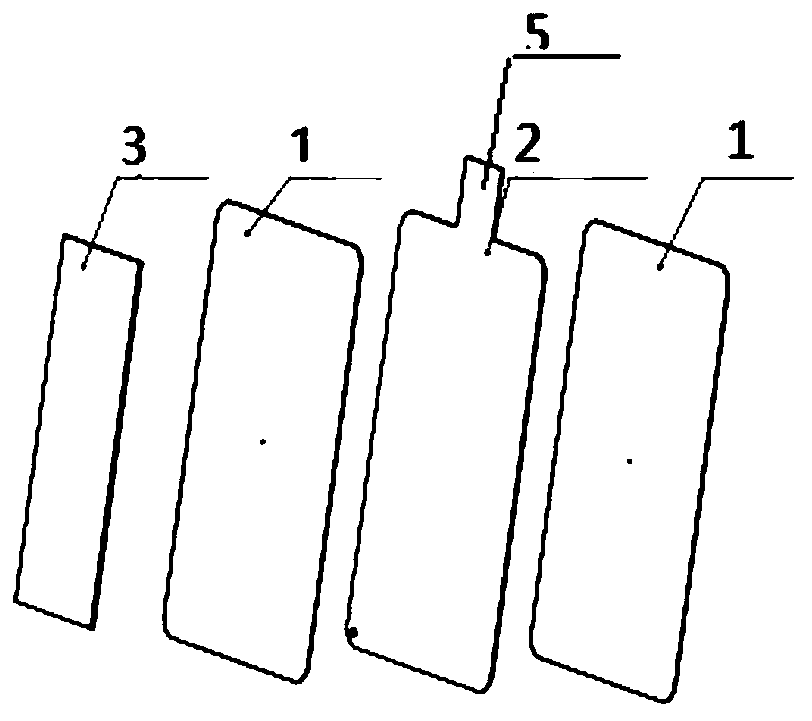

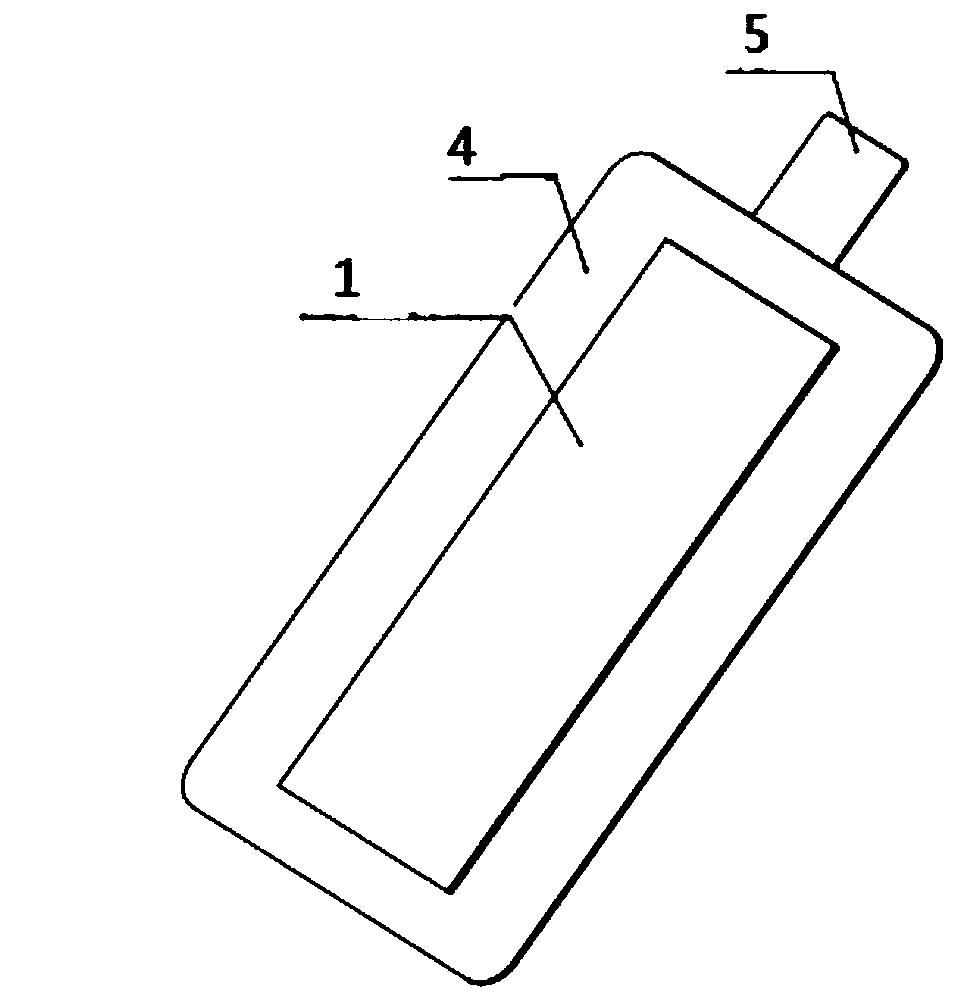

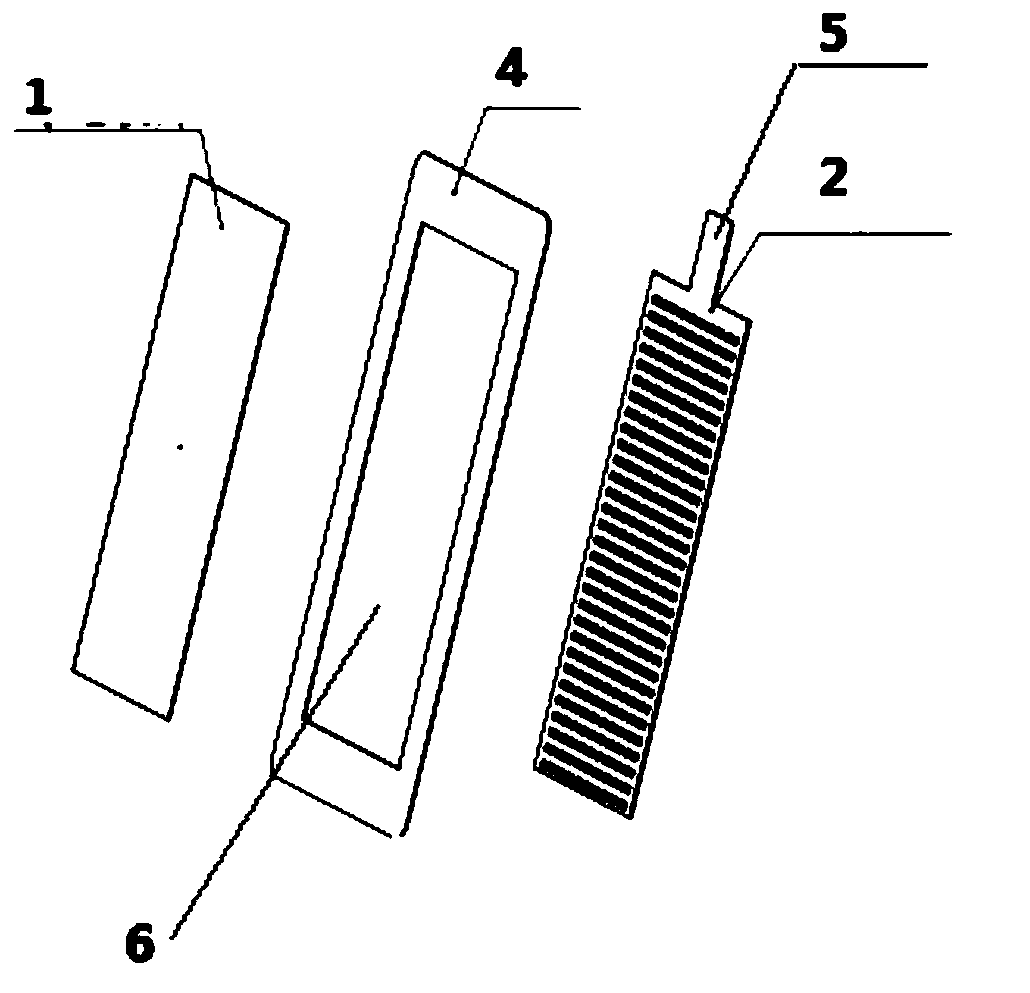

[0041] Embodiment 1 of the present invention: the preparation method of the composite terminal electrode of the all-vanadium redox flow battery comprises the following steps:

[0042] Step 1, cutting and preparing the terminal electrode assembly, cutting the size of the outer frame of the insulating plate according to the size of the inner cavity of the female mold, cutting the size of the copper electrode, the size of the electrode and the size of the carbon felt according to the size of the cavity in the insulating outer frame Size, according to the size of the lug fixing hole on the female mold, cut the size of the tab at the upper end of the copper electrode piece. The size of the inner cavity of the female mold is determined according to the model of the actual production terminal electrode. The thickness of the electrode sheet is 1.0mm, and the thickness of the outer frame of the insulating plate is 1.0mm.

[0043] Step 2, the terminal electrode blank is hot-pressed, whi...

Embodiment 2

[0051] Embodiment 2 of the present invention: the preparation method of the composite terminal electrode of the all-vanadium redox flow battery comprises the following steps:

[0052] Step 1, cutting and preparing the terminal electrode assembly, cutting the size of the outer frame of the insulating plate according to the size of the inner cavity of the female mold, cutting the size of the copper electrode, the size of the electrode and the size of the carbon felt according to the size of the cavity in the insulating outer frame Size, according to the size of the lug fixing hole on the female mold, cut the size of the tab at the upper end of the copper electrode piece. The size of the inner cavity of the female mold is determined according to the model of the actual production terminal electrode. The thickness of the electrode sheet is 1.25mm, and the thickness of the outer frame of the insulating plate is 1.25mm.

[0053] Step 2, the terminal electrode blank is hot-pressed, w...

Embodiment 3

[0061] Embodiment 3 of the present invention: the preparation method of the composite terminal electrode of the all-vanadium redox flow battery comprises the following steps:

[0062] Step 1, cutting and preparing the terminal electrode assembly, cutting the size of the outer frame of the insulating plate according to the size of the inner cavity of the female mold, cutting the size of the copper electrode, the size of the electrode and the size of the carbon felt according to the size of the cavity in the insulating outer frame Size, according to the size of the lug fixing hole on the female mold, cut the size of the tab at the upper end of the copper electrode piece. The size of the inner cavity of the female mold is determined according to the model of the actual production terminal electrode. The thickness of the electrode sheet is 1.5mm, and the thickness of the insulating plate outer frame is 1.5mm.

[0063] Step 2, the terminal electrode blank is hot-pressed, which is t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com